Super User

Strong petroleum products demand continues to boost refining sector in China, says GlobalData

China is likely to start the operations of 42 crude oil refinery projects or 26% of the total crude oil refinery projects in Asia between 2021 to 2025 to meet the growing demand for plastics and petroleum products, says GlobalData, a leading data and analytics company.

GlobalData’s latest report, ‘Global Crude Oil Refinery Projects Outlook, 2021-2025’, reveals that out of the 42 projects, six projects are new-build and 36 represent expansions of existing projects.

In China, 22 upcoming refinery projects are in the construction stage and likely to start operations between 2021 and 2025. Feasibility and approval are the other major project stages with 12 and six projects, respectively.

Bhargavi Gandham, Oil & Gas Analyst at GlobalData, comments: “China, the world’s largest oil and gas importer, and a leading consumer, continues to witness strong growth in the refinery sector. Growing demand, especially from petrochemicals and transportation sectors, will boost the refining activity in the country.”

During 2021-2025, Yulong and Jieyang are expected to be the leading projects in terms of refining capacity in the country with 400 thousand barrels per day of capacity, each. Shandong Yulong Petrochemical Ltd is the operator as well as 100% equity holder of the Yulong project, which is expected to start operations in 2023.

The Jieyang project is expected to start operations in 2022. Petrochina Pdvsa Guandong Petrochemical Co Ltd is the operator while China National Petroleum Corp and Petroleos de Venezuela SA hold 60% and 40% of equity in the project, respectively.

- Comments provided by Bhargavi Gandham – Oil & Gas Analyst at GlobalData

- Information based on GlobalData’s report: Global Crude Oil Refinery Projects Outlook, 2021-2025

- This report was built using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

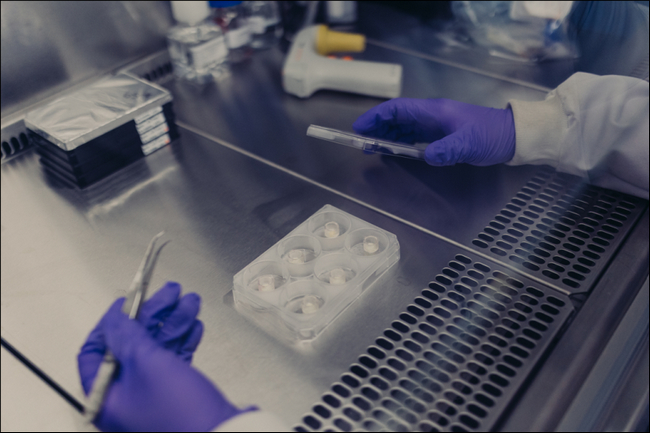

Gentronix adds capacity and services to market through laboratory expansion

UK-based Contract Research Organisation (CRO) Gentronix – a leading specialist toxicology CRO – has expanded its laboratory facilities to increase capacity for genetic, ocular, and skin toxicology testing and to provide new, specialist services amidst increasing global demand.

The business’s growth has enabled it to add a further 2,300sqft to its footprint at Alderley Park in Cheshire, allowing the firm to expand its offering to provide GLP services to assess chemicals for skin and eye toxicity potential using laboratory-based test systems.

Furthermore, this expansion allows the business to increase capacity for its existing GLP and screening studies within genetic toxicology, addressing continued increased market demand for its services.

Ocular damage and irritation tests using OECD 437 and OECD 492 studies, as well as phototoxicity testing services, are now being established directly within the new location. The new space will also enable Gentronix to expand the conduct of its in vitro 3D-skin irritation and corrosion services to full GLP compliance. These services complement the existing GLP in vitro skin sensitisation studies that the firm routinely conducts: DPRA, h-CLAT and KeratinoSensTM, offering sponsors a comprehensive battery of skin and ocular toxicity tests.

Also housed within the new space is a laboratory to support the post-life phase of Big Blue® transgenic mutation studies, acquired by the business in June 2021. As a result, Gentronix is now equipped to support its growing client base from their very first genetic toxicology screens right through to helping them manage complex mutagenicity risk assessments, becoming one of only a handful of CROs in the world able to deliver this end-to-end service.

