Uncategorised (4996)

GROB Systems Launches GROB-NET4Industry Manufacturing Execution System

AdministratorDesigned to Meet Industry 4.0 Requirements

GROB Systems, a global leader in the development of manufacturing systems and machine tools, announces GROB NET4Industry modules, designed to meet the needs of Industry 4.0 in a manner that is flexible, productive, and conserves resources.

GROB-NET4Industry features various modular components that can be combined in a highly customizable manner, ensuring the ideal solution for each application case. The modules within GROB-NET4Industry allow customers to manage direct and indirect areas around the machining process to achieve the most efficient utilization of high-precision, premium-quality machines. From production planning, monitoring, and analysis to the visualization of workpiece machining processes, proactive servicing, and maintenance, all areas of production are integrated.

Additionally, GROB-NET4Industry modules are equipped with integration platforms for all machine types, with the goal of implementing manufacturer-independent digitization concepts and offering comprehensive project support to all customers. The modules are available on the control systems of leading manufacturers like SIEMENS, HEIDENHAIN and FANUC.

Available GROB-NET4Industry modules include:

GROB4Portal Secure industry platform for all cloud services and other services

GROB4Line Monitor machines via smartphone

GROB4Analyze Machine feedback for the CIP process

GROB4Connect Connect the shop floor to the ERP system

GROB4Track Monitor machine axes at all times

GROB4Care Service and maintenance portal

GROB4Automation Intuitive control software for unmanned operation

GROB4Interface Machine communication the easy way

GROB4Pilot Multifunctional and interactive machine operation

In conjunction with GROB-NET4Industry, GROB4Pilot control enables almost entirely paperless production operations. The multifunctional and interactive operating concept is state of the art, featuring a capacitive touch screen, internet connectivity, and 3D support that makes it possible to depict all processes relating to machining. Boasting a feedback function and a walk through supported by visual features, the controllers also open up a whole new way of working.

For more information on GROB Systems please visit: https://www.grobgroup.com/en/

About GROB Systems

For over 90 years, GROB has been known worldwide for the development and manufacturing of machines and production lines for automotive OEMs. GROB has since expanded its portfolio to include universal 5-axis machining centers. The unique retractable spindle provides unmatched accessibility to the work piece, and even upside-down machining, in a collision-free environment. They are easy to install and maintain, and provide outstanding performance and precision from lot size 1.

GROB is a family-owned company located near Munich, Germany and has full manufacturing capabilities in Germany, Brazil, China, Italy and the United States. More than 500 employees at the 400,000 square foot facility in western Ohio support GROB customers across North America.

WAI continues to relentlessly meet the ever-changing needs of their customers in the heavy duty market. This includes an unwavering commitment to be “first-to-market” with the latest and most complete coverage for 100% new heavy duty alternators. WAI’s complete line of alternators are ideal for class one to class eight trucks and construction equipment.

WAI alternators offer superior field quality. Millions of units have been installed and tested to OEM specifications and include premium brand TRANSPO electronics manufactured by WAI, as well as premium grade WBD bearings. WAI alternators boast a high level of proven performance with thorough testing of output current at idle and full-load RPMs. Additionally, validation testing for all products includes endurance, humidity, power thermal cycling, vibration, salt spray and thermal shock. New alternators result in warranty rate reduction through extended field life of new units. Computerized test sheets are included in every box.

For more information on alternators visit www.waiglobal.com

About WAI

WAI is a premier global parts manufacturer for the automotive, heavy duty, agricultural, industrial, and power sports aftermarket. With world-class parts manufacturing facilities, WAI consistently meets the parts needs of its global customers, under one united goal – to provide customers with the products they need, when they need them. As a leading innovator and premier parts manufacturer, WAI has demonstrated an unwavering commitment to a “first-to-market” strategy and continues to work relentlessly to meet the ever-changing needs of its customers. For more information visit www.waiglobal.com

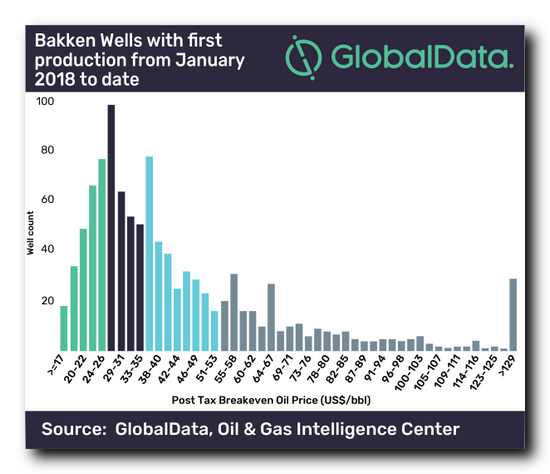

Production in Bakken formation expected to drop by 170 thousand boe per day in 2020, says GlobalData

AdministratorFollowing the expected cuts in capital expenditure (capex) for shale operators in the Bakken due to demand shock from the coronavirus (COVID-19) and supply shock from the Russia-Saudi price war;

Adrian Lara, Oil and Gas Analyst at GlobalData, a leading data and analytics company, offers his view:

“Whenever available, companies will try to focus on their best acreage but most operators have already squeezed their best land and so the room for improving well initial production (IP) rates might be limited. Moreover, Bakken operators need to make all their wells profitable, not only the new wells, and generate enough free cash flow to cover operating expenses.

“These legacy producing wells require different levels of oil price to recover their investment and cover expenses depending on when they were drilled. In particular, relatively recent drilled and completed wells, for instance wells brought to first production during the last two years, are very likely to still be in a period of recovering their investment and their required breakeven price is in average above US$46 per barrel (bbl).

