Uncategorised (4996)

Gulf of Mexico order underlines filter maker’s global oil and gas reach

AdministratorA specialist UK manufacturer has designed, made and supplied essential filtration components to help with offshore oil and natural gas production in the Gulf of Mexico.

Amazon Filters despatched a bespoke filter housing containing four large-format high-flow filters to a floating deepwater rig 280 miles south of New Orleans.

Amazon Filters designed and produced the filter housing for the Gulf of Mexico order at its Camberley, Surrey, manufacturing centre. The order came from the industry services provider Cameron International, working for US energy giant Chevron at its Jack and St. Malo fields.

Amazon Filters designed and produced the filter housing for the Gulf of Mexico order at its Camberley, Surrey, manufacturing centre. The order came from the industry services provider Cameron International, working for US energy giant Chevron at its Jack and St. Malo fields.

The 40-inch-long, six-inch-diameter SupaPleat FFC filters will be used to filter the CIP (clean in place) fluid that regenerates and keeps sulphate removal membranes working correctly.

The process will help to minimise filtration costs while still meeting the stringent design and environmental criteria related to offshore platforms.

The rig stands in 7,000 ft of seawater, with a well depth of 26,000 ft, and has a daily production capacity of 170,000 barrels of oil and 42 million cubic feet of natural gas.

As a result, it requires high-performance CIP filters capable of weathering the most challenging of conditions to ensure uninterrupted flows.

For this order, super-duplex steel was used for the constructions along with design elements such as Xylon-coated bolts on the lid closure. These prevent thread galling and ensure trouble-free filter element changeout throughout the system’s life.

Amazon Filters, headquartered in Camberley, Surrey, developed its SupaPleat FFC design specially to suit large-scale, long-life processes such as deepsea oil and gas applications.

Neil Pizzey, Amazon Filters Managing Director, said: “Delivering this contract successfully is a further demonstration of our ‘quick and able’ market proposition, in other words the capacity to support customers across the world working in critical applications such as oil and gas production.

“For 35 years now, clients working in a wide range of industries have come to us to help gain process efficiencies and competitive advantage.

“We will continue to support them by investing in the design and manufacture of filtration systems, including housings, depth and pleated cartridge filters, coalescing technology and other essential products.

“With Covid-19 impacting directly on the oil and gas markets, finding cost-effective and reliable solutions has never been more important for producers. We’re here to help.”

Founded in 1985, UK-based Amazon Filters Ltd is one of Europe’s leading manufacturers and suppliers of filter cartridges and housings. Our comprehensive range of products support critical liquid and gas applications in industries such as oil and gas, automotive, pharmaceuticals, food and beverage, chemicals and coatings, water treatment and building services. We operate a range of ISO-accredited Quality Management Systems to ensure excellence in customer service. For more information, visit www.amazonfilters.com or call 01276 670600.

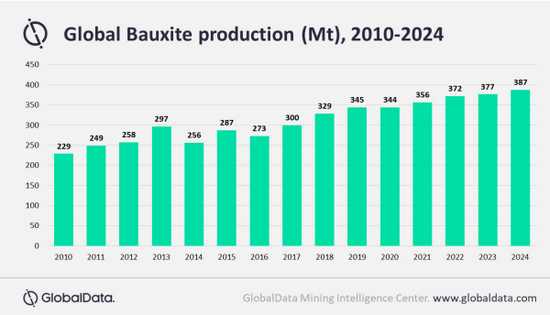

Global bauxite supply to be marginally affected amidst COVID-19 measures, says GlobalData

AdministratorThe global bauxite mine production is expected to be marginally affected by the temporary suspension of mines due to the COVID-19 pandemic and is forecast to decline by just 0.1% to 344Mt in 2020, says GlobalData, a leading data and analytics company.

Production in Australia is expected to increase by 1.9% to 107.2kt in 2020, accounting for 31.2% of the global total. The impact of COVID-19 has been limited in Australia, which is the world’s largest producer of bauxite, due to effective measures being taken by the government to contain the spread of the virus across the mining regions.

Rio Tinto, the largest bauxite miner in Australia, reported production of 24.8Mt of bauxite in the first half of 2020 – up by 8% year-on-year. This was primarily due to the ramping up of the Arum mine.

Vinneth Bajaj, Senior Mining Analyst at GlobalData, comments: “In India, the fifth largest producer, bauxite was exempted from the country’s first 21-day lockdown period, with no major hindrance for bauxite miners thereafter. As a result, the country’s bauxite production is expected to increase by 6.5% in 2020.”

Elsewhere, in China, despite mines returning to full capacity by mid-April, the country’s output is expected to fall by a marginal 1.8% in 2020. While in Brazil, depleting ore grades will be a key factor behind a forecast 4.2% decline in the country’s output this year.

The spread of COVID-19 has largely impacted small bauxite-producing countries such as Indonesia, Jamaica, Russia, Kazakhstan, Ghana and Guyana. Collective production from these countries is expected to decline from 37Mt in 2019 to 33.8Mt in 2020. These countries accounted for 10.8% of global bauxite output in 2019, with the share set to drop to 9.8% in 2020.

Bajaj continues: “Production over the forecast period (2021–2024) is expected to grow at a CAGR of 2.8%, to reach 387.4Mt in 2024, with Australia, Guinea, and India to be the key contributors. Combined output from these three markets is expected to increase from 226.8Mt in 2021 to 258.8Mt in 2024.”