Managing Director at Gentronix, Matt Tate, said: “Having identified the opportunity to expand our laboratory facilities at Alderley Park, we saw this as a vital part of our growth plans, enabling us to implement important new service lines and increase existing service capacity to meet continuing growth in demand.

“The implementation of a comprehensive ocular and skin toxicology GLP service will enable Gentronix to expand our collaboration with our existing client base in the chemicals sector, as well as driving new business growth within cosmetics, consumer products and personal care markets; newer service sectors for Gentronix. Having the ability to deliver the assessment of corrosion and irritation potential for both skin and eye, and then follow those studies up with phototoxicity and sensitisation testing all at one site, with a dedicated and highly experienced scientific team, will deliver real value to our clients.”

By adding new services and increasing existing genetic toxicology service capacity to the market, Gentronix can turn around requests and testing quickly, with significant commercial advantages for clients, whilst facilitating the growth of the Gentronix business.

As a leading predictive toxicology CRO, operating from its GLP laboratory base at Alderley Park, Gentronix’s work helps develop safe products used by millions of people around the world including pharmaceuticals, agrochemicals, fragrances, foods, flavours, personal care products and cosmetics.

For more information about Gentronix, please visit http://www.gentronix.co.uk/

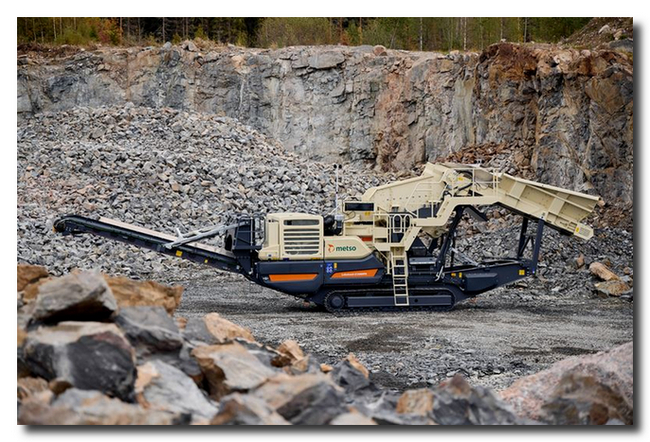

Metso Outotec expands Lokotrack mobile series for aggregates

Metso Outotec is launching two new models to the Lokotrack® mobile crushing and screening series. The new Lokotrack LT200HPX and Lokotrack LT220GP mobile cone crushers are compact but efficient units ideal for aggregate contractor customers, bringing up to 30% more capacity and added flexibility compared to earlier models. The new models will be premiered during Metso Outotec’s virtual studio events on 27th October, and in the new Lokotrack Liveroom 360 online experience together with services and parts offerings for Lokotrack. The new Lokotrack models are available globally as of 27th October.

Metso Outotec Lokotrack LT200HPX-3D

Metso Outotec Lokotrack LT200HPX-3D

More efficient aggregate operations

The launch models have many new features that are designed to improve the efficiency of customer’s operations. They are built on the same new chassis, allowing customers to choose between the two cone crusher types and various optional features based on their specific needs. The Lokotrack LT200HPX is equipped with an efficient two-deck pre-screen providing more capacity. Heavy duty chassis and wide conveyors facilitate high throughput, and a direct v-belt crusher drive ensures high fuel efficiency. Service and transportation are facilitated with extensive service platforms that fold down for transport. LT200HPX can be combined with Lokotrack LT106 and LT116 jaw crushers and Lokotrack ST3.8 and ST4.8 mobile screens.

The Lokotrack LT220GP provides additional crushing power and can be equipped with a pre-screen or with a belt feeder. LT220GP fits well with Lokotrack LT120/LT120E mobile jaw crushers and ST4.10 mobile screen for high-capacity aggregate production.

