Super User

Powder River’s ramp up in drilling activities could signify the end of a year-long downward trend

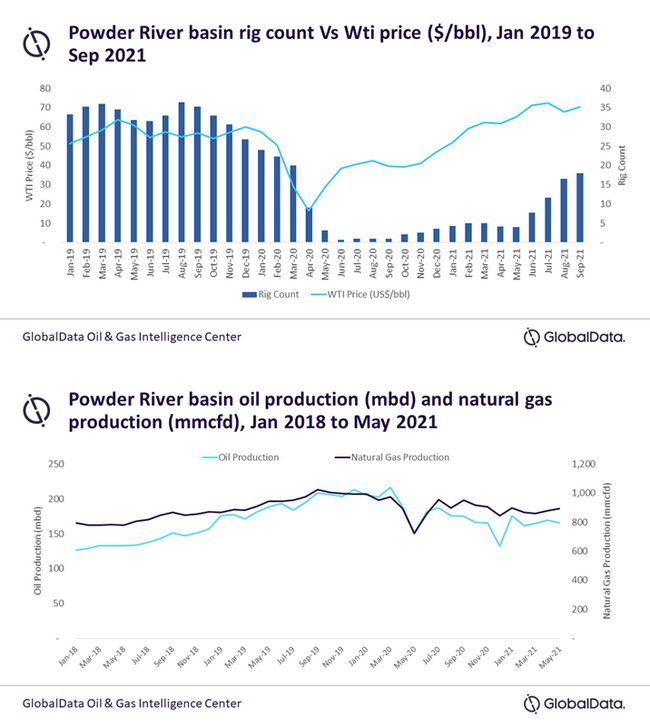

Rig count in the Powder River basin, situated in Wyoming and Montana, has increased almost four-fold from four in April 2021 to 17 in August 2021, according to GlobalData. The leading data and analytics company notes, considering the recent sustained upswing in US crude prices, production of both crude oil and natural gas in the basin is expected to grow by a respective 28% and 13% by December 2022*.

Svetlana Doh, Oil & Gas Analyst at GlobalData, comments: “Unlike other basins in the area, Powder River’s production nearly rebounded to pre-pandemic levels only four months after the onset of the pandemic. Production then kept a downward trend, at an average of -1% a month, but June 2021 saw an uptick in the number of rigs. This could signify a mitigation or even reversal of the trend.”

According to GlobalData’s latest report, ‘Powder River Basin Shale in the US, 2021 – Oil and Gas Shale Market Analysis and Outlook to 2025’, production in the Powder River basin somewhat recovered in June 2020 to 182 mbd of crude oil and 957 mmcfd of natural gas. However, levels stayed below this throughout H1 2021.

Doh continued: “Drilling activity in the region was very slow. Even when WTI price rose to $52 per bbl in January 2021, rig count was still only around four - 83% less than the number of rigs observed in February 2020 before the COVID-19 pandemic hit the US.”

The Powder River basin accounts for less than 5% of the country’s overall crude oil production in the country.

Doh adds: “Most players in the region have acreages elsewhere. For example, Occidental Petroleum, which holds the highest leaseholds of 400,000 net acres in Powder River, also owns significant positions across the Denver-Julesburg and Permian basins. The slow growth of drilling activities in Powder River could be because operators instead focused on high-return assets such as the Permian basin.

“Once oil price stabilized to over $70 per bbl in June 2021, there was a rapid boost in the number of rigs, with an average 50% increase in rig count each month - until August, when the total rig count reached 17 for the whole basin.”

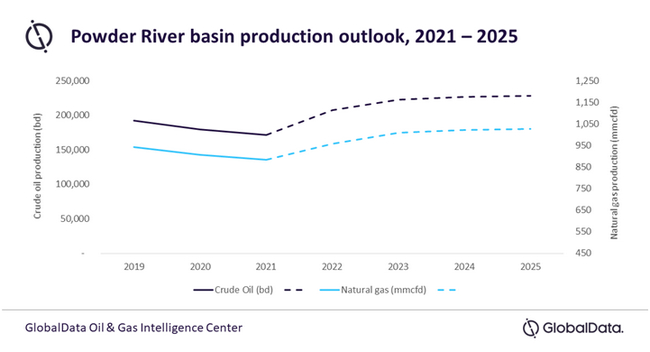

Looking forward, production of both crude oil and natural gas in Powder River is projected to see an upward trend to 2025. Indeed, natural gas production in the basin is expected to grow by 4% during 2021-25 to reach 1,026 mmcfd in 2025. On the other hand, crude oil production is expected to see steeper growth, at a compound annual growth rate (CAGR) of 7%.

