Uncategorised (4996)

Thy-Mors Energi Elnet increases data quality and professionalises its IT system

AdministratorThe Danish electric utility distribution company Thy-Mors Energi Elnet has received great help from the software house Powel to professionalise its data quality and IT setup, allowing it to meet current complex challenges in the power grid.

These advancements are of great value for Thy-Mors Energi Elnet, which has carried out a significant operational turnaround over the past two years.

“We can work far more efficiently and achieve higher-quality results. We now have a modern, future-ready IT system, and we look forward to developing the way we work in the field too,” says Kristian Tilsted, CTO of Thy-Mors Energi Elnet A/S.

“We can work far more efficiently and achieve higher-quality results. We now have a modern, future-ready IT system, and we look forward to developing the way we work in the field too,” says Kristian Tilsted, CTO of Thy-Mors Energi Elnet A/S.

In recent years Thy-Mors has worked hard toward its goal of a complete digitalised power grid, a central part of the ‘Digital Twin strategy.’

Inaccurate analyses and clunky manual processes

Powel employs both software developers and consultants, who have collaborated with Thy-Mors Energi Elnet to modernise their work.

Previously, data of the grid was split over several solutions, which had to be operated in part using clunky manual processes. Calculations and web analytics were hard to make because some systems were not updated.

Registered the grid in ArcGIS

The turnaround started with a complete online registration in ArcGIS, with support for the following business processes:

- Automated map generation for dig requests

- Valuation

- Grid planning and calculation

- Grid operation and ADMS

- Maintenance and reinvestment

This work required close collaboration between Thy-Mors Energi Elnet and Powel’s consultants.

“We had to figure out what data was at our disposal and how the conversion would ensure optimal utilisation of the data. Through this clarification, we found that it was possible to establish an overall registration with good data quality in ArcGIS,” says Jens Dalsgaard, Principal Business Process Consultant at Powel.

Powel delivered a migration leading to minimal manual follow-up:

- Updates to specific transformer assemblies, such as a new transformer or a new input.

- The standardisation of cable data – underground conductors, had previously been assigned different names in the system complicating use in various business processes.

- Service lines, the registration of which had been lagging.

Grid companies face increasingly strict demands

Since ArcGIS was a new system for many Thy-Mors Energi Elnet employees, Powel conducted training on using its standard functions. The consultants were also teaching the employees in other Powel solutions the Danish company has implemented in this process.

“Our goal was clear. We had to achieve top-notch data quality within a short period – and we have succeeded. The work was necessary to meet the increasingly tough demands imposed on us as a result of the electrification of society,” says Kristian Tilsted.

Thy-Mors Energi Elnetwill soon have access to a tailored web interface with up-to-date and detailed information about its grid, including dedicated tools for maintaining the data.

“It’s been great to work with the management team and employees of Thy-Mors Energi Elnet. In a short time, they have taken great strides towards achieving a modern IT setup and efficient working. They’re now much better prepared for the future than they were two years ago,” says Powel’s Jens Dalsgaard.

Adopting field solutions is the next step

Powel delivers easy-to-use field applications, which the Danish energy company also wishes to adopt.

"The applications make it easy for utility workers to register the grid while they're in the field. After all, no one knows the grid better than these workers. Another advantage is that the data automatically is stored in our large operating systems, which improves quality and reduces the chance of errors."

"We look forward to continuing our collaboration with Powel," says Kristian Tilsted of Thy-Mors Energi Elnet.

Croatia’s adopts auctions to drive renewable growth in power mix, with solar PV to represent 50% of tendered capacity, says GloblaData

AdministratorThe Croatian Government introduced a provision to assign 2.26GW of renewable energy capacity under an auction scheme, which includes technologies such as hydropower, wind, solar PV, biopower and geothermal energy. GlobalData predicts that auctions such as these will help develop the Croatian renewable sector and support the country towards its target of producing 36.4% of its electricity generation from renewables by 2030.

Somik Das, Senior Power Analyst at GlobalData, comments: “GlobalData estimates that generation from renewables (including small hydro) contributed around 20% of Croatia’s overall power generation in 2019. Wind has been the key technology in the segment, forming 12.7% of generation. However solar, which formed a negligible share last year, is on the rise and is anticipated to be the fastest-developing segment over the decade.

“With these auctions, it is anticipated that the solar PV project pipeline will see substantial increase from the current 109MW of small solar PV projects in the pipeline in various stages of development.”

“With these auctions, it is anticipated that the solar PV project pipeline will see substantial increase from the current 109MW of small solar PV projects in the pipeline in various stages of development.”

The auction comes as a portion of the decree adopted on quotas to incentivize the generation of electricity from renewable energy sources and high-efficiency cogeneration. The key objectives of the strategy are guaranteeing sustainable energy generation in Croatia over the following ten years, with projections until 2050.

Das added, “As renewables become more competitive and achieve grid parity across the globe, Croatia will not want to be left behind in the renewables race. The bigger picture encompasses the sustainable environment, where, until 2050, the strategy will aid the nation in accomplishing its objective of cutting down on carbon dioxide emissions by 36%.”

- Comments provided by Somik Das, Senior Power Analyst at GlobalData

- Among these technologies solar PV has the largest capacity share of over 1GW to be tendered in multiple auctions. The first auction saw Croatian electricity and gas regulator Hrvatski Operator Tržišta Energije (HROTE) announce a tender for 88MW of renewables capacity. The authority apportions 50MW of solar capacity, 15MW of biogas, 14MW of biomass, and 9MW of hydropower.

- To expand the competitiveness and allure of the solar PV segment, the maximum tariff was set at €0.084 (US$0.10)/kWh in comparison to €0.178 (to $0.21) per kWh for biomass and €0.10(US$0.114)/kWh for other technologies. Successful projects will be awarded a feed-in price premium, which will be paid on top of spot market prices.

