Uncategorised (4996)

Your Future Automation—Pepperl+Fuchs Invites You to Its First Online Summit

AdministratorFive days of solutions, trends, and digital networking

Pepperl+Fuchs’ 2020 Online Summit is a free digital platform that will allow customers and other interested parties to learn about the latest trends and solutions in factory and process automation—even during the COVID-19 pandemic.

"Your Future Automation” is the motto for Pepperl+Fuchs’ first online summit, which will take place from July 20 – 24. This free, fully digital event offers customers and other interested parties a way to get in touch with industrial sensor and electrical explosion protection experts and learn about the latest solutions and trends in the fields of factory and process automation. On each day of the summit, participants will be able to access keynotes, live shows, and panel discussions on a different topic from the field of automation technology via a browser-based online platform.

These topics include:

• Digital Kanban Management

• Mobile Devices and Services Drive Digital Transformation

• Smart Intralogistics Solutions with RFID and LiDAR Technology

• Ethernet Advanced Physical Layer (Ethernet APL)

• The Power of 3-D Measurement Technology

In the networking lounge, participants will also have the opportunity to talk to other attendees and experts from Pepperl+Fuchs and its partner companies. Other digital content, such as technical white papers, videos, and presentations, will be available for free download. All content areas will be offered in English and will be presented in both the morning and afternoon to enable interested parties from all over the world to participate without being tied to time zones.

We miss you! Even in this time of limited social interaction, we would like to stay in touch with you, our customers. That is why we are holding our first online summit from July 20 – 24. For five exciting and informative days, we will address topics that are propelling us forward. Everything will revolve around user-centered digitalization. What better way to communicate this than with a digital event tailored to the interests of our customers?" comments Dr. Gunther Kegel, Chairman of the Executive Board of Pepperl+Fuchs AG.

Register Now

Interested in attending? Register for Pepperl+Fuchs’ free online summit at www.pepperl-fuchs.com/summit.

Main Topics

Digital Kanban Management

It is hard to imagine manufacturing without Kanban systems and the advantages they offer. Nevertheless, error-prone, manual processes and low digitalization still leave plenty of room for improvement. Bosch Connected Industry (BCI), Pepperl+Fuchs, and Neoception have joined forces to develop a scalable system that prepares Kanban racks for Industry 4.0 and is equally suitable for greenfield projects and retrofits.

Mobile Devices and Services Drive Digital Transformation

Smartphones, tablets, and digital workflows have become an integral part of modern work environments. As the global market leader for intrinsically safe mobile devices, the Pepperl+Fuchs brand ecom supports its customers from configuration and management to the analysis and evaluation of (real-time) device data. The result? A sophisticated mobile worker concept that enables lean processes, improves data quality, and contributes to increased productivity and employee safety.

Smart Intralogistics Solutions with RFID and LiDAR Technology

Precisely coordinated materials and goods flows require more than just individual components: They need well designed and innovative solutions that cover everything from custom sensor technology, infrastructure components, and cabling to system integration and software development. Along with several customers, Pepperl+Fuchs will showcase projects that demonstrate how RFID and LiDAR technology can be used to create these custom solutions.

Ethernet Advanced Physical Layer (Ethernet APL)

With the new Ethernet advanced physical layer (Ethernet APL), Pepperl+Fuchs and other companies are laying the foundation for future IoT applications in the process industry. The new physical layer enables field devices to be directly connected to higher-level systems, allowing consistent, transparent, and uniform communication across all hierarchical levels for the first time. In doing so, Ethernet APL combines all the experience and requirements of the process industry: long cable runs, twisted-pair cables, interoperability, and use in hazardous areas up to Zone 0/Class 1, Div. 1.

The Power of 3-D

Efforts to achieve 100 % quality while reducing conversion times as a result of Industry 4.0 are creating increasingly complex engineering challenges in a range of industries. To implement the necessary measurement, quality, and positioning tasks, Pepperl+Fuchs and its subsidiaries VMT, 3D.aero, and Espace 6D are offering unique end-to-end solutions in the field of 3-D measurement technology. These transfer traditional tasks to a digital environment, thus furthering the development of the "digital twin."

Pepperl+Fuchs is one of the world’s leading providers of industrial sensors and explosion protection. Based on an intense dialogue with our customers for more than 70 years we continue to develop new components and solutions, which support their applications the best way possible. For the landmark topic Industrie 4.0 (Industrial Internet of Things) we develop innovative technologies that pave the way to the digital networked production and to data transfer across all hierarchy levels – even beyond companies’ boundaries.

Industrial sensors: focus on the market

Market-specific solutions dominate an extensive portfolio of industrial sensors that covers all applications the market requires from today’s automation technology. From the inductive and capacitive to the photoelectrical and highly precise ultrasonic sensors, identification systems and many more Pepperl+Fuchs offers all current operating principles in a broad variety.

Sensorik4.0® provides sensor technology for Industrie 4.0. Our technologies enable sensors without difficulty to communicate horizontally within the production process and to exchange data vertically – even into higher-level information systems such as MES or ERP.