Doh commented: “Both crude oil and natural gas are expected to exceed pre-pandemic production levels by 2022.”

* Compared to August 2021 levels

- Quotes provided by Svetlana Doh, Oil & Gas Analyst at GlobalData

- Data taken from GlobalData’s report: Permian Basin in the US, 2021 – Oil and Gas Shale Market Analysis and Outlook to 2025

- The report provides a comprehensive review of the DJ Basin shale play, comprising the effects of COVID -19 outbreak on operations in the Basin. The report also forecasts the future trend of oil and gas production supported by investment plans by major operators in the Basin.

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

PTC delivers ‘efficiency’ boost to manufacturers with new Digital Performance Management solution

One of the world’s leading authorities on Industrial Internet of Things (IIoT) platforms has launched a first-of-its-kind offering that will help manufacturers gain visibility of current performance, analyse production bottlenecks and validate investments.

PTC, which works with hundreds of companies and research centres in the UK, is bringing the new ThingWorx® Digital Performance Management Solution (DPM) solution to market, a self-monitoring, self-measuring tool for closed-loop problem solving.

DPM delivers one universal view of performance, communicated in an understandable business metric - hours.

This metric is easily understood across front line workers, managers, and executives, and provides a foundation for an enterprise-scale solution. It also supports investment accountability by validating outcomes for transformational investments with real-time production data and easy-to-calculate financial improvements.

“Manufacturers consider digital transformation essential, yet often see only incremental improvements as opposed to large-scale transformational improvements,” said Craig Melrose, EVP of Digital Transformation Solutions at PTC.

“The new ThingWorx DPM Solution enables companies to address the most valuable manufacturing improvements and solve common challenges to drive production efficiency and transformation at scale.”

With DPM, companies can identify the right performance issues to drive efficiency, empower frontline workers to take corrective action, gain visibility of bottlenecks, root causes, and the most critical areas to focus on for improvement.

Users can measure results with performance data to ensure actions produce the desired outcomes and achieve rapid time to value and scale, with initial results in as little as 90 days.

“All our manufacturing clients, regardless of industry, face the constant challenge of identifying and quickly eliminating production bottlenecks,” said Jerry Gootee, Global Advanced Manufacturing Sector Leader with Ernst & Young (EY).

“The market needs a scalable technology solution that can systematically and dynamically identify production constraints, prioritise root causes, recommend and manage corrective actions, and validate outcomes measured as new production hours of capacity.

“The release of our ThingWorx DPM Solution represents a significant milestone in our IIoT business,” said Jim Heppelmann, President and CEO of PTC.

“This software marks the beginning of a new phase in PTC’s IIoT growth strategy as we evolve our positioning of ThingWorx as a suite of powerful enterprise solutions that power significant enterprise efficiency and drive business value.”

For further information, please visit www.ptc.com

About PTC (NASDAQ: PTC)

PTC enables global manufacturers to realise double-digit impact with software solutions that enable them to accelerate product and service innovation, improve operational efficiency, and increase workforce productivity.

In combination with an extensive partner network, PTC provides customers flexibility in how its technology can be deployed to drive digital transformation – on premises, in the cloud, or via its pure SaaS platform. At PTC, we don't just imagine a better world, we enable it.

Baltimore Aircoil Company to Showcase Innovative New Condenser Technology at RETA 2021

Baltimore Aircoil Company (BAC) will showcase innovative commercial and industrial refrigeration solutions at RETA 2021 – The Refrigerating Engineers and Technicians Association National Conference, taking place November 9-11, 2021, at the Schaumburg Convention Center Hotel, Schaumburg, IL, Booth #304. Highlighted in the booth are the Vertex™ Evaporative Condenser, where peak reliability meets easy maintenance, and the TrilliumSeries™ Adiabatic Products which combine the best of evaporative and dry cooling to optimize energy and water savings.

The Hot Point presentation on “Drive for greater Sustainability, Maintainability and Efficiency with New Condenser Technologies” will be delivered by BAC Strategic Accounts Manager Dave Anderson and National Sales Manager Ross Sinclair on Tuesday, November 9th, 10:15-11:15am.