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

Valmet to supply automation to ECOFARIO’s technology that removes up to 99.9% of microplastics in wastewater

AdministratorValmet has signed a development, cooperation and service agreement with ECOFARIO GmbH regarding automation for its first industrial pilot plant. The German startup company has developed a technology, which removes up to 99.9 percent of microplastics, including the inherent and adhering pollutants from wastewater. According to the agreement, ECOFARIO will exclusively offer Valmet’s automation for its future installations.

The order was included in Valmet's orders received of the second quarter 2020. The value of the order will not be disclosed.

“Our patented break-through technology for removing microplastics from wastewater is a sustainable solution that will positively impact the wellbeing of all global ecosystems. To operate the process efficiently, we decided to base our process automation on Valmet’s reliable DNA automation system. Valmet is thus a key partner for our development process,” says Sebastian Porkert, Chief Executive Officer and founder of ECOFARIO.

“The removal of microplastics and toxins is currently a very important topic globally. We are excited to be part of this revolutionary development project and we are able to offer the best possible automation and know-how for it. Both ECOFARIO’s solution and our user interface represent a combination of totally new technologies in the world,” says Markus Foigtmannsberger, Manager, Service Solutions, Germany, Switzerland & Benelux, Automation, Valmet.

Valmet will supply the automation system to ECOFARIO GmbH’s first industrial pilot plant that can remove up to 99.9% of micro plastics from wastewater.

Valmet will supply the automation system to ECOFARIO GmbH’s first industrial pilot plant that can remove up to 99.9% of micro plastics from wastewater.

Information about Valmet’s delivery

Valmet’s delivery includes a Valmet DNA automation system. It is operated with Valmet’s up-to-date DNA User Interface that comes with a secure web-based access. This allows the plant staff to access relevant information whenever they need it, regardless of their location. The integration of measurements for analyzing the wastewater quality are already in planning and will complete the automation solution.

Information about the customer ECOFARIO GmbH

Munich-based ECOFARIO GmbH has been awarded as Germany’s most sustainable startup company in 2020. Its new type of separation process is based on hydrocyclone technology and will be installed as an end-of-pipe solution in municipal or industrial sewage treatment plants and significantly reduce the microplastic load and the associated pollutants.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2019 were approximately EUR 3.5 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward – every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Robot investments will be essential for food manufacturing recovery

Administrator~ TM Robotics launches robotics consultation service ~

Food manufacturing has experienced extraordinary change. Responding to the shifting needs of the sector, TM Robotics has launched a new robotics consultation service to advise manufacturers on how automation can aid recovery and growth. Held with a TM Robotics automation specialist, the free consultations can be managed remotely or by appointment. To book a consultation, visit the TM Robotics website.

Manufacturers in the food sector have long used robots to improve their processes. In fact, there were approximately 16,000 installations for this industry in 2018 alone. However, the needs of food manufacturing are changing.

Without a doubt, food manufacturing has been among the most heavily disrupted industries during COVID-19. Witnessing unprecedented demand during the early stages of the pandemic, as well as dramatic shifts in consumer buying habits, the industry has been forced to adapt. Moving forward, reports suggest that the industry is set for long-term changes in its operation and supply chains.

Assessing the state of manufacturing, the International Federation of Robotics (IFR) has suggested that manufacturers adopting and investing in robots will be key for achieving growth against the ongoing challenges of COVID-19. To steer towards recovery, manufacturers may be looking to increase their operational efficiency and reduce overheads with automation — but do so without excessive risk.

To support food manufacturers through their investments, TM Robotics’ new service will provide free consultations to help them determine the best approach for their recovery.

“Manufacturers in the food industry are experiencing unique challenges,” explained Nigel Smith, president and CEO at TM Robotics. “Some are frantically searching for ways to diversify, while others have dramatically increased or decreased output and have been forced to rethink their production methods. Naturally, different challenges require different approaches.

“TM Robotics’ global distributor network spans six continents and, within it, boasts unrivalled expertise in industrial robot installation. The launch of the robotics consultation service will provide manufacturers in the food sector with practical advice on which automation tools can prove most effective for them, based on an assessment of their unique situation.”

Consultations will be held virtually using a video conferencing service and will be hosted by one of TM Robotics’ robotic automation experts. Alternatively, consultations can be arranged by appointment.

To arrange a consultation, please contact TM Robotics directly at This email address is being protected from spambots. You need JavaScript enabled to view it. or visit the website at www.tmrobotics.com.

About TM Robotics: TM Robotics has installed thousands of robots in factories throughout the world, including North and South America, India, Russia, Europe, the Middle East, Africa and Australia. Many of the top manufacturing companies depend on TM Robotics’ product offerings for their reliability, performance, and overall value.

In partnership with Shibaura Machine, TM Robotics is the only company that offers a comprehensive range of all three categories of robots; 6-axis, SCARA, and Cartesian. These are designed and built in-house.

TM Robotics delivers cutting-edge solutions, training, and support services for industrial and commercial applications.

For further information please visit www.tmrobotics.co.uk

DeepGreen teams up with leading research institutions to understand and minimise impacts of collecting minerals for electric vehicles and clean energy from the deep sea

- The battery metals start-up is investing over U.S. $60 million to accelerate a massive collaborative program to address outstanding questions on the potential environmental impacts of collecting polymetallic nodules from the deep seabed in the Pacific Ocean

- Top experts from UK National Oceanography Centre, Natural History Museum (London), University of Gothenburg, University of Leeds, Heriot-Watt University — the Lyell Centre, Florida State University, University of Hawaii, Japan Agency for Marine-Earth Science and Technology, and Texas A&M will join the effort, while fully maintaining their academic independence and building society’s knowledge of the deep sea

- Ground-breaking in both scope and scale, the program will involve over 100 researchers to study the entire water column — from seabed to surface — involving ROVs, nets, sail drones and sophisticated sensors and moorings

DeepGreen Metals Inc., has just announced it has formalized partnerships with leading scientific research institutions and internationally-renowned universities in a significant investment into its ongoing deep-sea discovery program to characterize the potential impacts of lifting polymetallic nodules up from the bottom of the Clarion Clipperton Zone (CCZ) of the Pacific Ocean.

