Uncategorised (4996)

The Finnish nutrition pioneer discusses no compromise formulation with an esteemed Food Navigator panel

Simo Suoheimo, Co-founder of AmbroniteSimo Suoheimo, Co-founder of Ambronite shed new light on the company’s formulation philosophy and his approach to creating truly clean label plant-based products.

Simo Suoheimo, Co-founder of AmbroniteSimo Suoheimo, Co-founder of Ambronite shed new light on the company’s formulation philosophy and his approach to creating truly clean label plant-based products.

He joined an esteemed panel of industry experts, including food scientists, researchers, and academics for a webinar event entitled ‘Rethinking Reformulation: Balancing Health with Flavour and Aroma’ hosted by industry publication Food Navigator.

Tasked with dissecting the issues surrounding modern-day nutrition and identifying solutions to improve the nutritional value of everyday foods while maintaining customer expectations on price, flavor and accessibility, the group delved into an array of tough topics.

When asked why food and beverage manufacturers should invest in reformulation and whether there was an impact of COVID-19 Suoheimo said: “We’re seeing a desire from customers to know more about the origin of ingredients and this has only accelerated during the recent crisis. The source of our food is one of the key building blocks of health but the recent crisis has woken so many people up to just how connected we are to our environment and there is much more to improve in the food system, which is what we’re working on at Ambronite.”

The group moved on to discuss shifting dogmas in the food industry and widely accepted then refuted health advice on saturated fats, and today's big focus on sugar reduction.

Suoheimo added: “I think about it as two problems; how do we reduce the amount of sugar and sub-par sweeteners that are linked to diseases like Type 2 diabetes and increased mortality rates, but also how can we make sugar free products that are better tasting than current products. At Ambronite we are trying to introduce stealth health into everyday products. For example, meal shakes that are as tasty as a chocolate milkshake but with all the nutritional power and punch of real food ingredients, properly balanced to cover each and every need of the human body. There's also a massive psychological element and personally, we started the company to solve this problem for ourselves, wanting great taste without compromise. We need to bring back flavor into real foods with nutritional value. Complementing natural ingredients like bilberry we can extract powerful natural flavors.”

To watch the webinar in full head to the Food Navigator event page.

Urban professionals who prioritize health and productivity equally are a key customer group for Ambronite with many working in the technology sector. However, the burgeoning health movement represents a new chapter in consumer nutrition with growing numbers of followers from all walks of life, from sports stars and wellness coaches to explorers and touring DJs. Ambronite helps overcome daily food voids and presents a healthy option for those times when high-quality protein and healthy fats are hard to come by.

Ambronite launched in 2014 via Indiegogo as the platform's most successful crowdfunding round for a food brand and has since served customers in over 30 countries.

Ambronite's mission is to transform humans and the planet from surviving to thriving, through a sustainable plant-based lifestyle. To find out more about Ambronite shakes, bars and juices head to www.ambronite.com

Learn more about Ambronite products at https://www.ambronite.com/

Connector Subsea Solutions announces acquisition of Isotek Oil & Gas Ltd

AdministratorConnector Subsea Solutions (CSS) Bergen, Norway has announced (8 June 2020), that is has completed the acquisition of Isotek Oil and Gas Limited.

The acquisition adds Isotek’s remote welding technology to CSS’s existing range of subsea pipeline repair capabilities which are primarily focused on mechanical clamp and connector pipe joining solutions.

The deal strengthens CSS’s position as a complete solutions provider for critical offshore connections and is part of a strategic drive to meet growing industry demand for technologies which offer lighter, smaller and more reliable pipeline repair methodologies for complex subsea and remote intervention. Remote subsea welding is seen as a key link into future operational scenarios for tie-ins, repair, hot-tapping, Emergency Pipelines Repair Systems, and in particular, larger diameter pipeline applications.

Full Remote Welding Spread

Full Remote Welding Spread

The Isotek workforce which numbers 15 people is transferring over to CSS with immediate effect.

CSS and Isotek have a long-standing relationship and have been at the forefront of subsea and deep water pipeline repair for many years.

Isotek, in partnership with CSS, has been a key supplier and development partner for Equinor’s Pipeline Repair System since its inception in the early 1990s. This collaboration developed control systems and equipment for the subsea repair and installation spread, and fully remote welding equipment for hot tapping. A number of tie-ins have also been completed, along with the development and qualification with DNV-GL. In 2019 the partnership celebrated the first fully remote hyperbaric welded tie-in which was successfully completed on a 36” pipeline for the Johan Sverdrup field in Norway using equipment and technology developed and supplied by Isotek.

Isotek has also been involved in the control and automation of subsea equipment since the mid-1980s and developed key parts of the hyperbaric mechanised TIG (Tungsten Inert Gas) welding system which was first used on the Oseberg field tie-in in Norway in 1988.

More recently, Isotek has been developing small payload high voltage converters particularly suitable for the ROV and subsea drone market. This work has been fast-tracked and is in the final phase of completion on the back of projects with various ROV companies and is due to be available in Autumn 2020.