Key projects expected to commence operations during the forecast period include the Kindia project in Guinea, which is wholly-owned by Anglo-African Minerals. With an annual saleable production capacity of 5Mt, the project is expected to commence operations in 2021.

In addition, the Garafiri project, also in Guinea, has completed regulatory approvals and permissions. The project has an estimated development capital expenditure of US$1.4bn and saleable production capacity of 3Mt per year and is due to begin construction in 2021 with production to commence in the third quarter of 2022.

- Quotes provided by Vinneth Bajaj, Senior Mining Analyst at GlobalData

- This press release was written using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

How Scanjet PSM are Managing and Delivering During the COVID-19 Pandemic

Administrator2020 has brought many challenges to businesses and individuals, as the world has had to deal with the COVID-19 pandemic. The safety of Scanjet PSM’s staff and customers has always been paramount to them, and in line with UK government guidelines the company were able to continue trading through the difficult months of lockdown as production continued under controlled COVID-secure conditions.

As society has started to reopen, all non-production staff who had been working from home have now returned to working in the office in a safe and secure way. Scanjet PSM would like to thank all their staff, customers and suppliers for their support during this challenging period.

As society has started to reopen, all non-production staff who had been working from home have now returned to working in the office in a safe and secure way. Scanjet PSM would like to thank all their staff, customers and suppliers for their support during this challenging period.

Continuing to Deliver to Projects - Worldwide

Despite these unprecedented and uncertain times, Scanjet PSM have delivered major projects to customers around the world, including in Australia, Canada, China, Egypt, Saudi Arabia, Spain, the UAE and the UK. During the months of April to July, they have delivered around 2,000 sensors, including their latest APT500, APT1000 and 260 Tankstar, for a wide range of commercial and naval applications.

Scanjet PSM have a number of key projects which they are currently working on and they are focused on ensuring our customers receive the highest levels of customer service and business continuity from Scanjet PSM, whilst continuing to monitor the latest updates about the COVID-19 pandemic.

Please visit www.psmmarine.com or contact Mark Jones, Sales & Marketing Manager at PSM Instrumentation, by e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it. or telephone: +44 (0)144 410 040 for more information.

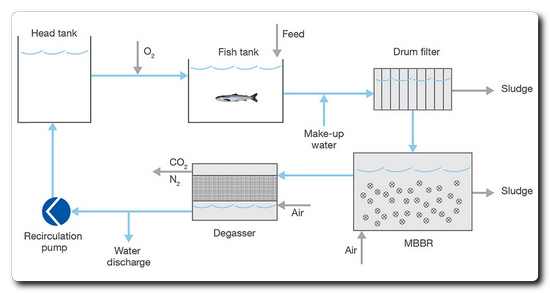

Sulzer pumps at the heart of the largest smolt facility in Norway

AdministratorNordlaks is a Norwegian fully integrated company that produces, processes and sells Atlantic salmon and rainbow trout worldwide. It has recently completed the building of a new smolt facility for fish up to 500 grams at Innhavet in Hamarøy municipality. This RAS (Recirculating Aquaculture System) fish farm is the biggest of its kind in Norway, with a special focus on smolt welfare. The land-based facility has state-of-the-art equipment for optimal biosecurity and sustainability. At the heart of the RAS process, all recirculation pumps were supplied by Sulzer.

New Nordlaks fish farm in Innhavet, Norway

New Nordlaks fish farm in Innhavet, Norway

The challenge

The Innhavet RAS plant has 34 fish tanks of different capacities (350 to 1’000 m3) in 5 separate main sections. Each section is independent from the others and includes its own complete water treatment system in a semi-closed loop (98% recirculation + 2% make-up water). The brackish water from the fish tanks first flows by gravity to a rotating drum filter for the removal of the main suspended solid particles. It then falls into an MBBR (Moving Bed Biofilm Reactor) for TAN (Total Ammonium Nitrogen) reduction. After passing through a countercurrent degasser for the stripping of nitrogen and carbon dioxide, the treated water is finally pumped to some head tanks, prior to oxygenation and return to the fish tanks.

In each fish tank, the water is fully renewed every half an hour. The well-being of the smolts is highly dependent on a constant flow of water through the facility. The reliability of the recirculation pumps is, therefore, of paramount importance.

High overall energy performance of the RAS plant means a better environmental footprint and reduced operating costs. Consequently, the main components of the water treatment loops must have top-class efficiencies, particularly the recirculation pumps.

Five AHLSTAR A43-500 recirculation pumping units for brackish water

Five AHLSTAR A43-500 recirculation pumping units for brackish water

The solution

As a long-term supplier of equipment (pumps and turbines) to other Nordlaks plants, Sulzer was involved at an early stage of the new project. In collaboration with the Momek Group, a large industrial service provider in Scandinavia, the pumps were carefully selected, not only to fulfil the requirements during the warranty period, but to run optimally and economically during the whole lifetime of the site. For the recirculation of the brackish water, 50 AHLSTAR and BE process pumps in duplex material have now been installed and are operating continuously. In addition, 5 VUPX submersible propeller pumps are used on intermittent duty when the fish tanks are emptied during the transfer of smolts.

Customer benefit

By choosing to work with a trusted partner, the client made sure to get fast and permanent technical support, in addition to the best products. The recirculation pumps have the following major advantages:

- Extremely high hydraulic efficiencies that by far exceed the strictest energy regulations for water pumps. This means huge energy savings over time and smaller total cost of ownership.

- Duty points close to BEP (Best Efficiency Points), low rotation speeds and rigid baseplates grouted in concrete. The pump units are working smoothly with minimized vibration levels.