DeepGreen Metals Inc., has just announced it has formalized partnerships with leading scientific research institutions and internationally-renowned universities in a significant investment into its ongoing deep-sea discovery program to characterize the potential impacts of lifting polymetallic nodules up from the bottom of the Clarion Clipperton Zone (CCZ) of the Pacific Ocean.

The program will include dozens of discrete studies of pelagic and benthic biology, bathymetry and ecosystem function of the CCZ as part of DeepGreen’s environmental and social impact assessment (ESIA) for its proposed polymetallic nodule collection project. The data collected will enable informed decision-making and regulatory development in advance of the commencement of a new resource industry which has the potential to provide billions of tonnes of the critical battery metals required for society’s transition to clean energy.

The participation of independent scientific institutions in DeepGreen’s ESIA underscores the company’s commitment to transparency during the exploration phase of an industry that some NGOs oppose on the grounds that there is currently insufficient information about the deep sea to make informed decisions about impacts.

“This is a collaboration of the best minds in ocean science coming together to answer many important questions about deep-sea ecosystem function and connectivity throughout the water column,” said DeepGreen Chief Ocean Scientist, Dr. Greg Stone. “The program will enable DeepGreen to put forward a rigorous, peer-reviewed environmental impact statement to the International Seabed Authority, setting a high bar for this new industry.”

One of the primary concerns that researchers will address is the impact of sediment plumes on deep-ocean fauna throughout the water column, and at varying spatial and temporal scales.

“We are pleased to take part in this important, wide-reaching and collaborative effort to study the impacts of collecting polymetallic nodules. We are also encouraged by DeepGreen’s proactive approach, desire to support high-quality science and commitment to make all of our findings publicly available,” said Dr. Daniel Jones from the UK National Oceanography Centre, whose team will investigate the seabed megafauna of the region.

The global team of environmental scientists will work to deliver a state-of-the-art baseline biological survey of DeepGreen’s NORI exploration area to meet or exceed international regulatory requirements under the International Seabed Authority (ISA), established by the UN Convention on the Law of the Sea (UNCLOS). DeepGreen will use the insights and knowledge gained from the comprehensive survey to inform engineering decisions in order to further develop technologies to collect and uplift polymetallic nodules with as little impact as possible to the ocean.

Contribution to wider science

The multi-year, integrated research program will characterize the marine environment and species from the seabed of the abyssal plain up through the water column, to the surface of the ocean, studying everything from microbes to whales. All output and data generated by this intensive research program will be shared with the international community, and samples collected from the deep sea will be sent to labs around the world for analysis. This collaborative effort will advance the wider fields of ocean science, medicine and technology.

The deep ocean has proven to be fertile ground for important scientific breakthroughs in recent years, including the isolation of enzymes critical to testing for coronaviruses, and DeepGreen is hopeful that, with a large catalogue of biological and deep-sea sediment samples in hand, researchers will be able to unlock the vast potential of these common heritage resources and advance the frontiers of deep-ocean science.

Mission to supply metals for the clean energy transition

With society’s demand for battery metals booming due to the transition to clean energy and electric vehicles, DeepGreen believes that polymetallic nodules from the deep sea — a rich, concentrated source of nickel, copper, manganese and cobalt — present significant opportunities to reduce the most serious impacts that arise from mining metals on land.

Deep-sea nodules have never been collected on a commercial scale. The work of the research team that DeepGreen has assembled will help to prepare a body of scientific evidence around potential impacts to enable the international community, through the ISA, to assess the likely environmental impacts of nodule collection in DeepGreen’s NORI area and make evidence-based decisions on granting exploitation contracts to DeepGreen and its sponsoring states.

About DeepGreen

DeepGreen Metals Inc., is a polymetallic nodules exploration and development company on a dual-mission: (1) supply metals for the green transition with the least possible negative environmental and social impact and (2) accelerate the transition to a circular metal economy. The company holds exploration rights to three polymetallic nodule contract areas in the Clarion Clipperton Zone sponsored by the governments of Nauru, Kiribati and the Kingdom of Tonga, and regulated by the International Seabed Authority. DeepGreen has developed a process for producing metals from polymetallic nodules with near-zero solid waste, eliminating the need for tailings dams on land. More information about DeepGreen is available at www.deep.green.

China to account for over 25% global offshore wind power capacity by 2030, says GlobalData

AdministratorThe global offshore wind segment is likely to grow seven folds by 2030 mainly driven by capacity additions from three major markets, China, the UK and the US. China will lead the race with more than 25% of the new offshore wind capacity expected to be added by 2030, followed by the UK (16%) and the US (11%). China is poised to dominate due to its conducive policy initiatives and presence of national or provincial governments’ targets resulting in building a sizeable offshore project pipeline, says GlobalData, a leading data and analytics company.

Ankit Mathur, Practice Head of Power at GlobalData, comments: “ GlobalData’s analysis reveals that China is anticipated to spearhead the global capacity from 2021 onwards shaping above 25% of the global cumulative installed capacity by 2030. It is expected that by 2030, the global offshore wind capacity is set to surpass 203GW, led by major contributions from China (41.6GW), the UK (27.5GW) and the US (18.9GW).

GlobalData’s power database has tracked around 60GW of ventures in the pipeline under different stages of development. The Chinese offshore wind industry is currently dominated by state-owned Chinese energy firms while foreign players are teaming up with the Chinese companies to become part of this long-term sizable market opportunity.

GlobalData’s power database has tracked around 60GW of ventures in the pipeline under different stages of development. The Chinese offshore wind industry is currently dominated by state-owned Chinese energy firms while foreign players are teaming up with the Chinese companies to become part of this long-term sizable market opportunity.