Ivar Hanson, Chief Executive Officer, Connector Subsea Solutions commented; “Having led the industry on every major milestone with regards to remote repair using mechanical connectors, CSS now also has a proven capability for remote welding. Adding Isotek’s expertise and experience to our portfolio of services allows us to offer an unrivalled range of capabilities in the repair of shallow and deep water pipelines of up to 48in diameter, in the most challenging operating conditions.”

Simon Fripp, General Manager, Isotek added; “The synergies already in place between the Isotek and CSS teams will create exciting opportunities for us to develop new products and solutions for the oil and gas industry, such as our ROV power converters. This will give us strong growth potential and allow us to play a key role in supporting the trend towards autonomous subsea operations, as the industry ventures into increasingly challenging environments.”

Connector Subsea Solutions delivers reliable, efficient and commercially competitive solutions for any subsea challenge. CSS are specialists in providing repair and tie-in solutions for pipelines, risers and subsea distribution systems.

In 2019, following six years of successfully collaborating together on deep water pipeline repairs, Connector Subsea Solutions acquired the MORGRIP® connectors products and business.

Headquartered in Norway, and with regional offices in the UK, Bosnia, Brazil and Croatia, CSS employs 60 people.

Isotek Oil & Gas Limited evolved from Isotek Electronics Ltd, a company founded in 1978. Its main focus is in developing control solutions for harsh environments and in particular subsea pipeline connection employing both welded and mechanical pipeline technologies.

Over its 40-year history, Isotek has supplied services to a broad range of industries including oil and gas, aerospace and space exploration via the Mars Beagle project.

Isotek is based in Leeds, England, and employs 15 people.

BP job losses symptomatic of challenges facing energy industry as firms review their operations

AdministratorProfessor David Elmes, who leads the Global Energy Research Network at Warwick Business School and has more than 20 years experience in the energy industry, said:

"The job losses at BP are symptomatic of the wider challenges facing the industry. Coronavirus has reduced oil demand and the price per barrel has plummeted, but that has happened in a wider context of short-term and long-term decline.

"The job losses at BP are symptomatic of the wider challenges facing the industry. Coronavirus has reduced oil demand and the price per barrel has plummeted, but that has happened in a wider context of short-term and long-term decline.

"Some industry forecasts had acknowledged a flattening off in long-term demand last year, before the pandemic began.

"All firms in the sector will all be looking at how they can cut costs, shift their activities to the lowest cost field, trim investment, and thinking hard about what dividend they can pay.

"BP and the other European-based international companies have already said they will become less focused on oil and gas over time. If this situation continues, there will be intense discussions about what can they do to move faster."

New enhanced digital smart positioner available from Rotork

AdministratorSuitable for all markets, the new digital smart positioner is appropriate for both control and on/off valve applications where enhanced diagnostics are required. It is ideal for highly critical applications in chemical/petrochemical processes.

The YT-3700 and YT-3750 pneumatic smart positioners employ continuous monitoring and graphic display of valve position, set point target over time and internal circuit board temperature over time.

With single and double-acting configurations available, they provide reliable control of pneumatic valve systems for linear and rotary applications.

Suitable for all markets, the new enhanced YT-3700 and YT-3750 digital smart positioners can be used for both control and on/off valve applications where diagnostics are required.

Suitable for all markets, the new enhanced YT-3700 and YT-3750 digital smart positioners can be used for both control and on/off valve applications where diagnostics are required.

Valve diagnostic information to NE107 standard is provided, with Hart® 7 communication protocol included as standard and a display for all settings and local device interaction. Commissioning can be handled locally without the need of an additional device, all indications are clear and simple to follow thanks to the clear visual identification on the local display and the four push buttons.

The enhanced diagnostic package offers position over time continuous monitoring, and graphical visualisation trough Device Description (DD) and Device Type Manager (DTM) files. Additionally, valve signature, advanced step tests and Partial Stroke Testing (PST) can be operated from local or remote positions. Auto-tuning functionality and non-contact sensor are included for high frequency operating valves and an enhanced lifetime.

The steady state deviation analysis that they provide can detect friction in the valve or actuator, leakage in pneumatics and instances where there is insufficient supply pressure. A deviation time out alarm occurs when the difference between the target position and the actual position exceeds the pre-set deviation alarm point (for more than the pre-set deviation time).

To match Emergency Shutdown (ESD) systems for on-off applications, the YT-3700 range offers a full package of offline diagnostic tests include both valve signature and partial stroke test. All information can be stored on the device or downloaded for customer records.

The YT-3700 and YT-3750 are certified to ATEX/LEXIEX standards and can operate in temperatures as low as -55 °C.

Q.E.D. Highlights Green-Line High-Performance Jacketed Tubing

AdministratorUL-rated Green-Line Tubing is constructed with enhanced polyamide material for improved toughness and lower water absorption

Q.E.D. Environmental Systems, Inc., a leading manufacturer of innovative environmental products, announces its Green-Line high-performance jacketed tubing, which enables users to expand the working range of pumping systems. The Green-Line Tubing offerings are part of QED’s unmatched range of connector and fitting options that make installation and maintenance easier and more efficient. QED is committed to delivering high quality and high performing products for customers, and the Green-Line High Performance Jacketed Tubing is the company’s latest cutting-edge product improvement.