- Superior-grade material for all wetted parts. For the choice of pump material in contact with brackish water, the long-term perspective favored duplex stainless steel rather than 316SS. Duplex steels have better design strength than austenitic stainless steels, as well as higher corrosion, abrasion and pitting resistance. In the end, maintenance costs and the risk of downtime are reduced.

Sulzer is a recognized supplier in the fish farm market, with innovative and proven pumping, mixing and aeration solutions, and provides highly energy-efficient products with low life-cycle costs and the smallest possible environmental footprint. As a material specialist in a wide range of fresh water, brackish water, seawater and brine applications, we can offer pumps in cast iron, 316 stainless steel, duplex, super duplex, SMO, etc.

Water treatment system process chart

Water treatment system process chart

Project data

50 AHLSTAR and BE recirculation pumps (continuous duty) in water treatment loops. The dry-installed single-stage overhung pumps are equipped with semi-open impellers and single mechanical seals.

| Pumps | Qty | Material (duplex) | Flow (m³/h) | Head (m) | Efficiency (%) |

|---|---|---|---|---|---|

| A43-500 | 30 | A890 3A | 1’080 | 4.5 | 88 |

| BE325-2532 | 20 | A890 4A | 430 | 5.3 | 85 |

Five VUPX-0402 (2’280 m³/h @ 3 m) submersible propeller pumps (intermittent duty) for the emptying of fish tanks.

Climate change still perceived as the most pressing problem of our time

AdministratorDespite the health crisis, climate change is still seen by the public in several European countries as the biggest issue that mankind faces. This is the finding of new research released today by Vattenfall.

The new survey complements a report by Vattenfall carried out in December 2019, which explored people’s attitudes and emotional response to the conversation on climate change. This first round of research found that climate change was seen as the most serious problem in the world – ahead of any other global issue such as poverty, wars and conflict, or economic recession. The follow-up study, undertaken in June 2020, was designed to find out if and how views on climate change have evolved in the wake of the global health pandemic.

While there is a sharp increase in people’s concern about epidemics and economic recession, nearly a third (28%) of people in Sweden, Germany, the Netherlands, Denmark, Finland, France and the United Kingdom indicate that they see climate change as the most pressing global issue in the world today. As many as 69% of people describe themselves as “quite” or “a great deal” worried about climate change. Both these results remain fairly stable when compared to December 2019. It therefore seems that climate change has established itself as a durable worry in the mind of European citizens.

While there is a sharp increase in people’s concern about epidemics and economic recession, nearly a third (28%) of people in Sweden, Germany, the Netherlands, Denmark, Finland, France and the United Kingdom indicate that they see climate change as the most pressing global issue in the world today. As many as 69% of people describe themselves as “quite” or “a great deal” worried about climate change. Both these results remain fairly stable when compared to December 2019. It therefore seems that climate change has established itself as a durable worry in the mind of European citizens.

Responses show a clear expectation that a long-term and meaningful commitment is needed by all actors who can affect climate change: governments, businesses and individuals alike. The results also found that most respondents (57%) believe that the highest priority should be given to continuing or increasing climate change commitments when it comes to ongoing financial recovery discussions across Europe.

Finally, the share of those who report feeling ‘hopeful that we will be able to stop climate change’ and ‘inspired by what I see people doing to stop climate change’ remains almost unchanged. This shows that it is more necessary than ever to highlight specific actions being taken to tackle climate change.

For the report, Vattenfall consulted American psychologist Renee Lertzman. She said:

“These results should provide comfort. They show that our concern and duty of care for the world can be awakened during times of immense crisis – when we feel part of something much bigger. They also indicate that the durable and consistent anxieties and worries about climate change amidst such global health challenges can be a good thing. Ultimately they will drive us to action.”

CEO of Vattenfall Magnus Hall said:

“It is clear that our emotions towards climate change remain unchanged even in the wake of a global health crisis. As a company that produces and supplies energy, our ability to make an impact is considerable and this report highlights that. We are fully committed, throughout our entire 20,000-person business, to make fossil free living possible within one generation and to help partners and industries to electrify transports and processes and thereby replace fossil fuels.”

The survey including an executive summary of the original report is attached

|

|

Sparrows Group wins prestigious industry award for its skills development programmes

AdministratorSparrows Group has won the SPE’s Outstanding Skills Development Award at the Offshore Achievement Awards (OAAs) 2020, which was held as a virtual ceremony for the first time, hosted by TV presenter Rachel Riley.

Now in its 34th year, the OAAs is the biggest and longest established oil, gas and renewables industry awards for the UK offshore energy sector, covering all aspects from supply to upstream operations and offshore renewables. This year, more than 80 companies submitted entries.

Sparrows was recognised by the judging panel for its investment in training and broadening the skills of its people internally. The Aberdeen headquartered firm delivers a range of apprenticeship schemes and engineering scholarships, as well as running successful development programmes for its engineering graduates and managers.

Sparrows was recognised for its investment in training

Sparrows was recognised for its investment in training

The global provider of specialist equipment and integrated engineering services to the energy and industrial markets was also recognised for its upskilling programme which promotes dual skills within the offshore workforce. The company was congratulated too for its schools’ engagement programme - the Engineering Education Scheme - which earlier this year saw the firm working with students from Oldmachar Academy.

Stewart Mitchell, chief executive officer at Sparrows said: “Winning this award is testament to our excellent team and their commitment to supporting others within the business and inspiring the next generation.