China has exceptional wind resource potential with an estimation of harnessable onshore potential of 2,380GW and 600GW on the sea (offshore). With several deep-sea ventures distancing above 40kms from the shore, key sites for project construction are identified, across the nation, with wind speeds extending from 6-10m/s.

Mathur concludes: “The growing appetite for expanding the green sustainable power in the country’s power generation mix has set the tone for expansion in the Chinese uncharted waters. Beyond the benefits of green power, the growth in the Chinese offshore wind sector is set to provide large employment opportunities across the sectors and value chain, and play a key role in long standing economic activities. In order to make this expansion a reality, the government and the industry players need to simplify the project approval processes, build a dependable supply chain and reduce the factors that provide financial uncertainties to the investors.”

- Comments provided by Ankit Mathur, Practice Head of Power at GlobalData

- This press release is written using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

UL to evaluate Azelio’s long-duration energy storage technology for the US market

AdministratorLeading global safety science company and certification body UL is working together with Azelio towards evaluating its long-duration energy storage technology to enable commercial operations in the US market. The objective of the evaluation is to achieve a field certification of Azelio’s technology in 2021 for a specific project in California.

As part of Azelio’s entry strategy for the US market, UL has been chosen as the certifying authority for the company’s long-duration energy storage technology with on-demand clean power production. Being developed and manufactured in Sweden, Azelio’s product will be CE certified following European standards, which are different in certain aspects to American standards when it comes to electrical safety and grid compliance. UL, being the reference for many of the North American grid standards, will evaluate Azelio’s technology to enable the full compliance with the local grid codes and safety directives in the context of a field certification for a project in California.

As part of Azelio’s entry strategy for the US market, UL has been chosen as the certifying authority for the company’s long-duration energy storage technology with on-demand clean power production. Being developed and manufactured in Sweden, Azelio’s product will be CE certified following European standards, which are different in certain aspects to American standards when it comes to electrical safety and grid compliance. UL, being the reference for many of the North American grid standards, will evaluate Azelio’s technology to enable the full compliance with the local grid codes and safety directives in the context of a field certification for a project in California.

In particular, Azelio’s Thermal Energy Storage needs to fulfil several requirements such as safety requirements according to NEC (National Electrical Codes), pressure regulations, local NFPA fire codes as well as regulations for connecting to the grid. UL who has more than 100 years of experience from working with standards and certification will among other standards use its recently updated UL9540 to evaluate the safety of the installation.

“The US market has shown great interest in Azelio’s technology and the need for long-duration energy storage is rapidly growing. We are now taking a big step towards market entry by partnering with UL to certify the technology for North American grid standards”, says Jonas Eklind CEO of Azelio.

About Azelio

Azelio is a public Swedish company specialising in thermal energy storage with dispatchable power. The technology is revolutionary for its unique capability to produce electricity and heat from the storage on demand at all hours of the day. The system stores energy in recycled aluminium and has a total efficiency of up to 90 % from energy to heat and electricity. It is scalable and cost-efficient from 0.1 MW up to 100 MW and suffers no reduced capacity over time. Azelio has 150 employees, is headquartered in Gothenburg with production facilities in Uddevalla, development centres in Gothenburg and Åmål (Sweden), as well as a presence in Stockholm, Beijing, Madrid, and Morocco. Azelio currently has installations in Morocco and Sweden. Another installation will be up and running in Abu Dhabi in the fall of 2020. Since its establishment in 2008, the company has invested over SEK 1.5 billion in technical development. Azelio is listed on Nasdaq Stockholm First North. FNCA Sweden AB is the company’s certified adviser: +46(0)8-528 00 399, This email address is being protected from spambots. You need JavaScript enabled to view it.. More about Azelio: www.azelio.com

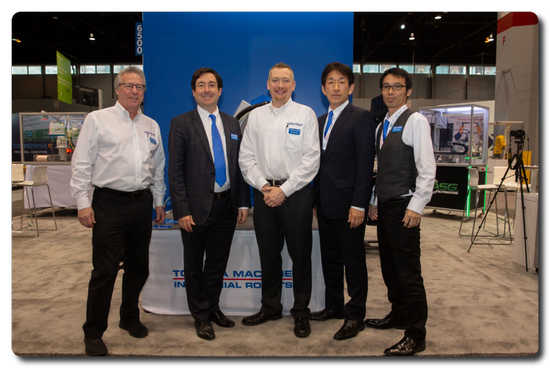

AFX is the new Air Fin Cooler range for cooling operations in power and heavy industry, chemicals and petrochemicals as well as turbine and compressor cooling according to API 661.

Higher heat transfer with new standardized AFX range of air fin coolers

Kelvion is adding two new solutions to the Air Fin Cooler market – the AFX Alu and the AFX HDG. AFX brings Kelvion’s extensive know-how and experience from countless customized Air Fin Cooler projects to a standardized and modular design to improve heat transfer and boost efficiency.

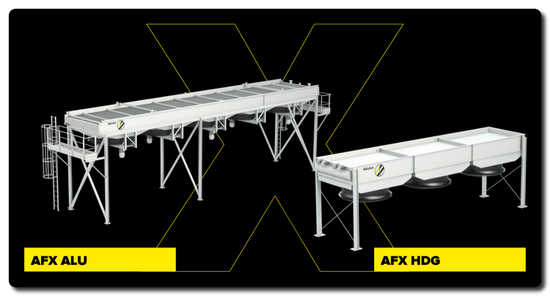

While differing in the range of application, both products have Kelvion’s advanced tube technology at the heart, with the advantages of reduced engineering effort, delivery times and payback periods.

Unique aluminum groovy finned tubes form the core of the AFX Alu, providing a higher level of heat exchange. It has been developed for cooling applications in the oil & gas and heavy industries. With the AFX HDG, hot dip galvanized, elliptical CW tubes offer increased heat exchange at reduced fan power consumption. Robust, corrosion resistant and easy to clean, the AFX HDG is ideal for heavy industry, power, chemical and petrochemical applications.