QED Green-Line High-Performance Jacketed Tubing is constructed with enhanced polyamide material for improved toughness and less water absorption. The material’s high tensile strength – 17% stronger than prior products – leads to less stretch and higher break strength, for a longer useful life in deeper wells. The material also delivers reduced humidity absorption – a 30% improvement – for longer service life, improved strength, and less weight gain over time. Green-Line is Underwriters Laboratory rated, meeting UL94 HB flame retardant specifications.

Green-Line Tubing is compatible with QED’s Easy Fitting™ Quick-release Connector for the AutoPump® (Patent Pending), which is designed for severe duty downwell conditions at landfills and remediation sites. The Easy Fitting allows the AutoPump to be quickly disconnected from its tubing and hose sets, eliminating the need to cut the tubing. Constructed of high-quality stainless steels, the Easy Fitting is designed to function well even with silt and solids present.

All dimensions of QED tube, hose and fittings are carefully designed and controlled to ensure high flow capacity, easy assembly, high pullout strength and leak-tight connections. QED offers an unmatched range of connector and fitting options to make installation and maintenance easier and more efficient.

For more information, visit QED online at www.qedenv.com.

About Q.E.D. Environmental Systems, Inc.

Q.E.D. Environmental Systems, Inc., a subsidiary of Graco Inc., is a leading manufacturer of innovative environmental pumping systems, landfill products, landfill gas products, and air strippers for use at landfills, mines, oil refineries and other industrial sites, as well as hazardous waste cleanup sites. Our products are used around the world for a wide range of environmental applications, including groundwater sampling, groundwater remediation pumping, landfill leachate and condensate pumping, landfill gas collection and control, landfill and biogas analysis, air stripping and VOC removal, and wireless data acquisition. Based in Dexter, MI, QED serves customers from support centers in Michigan and California. For more information, call 734-995-2547 or contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

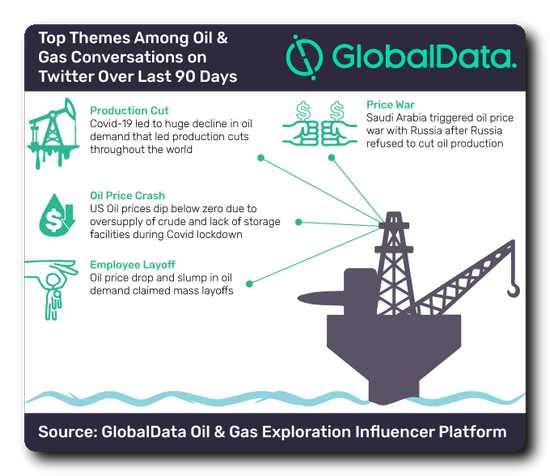

Oil and gas conversations surge 100% on Twitter over last 90 days, finds GlobalData

AdministratorThe COVID-19 crisis has affected a wide range of businesses, but its impact on the oil and gas industry is particularly severe due to restrictions on travel as well as other broader economic activities, causing a heavy blow to the global oil demand. A similar trend is observed on GlobalData’s Oil & Gas Exploration Influencer Platform, where there is more than 100% spike in conversation volume during February-April period in 2020 in comparison to the previous 90 days, says GlobalData, a leading data and analytics company.

An analysis of Oil & Gas Exploration Influencer Platform, which tracks more than 100 leading industry experts and their discussions around the emerging trends, insights and overviews, new fields of innovation and technology, and other popular areas on Twitter, revealed that ‘Production Cut’ and ‘Oil Price Crash’ as popular themes among the oil and gas conversations as slump in demand and insufficient storage capacity had forced companies to cut production and resulted in the US oil price to fall negative for the first time in the history.

Prashant Saxena, Influencer Expert at GlobalData, says: “The COVID-19 induced oil demand plunge combined with the price war has really thrown the oil and gas industry into chaos. This environment of depressed oil prices, and revenue and production declines will likely continue to present major challenges for oil and gas companies.”

‘Trade War’ was another theme that appeared prominently among oil and gas conversations, triggered by Russia’s refusal to reduce oil production in order to keep prices at moderate level. This move sent stocks crashing with more than 30%, which led energy traders stunned.

‘Employee Layoff’ also emerged as one of the leading themes as many oil and gas firms are struggling to survive quick drop in global demand due to COVID-19, combined with sharp price drop in the US markets. Companies like Halliburton Co., the world’s dominant fracking-services provider, said it would layoff 3,500 workers at its Houston headquarters.

Saxena concludes: “Since then, the outlook has somewhat improved across oil and gas markets as oil prices have rebounded from their April lows but, the situation still remains fluid with the potential second wave of COVID-19 infections, creating an extraordinary degree of uncertainty over what the full global impact of the virus will be.”