“GlobalData estimates that for key operators in Bakken, a reduction of 50% in the number of rigs brings down their capex an average of 40% and this translates into a drop of 36% in their remaining net present value (NPV). GlobalData’s modelling indicates a drop of around 170 thousand barrels of oil equivalent per day in total Bakken production by the end of 2020.

“Furthermore, as per GlobalData estimates, the average position full cycle breakeven oil price of top operators in Bakken is US$46 per bbl. The full cycle position is relevant since it takes into account wells brought into production during the last two years, which bring an important share of production and are arguably still recovering their investment. By contrast the remaining breakeven oil price is at an average of US$26 per bbl, which indicates that operators have become very efficient in keeping their operation economically robust to cover their ongoing expenses.”

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make timelier and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

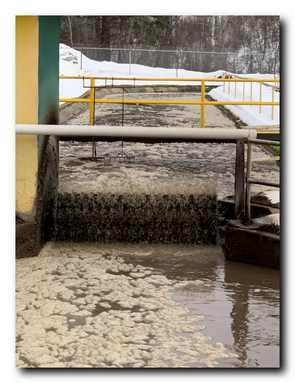

In the Trail Times, it was recently reported that:

‘…..the Village of Montrose has been successful in its application for funding under the Infrastructure Canada Grant Program for upgrades to the Village’s waste water treatment facility - a project that will modernize the 56-year-old plant….’

Not that one should be critical of a local newspaper that covers this village in south eastern British Colombia (two hours north of Spokane) – a publication which understandably knows that its readers won’t necessarily require all the finer details of a sewage treatment plant. However, it didn’t mention the fact that Montrose’s original aeration technology, installed by Lakeside Equipment….. back in 1963……is still in operation – and is very probably the longest lasting engineering of its type to still be in working order in the whole of Canada, North America, if not the world!

It was even further back in 1942 that Leon Simmons had the idea of developing what was then known as Woods Flats (an area of about 220 acres) into a retirement village for workers from the nearby Cominco (now Teck) smelter. In 1956, Woods Flats was incorporated as a village, and – consistent with so many historic connections between Canada and Scotland - was named after the Scottish coastal town of Montrose, which was once razed to the ground by the Danes in the year 980.

In the late 1950’s and early 1960’s, raw drinking water in Montrose BC came from a well that was drilled by the mouth of the Columbia River (that Beaver Valley Creek flows into) but one determined gentleman campaigned for a water treatment facility for his fellow villagers.

At first his concerns fell on deaf ears, but he formed a committee, then ran for council – eventually becoming mayor – during which time he successfully secured a grant for Montrose to have not only its fresh water treated, but for a sewer system too. The man behind this people power – and the introduction of Lakeside’s oxidation ditches back in 1963 was one Martin Walsh, whose son Mike, nearly six decades later, is now the current Mayor of Montrose.

‘Amazing for how old it is’

Lakeside equipment - still going strong at Montrose - since 1963!!!“At the time” said Mike Walsh, “the installation was state-of-the-art. All this time later we are going ahead with an upgrade, but the Lakeside equipment is amazing for how old it is – still working fine after all these years. My father pushed very hard for Montrose to have efficient and long-lasting treatment systems. Together with his colleagues, they certainly chose wisely”.

Lakeside equipment - still going strong at Montrose - since 1963!!!“At the time” said Mike Walsh, “the installation was state-of-the-art. All this time later we are going ahead with an upgrade, but the Lakeside equipment is amazing for how old it is – still working fine after all these years. My father pushed very hard for Montrose to have efficient and long-lasting treatment systems. Together with his colleagues, they certainly chose wisely”.

He added: “When the ‘race-track’ (now known as the Lakeside Closed Loop Reactor (CLR) Process) was installed, it was small of course for our small village, but even then, it was designed with room for expansion, which we took advantage of back in 1980. We’ve had no major problems at all. It has just kept on working away”.

For most wastewater treatment plants, Lakeside’s racetrack design with common wall construction has proved the most economical option, but over time, the reactor has been developed to take on several shapes, including the Folded U, Concentric Multichannel – and for small plants, a round packaged design with an internal final clarifier that offers the lowest construction and equipment cost.

The CLR Process form Illinois-based Lakeside consists of one or more reactors with a single feed point for raw wastewater and return sludge. The basic design at Montrose uses a simple racetrack configuration that provides a straight-line flow pattern for wastewater between the headworks and the final clarifiers. At the core of the CLR Process is the horizontal Magna Rotor, which sustains a high population of microorganisms in the reactor to provide simple process control. The Magna Rotor provides precise oxygen input into the biological process through adjustment of rotor immersion by raising or lowering the level control weir and by adjusting the rotational speed.

Warren Kersten, Vice President of Lakeside Equipment Corporation commented: “It’s hard to put into words just how proud we are as a company with the longevity of this equipment at Montrose. It was our first oxidation ditch installation – and remarkably, it still has the very original rotor aerators in use!”

‘Installation back in 1963’

He added: “I don’t mind saying that this installation in a beautiful part of British Colombia has actually been in operation much longer than most aeration companies have been in business! Since this inaugural installation back in 1963, more than 2,000 Lakeside systems of this type have been introduced to wastewater treatment plants all over Canada and the United States; equipment designed and made here in America. None are as old as this one from the early sixties, but there are a huge number that have an incredible track record and that are still going strong. Our products are also very low maintenance, but it is still a massive credit to the operators at Montrose that they clearly take very good care of their treatment plant equipment”.