“Over the years we have developed and implemented a number of programmes to help our people to thrive and progress their careers within the company, and we are proud to have a high number who started as apprentices or graduate trainees and are now in management and senior management roles.

“I would like to thank everyone at Sparrows involved in our development schemes for their dedication and drive, they are truly deserving of this award.”

About Sparrows Group

The Sparrows Group is a global provider of specialist equipment and integrated engineering services to the energy and industrial markets. The firm supports customers by delivering a broad range of expert solutions that optimise efficiency and ensure the performance, reliability and safety of critical equipment and people.

Emerson’s New Laser Welder Enhances Manufacturing Capabilities

AdministratorThe Branson™ GL-300 is a highly flexible quasi-simultaneous plastic joining solution, designed to deliver efficient high-quality welds in a wide range of applications and help manufacturers to increase production efficiency.

Emerson has launched a new laser welder platform that provides high mix and batch manufacturers of plastic components with greater production capability, without compromising product quality or performance. The Branson™ GL-300 is a highly flexible quasi-simultaneous plastic joining solution, designed to deliver efficient high-quality welds in a wide range of applications and help manufacturers to increase production efficiency.

Manufacturers increasingly need machines and processes that can be quickly and cost-effectively adapted to changing production demands and specifications. For low volume, high mix manufacturers especially, flexible welding solutions that allow faster production start-up, provide a critical advantage. The Branson GL platform meets this need by combining highly efficient and accurate welds with cost-effective and easy-to-change tooling that enables faster set-up and adjustment for changing product specifications.

Manufacturing capability is further enhanced by a range of unique features including a high-quality scanning system, easy-to-use HMI, large (300mm x 300mm) weld area, multiple weld modes, variable spot size as low as 0.5 mm and an adjustable laser power source height. These enable the Branson GL-300 to support applications with different materials, application sizes and production speeds.

“For batch manufacturers looking for more efficient production processes, quasi-simultaneous laser welders provide a very flexible, cost-effective joining solution,” said Priyank Kishor, global product manager for Branson products at Emerson’s Automation Solutions Business. “The Branson GL-300 extends this flexibility by enabling the assembly of a broader range of components, helping to increase manufacturing capability and profitability.”

For more information about the latest Branson welding solutions, visit Emerson.com/Branson

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and engineering company providing innovative solutions for customers in industrial, commercial, and residential markets. Our Emerson Automation Solutions business helps process, hybrid, and discrete manufacturers maximize production, protect personnel and the environment while optimizing their energy and operating costs. Our Emerson Commercial and Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency, and create sustainable infrastructure. For more information visit www.Emerson.com

~ Is all bearing surface damage troublesome? ~

Up to 40 per cent of a vegetable crop can go to waste due to the aesthetic requirements of some supermarkets. While a wonky vegetable may not be the most visually pleasing, it possesses the same nutritional value as its perfectly proportioned counterpart. Here, Chris Johnson, managing director of bearing specialist SMB Bearings, explains why not all bearing surface damage should cause alarm and future headaches for offshore oil and gas plant managers.

Bearing surface damage can take many forms, from spalls in the raceways, wear from ineffective lubrication, corrosion due to harsh chemicals to false brinelling marks caused by static vibration. While surface distress can result in problematic symptoms such as excessive heat, increased noise levels, increased vibration or excessive shaft movement, not all external bearing flaws point to compromised internal machine performance.

Corrosion is a naturally occurring phenomenon and a common form of bearing surface damage that offshore oil and gas plant managers must contend with. There are ten primary forms of corrosion, but bearing corrosion usually falls into two broad categories — moisture corrosion or frictional corrosion. The former is environment specific, but can appear on any component of the bearing, creating an alarming oxide layer as a result of a chemical reaction with a metal surface.

For example, in offshore mining, bearings are often exposed to moisture or mild alkalinity due to their contact with sea water. Mild corrosion may result in light surface stains, but in more serious cases, it can lead to etching on the surface of the bearing, resulting in flakes of rusted material entering the raceway. For this reason, corrosion is often known as the natural enemy of bearings.

Corrosion isn’t just visually alarming; it can also significantly impact a business’ finances. According to the IMPACT study conducted by NACE International, the world’s leading corrosion control organisation, it has been estimated that 15-35 per cent of annual corrosion could have been saved if optimum corrosion management practices were followed. This equates to savings between US$375 and $875 billion annually on a global basis.

The enemy?

It’s impossible to ignore the significance of corrosion costs, however corrosion resistance must be considered alongside other operating requirements such as bearing longevity and load.

Consider this as an example. A drilling machine is required to operate with precision but must also operate in unforgiving conditions. Due to the extreme environment of oil and gas rigs, corrosion resistant bearings would be recommended. If a design engineer were to opt for a highly corrosion resistant bearing fabricated from polyether ether ketone (PEEK), this would stop the corrosion in its tracks, but the precision of the machine would be compromised. In this scenario opting for a high precision stainless steel bearing with superior roundness while allowing some superficial corrosion may be preferable.

When assessing the suitability and quality of bearings, it is important to look beyond the external aesthetic. Corrosion control is just one performance requirement, which doesn’t necessarily equate to poor performance or affect the bearing’s internal rollability.