“The new models and our end-to-end offering displayed in the Lokotrack Liveroom, demonstrate our focus on improving aggregates customers’ operations and bottom line,” says Kimmo Anttila, Vice President, Lokotrack Solutions at Metso Outotec. “With these new models of 300 metrics tons per hour capacity and 40 metrics ton transport weight, the customers have even more choice and flexibility to select from our cone crusher range. Lokotrack is a sustainable and future-proof choice for any type of aggregate production.”

Metso Outotec Lokotrack LT200HPX

Metso Outotec Lokotrack LT200HPX

Extensive service and support portfolio

Metso Outotec offers extensive services and parts support for Lokotrack, including for example spare and wear parts recommendation lists and kits, full container load parts service, inspections and extended warranties and the Metrics remote monitoring solution. The service portfolio showcased in the Liveroom addresses the needs of aggregates customers in terms of equipment protection, availability, performance, and upgrades. These services are aimed at helping Lokotrack crushing and screening assets operate at their optimal levels.

Join the studio events and visit the Lokotrack Liveroom at live.mogroup.com.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Renewable Energy Jobs Reach 12 Million Globally

Report by IRENA and ILO underscores the jobs potential of an ambitious climate strategy and calls for comprehensive policies in support of a just transition

Renewable energy employment worldwide reached 12 million last year, up from 11.5 million in 2019, according to the eighth edition of Renewable Energy and Jobs: Annual Review 2021. The report was released by the International Renewable Energy Agency (IRENA) in collaboration with the International Labour Organization (ILO) at a high-level opening of IRENA’s Collaborative Framework on Just and Inclusive Transitions, co-facilitated by the United States and South Africa.

The report confirms that COVID-19 caused delays and supply chain disruptions, with impacts on jobs varying by country and end use, and among segments of the value chain. While solar and wind jobs continued leading global employment growth in the renewable energy sector, accounting for a total of 4 million and 1.25 million jobs respectively, liquid biofuels employment decreased as demand for transport fuels fell. Off-grid solar lighting sales suffered, but companies were able to limit job losses.

China commanded a 39% share of renewable energy jobs worldwide in 2020, followed by Brazil, India, the United States, and members of the European Union. Many other countries are also creating jobs in renewables. Among them are Viet Nam and Malaysia, key solar PV exporters; Indonesia and Colombia, with large agricultural supply chains for biofuels; and Mexico and the Russian Federation, where wind power is growing. In Sub-Saharan Africa, solar jobs are expanding in diverse countries like Nigeria, Togo, and South Africa.

“Renewable energy’s ability to create jobs and meet climate goals is beyond doubt. With COP26 in front of us, governments must raise their ambition to reach net zero,” says Francesco La Camera, IRENA Director-General. “The only path forward is to increase investments in a just and inclusive transition, reaping the full socioeconomic benefits along the way.”

“The potential for renewable energy to generate decent work is a clear indication that we do not have to choose between environmental sustainability on the one hand, and employment creation on the other. The two can go hand-in-hand,” said ILO Director-General, Guy Ryder.

Recognising that women suffered more from the pandemic because they tend to work in sectors more vulnerable to economic shocks, the report highlights the importance of a just transition and decent jobs for all, ensuring that jobs pay a living wage, workplaces are safe, and rights at work are respected. A just transition requires a workforce that is diverse – with equal chances for women and men, and with career paths open to youth, minorities, and marginalised groups. International Labour Standards and collective bargaining arrangements are crucial in this context.

Fulfilling the renewable energy jobs potential will depend on ambitious policies to drive the energy transition in coming decades. In addition to deployment, enabling, and integrating policies for the sector itself, there is a need to overcome structural barriers in the wider economy and minimise potential misalignments between job losses and gains during the transition.

Indeed, IRENA and ILO’s work finds that more jobs will be gained by the energy transition than lost. An ILO global sustainability scenario to 2030 estimates that the 24-25 million new jobs will far surpass losses of between six and seven million jobs. Some five million of the workers who lose their jobs will be able to find new jobs in the same occupation in another industry. IRENA’s World Energy Transitions Outlook forecasts that the renewable energy sector could employ 43 million by 2050.