- Quotes are provided by Prashant Saxena, Influencer Expert at GlobalData

- The information is based on GlobalData Oil & Gas Exploration Influencer Platform, which tracks most relevant activity of the industry influencers on Twitter

- This press release was written using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts

About GlobalData’s Influencer Platform

The Influencer Platform is a part of GlobalData’s Disruptor Database that decodes emerging tech-enabled opportunities with must-have information on promising start-ups, technology led innovations, latest sector trends, consumer insights, and venture capital portfolio investments. It helps monitor competitor strategies, predict emerging trends, monetize disruptive innovation, decode smart money, mine thought leadership, and capture digital consumers.

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make timelier and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

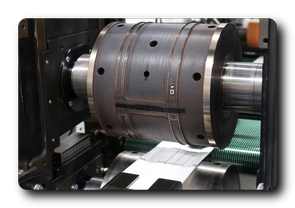

W+D/BICMA develops face mask line capable of up to 1 million disposable surgical masks per day with a lower cost mask design

Administrator Reacting to the worldwide shortage and peak demand for high quality lower cost face masks, the W+D/BICMA hygiene group of Winkler+Dünnebier has developed a fully automatic, high-speed face mask converting line for the production of high quality disposable face masks: Auxilium FM. This new converting line has a speed of up to 150 m/min (492 ft/min) and is able to produce up to 1 million high quality face masks per day making it one of the fastest mask production machines in the world.

Reacting to the worldwide shortage and peak demand for high quality lower cost face masks, the W+D/BICMA hygiene group of Winkler+Dünnebier has developed a fully automatic, high-speed face mask converting line for the production of high quality disposable face masks: Auxilium FM. This new converting line has a speed of up to 150 m/min (492 ft/min) and is able to produce up to 1 million high quality face masks per day making it one of the fastest mask production machines in the world.

Adding to the manufacturing throughput efficiency of up to 800 face masks per minute is also a unique product concept, reducing the costs per piece by using for the ear loops standard materials which are common in the hygiene industry. The machine comes with CE sign and is suitable for Industry 4.0 applications. It can be equipped with various options such as fully automatic stacking camera system for inline quality control, inline flexoprinting and many more.

The Auxilium FM mask line laminates and converts three or more layers of appropriate nonwoven materials (spunbond, meltblown, thermobonded or others). By converting suitable raw materials, producers may apply for EN 14683 I, II or IIR certification for masks they made on this quality machine. It combines W+D/Bicma’s proven technology in highspeed nonwoven processing with newly designed features like nose clip and earloop application.

The Auxilium FM mask line laminates and converts three or more layers of appropriate nonwoven materials (spunbond, meltblown, thermobonded or others). By converting suitable raw materials, producers may apply for EN 14683 I, II or IIR certification for masks they made on this quality machine. It combines W+D/Bicma’s proven technology in highspeed nonwoven processing with newly designed features like nose clip and earloop application.

ABOUT WINKLER+DÜNNEBIER GMBH

Winkler+Dünnebier GmbH (W+D) offers a wide range of highly efficient, integrated system solutions for the mail and postal industry, as well as for the tissue and hygiene industry. With more than 100 years of industry-shaping innovations, W+D has core competence in the converting and processing of thin and in-homogeneous materials—such as paper, tissue and nonwovens—at high speeds and tight tolerances. With innovative and tailor-made system solutions and services, W+D focuses on the entire internal value chain for its customers. Part of the Barry-Wehmiller family, W+D has production and distribution sites in Germany, the Netherlands, Malaysia and the United States, with sales and service support around the world. For more, go to w-d.de.

BICMA Hygiene Technologie GmbH

Founded in 1995, BICMA has established itself as an internationally recognized mechanical engineering company in the hygiene industry. The company develops and builds machines for the production of feminine hygiene products, baby and adult diapers, incontinence pads, pet and bed pads as well as food suction pads and face masks. BICMA was acquired by Winkler+Dünnebier GmbH (W+D) in 2018. Both companies belong to the American Barry-Wehmiller Group, one of the world’s leading suppliers of production technologies and solutions. For more information, go to bicma.com.

ABOUT BARRY-WEHMILLER

Barry-Wehmiller is a diversified global supplier of engineering consulting and manufacturing technology for the packaging, corrugating, sheeting and paper converting industries. By blending people-centric leadership with disciplined operational strategies and purpose-driven growth, Barry-Wehmiller has become a $3 billion organization with 11,000-plus team members united by a common belief: to use the power of business to build a better world. To see how, go to barry-wehmiller.com.

Apache lead the way with digital inspection service on Beryl Alpha Platform

AdministratorNorth Sea operator, Apache, is leading the way in deploying innovative digital inspection technology developed by engineering consultancy firm Arup, and EnerMech subsidiary MInteg, to improve safety and reduce asset inspection costs on offshore platforms.

Apache’s adoption of the Arup Inspect MInteg (AIM™) inspection service on the Beryl Alpha platform has significantly reduced offshore inspection hours of the topside structure whilst enhancing the quality and availability of inspection data.

The innovative digital service replaces high-risk offshore working-at-height inspection methods with the application of remote visual inspection tools. It also enables operators and asset owners to access their interactive inspection data 24/7 and make informed decisions about asset repair, replacements or improvements.

Beryl Alpha platform

Beryl Alpha platform

Gaming technology was used to create a baseline geometric digital twin of the Beryl Alpha platform to sufficiently capture inspection data, without the need for rope access work.