Ensuring the right equipment is selected is the first step — and this is imperative for both large-scale machinery and small components, such as bearings. Luckily, offshore facility managers can weigh up their design requirements and can choose to combat corrosion at the design stage. Here are three corrosion control methods to consider:

Material choice

Stainless steel is the most obvious choice for corrosion resistance and is widely used in the offshore oil and gas industry. It also has other advantageous properties such as durability and heat resistance. 440 grade stainless steel bearings have good resistance in damp environments and are often used in applications such as the food and beverage industry. However, 440 grade stainless steel bearings have poor resistance to salt water and many stronger chemicals, so for harsh offshore environments 316 stainless steel may be considered. However, as 316 stainless steel cannot be thermally hardened, 316 bearings are only suitable for low load and low speed applications. Their corrosion resistance is best when there is an ample supply of oxygen so these bearings are mainly used above the waterline, in flowing seawater or where the bearings can be washed down after submersion in seawater.

An alternative material option is ceramic. Full ceramic bearings made from zirconia or silicon nitride with PEEK cages can offer even higher levels of corrosion resistance and are often used fully submerged. Similarly, plastic bearings, with 316 stainless steel or glass balls, provide very good resistance to corrosion. These are often made from acetal resin (POM) but other materials are available for stronger acids and alkalis such as PEEK, polytetrafluoroethylene (PTFE) and polyvinylidene fluoride PVDF. Like 316 grade bearings, these should only be used in low load and low precision applications.

Another level of armour against corrosion, is a protective coating. Chromium and nickel plating offer good corrosion resistance in highly corrosive environments. However, coatings will eventually separate from the bearing and need continual maintenance. This isn’t the most practical option for offshore applications.

Lubricants

A lubricant provides a thin film between the contact areas in a bearing to reduce friction, dissipate heat and inhibit corrosion on the balls and raceways. Surface roughness and lubrication quality are extremely important influencing factors as to whether surface distress will occur or not.

Opting for the correct lubricant matters. In an environment where superficial corrosion may occur on the outside of the bearing, it should not be allowed to occur on the inside. SMB Bearings can supply sealed bearings with waterproof greases that contain corrosion inhibitors. These lubricants protect the internal surfaces of the bearing and can be matched to the specific offshore application environment. Full ceramic bearings are mostly specified without lubrication but can be lubricated with waterproof grease for extended life.

Seals

In harsh environments, contamination protection is of utmost importance, so opting for a contact seal is favourable to ensure contaminants do not enter the bearing. For equipment that may be exposed to moisture, a contact seal will also offer increased water resistance. This will stop grease washing out of the bearing, allowing it to do its job in lubricating and protecting the internal surfaces of the bearing. An alternative option is a metal shield but this offers greatly reduced protection against moisture.

By assessing the operational environment, required longevity and loads that will be applied to the bearing, the best bearing may be the humble ‘wonky vegetable’ and not the one that remains looking aesthetically pleasing for the longest. By considering a bearing’s full environmental operating conditions, design engineers can weigh up whether opting for a corrosion control design feature will be the most cost effective, increase the bearing’s lifespan and elevate a machine’s performance.

For further information about SMB Bearing’s range of bearings for corrosive environments, visit the website or contact a specialist today This email address is being protected from spambots. You need JavaScript enabled to view it..

About SMB Bearings: SMB Bearings originally specialised in miniature bearings, thin-section bearings and stainless steel bearings. By natural progression, the company expanded the range to include other corrosion resistant bearings such as plastic bearings, 316 stainless bearings and ceramic bearings.

Remaining a specialist business, SMB Bearings provide a high level of product knowledge, providing bearing and lubrication solutions to existing or potential customers, whether individuals or large corporations. SMB Bearings does not just sell bearings, but helps to solve your problems.

For further information please visit http://www.smbbearings.com/

Global Food & Beverage manufacturers look to smart finance to meet pandemic investment challenge

Administrator- The urgent challenges of the Covid-19 pandemic have required Food & Beverage manufacturers to rapidly adapt to changed circumstances and patterns of consumption, and will continue to impact processes as businesses and consumers embrace ‘the new normal’.

- Companies that invest in agile technologies including automation, digitalization and retrofit projects are best placed to react to shifting market demands with optimum flexibility and resilience. The size of the investment required is, however, considerable.

- New research from Siemens Financial Services (SFS) estimates that the global investment challenge for Food & Beverage industry for digital transformation alone is over $566 billion over the next five years.

- Smart manufacturers are deploying new financing models, mainly from manufacturing-specialist financiers, to provide commercially sustainable ways of maintaining the momentum of technology and equipment investment.

Siemens Financial Services (SFS) has released a new whitepaper entitled Rising to the New Challenge: The role of Smart Financing in helping the Global Food & Beverage Sector navigate the economic ‘new normal’. This is the second in a series of insight papers on the automation, retrofit and digital transformation investment challenges faced by manufacturers.

The pandemic crisis and its economic aftermath make the importance of investing in agile technologies even more critical. Historic evidence shows that companies that continued to invest in previous crises emerged ahead of their competitors. Such investments typically enable manufacturers to achieve levels of operating flexibility that can cope with uncertain and volatile markets – a flexibility that is becoming an increasingly important competitive advantage as patterns of supply and demand, as well as working and labour practices, are likely to fundamentally change as the crisis recedes and businesses and consumers embrace ‘the new normal’.

The size of the investment challenge is, however, considerable. SFS has developed a model which conservatively estimates the size of the investment challenge faced by the Global Food and Beverage manufacturing industry as it seeks to implement smart factory technology during the five-year period 2020-2024.

Expert commentators are advising companies to diversify their financing sources, nurture existing lines of relationship credit, and harness alternative financing sources, such as Smart Financing, in order to preserve existing lines of credit. New financing models to enable technology and equipment investment are often aligned to business outcomes, to integrate financing closely with the expected rate of return-on-investment delivered through the benefits of retrofitting existing installations and/or adopting new agile, digitalized technologies.