With back up in this part of Canada from Lakeside’s representative, Promag Enviro of Burnaby, the CLR Process is not surprisingly known for its very stable operation over a wide range of influent flows and organic loadings – designed to minimize the time and effort required to control or adjust the system. Even in cold weather conditions when microorganism activity is decreased, the process operates efficiently without special attention.

The primary component of the CLR Process is its horizontal rotor aerator. The Lakeside Magna Rotor provides oxygen to the biological mass, mixes microorganisms uniformly and adds mixing velocity to the channel to prevent solids from settling. With the Lakeside blades die-formed of 10-gauge AISI Type 304 stainless steel to produce greater stiffness and rigidity, it is perhaps no wonder that the original rotors at Montrose – capable of taking a 250 lb impact load (without deformation) are still in working order!

The Mayor of Montrose, Mike Walsh, continued: “Winning a joint federal and provincial grant through the Investing in Canada infrastructure plan and New Building Canada Fund to upgrade our water and wastewater treatment is great news for our village. It’s also welcome news for our operators, because much of the treatment plant operation has been a hands-on job, including the manual cleaning of screens, which isn’t the most pleasant.

“Since 1963 when my father helped introduce our treatment plant, the number of homes in Montrose has almost doubled from 250 to 430, so we’ve had to reinvest – and can’t expect the wastewater equipment to last forever. Upgrades to our plant should be completed by the fall of 2021. We know for sure that we have had great service from Lakeside and are pleased to be the owners of the longest serving oxidation ditches”.

At Optima in Schwaebisch Hall, 3D printing is now part of the company's range of machines. For this future-oriented technology, the company has specifically founded a 3D printing center – the Additive Innovation Center – and has presented a route map. 3D printing will massively change special purpose machine manufacturing.

Optima has invested in the advanced multi-jet fusion technology which enables parts to be produced faster than with the SLS process. (Source: Optima)

Optima has invested in the advanced multi-jet fusion technology which enables parts to be produced faster than with the SLS process. (Source: Optima)

“Machine parts that previously took a week to manufacture can now be printed in a significantly shorter time”, says Optima Vice President Manufacturing Volker Freisinger. At its Schwaebisch Hall site, Optima has invested around half a million euros in the new 3D printing center, known as the Additive Innovation Center. The Additive Innovation Center has been in operation since July 2019 and, after a test phase and staff training, went into production at the end of 2019. It features a 3D printing lab and a training and design area, known as the Innovation Space. Since December 2019, employees with key roles are being trained there in 3D-compatible design.

The 3D printing process enhances customer flexibilit

The consumer demand for specific products is changing at an ever increasing pace. Social media and e-commerce are accelerating this growth. This affects all the market segments for that Optima develops machines for, which include pharmaceuticals, paper hygiene, consumer goods and healthcare products. New agile and flexible processes and technology are needed to counter this trend. “That's why we are providing our customers with support in terms of flexibility with additive manufacturing technology”, says Michael Weber, Director Service at OPTIMA consumer GmbH. Machine, format and replacement parts can be produced in a significantly shorter amount of time. In addition, a better price/performance ratio can also be achieved over the entire manufacturing process, especially for complex components. Therefore, design solutions that could not be implemented before are now possible. Inspired by nature, existing parts can be made lighter, stronger and with less material than before, for example, by using honeycomb structures. This is also a positive development in terms of sustainability – after all, no shavings or waste are generated during production.

Additive manufacturing – the 3D printing process – enables Optima customers to respond with even greater flexibility to new market requirements. Among other processes, Optima uses the multi-jet fusion printing process (image). (Source: Optima)

Additive manufacturing – the 3D printing process – enables Optima customers to respond with even greater flexibility to new market requirements. Among other processes, Optima uses the multi-jet fusion printing process (image). (Source: Optima)

All current printing methods are possibl

In the Additive Innovation Center, all the standard 3D printing methods are used. To produce prototypes quickly, Optima uses the fused deposition modeling (FDM) process, which has been successfully used in the automotive industry for many years, and the selective laser sintering (SLS) process. The SLS process opens up a broad range of materials, colors and subsequent treatments. A partner company contributes to the team advanced SLS processes with a wide variety of post-processing options. These include, for example, tinting and smoothing the components. Optima has also invested in the advanced multi-jet fusion technology which enables parts to be produced faster than with the SLS process. The breakthrough of SLS and multi-jet fusion printing technology has paved the way for companies to take 3D printing to an industrial level, far beyond simply creating prototypes.

Optima will be presenting a platform where machine users can order their parts online.

Maka Central discovery needs at least 210 million boe recoverable resources to be economical, says GlobalData

AdministratorThe Maka Central discovery has the potential to bring more than US$50m in revenue per year to the Surinamese Government, if it sees similar success to Guyana’s Stabrook, according to leading data and analytics company GlobalData.

Gregory Bosunga, Oil and Gas Analyst at GlobalData, comments: “Due to a lack of onshore processing and export infrastructure in the Guyana-Suriname Basin, development through a floating production storage and offloading (FPSO) unit will be the most optimal option. Maka Central reservoirs are located at the same level as the nearby Stabroek play – around 400 feet - so it is reasonable to assume a potential of 300 million barrels of gross recoverable oil.

“Assuming there will be similar development and operating costs to Liza Phase 1, to breakeven from the estimated total costs of US$7.2bn, Maka Central will need minimum recoverable resources of 213 million barrels of oil equivalent at oil prices of US$56 per barrel.”