The disruption to cross-border supplies caused by COVID-19 restrictions has highlighted the important role of domestic value chains. Strengthening them will facilitate local job creation and income generation, by leveraging existing and new economic activities. IRENA’s work on leveraging local supply chains offers insights into the types of jobs needed to support the transition by technology, segment of the value chain, educational and occupational requirements.

This will require industrial policies to form viable supply chains; education and training strategies to create a skilled workforce; active labour market measures to provide adequate employment services; retraining and recertification together with social protection to assist workers and communities dependent on fossil fuels; and public investment strategies to support regional economic development and diversification.

Read the full report here.

About the International Renewable Energy Agency (IRENA)

IRENA is the lead intergovernmental agency for the global energy transformation that supports countries in their transition to a sustainable energy future and serves as the principal platform for international co-operation, a centre of excellence, and a repository of policy, technology, resource and financial knowledge on renewable energy. With 166 Members (165 States and the European Union) and 18 additional countries in the accession process and actively engaged, IRENA promotes the widespread adoption and sustainable use of all forms of renewable energy in the pursuit of sustainable development, energy access, energy security and low-carbon economic growth and prosperity.

COP26 ahead….. Holistic Offshore Wind Design Process can demonstrate rapid decarbonisation – says Wood Thilsted

With the UN Climate Change Conference in Glasgow less than two months away, the offshore wind industry can help lead the way in showing COP representatives that solutions are readily available to deliver rapid decarbonisation.

According to Danny Bonnett, Engineering Director at geotechnical and structural specialists, Wood Thilsted, politicians need to understand that in addition to all the sound environmental benefits, fast action on decarbonisation is needed because business is yearning for this transition.

“As we see demand for offshore power continue to soar across the globe”, he said, “governments need to think big when writing the next chapter at COP26 in Glasgow”.

“As we see demand for offshore power continue to soar across the globe”, he said, “governments need to think big when writing the next chapter at COP26 in Glasgow”.

He added: “As offshore wind engineering specialists, we for example, can show just how efficient the design process can be with a holistic approach to what we specify and where. We have the solutions to deliver rapid decarbonisation across the energy sector in the very short term, and in the rest of the economy in the medium term. COP26 is a golden opportunity for bold action by governments to allow businesses to invest, to innovate, to seek the fastest and most cost-effective ways of stripping out carbon”.

Bonnett also pointed to SteelZero (which Wood Thilsted strongly advocate) – a global initiative that he believes sends a very powerful message to steel producers, policymakers and investors to accelerate the transition to widescale production of net zero steel. Bonnett claims that many of the barriers currently facing the offshore industry in its steel supply chains can be removed.

He continued: “During these past 18 months of the pandemic, the world has grown up. I think we now have a much better insight into our human vulnerability than ever before. The Global Transition and its sub-set, the Energy Transition are critically important. COP26 must think big and act quick”.

NOV creates Fluid Motion Solutions with New Big Six

NOV, whose global expertise covers oil and gas, chemical, mining/mineral processing, food/beverage and portable power, has brought together six of its trusted, industrial pump and mixer brands to create a dynamic new business unit known as Fluid Motion Solutions.

Featuring proven, long-established names such as Mono, Moyno and Chemineer, established in the 1930’s and 1950’s respectively, Fluid Motion Solutions is backed by a vastly experienced team of specialists, as well as a global service and aftermarket team – plus customer access to application software for optimum pumping and mixing results.

Based in Manchester, England, alongside the existing manufacture of Mono progressive cavity pumps, screens and grinders, the Fluid Motion Solutions business unit will also produce Chemineer agitators, Kenics static mixers and heat exchangers, as well as heat exchangers, high shear Greerco mixers, and belt-driven side entry Prochem mixers for the highly engineered mixing solutions demanded by industrial processors.

“With such a comprehensive portfolio of pumping and mixing brands, we have the answer to almost any customer challenge”, said Irfan Rehman, Sales Director for Fluid Motion Solutions.

He added: “Bringing this new group together at one centre of excellence in Manchester is a very positive, forward-looking move that will allow us to expand our pump and mixer range; delivering a series of new, innovative products and services to industry”.