“The flexibility offered by upgrading existing platforms through retrofitting automation, or digitalization can be a significant competitive differentiator during this crisis,” says Brian Foster, Head of Industry Finance, Siemens Financial Services. “The ability to adapt swiftly and intelligently to rapidly changing markets remains an urgent need for businesses of all sizes. Smart finance enables sustainable investment based on clearly identified desired business outcomes for F&B manufacturers, facilitating access to the right technology and services with expert support from a specialist financier.”

Methodology

SFS has developed a model which conservatively estimates the size of the investment challenge faced by the Global Food and Beverage manufacturing industry as it seeks to digitally transform – even through the current economic difficulties. The model takes a variety of analyst predictions of the value of the Global Food & Beverage Industry’s investment in digital transformation for the five-year period 2020-2024 inclusive. The resulting figure is then adjusted by the proportion of digital transformation solutions that the Global Food & Beverage industry is already acquiring through smart finance. Additionally, the estimate is reduced to just half of the ‘available market’, to give a highly conservative view of the sheer scale of investment required even to reach 50% market penetration

SFS has developed a model which conservatively estimates the size of the investment challenge faced by the Global Food and Beverage manufacturing industry as it seeks to digitally transform – even through the current economic difficulties. The model takes a variety of analyst predictions of the value of the Global Food & Beverage Industry’s investment in digital transformation for the five-year period 2020-2024 inclusive. The resulting figure is then adjusted by the proportion of digital transformation solutions that the Global Food & Beverage industry is already acquiring through smart finance. Additionally, the estimate is reduced to just half of the ‘available market’, to give a highly conservative view of the sheer scale of investment required even to reach 50% market penetration

For further information, please see: www.siemens.com/new-challenge-food-and-beverage

For further information on SFS, please see www.siemens.com/finance

Siemens Financial Services (SFS) – the financing arm of Siemens – provides business-to-business financial solutions.

A unique combination of financial expertise, risk management and industry know-how enable SFS to create tailored innovative financial solutions. With these, SFS facilitates growth, creates value, enhances competitiveness and helps customers access new technologies. SFS supports investments with equipment financing and leasing, corporate lending, equity investments and project and structured financing. Trade and receivable financing solutions complete the SFS portfolio. With an international network, SFS is well adapted to country-specific legal requirements and able to provide financial solutions globally. Within Siemens, SFS is an expert adviser for financial risks. Siemens Financial Services has its global headquarters in Munich, Germany, and has almost 3,000 employees worldwide. www.siemens.com/finance.

Siemens AG (Berlin and Munich) is a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 170 years. The company is active around the globe, focusing on the areas of power generation and distribution, intelligent infrastructure for buildings and distributed energy systems, and automation and digitalization in the process and manufacturing industries. Through the separately managed company Siemens Mobility, a leading supplier of smart mobility solutions for rail and road transport, Siemens is shaping the world market for passenger and freight services. Due to its majority stakes in the publicly listed companies Siemens Healthineers AG and Siemens Gamesa Renewable Energy, Siemens is also a world-leading supplier of medical technology and digital healthcare services as well as environmentally friendly solutions for onshore and offshore wind power generation. In fiscal 2019, which ended on September 30, 2019, Siemens generated revenue of €86.8 billion and net income of €5.6 billion. At the end of September 2019, the company had around 385,000 employees worldwide. Further information is available on the Internet at www.siemens.com.

A leading provider of integrated logistics solutions has announced that its UK operation has secured work in excess of £2 million since the beginning of the year.

NorSea UK Country Manager Karen RussellNorSea UK is part of the NorSea Group and operates from premises in Aberdeen and Peterhead, providing supply bases and integrated logistics solutions to the energy and other industries.

NorSea UK Country Manager Karen RussellNorSea UK is part of the NorSea Group and operates from premises in Aberdeen and Peterhead, providing supply bases and integrated logistics solutions to the energy and other industries.

Since the start of 2020, the UK team has seen a steady increase in demand for products and services, including an upturn in vessel numbers and types at its growing Peterhead facility. NorSea has also reported that, following investment to the tune of £500,000, office accommodation at its Aberdeen base is at 90% capacity with warehouse and yard space also in high demand.

NorSea UK Country Manager Karen Russell commented: “As well as continuing to benefit from our refurbished base in Aberdeen, we are experiencing an ongoing increase in the volume of maritime traffic at Smith Quay and Merchants Quay in Peterhead. The additional quayside, marshalling and berthing space which has been added there in the last 18 months has been central to that increase.

“By increasing our customer base whilst simultaneously extending services to current customers, we have been able to grow our UK business in a steady way which gives us confidence and optimism as we look to the future.”

To find out more, call +44 (0) 1224 451000 or visit https://norseagroup.com/bases/norsea-uk

NorSea United Kingdom operates from HQ, warehouse and yard premises in Aberdeen’s Altens Industrial Estate from where the privately-owned company provides supply bases and integrated logistics solutions to the energy and other industries. Part of the 55-year-old NorSea Group, it operates recently-expanded bases at Peterhead’s Smith Quay and Merchants Quay and aims to deliver high-tech, innovative and complete supply chain solutions which are tailored to customer needs. To find out more, call +44 (0) 1224 451000 or visit https://norseagroup.com/bases/norsea-uk

More...