Process interfaces: secure applications

Components and technologies for use in hazardous areas are designed to fit the most specific requirements in the industries we serve. They guarantee maximum availability at maximum safety. Isolated barriers, signal isolators, remote I/O or fieldbus systems, HMIs and many other technologies offer solutions for a wide range of applications including certified packaged solutions and all types of explosion protection.

Ex-Protection4.0 brings digital networked Industrie 4.0-production structures to process industries. With concept studies like Ethernet for Process Automation integrated communication throughout all levels of an automation system via Ethernet becomes feasible – for the first time ever even down to the filed level.

Outotec introduces MesoTHERM BIOX process to significantly reduce cyanide consumption in refractory gold ore treatment

AdministratorTraditionally, cyanide consumption with conventional bio-oxidation residues is higher than with residues produced through other oxidative technologies. The Outotec® MesoTHERM BIOX® process, based on Outotec’s proven mesophile BIOX process, offers an easy, cost-effective upgrade path that can cut cyanide consumption by as much as 50% compared to conventional bio-oxidation.

The Outotec MesoTHERM BIOX process enhances the established mesophile BIOX process by combining mesophile bio-oxidation technology with a higher-temperature thermophile oxidative stage to enable an even more effective overall sulfide oxidation step.

The Outotec MesoTHERM BIOX process enhances the established mesophile BIOX process by combining mesophile bio-oxidation technology with a higher-temperature thermophile oxidative stage to enable an even more effective overall sulfide oxidation step.

Reduced cyanide consumption and simplified process operation

Outotec MesoTHERM BIOX cuts cyanide consumption by as much as 50% compared to conventional bio-oxidation and significantly reduce the formation of thiocyanate – a common and stable cyanide species traditionally formed as a further by-product. Solubilized species prevalent in the mesophile stage are decanted off in an inter-stage thickening step between the two oxidative processes, simplifying operation of the thermophile stage.

A simple, cost-effective upgrade path

Upgrading to BIOX MesoTHERM is a relatively simple process that involves reconfiguring the circuit with the addition of Outotec’s proven High Rate Thickeners for inter-stage thickening and Outotec OKTOP® Atmospheric Reactors for the thermophile step.

“Our conventional mesophile BIOX process has enabled the production of over 25 million ounces of gold to date. This novel process takes advantage of these proven technologies to help our customers achieve significant cost savings while also reducing their environmental footprint,” says Craig van Buuren, Senior Process Engineer, Outotec.

Key benefits

- Reduces cyanide consumption by up to 50% and lowers reagent storage requirements

- Produces cleaner BIOX product solids

- Offers easy, cost-effective upgrade for existing BIOX operations

- Based on proven technologies and standard processing equipment

For more information, please visit https://www.outotec.com/products-and-services/technologies/hydrometallurgy/mesotherm-biox-process/

Outotec develops leading technologies and services for the sustainable use of Earth’s natural resources. Our 4,000 top experts are driven by each customer’s unique challenges across the world. Outotec's comprehensive offering creates the best value for our customers in the mining, metal, and chemical industries. Outotec shares are listed on NASDAQ Helsinki. www.outotec.com

US petrochemical industry forced to rethink investment decisions amid COVID-19 pandemic, says GlobalData

AdministratorThe COVID-19 outbreak and crude oil price crash have pushed petrochemical companies in the US to announce project delays. With major complexes such as Shell Beaver County Complex and Formosa St. James Parish Complex having already been affected, prevailing uncertainties and economic slowdown due to the outbreak could push companies to make more such announcements over the short-term, says GlobalData, a leading data and analytics company.

John Paul Somavarapu, oil and gas analyst at GlobalData, comments: “Most of the upcoming projects that have been affected are concentrated in US gulf coast states such as Texas and Louisiana and primarily involve shale gas processing. A few of the delayed projects include the Corpus Christi Polymers Project, which was scheduled for Q4 2020 and has been postponed to Q4 2021, and the Formosa Plastics Point Comfort Polyethylene project, which set to come on-stream in Q1 2020 has been delayed to Q3 2020. The industry foresees more such delays, which would have a knock-on effect to impact the progress and start-up of subsequent projects.”

John Paul Somavarapu, oil and gas analyst at GlobalData, comments: “Most of the upcoming projects that have been affected are concentrated in US gulf coast states such as Texas and Louisiana and primarily involve shale gas processing. A few of the delayed projects include the Corpus Christi Polymers Project, which was scheduled for Q4 2020 and has been postponed to Q4 2021, and the Formosa Plastics Point Comfort Polyethylene project, which set to come on-stream in Q1 2020 has been delayed to Q3 2020. The industry foresees more such delays, which would have a knock-on effect to impact the progress and start-up of subsequent projects.”

The pandemic has compelled US petrochemical companies to re-evaluate their investment strategies, impacting their FID plans. Projects under early phases of development are expected to be hit hard. The FID of the PTTGC Belmont County project has been postponed indefinitely due to the outbreak, while CP Chem has also deferred the FID plans of its Gulf Coast Complex.