While continuing to engineer industry-leading pump and mixer ranges, Fluid Motion Solutions will also make grinders and screens specifically designed for industries requiring solids reduction or waste conditioning.

NOV

Fluid Motion Solutions

Greengate, Middleton, Manchester, England M24 1SA

+44 (0) 161 339 9000

This email address is being protected from spambots. You need JavaScript enabled to view it.

East Anglia Hub design contract clinched by UK’s Wood Thilsted for its next generation turbine record and cost focus

A proven track record working with next generation offshore turbines around the world pushed UK structural and geotechnical engineering specialists Wood Thilsted to first choice for the detailed design contract for ScottishPower Renewables’ East Anglia Hub.

Wood Thilsted, which has worked on monopile foundation designs for pioneering US and European offshore wind farms, will design foundations for more than 200 14+MW Siemens Gamesa turbines that will stand in waters more than 50m deep in the East Anglia Hub, off the Suffolk coast.

The turbines on East Anglia ONE North, TWO and THREE that form the 3.1GW East Anglia Hub will be among the world’s most powerful and productive, generating more than 7.5% of the UK’s 40GW target for offshore wind power by 2030 and a key part of the UK’s race to net zero, a green recovery post-Covid and action on climate change.

East Anglia Hub will build on the success of SPR’s flagship East Anglia ONE project, now more than a year into its operations. East Anglia THREE has consent and results of the planning process for /east Anglia ONE North and TWO are expected by January 2022.

Ross Ovens, East Anglia Hub project director, said:

“Wood Thilsted’s expertise is vital to us being able to deliver the safest and most efficient foundations for this hugely significant project.

“Design has a major bearing on costs, safety and installability so bringing in an international team that has the right level of experience – in this case with the latest generation turbines – is extremely beneficial to the future success of the East Anglia Hub.”

Ed Crammond, director at Wood Thilsted, added:

“We are working very closely with ScottishPower Renewables, who share our strong belief in the importance of a multi-disciplinary design approach to continually improve offshore wind’s LCOE (levelised cost of energy). Together with parent company, Iberdrola, they are setting a very good example for the industry.”

The contract award comes weeks before all eyes turn to COP26 in Glasgow, where world leaders will converge to discuss how to tackle climate change.

Energy minister Greg Hands this week described offshore wind as “the lynchpin in our efforts to reach net zero” at Renewable UK’s (RUK) Global Offshore Wind Conference and Exhibition, with RUK chief executive Dan McGrail calling for support to further build scale and, importantly, speed, reflecting on a development process that can take a decade to deliver a single farm.

The partnership of SPR and Wood Thilsted pivots on a shared ethos to bring down the levelised cost of energy (LCOE) by foundation design improvements with a keen focus on installability and safety.

Crosser and Moxa join forces for IT/OT edge convergence

Moxa Europe GmbH and Crosser, a pioneer in edge analytics for the Industrial Internet of Things (IIoT), announce their cooperation. Together, Crosser’s edge analytics platform and Moxa’s reliable network, connectivity and edge computing solutions will help manufacturing companies to connect their devices to offer better collaboration between systems, processes, and people.

Smart manufacturing centers around creating an environment where all available information — from the shop floor itself and from every other point along the supply chain — is captured in real-time, made visible and transformed into actionable insights.

This need for interconnectivity across IT and OT networks has created a demand for intuitive, scalable cloud services and edge computing solutions. That’s why, in a recent IBM study, 91 per cent of respondents stated their organizations plan to implement edge computing in the next five years. However, to realize these technologies, manufacturers require both the technology itself and support to implement it.

Moxa helps organizations digitize their infrastructure. By providing secure and reliable IIoT solutions that let customers rapidly develop and deploy applications in the field, Moxa’s cloud-ready gateways and long life-cycle software act as the ideal starting point for manufacturers upgrading to Industry 4.0.

Moxa’s IIoT edge gateway family includes industrial computers that are optimized for edge computing applications. For instance, Moxa’s IIoT gateway software ThingsPro® Edge provides a cloud-ready gateway solution for easy and secure connectivity between the edge and cloud, ensuring transparent data exchange between OT and IT systems.