AFX Alu

The AFX Alu builds on Kelvion’s decade-long experience of customized air fin coolers with aluminum fins. These have a successful track record within the oil & gas industry. To comply with air entrance requirements from API 661, AFX Alu is available in three different heights, 3.1 m / 10.17 ft.; 4.1 m / 13.45 ft., 5.1 m / 16.73 ft. Up to 25 modules in five bays, with five modules in line, can be connected to one cooling unit, to suit operational requirements. Each module is equipped with a forced draft fan blowing the ambient air through the tube bundle. Without mounted steel structure and motors bays of up to five modules can be transported by truck. The carbon steel or stainless-steel tubes with embedded aluminum groovy fins feature a patented shape to maximize the heat exchange surface. This geometry leads to an 8% to 15% improvement in heat transfer at constant power consumption, while providing optimal fouling resistance and cleaning capability. This model is designed for temperatures up to 130 °C (266 °F) and pressures up to 16 bar g (232 PSI). AFX Alu has been developed for the cooling of turbo machinery power generation in the fields of heavy industry and oil & gas.

AFX HDG

Up to seven modules can be combined into one cooling unit. Two different draft options and three different flow options provide flexibility to suit a range of operational requirements.

The hot dip galvanized CW tube is the culmination of 100 years of innovation in elliptical tube technology. The patented shape leads to increased heat transfer combined with a lower air side pressure drop at same air velocity. This means either reduction of operational costs through energy savings or increase of output at same level of energy consumption. This way or another a boost of efficiency is given. Ultimately the AFX HDG embraces all benefits of elliptical galvanized tubes, combined with a modular and flexible approach that leads to a competitive, efficient and reliable air-cooled heat exchanger.

Kelvion Holding GmbH

The company supplies customers in global markets for power generation, oil and gas, chemicals and marine, food and beverage as well as sugar, heavy industry, transportation and the HVAC and refrigeration technology sectors. Customers in these industries benefit from durable, secure solutions and low operating costs, and are supported by a global service network. As of 31 December 2017, the company had generated annual sales of approx. 800 million euros and employed around 5,000 staff around the world.

For more details on Kelvion, please consult www.kelvion.com

New iSYS-6030 radar system detects filling levels and prevents collisions

AdministratorInnoSenT's new edition of a classic product offers high-precision distance measurement

The radar experts at InnoSenT GmbH have developed a new system for focused distance measurement. The iSYS-6030 is the new edition of the successful iSYS-6003 filling-level radar. The product update is more economical, faster, and more accurate than its predecessor. The sensor’s features are adapted to the application of filling-level measurement and collision avoidance. The technical enhancements also extend the scope of applications.

Current filling-level always in focus

Using contactless radar detection, the product accurately detects the filling level of a manufacturing or storage container. The iSYS-6030 radar system sporadically determines the distance between the sensor and an object’s surface. Thanks to its narrow antenna orientation, the product has a focused radar beam for high-precision measurements.

The iSYS-6030 detects a wide variety of materials regardless of their properties and reflection characteristics: Whether cohesive or coarse bulk materials, fine powder, granulate, slow-flowing liquids, or viscous pastes, the system detects any of these materials precisely thanks to its 60 GHz radar technology.

Impressive in dealing with challenging measuring conditions

The new product handles the measurement of filling levels even in challenging indoor and outdoor measuring environments. Extreme temperatures, dust, fog, steam, formation of foam, vibrations, or pressure do not impede radar detection. Due to its focused field of view of 6° in azimuth and elevation, the system is also suitable for use in narrow vessels, asymmetrical special structures, or containers with internal mixing systems installed. The iSYS-6030 also provides reliable measurement results in this area by means of sporadic radar detection.

The robust technology is not susceptible to interference due to aggressive filling materials, harsh work environments, or dirt. No regular maintenance is necessary. This makes the product well-suited for use in many different sectors, such as the water, energy, construction materials, food, chemical, pharmaceutical, and environmental technology industries.

Reliable radar measurement to protect against collisions

While the predecessor product was primarily focused on determining filling levels, the iSYS-6030 boasts a further area of application: thanks to its continuous and reliable distance monitoring, the system is ideally suited for collision protection.

Thanks to technical optimisation, the new product enables faster measuring cycles. The system is booted up and ready to collect data within 90 ms. The update rate in single-target mode is only 20 ms. This enables intervals to be monitored in real time and timely warnings in the event of an impending collision.

In another application, the radar helps to initiate safety measures such as speed reduction when a predefined zone is reached. The user defines the zone individually using the distance information. The iSYS-6030 radar system provides information on when the safety distance is neared or the zone is reached.

Integrating such a system proves beneficial not only with semi-autonomous and autonomous vehicles, but also for controlling complex systems. The radar system continuously collects accurate measurement data. These are useful in maintaining minimum distances and precise positioning. At port facilities, this enables a distance between cranes, transport units, buildings, or containers to thus be determined on site with millimetre precision.

Technical highlights

The iSYS-6030 radar system operates in the frequency band from 57 to 64 GHz. The sensor is compact and equipped with a signal-processing unit and a dome-shaped radome. The radar component can thus be easily integrated into end products or customer housings. The measurement data (signal strength and distance) are provided as a target list via a UART interface. The maximum range is 40 metres.

Customers choose between two detection variants, depending on the application: single-target and multi-target mode. This way, the system measures the distance to the object surface either at a single point or at different points within the detection area. The radar distinguishes between two targets with the same radar cross-section with a resolution of 12 cm.

The low deviation rate of ±0.1% ensures outstanding precision even with increasing distance between the object and the sensor. The system can be operated in a temperature range of -40 to +85° C.

Drop-in replacement

Since the new system has the same structural design, it can directly replace the old iSYS-6003 product version and offers useful enhancements to existing customers.