John Paul concludes: “Petrochemical demand has been knocked down, as the end markets such as automotive, housing and construction have also experienced a decline in demand. However, some end markets such as consumer and food and medicinal packaging have maintained steady demand and avoided similar drops. Demand of key polymers in the US is expected to decrease by around 4% in 2020, and later rebound in 2021.”

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, technology, energy, financial and professional services sectors.

GSSI Releases PaveScan® RDM 2.0 Asphalt Density Assessment Tool

AdministratorGSSI, the world’s leading manufacturer of ground penetrating radar (GPR) equipment, announces PaveScan® RDM 2.0 – an innovative asphalt density assessment tool that provides accurate real-time measurements to ensure pavement life and quality.

GSSI unveiled PaveScan® RDM 2.0 for the U.S. and Canada at the Transportation Research Board 2020 Conference in January. PaveScan 2.0 incorporates a new sensor design built specifically for the extremes of the asphalt paving environment, foldable deployment arms with high-visibility for work site safety and has a warm-up time of under one minute when ambient temperature is over 70° F.

PaveScan RDM is ideal for uncovering problems that occur during the paving process, including poor uniformity and significant variations in density. By avoiding these problems, PaveScan RDM helps avoid such premature failures as road raveling, cracking, and deterioration along joints.

This system automatically measures the dielectric value to identify anomalies in real-time. In addition, the dielectric values can be used to as a means to correlate percent voids and density in new pavement. The innovative technology enables users to obtain critical density data for QA/QC of new pavements. Unlike other options, like nuclear density gauges or radioactive alternatives, PaveScan does not result in any site hazards or require closing off work areas.

Seamlessly integrating with GPS systems, PaveScan features a flexible, modular design that facilitates easy and efficient operation and data collection. It is offered as a single sensor or a three-sensor cart based configuration.

As of April 2019, this pavement density measurement technology is an accepted American Association of State and Highway Transportation Officials (AASHTO) specification, PP 98-19.

About GSSI

Geophysical Survey Systems, Inc. is the world leader in the development, manufacture, and sale of ground penetrating radar (GPR) equipment, primarily for the concrete inspection, utility mapping and locating, road and bridge deck evaluation, geophysics, and archaeology markets. Our equipment is used all over the world to explore the subsurface of the earth and to inspect infrastructure systems non-destructively. GSSI created the first commercial GPR system 50 years ago and continues to provide the widest range and highest quality GPR equipment available today.

Valmet to supply automation and solids measurements to Oulu Waterworks’ wastewater treatment plant in Finland

AdministratorValmet will supply automation system extension and solids measurements to Oulu Waterworks’ Taskila wastewater treatment plant located in Oulu, Finland. With modern wastewater treatment solutions, the plant can stabilize the sludge and treat it more efficiently and meet the environmental criteria also in the future.

The order was included in Valmet’s orders received of the first quarter 2020. The order will be delivered during the second half of 2020 and the commissioning will be in the first quarter of 2021. The value of the order is not disclosed.

“The collaboration with Valmet has been smooth both in this project and before. The current sludge treatment facility in Taskila has reached the end of its lifecycle after 20 years operation. A new plant with modern sludge treatment solutions will ensure trouble-free and efficient treatment of Oulu's sewage sludge well into the future,” says Jarmo Lahtinen, Operations Manager, Oulu Waterworks.

"Valmet DNA is a reliable automation system for managing wastewater treatment processes. We are pleased that Oulu Waterworks, our long-term partner, has decided to extend and upgrade their existing system," says Jarmo Harjuoja, Manager, Customer Service, Automation, Valmet.

"We are confident that our solid measurements and innovative technology will increase reliability and sustainability when optimizing the wastewater treatment process," tells Juha Kesti, Sales Manager, Measurements and Analyzers, Automation, Valmet.

Information about the delivery

Valmet's delivery includes an extension and upgrades to the existing Valmet DNA automation and information management system, Valmet Total Solids Measurements (Valmet TS), Valmet Low Solids Measurements (Valmet LS), and Valmet Dry Solids Measurements (Valmet DS). Additionally, the delivery includes field engineering of the automation application and instrumentation, factory acceptance testing, automation system installation, commissioning, and training.

Information about the customer Oulu Waterworks

Oulu Waterworks is a municipal water treatment institute that is responsible for water supply and sewerage in Haukipudas, Kiiminki, Oulu, Oulunsalo, Yli-Ii, and Ylikiiminki in Finland. Oulu Waterworks provides high-quality and reliable water services to almost 200,000 residents of the Oulu region.

Oulu Waterworks has two wastewater treatment facilities. The majority of the wastewater is treated in the City of Oulu’s Taskila treatment plant which is the biggest wastewater treatment plant in Northern Finland.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2019 were approximately EUR 3.5 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Nouryon has completed a project to more than double capacity for organic peroxides at its plant in Itupeva, Brazil. The expansion will add capacity for products including methyl ethyl ketone peroxides (MEKP) as well as dibenzyl peroxide (BPO) pastes and waxes. These are essential ingredients used in the production of composites serving fast-growing markets such as wind turbines and civil construction.