More than 60,000 images, including 360° panoramic views, captured ultra-high-resolution inspection data. These enhanced records have contributed to improved reporting reliability and the 3D model-based tablet application will help Apache on its journey to adopting a digital approach for the platform.

Jim Saunderson, Integrity Manager for Apache’s North Sea operations, said: “Deploying the Arup and MInteg inspection solution achieved the requirements of our inspection plans while significantly reducing the risk profile of the activity. The enhanced data capture and storage within the 3D model has aided our post-inspection review by removing any ambiguity and enabling users to challenge information beyond what is captured in reports. We can see opportunities of this data enhancing the quality and efficiency of our inspection plan going forward and is already aiding day to day communications.”

Simon Evans, Digital Energy Leader at Arup, said: “This successful use of the AIM tool to inspect the Beryl Alpha, which is one of the largest functioning offshore platforms in the United Kingdom and one of the oldest concrete gravity base structures, marks a significant turning point for the oil and gas industry. It’s a best in class example of how digitalisation and automation techniques can deliver revolutionary benefits, including valuable reductions in costs, time, resource and risk.”

Patrick Gallagher, Head of Integrity at MInteg, added: “Apache’s adoption of digital inspection on the Beryl Alpha platform has resulted in a significant risk reduction to personnel by minimising or completely negating the reliance on rope-access. They are also benefitting from a marked increase in the asset condition knowledge, leading to a far greater understanding of potential future risks.”

Arup and MInteg will continue to work with Apache on digitalising and streamlining future asset inspections.

About Arup

Arup is the creative force at the heart of many of the world’s most prominent projects in the built environment and across industry. Working in more than 140 countries, the firm’s designers, engineers, architects, planners, consultants and technical specialists work with our clients on innovative projects of the highest quality and impact.

EnerMech provides a broad range of asset support services to the international energy and infrastructure sectors, from pre-commissioning through operations and maintenance and late-life support/decommissioning. The business is focused on offering a safer, more customer-focused, responsive service at lower cost, while delivering a much greater level of engineering and technical support than competitors can offer.

EnerMech specialises in providing integrated supply, operations, maintenance and engineering solutions in its core services of Cranes and Lifting, Electrical and Instrumentation, Equipment Rental, Hydraulic products and services, Industrial Services, Process, Pipeline and Umbilicals (PPU), Maintenance and Integrity Services, Training and Valve supply and services.

The group is headquartered in Aberdeen with bases in Great Yarmouth, Bristol (UK); Stavanger (Norway); Houston, Pasadena, Sulphur, Casper, Williston (USA), Trinidad, Mexico, Abu Dhabi, Iraq, Qatar, Saudi Arabia, Azerbaijan, Kazakhstan, Singapore; Perth, Melbourne, Sydney, Brisbane, Darwin, Gladstone, Chinchilla (Australia); Malaysia, China, South Korea, India, Guyana, Ghana, Nigeria, Angola and South Africa.

Website: www.enermech.com

TietoEVRY and Aimo Park, the leading parking company in the Nordics, have entered into a strategic partnership to accelerate Aimo Park’s digital transformation and embrace of cloud technologies. The new collaboration will fuel development of innovative parking and mobility solutions by increasing automation and utilizing a variety of cloud services where TietoEVRY is leading the integration process.

In March 2019, Japan-based Sumitomo Corporation acquired Q-Park in Sweden, Norway and Finland. As a result, Q-Park has become Aimo Park and the company is now embarking on a digital transformation. Now, Aimo Park has chosen TietoEVRY as a strategic IT partner to support in its cloud journey and to create a whole new and scalable IT landscape.

The new landscape consists of several cloud solutions from a variety of providers that cover systems such as Enterprise Resource Planning (ERP), Customer Relation Management (CRM) and Content Management (CMS). These solutions will enable faster time to market, more agile development of services and an improved end-user experience. Aimo Park will also be able to achieve better cost predictability and management with one single service provider to orchestrate its IT landscape.

The new landscape consists of several cloud solutions from a variety of providers that cover systems such as Enterprise Resource Planning (ERP), Customer Relation Management (CRM) and Content Management (CMS). These solutions will enable faster time to market, more agile development of services and an improved end-user experience. Aimo Park will also be able to achieve better cost predictability and management with one single service provider to orchestrate its IT landscape.

“We sought a stable and reliable IT partner with broad expertise, adaptability and strong Nordic presence. We are glad to partner with TietoEVRY in this important phase to build a best in class cloud-based IT architecture. They will help us to get at the forefront of digitalization quickly and to utilize the best cloud services for our organization’s needs. Innovative and digital capabilities are imperative for us to “Rethink parking” and deliver the best possible services to our customers. We strive to offer a new type of space and experience – not just a place for parking a car,” says Peder Ståhlberg, CEO Aimo Park, Nordics.

“We are delighted to partner with Aimo Park and guide them in their digital transformation. TietoEVRY will not only implement external cloud services but also implement our own cloud services to connect all systems and enable a full overview of their IT infrastructure. Our delivery to Aimo Park will provide the increased stability and agility the company seeks as it develops the mobility and smart city services of the future,” says Claes Karlsson, Head of Retail and Consumer Services, TietoEVRY.