‘We have made significant progress in radar development in recent years. In addition, we have learned quite a bit about our customers’ needs through the practical use of our filling-level radar. We thus decided to optimise the system’, explains Product Manager Dr Eva Buchkremer regarding the product update, and she adds:

‘Compared to its predecessor, the iSYS-6030 is more energy-efficient and accurate, longer-range and faster. We thus provide our customers with greater flexibility in using the product. We also offer more customisation options. Its technical features make the new system the ideal radar solution in industry for avoiding collisions and measuring filling levels.’

Using the user manual and the API software protocol, the customer adapts the radar detection to their intended purpose. For example, they can limit the range or use the signal strength setting as a filter. In addition, customers have the option of configuring the effective isotropic radiated power (EIRP) in 1 dBm increments, for example in order to comply with technical limits required for approval purposes.

The system also has four digitally, freely assignable and programmable outputs. These enable simple control tasks and can be used as targeted signal triggers. For easy integration and configuration of the sensor, InnoSenT also provides an evaluation kit with a GUI.

Further information on the product and the radar technology from InnoSenT can be found on the company website at www.innosent.de.

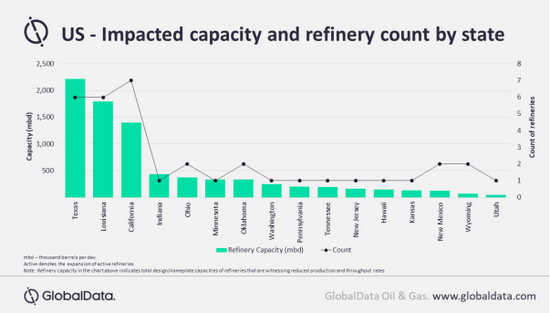

Refiners in US grapple with loss of fuel demand and COVID-19 outbreak, says GlobalData

AdministratorThe demand for gasoline and jet fuel has taken a hit as a result of nation-wide lockdown across the US since late March 2020 due to the COVID-19 pandemic. Piling up of stocks caused challenges in the form of mounting inventory costs while storage concerns of refined products with shorter shelf life added additional strain to the diminishing profit margins. Lack of contingency plans to address these challenges has forced the US refining companies to fall back on implementing remedial actions such as reducing operational capacity and slashing capital expenditure that can see off the current depressed market situation, says GlobalData, a leading data and analytics company.

Haseeb Ahmed, Oil and Gas Analyst at GlobalData, comments: “Several refineries have reduced their operating capacities while a few others have decided to suspend operations to navigate through the current crisis. BP plc’s Whiting refinery, with a capacity of 430 mbd, has decreased its crude runs by 30% due to a sharp fall in fuel demand amidst the COVID-19 outbreak; Total SA’s 238 mbd Port Arthur III refinery has reduced production rate to nearly 60%. Few other refineries, such as the Martines I operated by Andeavor in the US, has suspended the operations to tackle the devastating impacts caused by the virus.”

Few refiners in the US have also reduced their capex in response to the economic slowdown and adverse impacts of COVID-19. ExxonMobil Corp slashed its overall consolidated capex by US$10bn in 2020, from the initial plan of US$33bn, while Chevron Corporation has reduced by US$6bn, indicating the magnitude of the impact that the current crisis has on the region’s refinery sector.

Ahmed concludes: “Besides prioritizing capex and saving on cash to mitigate the effects of economic slowdown and lockdown, companies may look to restructure their businesses to evaluate diverse opportunies. Refiners are likely to continue analyzing the impact of COVID-19 on their operations and investments while keeping operational readiness for new business opportunities. However, they are expected to remain focused on key growth projects, ensuring long-term competitiveness.”

- Quotes provided by Haseeb Ahmed, Oil and Gas Analyst at GlobalData

- This press release was written using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

More...

Eficode reaches 37% growth rate and keeps expanding internationally

AdministratorKey growth drivers are recurring revenue from Eficode ROOT DevOps Platform and increasing share of international customers

Eficode, Europe’s leading DevOps company, announced that its revenue grew over 37 % in the last six months of the fiscal year ending June 30th, 2020. The total revenue in the fiscal year exceeded 30 million euros, of which more than 30% from outside Finland.

The challenging global economic situation has created a demand for DevOps culture and DevOps tools in many ways: to improve efficiency in software development and operations, or to capitalize on the business potential in the changing market conditions. The DEVOPS 2020 event organized by Eficode in April had record attendance. A significant majority of the audience participated in this online event from outside Finland, reflecting an overall shift to Eficode’s business becoming international.

During recent months, a number of customers have selected Eficode ROOT DevOps Platform, including S-Pankki and Lähitapiola in Finland, and Bankdata in Denmark. The upcoming deadline for EU Website Accessibility Directive has resulted in over 120 accessibility projects, making Eficode the largest provider of accessibility and UX research. Most recently, Oikeusrekisterikeskus (Legal Register Centre) in Finland selected Eficode to ensure accessibility to its digital services.

In March, Eficode received Atlassian’s global Partner of the Year award in DevOps - second time in a row. The close collaboration and the recognized expertise in Atlassian solutions resulted in several new customers, and expansions with existing customers, especially in Scandinavia. Eficode also became one of the first Atlassian partners in Europe to provide Jira Align, an enterprise agile solution, for its clients and is now offering help for companies around the world to scale their agile ways of working.

As a significant achievement, Eficode was recognized in Gartner’s Hype Cycle for Agile and DevOps, 2020. The Hype Cycle includes key approaches and technologies used to support a DevOps initiative.

“Despite the challenging market conditions, I am very pleased with the strong revenue growth and growth of our international business,” said Ilari Nurmi, CEO at Eficode. “As we grow, we continue to deliver the benefits of DevOps culture and tools more widely: gaining confidence in software development, improving cost-effectiveness in development and operations, and delivering more competitive software. I want to extend my gratitude to all Eficode employees for their dedication and perseverance and to customers for their trust and support.”