“This investment in Itupeva has transformed our site into a state-of-the-art production facility and gives our composites customers greater supply reliability across our entire organic peroxides product portfolio,” said Alain Rynwalt, Vice President of Polymer Catalysts at Nouryon. One key upgrade at the site is installation of an advanced Safety Instrumented System (SIS).

This is the latest in a series of investments Nouryon has made to strengthen its Polymer Catalysts business, which includes organic peroxides and metal alkyls. Last year, the company acquired Zhejiang Friend Chemical Co., the largest producer of triethyl aluminum (TEAL) in China. In April of this year, Nouryon announced an agreement to acquire the merchant TEAL business of Sasol.

This is the latest in a series of investments Nouryon has made to strengthen its Polymer Catalysts business, which includes organic peroxides and metal alkyls. Last year, the company acquired Zhejiang Friend Chemical Co., the largest producer of triethyl aluminum (TEAL) in China. In April of this year, Nouryon announced an agreement to acquire the merchant TEAL business of Sasol.

“Nouryon is a world leader in essential ingredients for the polymer industry,” said Johan Landfors, President of Technology Solutions at Nouryon. “We supply our growing customer base from production facilities in Europe, Asia and the Americas, and our most recent investment in Itupeva strengthens even more our supply position in this fast-growing region.”

Click here for more information about Nouryon’s growth investments.

About Nouryon

We are a global specialty chemicals leader. Markets worldwide rely on our essential chemistry in the manufacture of everyday products such as paper, plastics, building materials, food, pharmaceuticals, and personal care items. Building on our nearly 400-year history, the dedication of our 10,000 employees, and our shared commitment to business growth, strong financial performance, safety, sustainability, and innovation, we have established a world-class business and built strong partnerships with our customers. We operate in over 80 countries around the world and our portfolio of industry-leading brands includes Eka, Dissolvine, Trigonox, and Berol.

Niramax overhauls SRF production line with new shredding technology

AdministratorWaste management specialist The Niramax Group, has overhauled its alternative fuel production line with the switch to new shredding technology. The move is expected to boost capacity for the Hartlepool-headquartered organisation, by as much as 30% per year.

Previously operating a high-speed system to transform pre-sorted commercial and industrial waste into a refined SRF for use in combined heat and power plants, the Niramax development team was encountering repeated problems with machine damage, unplanned downtime and excessive wear costs.

Keen to boost the reliability, throughput and profitability of the plant, Niramax has therefore re-evaluated the marketplace and made the switch to an UNTHA XR3000 mobil-e with new XC cutting configuration.

The purchase of the energy-efficient machine follows a successful trial on the Hartlepool site, where operators put the XR to the test using their own materials.

UNTHA XR3000 mobil-e with new XC cutting configuration

UNTHA XR3000 mobil-e with new XC cutting configuration

Despite the varying and often challenging nature of the input waste, the shredder was able to achieve a homogenous, on-specification <80mm SRF at a continued rate of 30 tonnes per hour. With in-built foreign object protection mechanisms, the shredder came to a stop – safely and without causing machine damage – so that any unshreddables could be safely ejected.

Elaborating on the trial, Niramax’s Managing Director, Nick Elliot said: “We soon learned that UNTHA’s clever foreign object design feature protects our operators as they don’t need to ‘enter’ the machine at any point to investigate the issue. Our machine is protected from excessive wear and potentially costly damage too.

“At the same time, we’re safeguarding the quality of our fuel and maintaining consistent throughputs, which means we can deliver clients’ expectations with ease, and further boost the capacity of our site.”

Now fully operational, the UNTHA SRF shredder is expected to achieve fuel consumption savings of up to 40%. Supplied on rubber tracks with integrated discharge conveyor and cross-belt magnet, it boasts a quick-change cutting system which provides maximum flexibility should Niramax wish to vary their in-feed processes or output specifications.

Commenting on the project, UNTHA UK’s sales director Gary Moore said: “For years, the industry has been persuaded that high speed operations are the only way to achieve impressive throughput volumes. But the production of RDF and SRF is a complex process, not least because the input materials can contain anything from chunks of metal to rigid plastics, textiles, film and more.

“High speed machines simply can’t withstand the pressures that come with processing these tricky and often unexpected wastes, which means at best they encounter continued, costly wear, if not disruptive breakdowns that soon limit the throughputs the operator seeks.

“They risk jeopardising the safety of the plant too, which can no longer be tolerated. Engineering advancements mean slower speed, high torque operations can now satisfy capacity requirements without the same downtime, environmental, financial and safety risks.”

UNTHA UK has launched a series of flexible finance packages with zero deposit and VAT deferment options – plus varied customer support programmes – to help the waste industry keep moving during the COVID-19 pandemic.