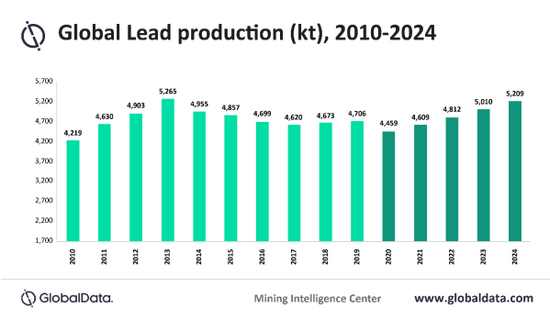

COVID-19 to reduce global lead production by 5.2% in 2020, says GlobalData

AdministratorGlobal lead production is expected to decline by 5.2% to 4.5 million tonnes (Mt) in 2020. The outbreak of the COVID-19 pandemic in late December 2019 significantly impacted the mining industry in the first half of 2020, and continues to do so, says GlobalData, a leading data and analytics company.

Overall global lead mine production declined by 3.4% in Q1 2020, compared to the same period in 2019. This was primarily due to the decline in production in China, India and Kazakhstan due to COVID-19 restrictions.

Vinneth Bajaj, Senior Mining Analyst at GlobalData, comments: “In China, production is forecast to decline by 3.5%, to reach 1,985 thousand tonnes (kt) in 2020. The country’s lead mine production declined in the first quarter of 2020, primarily due to restrictive measures taken by the government to contain the virus.

“Several mines and plants had to temporarily cease production activities due to the shortage of workers who could not return to mine sites, owing to the prolonged Lunar New Year holidays, followed by transportation issues due to the lockdown. Although most of the lead producers gradually restarted mine operations, lower demand from the automotive sector is expected to constrain mine production in 2020.”

In Australia, production is forecasted to fall by 4.2%, even though mining in the country has not been as severely impacted as in other countries. Production from the rest of world is anticipated to decline from 2.2Mt in 2019 to 2Mt in 2020 – a drop of 7.1%. Significant declines will be in Peru (8.4%), the US (6.1%) and India (14.1%).

Bajaj continues: “Looking ahead, lead production over the forecast period (2021–2024) is expected to grow at a compound annual growth rate (CAGR) of 4.2%, to reach 5.2Mt in 2024. Peru, Australia and China will be the key contributors to this growth. Combined production in these countries is expected to recover from a forecasted 2.8Mt in 2021 to 3.3Mt in 2024.”

Bajaj adds: “Key projects expected to commence operations during the forecast period include the Abra in Western Australia and the Prairie Creek project. The Abra in Western Australia is currently undergoing construction. The project’s debt financing has been slowed due to the outbreak of COVID-19, however, the company is targeting its initial production in 2021, with an annual lead capacity of 95kt. The Prairie Creek project is currently awaiting regulatory approvals and permissions. With a total US$279mn pre-production capital cost, the project is expected to commence operations in 2022. Once commenced, the project is expected to produce 47.6kt of lead annually.”

Quotes provided by Vinneth Bajaj, Senior Mining Analyst at GlobalData,

This press release is written using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors. Q2MIN0014.

AMADA WELD TECH Announces MM-410A Handheld Resistance Weld Checker

AdministratorCompact unit supports process development and production applications for a range of resistance welding technologies

AMADA WELD TECH announces the new MM-410A handheld resistance weld checker, ideal for both monitoring and troubleshooting issues in production. The compact unit supports a wide range of resistance welding technologies, including AC, DC inverter, AC inverter, transistor, and capacitive discharge. Featuring a simple and intuitive user interface and colour touch panel display, the MM-410A provides information on current, voltage, weld time, and force.

The MM-410A is ideal for use in process troubleshooting, where it can be used to correlate waveform and numeric data with process results and provide detailed weld data for process optimization and validation. If used continuously in a production environment, it reduces scrap by detecting drifts in the weld process and alerting operators before process failure. The MM-410A also reduces the frequency of destructive testing and provides an independent way of monitoring the welding power supply by detecting any drifts in welding power supply calibration.

The unit provides ISO17657-compliant measurement for current (when used with available ISO-compliant toroidal coil). It offers easy set up using the 5.7-inch colour touch panel. The unique seam welding mode monitors AC current and voltage or DC voltage for up to 5 minutes. Data storage is available using an onboard flash drive. The MM-410A offers Ethernet (TCP/IP), and RS-232/485 communication. Multi-language support includes English, Spanish, Japanese, Chinese, Korean, German, and French.

Available accessories for the MM-410A handheld resistance weld tester include toroidal coils, force sensors, and current/force sensors.

About AMADA WELD TECH

AMADA WELD TECH is a leading manufacturer of equipment and systems for Laser Welding, Laser Marking, Laser Cutting, Resistance Welding, Hermetic Sealing and Hot Bar Reflow Soldering & Bonding. We customize our products around specific micro-joining applications for all our customers around the globe. AMADA WELD TECH product markets include medical devices, battery, automotive, solar industry, electronic components and aerospace. We are an ISO9001 certified company. Contact AMADA WELD TECH at This email address is being protected from spambots. You need JavaScript enabled to view it.. Find out more about the company’s products and services at www.amadaweldtech.eu.

Winners announced at the 34th Offshore Achievement Awards virtual ceremony

AdministratorBP and Pale Blue Dot take home the highly anticipated ‘Energy Transition for Future Generations’ Award

The winners of the 2020 Offshore Achievement Awards were revealed in a virtual ceremony on 14 August, with joint prize-winners announced across several categories, demonstrating the high calibre of entries this year and the tough job faced by judges.