For more information, please contact:

Peder Ståhlberg, CEO Aimo Park, This email address is being protected from spambots. You need JavaScript enabled to view it., +46 (0)8 7221589

Claes Karlsson, Head of Retail and Consumer services, TietoEVRY, This email address is being protected from spambots. You need JavaScript enabled to view it.

Aimo Park is today Nordic’s largest parking operator with around 370,000 parking spaces distributed across 6,000+ parking facilities around the countries Sweden, Norway and Finland. In 2019, the company had >650 employees and had a turnover of almost 228 million EUR.

Sumitomo Corporation has a century-long history of long-term, successful investments and partnerships. In 2018, for example, behind the introduction of Aimo in Stockholm - Sweden's first free-flowing electric car sharing service. And from August 2019 also scooters are being tested. The acquisition of Aimo Park further reinforces the strategy to invest in companies and initiatives in mobility with the aim of facilitating everyday life.

TietoEVRY creates digital advantage for businesses and society. We are a leading digital services and software company with local presence and global capabilities. Our Nordic values and heritage steer our success.

Headquartered in Finland, TietoEVRY employs around 24 000 experts globally. The company serves thousands of enterprise and public sector customers in more than 90 countries. TietoEVRY’s annual turnover is approximately EUR 3 billion and its shares are listed on the NASDAQ in Helsinki and Stockholm as well as on the Oslo Børs. www.tietoevry.com

AMADA WELD TECH announces increased production and support for critical manufacturing applications

AdministratorAMADA WELD TECH announces increased strategical partnerships with manufacturers of battery modules, used in vital life support systems, as part of the effort to meet the increased demand for ventilators and their component parts during the current global health crisis. AMADA WELD TECH is a key supplier to both the medical and battery industries and has been additionally listed with the UK government as a supporting manufacturer for the production of ventilators and medical systems. As a result, the company has increased production in recent weeks, all whilst maintaining the safety and health of employees and customers.

As the COVID-19 pandemic continues to unfold and governments work to contain the spread of the virus, hospital electrical power failure represents a more significant challenge than ever before. While backup generators offer the first line of defence, in the case of total or extended power failure, battery technology is critically important to life-sustaining care. Life-support equipment, such as the ventilators in such high demand during this crisis, must have a reliable battery back-up solution to ensure continued patient care in the event of a total power failure. Battery technology is also necessary to ensuring continued operation of vital equipment between a power failure and the switchover to backup generators. In addition, battery power ensures that essential support and monitoring can be maintained safely as patients are moved between wards and departments.

As the COVID-19 pandemic continues to unfold and governments work to contain the spread of the virus, hospital electrical power failure represents a more significant challenge than ever before. While backup generators offer the first line of defence, in the case of total or extended power failure, battery technology is critically important to life-sustaining care. Life-support equipment, such as the ventilators in such high demand during this crisis, must have a reliable battery back-up solution to ensure continued patient care in the event of a total power failure. Battery technology is also necessary to ensuring continued operation of vital equipment between a power failure and the switchover to backup generators. In addition, battery power ensures that essential support and monitoring can be maintained safely as patients are moved between wards and departments.

AMADA WELD TECH has provided technology such as its High Duty DC Resistance Welding Power Supply DC2013‑T and parallel gap weld heads to battery pack manufacturers who are rushing to increase production at this critical time. AMADA WELD TECH has also increased its own production in line with industry requirements in order to continue providing the most advanced welding solutions for the production of battery modules.

In the meantime, AMADA WELD TECH has taken measures to ensure that as many members of staff whom are able to work from home do so. Most of the company’s regional sales and service offices are now closed, with staff members available remotely to assist and support its customers with minimal disruption. In the production facilities that are manufacturing the equipment and systems crucial for continued production of ventilators and other critical technology, the company has introduced many measures to protect both its valued workforce and customers who receive their products.

About AMADA WELD TECH

AMADA WELD TECH is a leading manufacturer of equipment and systems for Laser Welding, Laser Marking, Laser Cutting, Resistance Welding, Hermetic Sealing and Hot Bar Reflow Soldering & Bonding. We customize our products around specific micro-joining applications for all our customers around the globe. AMADA WELD TECH product markets include medical devices, battery, automotive, solar industry, electronic components and aerospace. We are an ISO9001 certified company. Contact AMADA WELD TECH at This email address is being protected from spambots. You need JavaScript enabled to view it.. Find out more about the company’s products and services at www.amadaweldtech.eu.

More...

US technology industry sees a drop of 29.7% in deal activity in April 2020

AdministratorThe US technology industry saw a drop of 29.7% in overall deal activity during April 2020, when compared with the last 12-month average, according to GlobalData’s deals database.

A total of 436 deals worth $4.52bn were announced in April 2020, compared to the 12-month average of 620 deals.

Venture financing was the leading category in the month in terms of volume with 296 deals which accounted for 67.9% of all deals.

Venture financing was the leading category in the month in terms of volume with 296 deals which accounted for 67.9% of all deals.