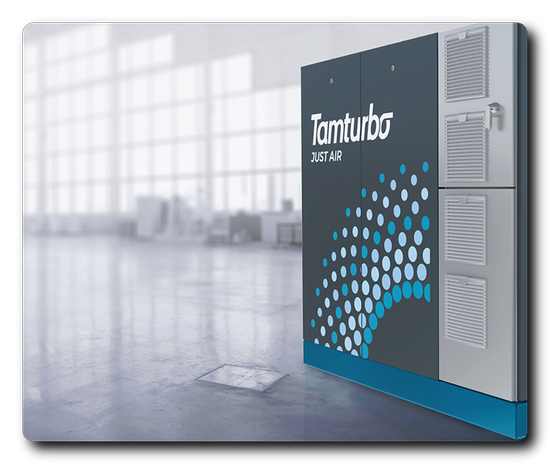

Sulzer has made an investment to acquire 25% of Tamturbo Plc. Founded in 2010, Tamturbo is a technology company that develops and manufactures oil-free industrial air compressor systems. Tamturbo’s disruptive solutions enable cleaner, more energy-efficient and close-to maintenance-free compressed air production with next generation Touch-Free™ compressor technology.

The successful co-operation with Sulzer started in 2018 with a sales and supply agreement as Tamturbo’s oil-free industrial air compressors fit well with Sulzer’s lower pressure compressor offerings in industries such as pulp and paper, food, metals, mining and chemical processing. Tamturbo will complement Sulzer’s portfolio well, leading to scale effects from Sulzer’s strong industrial brand reputation, its experience in manufacturing similar compressor products, its capillary worldwide sales and service network, and its access to key suppliers.

Tamturbo sold their first air compressors in 2017. The company’s sales grew strongly in 2019. In 2019, the company served several of the world’s largest companies within the food, beverage, paper and electronics industries, and is already making in-roads into providing compressed-air products to large household names.

Frédéric Lalanne, President of Sulzer’s Pumps Equipment Division, says, “Tamturbo complements our existing offering in industrial air compressors with its disruptive technology that minimizes cost of ownership. By joining forces, we’ll be well placed to serve a strongly growing industrial automation market with increasing demand for compressed air. Tamturbo has done an outstanding job since inception and we are very happy for Sulzer to have a tight collaboration and support their growth”.

“We are excited to welcome a company with the size and reputation of Sulzer as a significant partner in our venture. Sulzer have had a leading position in the low-pressure market with high-speed turbo compressor products in the past 20 years. We can now join our efforts together using Tamturbo’s higher-pressure products to address a market which is significantly larger.” – says Timo Pulkki, CEO of Tamturbo.

About Sulzer

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and application technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class manufacturing facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2019, our 16’500 employees delivered revenues of CHF3.7 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN).

About Tamturbo

Tamturbo is a Finnish industrial growth company in the cleantech sector that enables cleaner and more energy-efficient industrial compressed air production with a new generation of Touch-Free™ compressor technology and service models that add value to customers. Tamturbo develops and manufactures air compressors, which offer a more environmentally friendly solution that is completely oil-free, energy-efficient and a long-lasting option which is significantly cheaper for the customer than traditional technology in terms of total cost of ownership. It is possible to implement the solution as an Air-as-a-Service business model, in which case the customer only pays for the compressed air they use. Tamturbo operates in a fast-growing market and its growth is supported by global megatrends. The Company aims to continue its strong growth in the medium and long term.

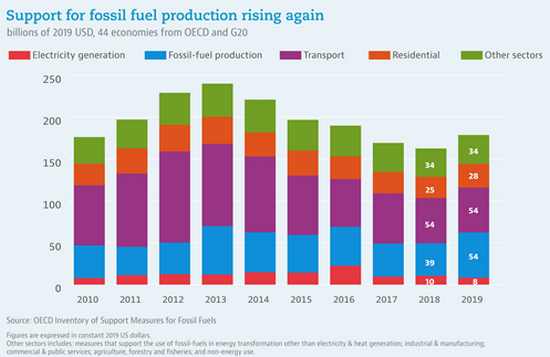

Governments should use Covid-19 recovery efforts as an opportunity to phase out support for fossil fuels, say OECD and IEA

Administrator2019 data shows a 38% rise in overall support for the production of fossil fuels

As governments design stimulus measures for economies hit by the Covid-19 crisis, they should seize the opportunity of historically low oil prices to redirect some of the half a trillion dollars spent annually supporting fossil fuels into sustainable investment including low-carbon energy, according to the OECD and the International Energy Agency (IEA).

Government support for the production and consumption of fossil fuels totalled USD 478 billion in 2019, according to analysis of 77 economies by the OECD and the IEA. While that marks an overall decline from 2018 as lower oil prices meant governments spent less subsidising energy costs for end-users, the data also show a 38% rise in direct and indirect support for the production of fossil fuels across 44 advanced and emerging economies.