This year Jeanette Forbes, a successful industry entrepreneur and founder of the PCL Group, inspiring STEM mentor and energy sector ambassador, clinched the ‘Significant Contribution’ Award for demonstrating unparalleled support in promoting STEM to young women in education and her business mentorship efforts in the community.

PCL Group CEO, Jeanette Forbes

PCL Group CEO, Jeanette Forbes

In the new ‘Energy Transition for Future Generations’ category, the judges received a wide range of applications, from exceptional company efforts to reduce the carbon footprint of their operations, to technology advances which will help Scotland and the UK achieve their net zero targets.

With a high number of exceptional entries, the judges decided it was only fair to name two award winners in this category. BP was recognised for its company-wide approach to decarbonisation, whilst Pale Blue Dot Energy was hailed for its pioneering Acorn hydrogen and CCS projects which aim to move the dial in the industry’s energy transition ambitions.

Other award winners included:

- Modus for ‘Innovator’

- JFD Global for ‘HSE Innovation’

- N-Sea for ‘Internationalisation’

- ITC Hydraulics for ‘Great Company – SME’

- Sparrows Group for ‘Outstanding Skills Development’

- Serica Energy for ‘Great Company – Large’

- Deep Casing Tools and Tendeka for ‘Emerging Technology’

- Gavin Morris, Bilfinger Salamis UK and Erin Ingram, TAQA for ‘Young Professional’

Commenting on the virtual celebration, Ian Phillips, chairman of SPE Aberdeen said:

“I want to commend our 2020 award winners and finalists, each of whom embody the excellence, innovation and ambition in the UK offshore industry. It is clear from the calibre of entries, and the number of joint winners this year, that there is an exceptional pool of talent present in the sector.

“From strong, passionate individuals making admirable contributions, to large organisations striving to make the industry a better place for generations to come, our finalists and winners should be justifiably proud of their success.

“The evening’s virtual celebrations honoured the brightest and best, giving a much-needed boost to the sector after weathering Covid-19, inspiring all of us to push ahead and support each other in the net zero journey.”

Donald Taylor, Europe managing director at principal sponsor, TAQA said:

“TAQA is a long-term supporter of the SPE Offshore Achievement Awards, and we’re pleased to once again support the SPE and help celebrate and showcase the ingenuity and dedication of the companies and individuals in the offshore industries.

“Despite not being able to be together physically to celebrate this year, it continues to be vital to recognise and celebrate achievements during challenging times.

“A huge thank you to everyone who took the time to support the awards this year, a spirit of collaboration has been key to making this year’s virtual event such a success. Finally, congratulations to the all the well deserving winners.”

‘Significant Contribution’ winner and PCL Group CEO, Jeanette Forbes said:

“I am absolutely delighted to be only the second woman to win the Significant Contribution Award and I look forward to hearing of other female recipients in the coming years as we look to the future of our industry. Piper Alpha changed the world for those working in O&G. We that continue to work in the industry must, and I emphasise must, change the environment and transition to leave a significant legacy built around new energy innovation”.

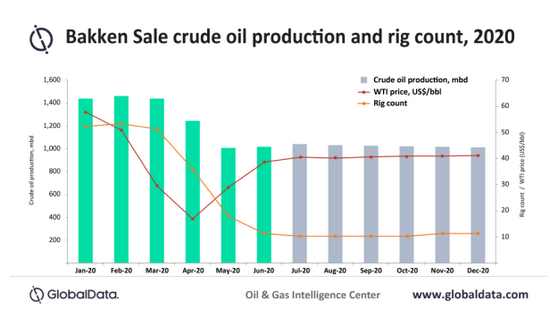

Bakken shale registers drop in drilling activity amid substantial decline in oil prices, says GlobalData

AdministratorThe Bakken Shale play, the second largest oil producing region in the US after the Permian Basin, has witnessed a considerable fall in drilling activity in 2020. The crude price crash was the main driver to the shut in of producing wells and decrease in drilling activity in this region, says GlobalData, a leading data and analytics company.

GlobalData’s latest report, Bakken Shale in the US, 2020, reveals that the gross crude and condensate production from the Bakken Shale play is expected to be 1.1 million barrels per day (mmbd) in 2020, an annual decline of 28% from 2019.

Andrew Folse, Oil & Gas Analyst at GlobalData, comments: “Operators with higher lease operating expenditures have begun shutting in wells since March 2020 while waiting for the prices to recover. Operators have slashed the amount of capital they have planned to spend in 2020, subsequently slowing down the drilling activity with over an 80% decrease in rigs from the January count of 52 to the July count of just ten.”

Initially, for the first quarter of 2020, crude production averaged at more than 1.4mmbd. However, with an unprecedented fall in global oil prices, operators had to recalibrate their capex outlook to maintain liquidity. This led to a drastic drop in rig count in the Bakken shale, resulting in sharp decline in crude production in the recent months.

Folse adds: “Despite the relative stability in oil price over the last two months, operators may continue to shut in production with the rise in transportation cost due to the anticipated closing of the Dakota Access Pipeline (DAPL) from August 2020. The higher cost associated with transporting oil by rail or truck could keep wells shut in for an extended period of time even with higher commodity prices.”

- Quotes provided by Andrew Folse, Oil & Gas Analyst at GlobalData

- Information based on GlobalData’s report: ‘Bakken Shale in the US, 2020’

- This press release was written using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis, and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, technology, energy, financial and professional services sectors.