In second place was M&A with 116 deals, followed by private equity with 24 transactions, respectively accounting for 26.6% and 5.5% of overall deal activity in the country’s technology industry during the month.

In terms of value of deals, private equity was the leading deal category in the US technology industry with total deals worth $3.77bn, while M&A and venture financing deals totalled $608.37m and $150.22m, respectively.

US technology industry deals in April 2020: Top deals

The top five technology industry deals accounted for 22.3% of the overall value during April 2020.

The combined value of the top five technology deals stood at $1.01bn, against the overall value of $4.52bn recorded for the month.

The top five technology industry deals of April 2020 tracked by GlobalData were:

- Altimeter Capital Management, Coatue Management, Franklin Resources, Index Ventures and Sequoia Capital Operations’ $250m venture financing of Confluent

- The $250m venture financing of Cohesity by Baillie Gifford &, Cisco Investments, DFJ Growth Management, Foundation Capital, Greenspring Associates, Hewlett Packard Enterprise, Sequoia Capital Operations, SoftBank Vision Fund 1, Sozo Ventures and Wing Venture Capital

- M12 Ventures’ $215m venture financing of PsiQuantum

- The $150m asset transaction with Intel by MaxLinear

- Rapid7’s acquisition of DivvyCloud for $145m.

This analysis considers only announced and completed deals from the GlobalData financial deals database and exclude all terminated and rumored deals. Country and industry are defined according to the headquarters and dominant industry of the target firm. The term ‘acquisition’ refers to both completed deals and those in the bidding stage.

GlobalData tracks real-time data concerning all merger and acquisition, private equity/venture capital and asset transaction activity around the world from thousands of company websites and other reliable sources.

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis, and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, technology, energy, financial and professional services sectors.

A wake-up call to manufacturers: how coronavirus is driving digital transformation and continuity planning

AdministratorThe current pandemic is forcing the manufacturing sector to re-evaluate traditional production processes. The combination of supply chain disruption, shortage of materials, dependence on globalised production, and a national workforce with restricted movements, is not only affecting the industry, but the wider economy. While many have struggled to adapt within the current environment, there are those taking this opportunity to transform.

Manufacturers are collectively being forced to devise and implement new and agile approaches to product monitoring and quality control. One of their biggest logistical challenges involves ensuring their production lines are running, despite the lack of available staff due to social distancing rules. This is where digital innovations in smart manufacturing can offer many benefits.

Jason Chester, Director of Global Channel programs at InfinityQS, explains further: “Before the lockdown started, business continuity in the event of a global pandemic was not a priority, as the risk or likelihood was not deemed high enough and the ROI was not clearly evident. Therefore, very few organisations were investing in the necessary tools and technologies to effectively respond to such a crisis situation on the scale that we are witnessing today.

Jason Chester, Director of Global Channel programs at InfinityQS, explains further: “Before the lockdown started, business continuity in the event of a global pandemic was not a priority, as the risk or likelihood was not deemed high enough and the ROI was not clearly evident. Therefore, very few organisations were investing in the necessary tools and technologies to effectively respond to such a crisis situation on the scale that we are witnessing today.

“COVID-19 has forced the industry to think smarter and ultimately build more resilience into their production environments. The rise of digitalisation and steady move towards cloud-based SaaS solutions have thrown manufacturers a welcome lifeline to help them stay afloat and maintain continuity against a very challenging environment. Those who have not yet started to develop a smart production environment are finding it difficult to cope and are looking for new ways to adapt,” he explained.

Jason comments: “Organisations are trying to achieve a level of robustness and flexibility that will help them respond to any future internal or external disruptions and those who are proactively investing in smart production lines have a distinct advantage over those who are not. We understand it isn’t possible to plan for everything, but you can start prioritising the key areas of your operations to ensure you can remain as agile, responsive, and efficient as possible.”

He continued: “Today’s digital cloud-based technology services and solutions offer an unprecedented level of flexibility, with factory managers able to remotely monitor and manage their production lines from any location with an internet connection. This allows resources to be deployed effectively, as staff do not have to be on the actual production floor. Instead they can use remote access cloud interface dashboards from the comfort of their homes to monitor production and pinpoint areas of improvement or quality issues.”

“Now anyone has the capabilities to easily spin-up highly capable manufacturing and quality intelligence solutions in a secure cloud architecture. This quickly enables an agile environment to be created which helps to ensure yield optimisation, product quality, and production efficiency, which are all vital for those within the manufacturing community to succeed at this time. Additionally, the real-time remote features of these solutions mean staff can also be trained in using these systems and upskilled from anywhere in the world.”

Jason concluded: “Factory workers are essential to the nation’s health and prosperity. Regardless of the products you are making or the size of your company, you need to reduce the impact of potential disruptions by investing in the tools and talent to build a ‘factory for the future.’ This will enable you to keep things moving, even if the unexpected happens.”

About InfinityQS International, Inc.