“Assuming there will be similar development and operating costs to Liza Phase 1, to breakeven from the estimated total costs of US$7.2bn, Maka Central will need minimum recoverable resources of 213 million barrels of oil equivalent at oil prices of US$56 per barrel.”

Block 58 comprises 1.4 million acres and offers significant potential beyond the discovery at Maka Central. Seven distinct play types, and more than 50 prospects, have been identified. However, although initial indicators are encouraging, such expectation could be premature. A comprehensive exploratory program over this large block with further drilling and testing needs to be carried out to appraise the resources and productivity of the reservoirs.

Bosunga concludes: “It is far too early to know whether this new discovery by Apache and Total might eventually bring a similar positive financial impact for Suriname as the Stabroek block is expected to do for Guyana. Nonetheless, the initial indicators are encouraging and it is worth noticing that Apache has the ability to retain the entirety of Block 58 with no relinquishment requirements until June of 2026”

The Maka Central discovery is along the same geological cretaceous targets as recent discoveries in Guyana, in the Campanian and Santonian intervals. Block 58 in offshore Suriname can be interpreted as continuation of the Stabroek Block geological trend in Guyana. Estimations have been made assuming that Maka Central discovery will see similar success to Guyana’s Stabroek.

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

Uncertainty looms over oil and gas M&A deals landscape amidst coronavirus outbreak and drop in oil prices, says GlobalData

AdministratorThe recent coronavirus (COVID-19) outbreak is adding further woes for the oil and gas industry, which is already plagued by oversupply and declining prices. This is expected to affect the completion of announced and planned mergers and acquisitions (M&A) deals, according to GlobalData, a leading data and analytics company

GlobalData’s deals database identifies that a total of 262 M&A deals were announced in the global oil and gas sector during January 1, 2020 – March 15, 2020, which indicates a decline of 26% over the 354 deals announced during the same period in 2019. The corresponding deal value also declined by 15%.

Oil prices have been falling with concerns around oversupply. The production race and price war between Saudi Arabia and Russia are also contributing to the decline. Moreover, on the back of canceled events and travel restrictions due to the COVID-19 outbreak, the demand for jet fuel, as well as other fuel types, has been declining -resulting in a further drop in oil prices.

Oil prices have been falling with concerns around oversupply. The production race and price war between Saudi Arabia and Russia are also contributing to the decline. Moreover, on the back of canceled events and travel restrictions due to the COVID-19 outbreak, the demand for jet fuel, as well as other fuel types, has been declining -resulting in a further drop in oil prices.

The Organization of the Petroleum Exporting Countries (OPEC) also revised and reduced its 2020 global oil demand forecast due to the outbreak. The average price of crude oil, which stood at US$63.4 per barrel (b) in December 2019, fell to US$61.6/b in January 2020 and US$53.3/b in February 2020. Furthermore, according to OPEC, oil prices fell by more than 30% during the first ten days in March 2020.

With a slowdown in demand amidst the COVID-19 pandemic and the drop in oil prices, a cloud of uncertainty looms over several announced and planned M&A deals in the oil and gas sector.

Aurojyoti Bose, Lead Analyst at GlobalData, comments: “Arranging finance for pursuing deals may emerge as a challenge. Completion of some of these deals is likely to be delayed, while some may be called off.

“For instance, in January 2020, BCE-Mach III LLC entered an agreement to acquire assets of Alta Mesa Holdings. However, on March 10, 2020, BCE-Mach III said that completion of the transaction fell into doubt, as the US$320m financing from UBS fell apart over the COVID-19 epidemic and the drop in oil prices.”

- Quotes are provided by Aurojyoti Bose, Lead Analyst at GlobalData

- The information is based on GlobalData’s Financial Deals Database

- This press release was written using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make timelier and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

Internet Infrastructure Demand Rises during COVID-19 Pandemic by 30 Percent

AdministratorInternet infrastructure has experienced significant growth in demand due to the increased amount of people confined to their homes, consequently working and shopping remotely due to the enforced precautionary measures.

Having most of our daily activities migrating to the digital space, internet infrastructureis being strained by the sheer amount of users. As a result, e-commercehas been booming as many stores remain shut due to safety policies. Additionally, there has been anotable increase in subscription-based digital services, as out-of-home entertainment is no longer a viable option.

Internet service providers areextending data caps to meet the newfound reliance on the network, however, some experts express uncertaintyconcerning internet infrastructure’s ability to keep up with the rapidly growing demand.

“The amount of time people are spending online, whether it be for work or leisure, has been immense, which is not surprising, considering all the restrictions that have been enforced,” says Vincentas Grinius, CEO of Heficed.

With millions bound to their homes due to the pandemic, people are moving most of their activities to the digital space, which has tremendously increased global usage of the internet network.

With millions bound to their homes due to the pandemic, people are moving most of their activities to the digital space, which has tremendously increased global usage of the internet network.

“In pursuance to maintain stability, the demand for internet servers has risen by at least 30 percent, and, based on how the current events are developing, the need to accommodate the reliance will only continue to grow,” adds Mr. Grinius.

According to Mr. Grinius,Heficed has accumulated enough server stock supply to meet the current demand and lessen the strain on the infrastructure, as a wide range of hardware is kept in storage facilities throughout the US and Europe. Furthermore, Heficed is encouraging companies to lease their unused IP resources via the IP address market in order to facilitate more resources for ISPs and others in need of network infrastructure.