“I am saddened to see some backsliding on efforts to phase out fossil fuel support. This rise in production subsidies seems set to continue in 2020 with some countries targeting state aid to fossil fuel and related industries,” said OECD Secretary-General Angel Gurría. “Subsidising fossil fuels is an inefficient use of public money and serves to worsen greenhouse emissions and air pollution. While our foremost concern today must be to support economies and societies through the Covid-19 crisis, we should seize this opportunity to reform subsidies and use public funds in a way that best benefits people and the planet.”

G20 countries pledged in 2009 to gradually phase out inefficient fossil fuel subsidies. As well as encouraging consumption, fossil fuel subsidies are an ineffective way to support low-income households compared to targeted benefits and tend to favour wealthier households that use more fuel and energy. Money spent supporting coal, oil and gas could instead be invested in sustainable energy infrastructure, research and job training. In the Covid-19 climate, subsidies drain resources that could be spent on strengthening health system preparedness and resilience, for example.

The combined OECD-IEA estimate of fossil fuel support in 2019 shows an 18% decline from USD 582 billion in 2018 that is due mostly to the mechanical effect of the drop in global oil prices on consumption subsidies. On the production side, while several countries reduced support for coal production and state aid to coal-fired power plants, others increased support to oil and natural gas industries, mostly through investments in infrastructure, budgetary support to absorb corporate debt or preferential tax treatment for spending on production.

The OECD’s analysis of budgetary transfers, tax breaks and spending programmes linked to the production and use of coal, oil, gas and other petroleum products in 44 OECD and G20 countries showed total fossil fuel support rose by 10% to USD 178 billion in 2019, ending a five-year downward trend. (See the OECD Inventory of Support Measures for Fossil Fuels and a data visualisation with support by fuel, economic sector and indicator.)

IEA analysis of government interventions that keep end-user prices artificially low in 42 economies finds that consumption subsidies dropped by USD 120 billion in 2019, largely due to lower market prices. The further plunge in oil prices this year offers a clear chance to wean economies off this support. (See IEA key findings on energy consumption subsidies.)

“Fossil fuel subsidies are a roadblock to achieving a sustainable recovery from the Covid-19 crisis,” said Dr Fatih Birol, Executive Director of the IEA. “Today’s low fossil fuel prices offer countries a golden opportunity to phase out consumption subsidies. As governments look to boost jobs and plan for a better and more resilient future, it is essential to avoid market distortions that favour polluting and inefficient technologies.”

The IEA predicts that the plunge in fossil fuel prices and use catalysed by Covid-19 is set to bring down consumption subsidies to USD 180 billion in 2020, which would be the lowest level since it began tracking the data in 2007. Meanwhile, sharp declines in revenues from oil and gas production make subsidy reforms crucial to ease pressure on public finances in producer economies. (Read more.)

A separate OECD report published today, Building Back Better: A Sustainable, Resilient Recovery after Covid-19, examines ways governments can use stimulus measures to make investments and societal changes that can reduce the likelihood of future shocks and build more resilient and environmentally sustainable societies.

Fossil fuel support data by country

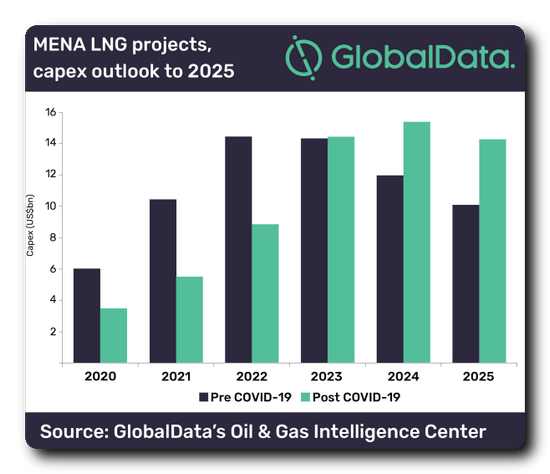

MENA LNG companies likely to put off upcoming projects due to economic slowdown, says GlobalData

AdministratorReduced demand due to economic slowdown in the Middle East and Africa (MENA) region, fueled by the COVID-19 outbreak, has led to long-term liquefied natural gas (LNG) supply contract cancellations and cargo deferments by importing countries. This has resulted in low liquefaction capacity utilization. The cascading impact of global LNG supply overhang coupled with reduced demand may lead companies to withhold or delay their capital spends on upcoming multi-billion-dollar gas projects, says GlobalData, a leading data and analytics company.

Haseeb Ahmed, Oil and Gas analyst at Global Data, comments: “Amid weakening demand and falling oil and gas prices, capex spends on LNG projects in the MENA region are likely to be deferred during the period 2020-2025. This is likely to cause delayed commencement of operations of capital intensive projects in the region. Although the duration of these disruptions is uncertain, the capex guidance would likely remain undeterred in the longer term to meet future LNG demand.”

The bidding process of Qatar Petroleum’s Ras Laffan–North Field Expansion project was hampered, leading to the delay in start year by a few months. The financial investment decision (FID) of the project, which was expected to be in 2020, is also likely to be pushed to 2021. Similarly, the start of the Rovuma LNG project, operated by Mozambique Rovuma Venture SpA, is likely to be delayed by a year, as the current crisis has deferred its FID by a year.