About Eficode

Eficode is the leading DevOps company in Europe, driving the DevOps movement and building the future of software development across seven countries with more than 300 professionals in DevOps, and sustainable software development. Our managed service, Eficode ROOT DevOps platform, provides centralized access control and real-time visibility of project status, quality, and performance, integrating over 40 of your preferred tools such as Atlassian stack, and open source systems like Jenkins and Kubernetes. For more information, visit https://www.eficode.com/

Shutdown Battery option added to IQ range to provide continued operations in a power outage and fail-to-position functionality

AdministratorThis pre-programmed movement of the valve on loss of power or communications means our customers retain important control over their operations during a power outage or Emergency Shut-Down (ESD). This is the first time that the IQT3 has been offered with a shutdown battery option in an explosionproof design. A lithium-ion battery supplies the potentially vital backup power from within the actuator enclosure. The integral battery pack provides a compact, explosionproof shutdown solution.

In the event of mains power loss, the Shutdown Battery can continue to function automatically to a site configurable end of travel safe position, providing fail-to-position functionality on critical valves. The failure mode can change depending on customer requirements. This fail-to-position can be fail-closed, open, stayput or go-to-a-per-cent position, depending on what fail-to-position action is needed to ensure the process fails to a safe operating state. This means the process finishes in a safe operating state, preventing any safety issues and avoiding monetary consequences due to loss of control. With the Shutdown Battery there is no need for additional back-up systems, such as compressors, to provide this functionality.

The IQT Shutdown Battery also features an Uninterruptible Power Supply (UPS) mode. This ensures that there is continued control and operation of the actuator on loss of mains power until the battery charge has run out. Operations can continue as normal while the battery charge lasts, mitigating the risk of deferred or lost revenue due to power outages.

A new integral battery option provides fail-to-position functionality in explosionproof applications

A new integral battery option provides fail-to-position functionality in explosionproof applications

Solar-powered installations are increasingly required for remote installations, such as pipeline pump stations. Here, the IQT Shutdown Battery mitigates fluctuating solar power and eliminates the need for expensive external batteries.

The IQT Shutdown Battery is ideally suited to unmanned applications which require further fail-safe functionality when power is lost; it is appropriate for applications on PSD/ESD valves such as well heads, line breaks and high/low pressure scenarios. Programmable logic allows for a delay before the fail operation occurs. Local battery power at the actuator offers further operational flexibility unavailable with ‘hair-trigger’ spring-based ESD systems. If power or communications systems temporarily drop out through unreliable power supplies, operation can continue; this maintains crucial operation time and prevents costly restarts.

The IQT Shutdown Battery is ideal for control valves, blow down valves and control process applications which must be shut down in a phased or staged sequence. It is also perfectly suited for the transfer of crude oil and valves at often unmanned natural gas custody transfer stations, where valves should ‘fail-to-divert’ process fluid back to the storage tanks on loss of power. The Shutdown Battery can also be used as a compact alternative to spring-return fail-safe actuators.

The new models are able to provide the same functionality as the existing IQT3 range. Applications with many valve functions, such as tank farms, will benefit from the commonality of the IQT3 Shutdown Battery with other IQ and Rotork actuators, as an integrated change control network with common user-interfaces and diagnostics. This interchangeability also reduces training and commissioning time. Ingress protection and hazardous area classification to ATEX, ICEx, CSA and CSAus from IQT actuators is maintained, providing increased flexibility and reliability. Partial stroking, site configurable speed setting, a non-intrusive IP68 double sealed enclosure and Bluetooth® Communications remain. They are capable of up to 1,200 starts per hour and are fully compatible with all networks.

LBS start-up CarbonChain secures investment from VC fund Y Combinator

AdministratorCarbonChain, a UK government backed software as a service company that helps companies automate the accounting of the carbon emissions in their supply chain, has secured investment from the prestigious San Francisco based venture capital fund, Y Combinator.

Established in 2017, CarbonChain has a mission to make ‘supply chains green’. The company’s products enable companies in some of the most polluting industries, such as oil & gas, mining, agriculture, and logistics, to measure and reduce greenhouse gas emissions

A distinguished product of the London Business School’s Institute of Innovation and Entrepreneurship’s Incubator programme, CarbonChain was co-founded by Adam Hearne (LBS MBA 2015; CEO of CarbonChain), and Roheet Shah (LBS MBA 2015; COO of CarbonChain) along with Imperial College computer scientists Yury Oparin (CTO of CarbonChain) and Jeremiah Smith, Ph.D (CPO of CarbonChain). Together, the team possess deep expertise across a wide spectrum of commodities industries, supply chain management, and software development.

A distinguished product of the London Business School’s Institute of Innovation and Entrepreneurship’s Incubator programme, CarbonChain was co-founded by Adam Hearne (LBS MBA 2015; CEO of CarbonChain), and Roheet Shah (LBS MBA 2015; COO of CarbonChain) along with Imperial College computer scientists Yury Oparin (CTO of CarbonChain) and Jeremiah Smith, Ph.D (CPO of CarbonChain). Together, the team possess deep expertise across a wide spectrum of commodities industries, supply chain management, and software development.

Both acknowledge the support of LBS in the rapid success of CarbonChain, and that Y Combinator’ investment is now another important milestone for the company. With an acceptance rate below two per cent, Y Combinator's accelerator programme has been described as "harder to get into than Harvard" by Business Insider. Notable companies that have gone through Y Combinator include AirBnB, Dropbox, and Stripe. Y Combinator has created a new model for funding early stage start-ups and twice a year invests money in start-ups.

CarbonChain is an accredited solutions provider of the Carbon Disclosure Project, and a proud member of ResponsibleSteel™, a not-for-profit organisation which is the steel industry’s first global multi-stakeholder standard and certification programme. The UK government’s innovation arm, InnovateUK, has supported CarbonChain in developing its technology via £460,000 in grant funding.