Current events have revealed how well businesses are prepared to accommodate a remote workforce. Business VPNs, that give workers direct access to their company’s system through a private network,have been overwhelmed by the employee usage. High-capacity VPNs are essential for companies seeking to continue their work, as organizations that are less equipped will eventually succumb to the increased load. Adapting a highly developed network infrastructure, such as offered by Heficed, can aid in handling the escalating use and help maintain operational stability.

The Internet may need to strengthen its backbone, as the ever-growing online activityhas attracted a new wave of cyberattacks.Novel threats are targeting internet users in an attempt to retrieve sensitive data. Heficed offers abuse management as part of their service package, seeking to combat any malicious activity, directed at their clients' resources.

The present state of affairs has highlighted some of the weaknesses concerning the current network infrastructure however implementing some additional measures to improve its stability may prevent companies from compromising their operations and ensure they continue to work during the pandemic.

ABOUT HEFICED

Headquartered in London, Heficed provides full-range services for IP lease, monetization, and management services. Heficed serves around 60 multi-billion industries starting from hosting to automotive or healthcare. With the millions of IP addresses and 12 years of industry experience and the operations globally Heficed can meet any demand needs. That includes automated provisioning bare-metal solutions and cloud services in 8 locations around the world. More information: https://www.heficed.com.

Rohde & Schwarz presents cutting-edge conformance testing solution for 5G NR FR2

AdministratorRohde & Schwarz highlights its innovative 5G conformance solution for both FR1 and FR2, featuring the latest version of the popular R&S TS8980 RF test system, now covering 5G NR. To enable over the air (OTA) testing, the solution includes the new R&S ATS1800C compact antenna test range (CATR) based 5G NR mmWave test chamber.

5G NR necessitates new testing approaches. The introduction of the new, mmWave based FR2 frequency range for 5G and the increased use of active antennas without physical connectors requires testing to be performed over the air (OTA). Rohde & Schwarz has developed a test solution able to perform the first tests for RF conformance in 3GPP FR2. The device under test, a 5G smartphone, is placed in the R&S ATS1800C chamber. The chamber is also available in a new special configuration for extreme temperature testing in 3D.

A test system for mobile technologies up to 5G

The R&S TS8980 is a well-established family of RF conformance test systems. With the addition of the new R&S CMX500 radio communication tester, the RF conformance system gets 5G NR signaling functionality.

The upgraded R&S TS8980FTA is the only RF conformance test system in the market supporting mobile technologies all the way from 2G to 5G on one platform. A unique feature of the R&S TS8980FTA is the smooth upgrade path to 5G. Users who already have the previous version of the R&S TS8980 can upgrade to 5G RF FR1 testing by adding the R&S CMX500 as an extension box. While in FR1 all the tests are done in conducted mode the need in FR2 is to test over-the-air. This is realized by extending the TS8980FTA by a very compact CATR system.

Compact, flexible CATR system for FR2 testing

A CATR testing solution features a reflector to minimize the space requirements for OTA tests. For the 5G frequency range FR2 user equipment conformance test, CATR designs are the best practical choice since the required plane wave signals are available in distances measured in decimeters from the reflector, instead of meters as in direct far field chambers. A CATR setup is reciprocal and can be used for the transmission characteristics of the device, as well as the receiver characteristics.

The setup includes the new CATR based R&S ATS1800C for FR2 testing. It is a turnkey, high-end chamber with the smallest footprint in the industry of only 1.3 m², featuring class-leading signal integrity and shielding in a small space. The solution includes a gold-coated reflector providing a large quiet zone of 30 cm, fulfilling 3GPP 5G NR conformance test requirements. Completing the test setup is a configuration for extreme temperature testing. With a frequency range 18-90 GHz, the solutions have potential applications well beyond the current FR2 bands.

Rohde & Schwarz

Rohde & Schwarz is a leading supplier of solutions in the fields of test and measurement, broadcast and media, aerospace | defense | security and networks and cybersecurity. The technology group's innovative communications, information and security products help industry and government customers ensure a safer and connected world. On June 30, 2019, Rohde & Schwarz had 12,100 employees. The independent group achieved a net revenue of EUR 2.14 billion in the 2018/2019 fiscal year (July to June). The company is headquartered in Munich, Germany, and has subsidiaries in more than 70 countries, with regional hubs in Asia and America.

R&S ® is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

Tendeka pens four-year zonal isolation contract in Malaysia

AdministratorIndependent global completions service company Tendeka has secured a four-year contract to supply its zonal isolation technologies across a leading operator’s Malaysian assets.

The contract was awarded through Tendeka’s partner in the region, Dialog Systems Sdn Bhd (DSSB), a wholly owned subsidiary of Dialog Group Bhd, one of Malaysia’s leading technical service providers in the oil, gas and petrochemical industries.

This is the third time Tendeka has won this contract, which first started in 2013. This latest extension, worth more than USD1million, will see the company carry out the work until 2023.

Keith Parrott is Tendeka’s South East Asia Area ManagerTendeka’s SwellRight swellable packers help reduce well construction costs, extend well life, and improve well integrity. The company’s swellable packers provide long-term stability and reliability required to isolate producing zones. The retrievable option has been designed to isolate the wellbore while enabling the easy removal of the entire assembly from the wellbore without any milling operations.

Keith Parrott is Tendeka’s South East Asia Area ManagerTendeka’s SwellRight swellable packers help reduce well construction costs, extend well life, and improve well integrity. The company’s swellable packers provide long-term stability and reliability required to isolate producing zones. The retrievable option has been designed to isolate the wellbore while enabling the easy removal of the entire assembly from the wellbore without any milling operations.