Crosser’s low-code platform gives users access to a rich library of pre-built modules that enable non-developers to apply any data transformation, harmonization, or data reduction to their streaming data. The platform runs on a hybrid architecture, which means that the partly cloud-based, real-time analytics engine can be installed anywhere: on an edge gateway, on a factory floor, or in the cloud — giving customers maximum flexibility.

By joining forces, Crosser and Moxa can give manufacturers a complete IIoT solution.

“Crosser solves one of the most common challenges our customers face — making data analytics scalable,” said Hermann Berg, Head of IIoT at Moxa. “Most customers can adopt new technologies, like edge computing, on a single device. However, the real challenge comes when an organization wants to make changes to their analytics software in the field or implement a new technology across multiple devices. That’s where Crosser comes in.”

Crosser’s unique hybrid architecture allows companies to innovate centrally with a low-code approach. The architecture combines the best of two worlds: the simplicity of modern cloud technologies and the secure and low-cost processing of data close to the data source, on premise or on an edge device.

“Being low-code, Crosser helps industrial companies move faster in their digitalization journeys by putting the power of innovation in the hands of non-developers,” explained Martin Thunman, Co-Founder and CEO of Crosser. “Our goal is to make edge analytics possible for all manufacturing companies, no matter their size or in-house skillset. But to make digitalization happen, we need an equally scalable IIoT toolkit that can bring software to manufacturers. For Crosser, Moxa is the perfect partner.

“What’s more, Moxa can pre-integrate its partners’ software. This is another key benefit for Crosser, as it will help to accelerate our time to market and help us to reach even more industries,” concluded Thunman.

You can learn more about the joint solutions and use cases visiting Moxa’s IIoT Partner website or by registering to Moxa’s upcoming IIoT TechTalk “Edge Infrastructure Meets Edge Analytics – At Scale” on November 4th 11:00 am, where both Moxa and Crosser will speak about use cases that demonstrate how IIoT infrastructure can accelerate the phases of the IIoT project lifecycle.

About Moxa

Moxa is a leading manufacturer of solutions for industrial networking as well as for computing and edge connectivity applications that establish the connectivity for the Industrial Internet of Things. With over 30 years of industry experience, Moxa has connected more than 71 million devices worldwide and has a distribution and service network that reaches customers in more than 80 countries. Moxa's customers benefit from reliable industrial networks and communication infrastructures. All true to the motto: Reliable Networks, Sincere Service. You can find more information about the solutions from Moxa at www.moxa.com

About Crosser

Crosser designs and develops Streaming Analytics, Automation and Integration software for any Edge, On-premise or Cloud. The Crosser Platform enables real-time processing of streaming, event-driven or batch data for Industrial IoT and Intelligent Workflows. It is the only platform of its kind that is purpose-built for Industrial and Asset Rich organizations.

The solution is built to fight complexity with simplicity through the Crosser Flow Studio, the visual design tool that enables teams to innovate faster than ever without developers. The software is ideally suited for Enterprise customers of various industries and applications, including Edge Analytics, Industrial Connectivity, Industry 4.0, Streaming Analytics, Hybrid Integration, and Intelligent Workflows. www.crosser.io

The MOXA logo is a registered trademark of Moxa Inc. All other trademarks or registered marks in this manual belong to their respective manufacturers.

OPITO reconfirms commitment to the energy workforce through standardised training approach

Ahead of the United Nations Climate Change Conference (COP26) in Glasgow, OPITO, the global safety and skills body for the energy industry, has reconfirmed its intention to identify commonalities between existing energy skills training and assessments to support global standards for hydrogen, carbon capture usage and storage (CCUS) and floating offshore wind.

With a 50-year legacy in oil and gas and a global footprint, OPITO’s well established emergency response frameworks, for on and offshore, will act as a basis for the development of hydrogen-specific, CCUS and floating offshore wind workforce training.

Andy Williamson, Head of New Ventures, OPITOAndy Williamson, Head of Energy Transition at OPITO, said: “Government’s plans to create a thriving green economy in the UK over the next ten years will create thousands of jobs, billions of investment and export opportunities for the supply chain.