Companies work with CarbonChain to automate the accounting of their supply chain carbon emissions to: access cheaper, greener financing; avoid financial penalties, and track internal sustainability KPIs.

“Disruption and 'supply shock' is coming for companies that do not factor in the rising price of carbon. The price of carbon is going from the global average of $2/ton right now to the anticipated $100/ton in 2030,” says Shah. “This is where CarbonChain comes in. Our accounting platform can extract data from standard supply chain documents, and generate a comprehensive carbon emissions report for the end-to-end supply chain.”

The CarbonChain founders discovered the need for supply chain carbon emissions accounting in oil & gas and mining while working for BCG and Rio Tinto. CarbonChain has built models for every single asset in the supply chain for these primary industries, creating digital twins of every piece of equipment used in heavy industry. If CarbonChain is unable to obtain the information about the equipment from the companies that use its services, they then go to the engineering firms that built the equipment or facility for the company.

“Transparent supply chains are the hallmark of sustainable businesses, and the objective of CarbonChain is to assist corporations and governments alike to take a proactive step in carbon reporting so they can work together and make large scale reductions in CO2 emissions year after year,” says Hearne.

About London Business School

London Business School's vision is to have a profound impact on the way the world does business and the way business impacts the world. The School is consistently ranked among the best business schools globally* and is widely acknowledged as a centre for outstanding research.

As well as its highly ranked degree programmes, the School offers award-winning Executive Education programmes* to business leaders from around the world.

London Business School has campuses in London and Dubai, and a presence in three additional international cities – New York, Hong Kong and Shanghai. The School equips its diverse student body with the tools needed to tackle today’s business challenges and connects them with many of the world’s leading thinkers.

The School has more than 44,000 alumni working in over 155 countries. Together, they are a community defined by a wealth of knowledge, business experience and worldwide networking opportunities.

London Business School’s 174 faculty members come from over 30 countries. They cover seven subject areas: accounting, economics, finance, management science and operations, marketing, organisational behaviour, and strategy and entrepreneurship.

*The Financial Times (FT) has named London Business School the top European business school for the fifth consecutive year in 2018; its Executive Education programmes ranked in the top four overall by the FT in 2018. London Business School was awarded the 2013 EFMD Excellence in Practice Award for its 10-year partnership with Danone.

Greg Gumbs is to be appointed as the new President and CEO of Bosch Rexroth North America

► Paul Cooke retires after 38 years with Bosch Rexroth

Paul Cooke, President and CEO of Bosch Rexroth North America, based in Charlotte, NC, USA, will retire on December 31, 2020 after 38 years of distinguished service in various international positions within Bosch Rexroth.

His successor as of December 1, 2020 will be Greg Gumbs, most recently Vice President & General Manager Electrical Automation Solutions at EATON Corporation. Greg will join Bosch Rexroth effective September 1, 2020 in preparation for his future responsibility and will be based at Bosch Rexroth North American headquarters in Charlotte, NC.

After completing his degree in electrical engineering, Greg started his professional career in 1997 as an application engineer in the Global Technical Service Group of Rockwell Automation, Inc. He later held various drive systems engineering, sales, marketing, services and management positions within Rockwell before taking over as Director Commercial Sales Support and Market Development.

After completing his degree in electrical engineering, Greg started his professional career in 1997 as an application engineer in the Global Technical Service Group of Rockwell Automation, Inc. He later held various drive systems engineering, sales, marketing, services and management positions within Rockwell before taking over as Director Commercial Sales Support and Market Development.

In 2007, Greg joined the EATON Corporation Industrial Sector as Vice President Sales Americas for Hydraulics Business. In 2013, he became General Manager for the Hydraulic Hose and Fittings Business. In 2015, he moved to EATON Electrical Sector as Vice President & General Manager of EATON Electrical Automation Solutions.

“Bosch Rexroth is an amazing organization with a bright future given the strong foundation of technology leadership and customer focus. I am honored to join the Bosch family and looking forward to leading this talented team forward in close partnership with our channel partners,” said Greg.

In addtion to an electrical engineering degree from DeVry University, Greg obtained his MBA with a focus on Leadership and Global Business Management from Weatherhead School of Management at Case Western Reserve University.

About Bosch Rexroth:

As one of the world’s leading suppliers of drive and control technologies, Bosch Rexroth ensures efficient, powerful and safe movement in machines and systems of any size. The company bundles global application experience in the market segments of Mobile Applications, Machinery Applications and Engineering, and Factory Automation. With its intelligent components, customized system solutions and services, Bosch Rexroth is creating the necessary environment for fully connected applications. Bosch Rexroth offers its customers hydraulics, electric drive and control technology, gear technology and linear motion and assembly technology, including software and interfaces to the Internet of Things. With locations in over 80 countries, roughly 31,000 associates generated sales revenue of roughly 6.2 billion euros ($7.3 billion) in 2019.

To learn more, please visit www.boschrexroth-us.com.

About Bosch:

The Bosch Group is a leading global supplier of technology and services. It employs roughly 400,000 associates worldwide (as of December 31, 2019). The company generated sales of 77.7 billion euros ($84 billion) in 2019. Its operations are divided into four business sectors: Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology. As a leading IoT provider, Bosch offers innovative solutions for smart homes, Industry 4.0, and connected mobility. Bosch is pursuing a vision of mobility that is sustainable, safe, and exciting. It uses its expertise in sensor technology, software, and services, as well as its own IoT cloud, to offer its customers connected, cross-domain solutions from a single source. The Bosch Group’s strategic objective is to facilitate connected living with products and solutions that either contain artificial intelligence (AI) or have been developed or manufactured with its help. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is “Invented for life.” The Bosch Group comprises Robert Bosch GmbH and its roughly 440 subsidiary and regional companies in 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. The basis for the company’s future growth is its innovative strength. Bosch employs some 72,600 associates in research and development at 126 locations across the globe, as well as roughly 30,000 software engineers.

Additional information is available online at www.bosch.com