Keith Parrott, Tendeka’s South East Asia Area Manager, said: “We are proud to have secured this contract for a further four years, which is recognition of both our team and the technology.

“Our zonal isolation swellable and mechanical packer technologies are designed to prevent fluid communication between individual reservoir sections. These sustainable solutions are recognised around the world to help reduce costs and extend the life of wells.”

Tendeka also offers SwellRight Ultra Packer, a cost-effective solution for high pressure applications, providing the highest-pressure rating on the swellable market. Enabling operators to utilise smaller pup joints, the Ultra Packers can effectively reduce the amount of rubber element required for high pressure applications, for use in horizontal and vertical wells.

About Tendeka

Tendeka is a global specialist in advanced completions, production solutions and sand management for the oil and gas industry. From simple to complex well designs, the company has an extensive track record in enhancing productivity for clients’ reservoirs offshore and onshore. Tendeka invests in research and development, bringing to market disruptive technologies and offering solutions targeted to operators’ specific production challenges.

Established in 2009 and headquartered in Aberdeen, UK, Tendeka operates in strategically positioned bases, located at global energy hubs including the North Sea, Asia-Pacific, Middle East and USA.

To find out more, please visit: www.tendeka.com

More...

Unity secures multi-million-pound contract with Spirit Energy for well integrity services

AdministratorUnity, Europe’s largest provider of well integrity technology, services and engineering solutions, has been awarded a three-year contract by Spirit Energy to maintain wellhead equipment across twelve platforms in the East Irish Sea, Southern North Sea and the Dutch sector of the North Sea.

As part of the work-scope Unity will deliver surface wellhead and Xmas tree maintenance services offshore, covering around one hundred wells, as well as providing onshore equipment testing, repair, refurbishment and storage from its base in Great Yarmouth. The contract, worth an annual seven figure sum, has two additional two-year extension options.

Gary Smart, Unity CEO commented: “Having previously worked with Spirit Energy to provide well integrity and technology solutions, we have a strong understanding of the company’s operations. We are thrilled to add this service agreement to our growing portfolio of offshore contracts, which now includes over half of all major North Sea operators.

Spirit Energy’s Central Platform, located in Morecombe Bay, one of the assets to be supported by Unity.

Spirit Energy’s Central Platform, located in Morecombe Bay, one of the assets to be supported by Unity.

“We are well placed to deliver an all-encompassing service to our clients through a workforce of highly experienced offshore technicians. Our team has exceptional knowledge of all OEM wellhead equipment which will add value throughout this project. Our own range of spare parts, rental assets, innovative technology and specialised engineered solutions also offer reassurance for rapid equipment availability and solving any integrity challenges which may arise.”

Unity is currently developing additive manufactured wellhead components at its base in Aberdeen, to complement its maintenance and spare parts offering. These strong but lightweight products will be delivered to clients with significantly reduced cost and lead times.

Mr Smart continued: “We believe that part of the reason we are a preferred supplier for many of our clients is not only the fast turnaround, competitive pricing and expertise within the company, but crucially, the additional value we can deliver through our own in-house product technology and engineering. We continue to invest in research and development to enhance this capability and are looking forward to introducing our additive manufactured components to the market later this year.”

Unity, part of the FrontRow Energy Technology Group, employs more than 120 skilled personnel across its bases in Aberdeen and Great Yarmouth, UK and Esbjerg, Denmark.

About Unity

Unity is Europe’s largest provider of well integrity technology, services and engineering solutions for the global upstream oil and gas industry. The company collaborates with its clients to deliver long-term solutions which enhance performance and drive savings over the life of their wells. Unity combines:

- Integrity support services: a full range of wellhead inspection, maintenance and repair; equipment rental, refurbishment, upgrade and recertification.

- Engineered solutions: unique in-house designed solutions that remediate well and conductor integrity problems.

- Technology: innovative products and services that reduce operating costs, improve performance, extend well life and simplify abandonment.

Unity, along with Pragma, Well-SENSE and ClearWELL are part of Aberdeen-based FrontRow Energy Technology Group.

About FrontRow

FrontRow Energy Technology Group is a dynamic upstream oil and gas services group focused on dramatic cost reduction through the application of innovative technologies and ways of working. FrontRow comprises a number of complementary businesses, with a collaborative work ethic, to find smarter and more efficient ways for its customers to manage and exploit their producing assets. FrontRow specialises in production enhancement, well intervention, flow assurance, well integrity, field life extension and well control.

Jason Chester of InfinityQS earns award recognition from Food Logistics and Supply & Demand Chain Executive

AdministratorJason Chester, Director of Global Channel Programs at InfinityQS, the global authority on data-driven enterprise quality solutions, has been named on the 2020 Food Logistics Champions: Rock Stars of the Supply Chain and Supply & Demand Chain Executive’s Pros to Know awards.

The Food Logistics Champions: Rock Stars of the Supply Chain recognises influential individuals across the food industry whose achievements, hard work, and vision have shaped and attained milestones in safety and efficiency through the global food supply chain. From early pioneers and entrepreneurs to non-conformist thinkers and executive standouts, this award aims to honour business leaders and their contributions to the food industry.

The Pros to Know award looks at the wider supply chain, highlighting executives that are leading initiatives to prepare their companies’ supply chains for the significant challenges of today’s business climate.

The Pros to Know award looks at the wider supply chain, highlighting executives that are leading initiatives to prepare their companies’ supply chains for the significant challenges of today’s business climate.