Andy Williamson, Head of New Ventures, OPITOAndy Williamson, Head of Energy Transition at OPITO, said: “Government’s plans to create a thriving green economy in the UK over the next ten years will create thousands of jobs, billions of investment and export opportunities for the supply chain.

“This is already underway with major oil and gas operators announcing plans to create offshore wind and hydrogen hubs, based in the UK. OPITO’s leading role in energy skills, development and competency means we recognise the importance of our highly skilled oil and gas workforce and the role they can play in a low carbon economy, both domestically and further afield.”

Mr Williamson continued: “Collaboration is key. Our workgroups reviewing the standards currently in use throughout the oil and gas industry to understand transferability between sectors continue to gather momentum. The aim is to minimise duplication and standardise training for the workforce, thereby reducing cost and helping the supply chain to remain competitive.

“We are already working with major project developers globally, focused on technologies including offshore wind, hydrogen and CCUS, to ensure that our existing standards are embedded into these projects and the workforce can operate to the highest standard possible in a safe and skilled manner.

“Together with our partners and stakeholders, this approach will be upheld throughout the energy transition to ensure safety is never compromised and we secure high value renewable jobs in the UK.”

OPITO’s commitment to supporting the energy transition is underlined by its role leading the development of a People and Skills Plan as part of the North Sea Transition Deal, launched in March 2021.

About OPITO: OPITO is the global skills organisation for the energy industry. Up to 375,000 people are trained to OPITO standards every year, across 50 countries through 230 accredited training centres.

OPITO works to develop a safe and skilled workforce by driving global standards and qualifications, creating workforce development solutions and leading dialogue with industries and governments. With operation centres in four regions - UK and Europe, Middle East and Africa, Asia Pacific and the Americas - OPITO is driving safety and competency improvements to benefit the industry and providing career pathways and training opportunities for the current workforce and the next generation.

For more information, please visit www.opito.com

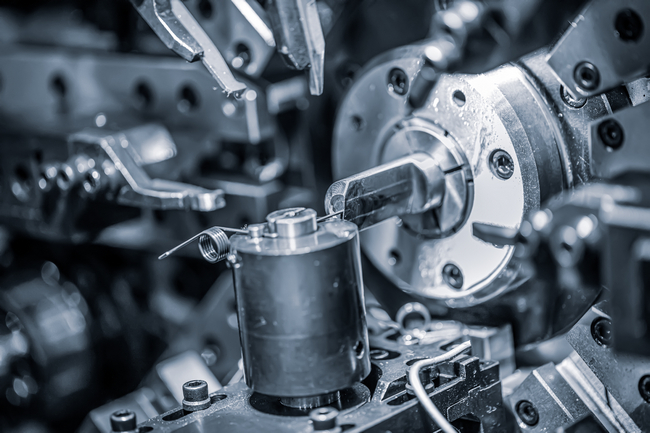

Putting the spring back into manufacturing equipment

It doesn’t take long to find videos of springs being manufactured. The process is almost hypnotic as a series of carefully choreographed motions bend, twist, and form wire into tension, torsion, and compression springs. The equipment used to form these essential metal parts, which are integrated into everything from beds and doors to cars and home appliances, requires significant investment. Hence, when a spring former shows signs of aging, retrofitting to a more modern CNC-controlled system is one potential option.

While retrofitting sounds attractive, allowing the bulk of the machine to be reused, it is difficult to predict all of the possible challenges that will arise. Furthermore, the retrofitted version of the equipment needs to offer additional advantages, such as flexibility, speed enhancements, and an improved user interface. With around 60 spring formers spread across three manufacturing sites, one recent Delta customer faced precisely this dilemma. However, after close support from Delta’s Field Application Engineer Enric Tamarit and his team, together with a trusted system integrator with mechanical engineering expertise, the customer agreed to trial the retrofitting approach.