Even active terminals are being confronted with challenges induced by COVID-19. The Egyptian LNG terminal has suspended its work till mid-July 2020 given the current market conditions, while the deal among its shareholders - ENI, Naturgy (Union Fenosa’s owners), the Egyptian government, and EGAS, to revive Damietta LNG terminal, fell through.

Ahmed concludes: “While the depressed financial market can prove challenging for LNG companies to find new investors to fund their projects, LNG buyers and suppliers would contemplate strategy revisions to remain competitive in the mid-term. Possible economic recovery coupled with favorable gas policies in the long-term can drive natural gas demand growth in the region; Integrated gas projects, already announced, will be developed.”

- Comments provided by Haseeb Ahmed, Oil and Gas analyst at GlobalData

- This report was built using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, technology, energy, financial and professional services sectors.

More...

Wärtsilä to deliver advanced emissions abatement technology for two new shuttle tankers

AdministratorThe technology group Wärtsilä’s emissions abatement technology is again recognised with a new order. The company will provide its Volatile Organic Compounds (VOC) Recovery System, together with an LNG Fuel Gas Supply System, for two new 124,000 DWT shuttle tankers. The ships have been ordered by Knutsen NYK Offshore Tankers (KNOT), a leading independent owner and operator of shuttle tankers, and will be built at the Daewoo Shipbuilding & Marine yard in Korea. The order with Wärtsilä was placed in April.

With this technology, the liquefied VOC is mixed with LNG and used as fuel for the main and auxiliary engines. By using LNG as the primary fuel and supplementing this with the energy recovered from the VOC, these vessels will be able to lower their emissions of CO2 equivalents by 30 to 35 percent, a minimum of 30,000 tons per year, compared to conventional oil-fuelled shuttle tankers. These savings are roughly the equivalent of the total emissions from approximately 20,000 cars.

The two new shuttle tankers for the KNOT Group will feature Wärtsilä’s unique technology combining VOC recovery with an LNG fuel gas supply system.

The two new shuttle tankers for the KNOT Group will feature Wärtsilä’s unique technology combining VOC recovery with an LNG fuel gas supply system.

“Wärtsilä has developed its VOC abatement technology over the past 20 years, and our competence in this field is unmatched in the marine sector. It means that for these vessels, with the combination of Wärtsilä’s VOC Recovery and LNG fuel systems, they will not only be extremely sustainable environmentally, but will also be commercially attractive. The VOCs that would otherwise be emitted to the atmosphere can instead be burned as fuel,” says Hans Jakob Buvarp, General Manager, Sales, Wärtsilä Marine.

“Our industry is rapidly changing towards greater environmental awareness and improved operational efficiency. These two new ships will reflect this change, thanks largely to Wärtsilä’s advanced technology. They will truly represent the new generation of shuttle tankers, with vastly reduced emissions and lower fuel costs,” says Jarle Østenstad, New Building Director, Knutsen OAS.

The Wärtsilä solutions will be delivered to the yard commencing in November of this year. When delivered, the tankers will operate in the North Sea oil fields.

Wärtsilä in brief:

Wärtsilä is a global leader in smart technologies and complete lifecycle solutions for the marine and energy markets. By emphasising sustainable innovation, total efficiency and data analytics, Wärtsilä maximises the environmental and economic performance of the vessels and power plants of its customers. In 2019, Wärtsilä’s net sales totalled EUR 5.2 billion with approximately 19,000 employees. The company has operations in over 200 locations in more than 80 countries around the world. Wärtsilä is listed on Nasdaq Helsinki.

www.wartsila.com

Forum Energy Technologies appoints Chinese partner to support Asian growth strategy

AdministratorForum Energy Technologies has announced that Wuxi Haiying-Cal Tec Marine Technology Co., Ltd will represent Forum for the sale of the company’s extensive range of remotely operated vehicles (ROVs) in China, including its recently launched XLe Spirit electric ROV.

the XLe Spirit ROV is the first in a new generation of electric ROVs

the XLe Spirit ROV is the first in a new generation of electric ROVs

The vehicle, which recently completed successful sea trial in Norway, is the first of a new generation of electric observation class ROVs. It is the smallest in the new range, and powerful enough perform subsea maintenance and repair work.

Kevin Taylor, Vice President -- Subsea Vehicles at Forum Energy Technologies, said: “We continue to see strong demand for our products in China and the wider Asian market, and recognised the need for a local partner to support our long-term growth strategy.

“It’s important that we work with the best and most well-respected partners in country and Wuxi Haiying-Cal Tec Marine Technology Co., Ltd provides us with another strong channel to complement to our existing framework across the academic, survey and energy markets.

Representatives from Wuxi Haiying-Cal Tec Marine Technology Co., Ltd visiting Forum Energy in 2019

Representatives from Wuxi Haiying-Cal Tec Marine Technology Co., Ltd visiting Forum Energy in 2019

“This agreement ensures that our clients in China receive the same streamlined and consistent support they are accustomed to around the globe. We look forward to engaging with new and existing companies through this partnership to grow our foothold in China and deliver our world-class range of reliable ROVs.”