Both award programs commend Jason for his hard work and ongoing thought leadership to educate InfinityQS’ strategic channel partners and industries at large, in how manufacturing optimisation can be achieved by leveraging next-generation information technologies like InfinityQS’ cloud-native Quality Intelligence platform, Enact®.

Jason is helping InfinityQS Partners integrate the Enact Manufacturing Quality Intelligence Solution into their clients’ manufacturing environments. This allows them to modernise their data collection methods, gain real-time visibility into global production and quality processes, and uncover operational insights through advanced statistical analysis. The derived intelligence enables timely remedial action and reveals opportunities to optimise quality, consistency, safety, and compliance—at the individual plant and enterprise levels.

Marina Mayer, editor-in-chief of Food Logistics says: “The 2020 Food Logistics Champions: Rock Stars of the Supply Chainexhibits the true celebrities of the industry that go the extra mile to ensure their company’s supply chains are being operated in an efficient, safe and transparent manner. These professionals are an example for today’s youth to consider the supply chain and logistics industry as a possible path of employment.”

Jason Chester says: “It’s an honour to be presented with the 2020 Food Logistics Champions: Rock Stars of the Supply Chain Awardand the Supply & Demand Chain Executive’s Pros to Know award, alongside other incredible industry peers. The individuals receiving these awards have helped to shape the industry by promoting innovation and providing exceptional thought leadership and I am proud to be recognised alongside these inspirational leaders.”

Recipients of this year’s Food Logistics Champions: Rock Stars of the Supply Chain award will be profiled in the March 2020 issue, as well as online at www.foodlogistics.com. For the full list of 2020 Pros to Know winners, visit Supply & Demand Chain Executive’s website at www.sdcexec.com.

About Food Logistics

Food Logistics is published by AC Business Media, a business-to-business media company that provides targeted content and comprehensive, integrated advertising and promotion opportunities for some of the world’s most recognised B2B brands. Its diverse portfolio serves the construction, logistics, supply chain and other industries with print, digital and custom products, events and social media.

About Supply & Demand Chain Executive

Supply & Demand Chain Executive is the executive's user manual for successful supply and demand chain transformation, utilizing hard-hitting analysis, viewpoints and unbiased case studies to steer executives and supply management professionals through the complicated, yet critical, world of supply and demand chain enablement to gain competitive advantage. Visit us on the web at www.SDCExec.com.

About InfinityQS International, Inc.

For over 30 years, InfinityQS has been the leading global provider of Manufacturing Quality Intelligence software and services. Powered by a robust Statistical Process Control (SPC) analytics engine, the company’s solutions—Enact® and ProFicient™—deliver unparalleled visibility and strategic insight across the enterprise, from the shop floor to the boardroom. This extensive deep-dive capability enables manufacturers to improve product quality; decrease cost and risk; improve compliance; and make strategic, data-driven business decisions. Headquartered near Washington, D.C. and with offices in Seattle, London, and Beijing, InfinityQS has thousands of customers around the world, including Ball Corporation, Boston Scientific, Graham Packaging, and Medtronic. For more information, visit www.infinityqs.com.

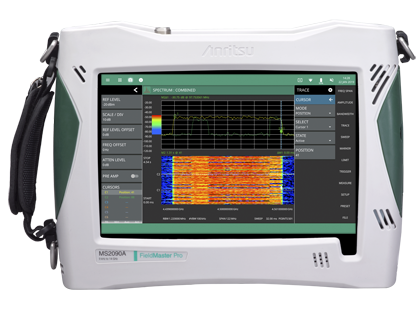

Anritsu Adds IQ Capture, Streaming Capability to Field Master Pro™ MS2090A RTSA

Administrator― New Options Combine with Best-in-Class Wide Bandwidth, Long Memory, and Fast Transfer Speed to Provide Comprehensive Signal Analysis in General Purpose Applications ―

Anritsu Company introduces IQ capture and IQ streaming options for its Field Master Pro™ MS2090A that make the real time spectrum analyzer (RTSA) the first handheld analyzer to capture 110 MHz of IQ data. When combining the new features with the best-in-class wide bandwidth, long memory, and fast transfer seeds, the MS2090A can conduct comprehensive spectrum analysis in a variety of general purpose applications, including military intelligence and government regulations.

With 110 MHz bandwidth and 200 MSps sample rate, the MS2090A can capture and stream twice as much data as any other handheld analyzer. Additionally, having IQ capture and streaming in RTSA mode allows for the capture and/or streaming of data without pausing the sweep, so users can monitor the spectrum visually while the capture is being conducted. The result is more information is acquired on spectrum surrounding bands of interest.

Of particular benefit for intelligence and government applications, the MS2090A RTSA can stream data to Bird Technology’s IQC5000B dual-channel RF record and playback system. The turnkey solution enables 110 MHz of bandwidth to be streamed at 16-bit format and up to 15 TB of data to be stored. Powerful post-processing analysis, including evaluating data in various domains, replaying data as spectrum with full-time resolution, and smart algorithms to search for signals, can be performed. Data can also be streamed to a USB 3.0 drive or PC over Ethernet.

Signal data can be captured and segmented into I and Q samples with the options. Capturing the actual IQ data and analyzing it sample by sample allow the finest details of signal and spectrum behavior to be monitored. Additionally, unknown signals in spectrum where secure communications are required can be identified and evaluated to determine if they are harmless or nefarious. IQ data also allows regulation officials to gather more information on unknown signals to better locate and identify unauthorized communications in all bands, for more efficient spectrum clearing.