At its core, the new design used the AX-864E, a CODESYS-based motion controller that is ideal for such complex control applications. The compact, fan-less design, built around an Intel x86 CPU, ensured robust mounting coupled with support for EtherCAT to control the selected drives. The unit also features an HDMI display port, gigabit LAN, four USB interfaces, and a connector for RS-485/422 and a differential input motor encoder. Eight GPIOs provide NPN (sink) or PNP (source) control or input signals dependent on the model chosen. A watchdog timer, configurable through the BIOS, ensures the system automatically resets in the event of abnormal operation. Additionally, a range of security features, including BIOS passwords and Delta’s PAC Tool for restricting writes to the integrated solid-state drive, are also included. Thanks to its support for CODESYS, an industry-standard IEC 61131-3 PLC language, the control system software was rapidly iterated to optimize the implementation.

The wire forming was realized with ECMA Series servo motors. Their state-of-the-art design provides a high torque-to-size ratio, low flux loss, and delivers low cogging suited to the smooth motion control required for spring manufacture. They could also be adapted to different spring-forming equipment needs thanks to a range of shaft options and encoders. Coupled with ASDA-A2 Series servo drives, connected via high-speed EtherCAT, simultaneous control of the servo motors was ensured. The characteristics needed for the retrofitted design were easily achieved thanks to the available high precision control, with a 1 kHz frequency response and 1 ms settling times, and superlative vibration suppression. Programmable positioning modes (Pr Mode) also allow up to 64 internal position settings, supporting continuous motion control.

An essential aspect of the retrofit was an improved user interface, allowing operators to configure the desired spring from a choice of recipes. With a 7-inch color TFT display, the DOP-H07 Series provided the flexibility needed by machine operators. This IP55 rated handheld device weighs just 750 g and includes an emergency stop button together with a hook for convenient storage when no longer in use. Connected to the AX-864E via a TCP Modbus, the handheld display allows simultaneous configuration of the spring former while overseeing the actions executed by the servos. Delta’s DOPSoft configuration software enables visually appealing, clear, and easy-to-use interfaces in multiple languages, ensuring simplicity for users. Simulation of the production process was also implemented, saving time and resources before committing to manufacturing.

The retrofitted electronic CAM spring former provides a more streamlined operating experience. Switching between the manufacture of different spring types is simplified, thanks to the user-friendly, recipe-style selection offered by the human-machine interface (HMI). Furthermore, new recipes can be easily developed by extending and modifying existing designs as and when required. In operation, the upgraded solution proved to be significantly more efficient. Tooling changes to manufacture a different spring previously required a day of effort. This has been reduced to half a day with the new approach. Furthermore, productivity has been improved by 50% in most cases, while the most straightforward spring designs can now be manufactured at double the previous rate.

Although the initial retrofit has taken around a year of close cooperation and work to complete, the results have been so impressive that the customer has decided to continue upgrading further spring formers. Because a CODESYS-capable motion controller was chosen, coupled with Delta’s easy-to-integrate HMI, servo drives, and servos, this approach will continue to be a cost-effective and reliable alternative to machine replacement.

About Delta

Delta, founded in 1971, is a global leader in switching power supplies and thermal management products with a thriving portfolio of smart energy-saving systems and solutions in the fields of industrial automation, building automation, telecom power, data centre infrastructure, EV charging, renewable energy, energy storage and display, to nurture the development of smart manufacturing and sustainable cities. As a world-class corporate citizen guided by its mission statement, “To provide innovative, clean and energy-efficient solutions for a better tomorrow,” Delta leverages its core competence in high-efficiency power electronics and its ESG-embedded business model to address key environmental issues, such as climate change. Delta serves customers through its sales offices, R&D centres and manufacturing facilities spread over close to 200 locations across 5 continents.

Throughout its history, Delta has received various global awards and recognition for its business achievements, innovative technologies and dedication to ESG. Since 2011, Delta has been listed on the DJSI World Index of Dow Jones Sustainability™ Indices for 10 consecutive years. In 2020, Delta was also recognized by CDP with two “A” leadership level ratings for its substantial contribution to climate change and water security issues and named Supplier Engagement Leader for its continuous development of a sustainable value chain

For detailed information about Delta, please visit: www.delta-emea.com