For over 30 years, InfinityQS has been the leading global provider of Manufacturing Quality Intelligence software and services. Powered by a robust Statistical Process Control (SPC) analytics engine, the company’s solutions—Enact® and ProFicient™—deliver unparalleled visibility and strategic insight across the enterprise, from the shop floor to the boardroom. This extensive deep-dive capability enables manufacturers to improve product quality; decrease cost and risk; improve compliance; and make strategic, data-driven business decisions. Headquartered near Washington, D.C. and with offices in Seattle, London, and Beijing, InfinityQS has thousands of customers around the world, including Ball Corporation, Boston Scientific, Graham Packaging, and Medtronic. For more information, visit

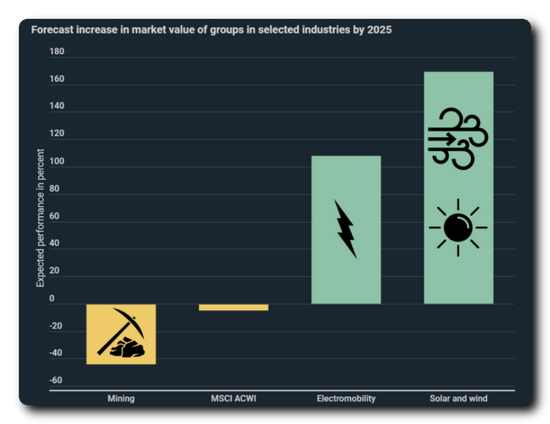

Wind and Solar Shares 5 Year Outlook, Study Forecasts 169% Price Gains

AdministratorBy 2025, publicly traded companies from the solar and wind energy sectors could boast share price gains of up to 169%. This emerges from the findings of a new infographic from Kryptoszene.de. According to the results of the study, this could even be the biggest growth industry. In contrast to the renewable energy sector, the value of the international stock index MSCI World ACWI is set to fall by up to 4.5%.

- Wind and solar stocks expected to grow 169% by 2025

- Fastest growing sector

- 80% of Germans expect growing importance of wind and solar energy

According to the authors of the study, the field of electromobility could be the second greatest beneficiary. Experts are predicting share price gains of up to 108% by 2025 for leading companies in this field.

In the future, policymakers are likely to intervene more substantially to promote climate protection, while the risk of climate change still appears undervalued on the stock exchange floor.

As can be seen in the infographic, a majority of German citizens also believe in the potential of renewable energies. 59% of the population favour solar energy, while only 4% approve of coal-based electricity. 8 out of 10 of those surveyed also stated that they expect wind and solar energy to grow in importance in the years to come.

"An evaluation of Google search queries reveals a growing interest in listed companies from the wind and solar sectors," notes cryptoscene analyst Raphael Lulay. "It remains to be seen whether the price gains live up to this - though all the signs are pointing towards a longer-lasting growth trend".

The full story with the infographic, facts and more statistics:

https://kryptoszene.de/wind-and-solar-shares-5-year-outlook-study-forecasts-169-price-gains/

About Kryptoszene.de

Kryptoszene.de is a news and information platform that publishes cryptocurrency forecasts, investment news, background reports, analyses and instructions for buying and trading cryptocurrencies and other assets.

The NovusBloc welded plate heat exchanger – Introducing an innovative design for welded plate heat exchangers.

AdministratorAvailable for global energy intensive markets the NovusBloc™ welded plate heat exchanger encompasses a Tranter premium design concept offering a boost in heat exchange performance and durability for these processes in comparison to substitutable products.

With a patented novel plate design the NovusBloc provides state of the art weld quality and enhanced resistance against cyclic pressure and temperature process conditions while also minimizing unnecessary additional pressure loss. Moreover, the design has an innovative design of the wetted linings that protect non-wetted components from the process fluid which enhances the mechanical durability as the design enables mechanical stress reduction and uniform stress contours in the weld seams.

The product belongs to the category of all-welded plate heat exchanger and thus has no gaskets for fluid separation which eliminates fluid compatibility issues for aggressive fluids. The NovusBloc is able to withstand tough operating conditions in both single-phase and two-phase flow applications with performance verified by R&D through heat transfer, plus both pressure- and temperature fatigue qualification testing.

The NovusBloc welded plate heat exchanger – Introducing an innovative design for welded plate heat exchangers.

The NovusBloc welded plate heat exchanger – Introducing an innovative design for welded plate heat exchangers.

Furthermore, the NovusBloc offers outstanding potential for reduced unit size, weight and footprint and comes in four different model sizes depending on the users’ heat transfer duty requirements. Each model can be pressed in many different materials to cope with corrosion aggressive environments.

In terms of maintenance, The NovusBloc is fully accessible for mechanical cleaning and visual inspection thus making it fulfill buyer choice-criteria for applications with high fouling tendency where clean-ability is a must.

”It’s truly exciting to get this product into the Tranter product range as it gives us a real differential advantage towards some key buyer choice-criteria” says Stefan Gavelin, Director of Global Sales Enablement.

Tranter is a global manufacturer of gasketed and welded plate heat exchangers and an aftermarket service provider for the plate heat exchanger industry. Significant manufacturing, research, design engineering and product development activities are based in the USA, Brazil, Sweden, China and India and enable responsiveness to local demands. Tranter is represented globally by a network of our own sales companies, licensees and agents. www.tranter.com.