For 5G applications, the 110 MHz of capture bandwidth allows mobile operators to gather data on a full 5G NR signal in a single sweep. It can also post process the data to locate any anomalies that will adversely affect network performance.

IQ sample formats of 8, 10, 16, and 32 bits are available with the options. The higher bit depths provide greater resolution for highly accurate narrow bandwidth captures. In applications in which dynamic range is not essential, the lower bit depth can create more efficient storage and improve data processing time.

Field Master Pro MS2090A Outline

The Field Master Pro MS2090A RTSA provides a continuous stream of FFT measurements over a 110 MHz analysis bandwidth, as well as 2.055 µs probability of intercept (POI). The result is users can more accurately detect signals that are short in duration or hop compared to standard swept-tuned spectrum analyzers. Density and spectrogram displays are available to more easily identify and track intermittent or pulsed signals. Seven models are available with frequency coverage of 9 kHz to 9/14/20/26.5/32/43.5 and 54 GHz.

About Anritsu

Anritsu Corporation (www.anritsu.com), a global provider of innovative communications test and measurement solutions for 120 years. Anritsu’s “2020 VISION” philosophy engages customers as true partners to help develop wireless, optical, microwave/RF, and digital solutions for R&D, manufacturing, installation, and maintenance applications, as well as multidimensional service assurance solutions for network monitoring and optimization. Anritsu also provides precision microwave/RF components, optical devices, and high-speed electrical devices for communication products and systems. The company develops advanced solutions for 5G, M2M, IoT, as well as other emerging and legacy wireline and wireless communication markets. With offices throughout the world, Anritsu has approximately 3,500 employees in over 90 countries.

Mining Goes Electric: Goodbye People, Poisoning, Poor Profits

AdministratorElectrics and robotics squares the circle of seeking a wider variety of depleting materials in nastier, more remote places from the seafloor to four kilometres underground, up remote mountains and later outer space. Zero-emission microgrids on-site, sensors everywhere and new information and communications technology lubricate the process. Mining embraces about 1500 large mines yielding metal-bearing material, diamonds and coal, down to tens of thousands of smaller sites such as gravel pits and marble quarries. Despite these greater challenges, mine operators must improve safety, environmental and financial aspects. The man working a tool and the static processor are replaced by vehicles but those vehicle suppliers pushing only diesel-alone vehicles with diesel gensets as a sideline are starting to look retro and rejected.

Unique new report

The new IDTechEx report, “Electric Vehicles and Robotics for Mining 2020-2030” shows how electric vehicles and robotics progress to the newly-arrived unmanned electrical mines. See uniquely up-to-date, penetrating analysis and forecasts of the technology and markets globally. It is for all in the mining vehicle value chain. Many mining vehicles are among the most power-hungry EVs, yet they are located where pressure for zero-emission local electricity supply is strengthening. It is therefore futile to analyse mining electrification without addressing where that zero-emission electricity will come from, so IDTechEx does that too – zero-emission microgrids on-site, increasingly multi-mode and transportable.

This 280-page report has an “Executive Summary and Conclusions” sufficient in itself because it gives ten-year forecasts in five categories, six key market drivers in detail and infograms of the mines of the future and the many new challenges. See 20 key conclusions grouped by industry, regional and technological. Mining CapEx content and trend is clarified by new infograms. Development timeline, patent trend and progress 2020-2040 to price parity with diesel by vehicle type are graphed. The “Introduction” then scopes mining basics, leading miners and new challenges, threats and incentives, the mining equipment market and what is and is not an electric vehicle. Here are powertrain options emerging, huge scope for vehicle simplification, emissions data and targets, future types of mine, progress to electrification and unmanned mines.

Battery electric BEV mining vehicles

Chapter 3 brings it to life with profiles and products in “Mining BEV Appraisal: 23 Manufacturers”. See SOFT reports on leaders, executive responses, latest products. Chapter 4 introduces six key enabling technologies and their future for mining electric vehicles, pure electric and hybrid with a ten-year roadmap. See electric motor options that work inversely as generators for hybrid and full electric, with examples. Electric traction is more even, controllable, faster responding and stronger from start. Motors are key to achieving long-range/ endurance and best performance. Traction battery systems include battery charging and advances to 2030. Why have supercapacitors come center stage in mining vehicles? Learn power electronics proliferation and extension to solar bodywork, including microgrid trucks.

Making clean electricity on-site

Chapter 5 “Energy Independent, Zero Emission Mines”, includes the new transportable, lower-intermittency options of open-sea wave and tidal power, river power and airborne wind energy to supplement or replace today’s battery solar and wind turbines.

Robotics resurgent

A seventh key technology – Autonomy - is important enough to have a Chapter 6 and 7. Chapter 6 is “Autonomous and Remotely Operated Mining Vehicles in Action”, and Chapter 7 is “Autonomy Components and Integration” – lidar, radar, ultrasound, sensor fusion.

The report “Electric Vehicles and Robotics for Mining 2020-2030” uniquely gives the full picture, visit www.IDTechEx.com/Mining to find out more.

To find out more about Electric Vehicle research available from IDTechEx visit www.IDTechEx.com/research/EV or to connect with others on this topic, IDTechEx Events is hosting: Electric Vehicles - Everything is changing, November 18-19 2020, Santa Clara, USA www.IDTechEx.com/EVUSA.

IDTechEx guides your strategic business decisions through its Research, Consultancy and Event products, helping you profit from emerging technologies. For more information on IDTechEx Research and Consultancy contact This email address is being protected from spambots. You need JavaScript enabled to view it. or visit www.IDTechEx.com.