Forum Energy Technologies, Inc. is a global oilfield products company, serving the subsea, drilling, completion and, production sectors of the oil and natural gas industry. The Company’s products include highly engineered capital equipment as well as products that are consumed in the drilling, well construction, production and transportation of oil and natural gas. Forum is headquartered in Houston, TX with manufacturing and distribution facilities strategically located around the globe.

For more information, please visit www.f-e-t.com

ACWA Power acquires 4.99% of Samsung C&T’s share in Hajr Electricity Production Company

AdministratorACWA Power, a leading developer, owner, and operator of power generation and water desalination plants, signed a share purchase agreement with Samsung C&T to acquire 4.99% of its shares, with an option to purchase the remaining stake of Samsung C&T in Hajr Electricity Production Company (HEPC) – the project company running Qurayyah Independent Power Plant (IPP) in Saudi Arabia.

- ACWA Power’s stake in Hajr Electricity Production Company will increase from 17.5% to 22.49% following the partial acquisition of Samsung C&T’s equity

- Hajr Electricity Production Company is the project company responsible for Qurayyah Independent Power Plant in Saudi Arabia

HEPC is currently majority owned by Saudi Electricity Company with a 50% stake, and through a holding company, the remaining 50% ownership is held by a consortium of ACWA Power; MENA Infrastructure Fund; and Samsung C&T with shareholdings equivalent to 22.49% (up from 17.5%); 15%; and 12.51% (reduced from 17.5%) respectively. With the purchase of the stake from Samsung C&T, ACWA Power will further solidify its position as the second largest shareholder after the Offtaker Saudi Electricity Company (SEC). The total cost of the project was USD 2.7 billion, with approx. 75% of financing through long term project financed debt and the remaining in the form of equity.

The project was signed in 2011 and units commenced power delivery to the grid in 2013 - marking the project as one of the world’s largest IPP combined cycle gas-fired power projects to date. With a net capacity of 3,927 MW, Qurayyah IPP is considered one of the most efficient projects of its kind in KSA. Environmentally, the project has the potential to save more than six thousand cubic meters of carbon emissions annually.

Qurayyah IPP has won numerous awards including Top Plant (2015) recognition by “Power” magazine; GCC Winner Power & Water Project of the Year (2015) and Quality Award (2015) by MEED; Best Project Finance Deal for Islamic Finance (2012) by Euromoney; Middle East IPP Deal of the Year award (2011) by Project Finance magazine; Best Project Finance Deal (2011) by Euromoney’s Islamic Finance; and Best Power Deal from EMEA Finance Magazine.

Open the office door with your smartphone: Technopolis enters mobile access era with IDcontrol

AdministratorUMA Workspace, the co-working concept by Technopolis, implements a mobile-based access solution in partnership with IDcontrol. The solution has been installed in the first locations in the Nordic and Baltic countries, and a new locations will be available soon elsewhere in Europe. Flexible mobile access has been greeted enthusiastically by users of UMA Workspaces, and modern access solutions are expected to be more common in the future.

UMA Workspace is a network of international, flexible community work spaces in the Nordic countries and countries around the Baltic Sea. Currently such locations are available in Finland, Sweden, Norway and Denmark, and in Estonia and Lithuania of the Baltic countries. The UMA Workspace concept consist of flexibly rentable, high-quality office and collaboration facilities for companies of all sizes.

A flexible location concept requires an equally flexible and modern access solution. Mobile access takes place by means of a smartphone application. With the application, you not only make the reservation but also open the doors.

"For us, the most important aspect in the mobile key, in addition to being digital, is that it's very easy to use. You no longer need keys or access cards. Because this is a pioneering solution, we wanted to have a partner that can not only provide the technical solution but also to build a new kind of implementation on a tight schedule. We wanted a partner that we can genuinely trust. IDcontrol has provided all of this and we are extremely happy with our cooperation," says Technopolis Chief Information Officer Risto Kivisilta, who’s in charge of the mobile access project.

Solution with great promise

Modern mobile access has been received enthusiastically. It has been praised not only because it's flexible and easy to use but also because an application-based solution seems so natural.

“Our customers and users of UMA Workspaces are modern professionals who value reliable, new digital tools and the superior user experience they bring. I believe that mobile access will in any case be a more popular solution, especially for rental spaces like ours," says Kivisilta.

Mobile access to all UMA Workspaces

In the years to come, all UMA Workspaces will be installed with the IDcontrol mobile access solution.

"The technical solution for mobile access for various locations has been available from us for some time already, and this extensive package used in a number of places internationally shows that our technology is solid. The mobile access solution for UMA Workspace serves as a good example and will certainly pave the way to many mobile access solutions for rental premises in the future," says IDcontrol’s Managing Director Markku Raitanen.

Additional information

IDcontrol, Managing Director Markku Raitanen, This email address is being protected from spambots. You need JavaScript enabled to view it., +358 40 532 7734,