The Hot Point presentation on “Drive for greater Sustainability, Maintainability and Efficiency with New Condenser Technologies” will be delivered by BAC Strategic Accounts Manager Dave Anderson and National Sales Manager Ross Sinclair on Tuesday, November 9th, 10:15-11:15am.

Stop by the booth to learn about how the Vertex Evaporative Condenser offers maximum uptime with easy and safe accessibility. It also has the lowest total cost of ownership with the lowest installation, maintenance, and operating costs. Installation costs are reduced by 30 percent, in part by aligning the upper section to the lower section in less than 15 minutes per cell, due to the industrial-grade rigidity of the unit. Water volume is reduced by up to 30 percent, saving on water and chemical costs.

By combining evaporative and dry cooling, the TrilliumSeries Adiabatic Products can reduce peak and annual energy use by 44% versus traditional air-cooled products or reduce water use by 90% versus traditional evaporative products. Users also can save on refrigerant charge with coil volumes reduced up to 90% compared to traditional equipment.. CO2, ammonia, and fluid cooler models are available.

BAC offers a wide selection of reliable, easy-to-install and maintain industrial refrigeration products that provide a constant cold temperature with the lowest refrigerant charge and the highest operational efficiency.

For more information, visit www.BaltimoreAircoil.com.

With over 80 years of industry-leading innovation and experience, BAC creates cutting-edge cooling equipment for the HVAC, Industrial, and Refrigeration marketplaces. We solve customers’ unique needs with our expertise and wide range of high-performance systems. BAC leverages the power of evaporative cooling by optimizing the balance of water and energy, but the true BAC difference lies in our absolute commitment to creating sustainable solutions and delivering value to our customers. For more information about Baltimore Aircoil Company, visit www.BaltimoreAircoil.com.

Elkem announces expansion to support demand growth for specialty silicones in EMEA and the Americas

Elkem, a global leader in silicon-based advanced materials, has just announced a strategic investment plan to unlock new specialty silicones supply for customers in Europe, the Middle East and Africa (EMEA) and the Americas. The company will invest around €36 million (NOK 350 million) to upgrade and debottleneck its silicone upstream plant in Roussillon, France.

The board of directors has approved a 20,000 metric tons capacity expansion, bringing the effective silicone intermediates capacity from Elkem’s upstream plant in Roussillon, France to 100,000 metric tons per annum, while delivering productivity, cost, sustainability and climate protection improvements.

“At a time when silicones and their raw materials are in shortage, the expansion is cornerstone to meeting the future needs of our specialty silicones customers in EMEA and the Americas, where the market is expected to grow by around 6% per year between 2020 and 2025,” said Frédéric Jacquin, Senior Vice President in charge of Elkem’s Silicones Division. “This investment complements the ongoing capacity expansion at our Xinghuo site in China, which primarily serves growth in the Asia-Pacific region and further strengthens our cost position as well as environmental performance.”

Specialty silicones bring unique properties and performances to a wide panel of cutting-edge and sustainability-aligned markets – from electric and hybrid vehicles, to semi-conductors, decarbonized energies, 3D printing, healthcare & medical devices, aerospace, defense, or sustainable buildings.

The investment plan includes installing new equipment and major technology upgrades in key parts of the plant to improve Elkem Roussillon’s cost position and environmental performance, through higher materials efficiency, more energy efficient processes, reduced waste, and state-of-the-art water effluents treatment. It is the largest organic investment project in Elkem’s European silicones franchise in a decade. It is anticipated to come online during the third quarter of 2023.

The decision confirms the strategic importance of the Rhône Valley for Elkem’s silicones division, after the company announced an agreement to acquire a third manufacturing site in the area, and the opening of a new global research & innovation center over the past few months.

It also highlights Elkem’s commitment to the Roussillon chemical platform, which is undergoing landmark transformations to protect its competitiveness and decarbonize its operations, thanks to dynamic partnerships between industrial and local stakeholders – including Elkem.

About Elkem Silicones

Elkem Silicones has more than 4,200 employees dedicated to delivering your potential by providing you innovative silicone solutions with a personal touch. Elkem Silicones, a division of Elkem, is a global leader in fully integrated silicone manufacturing, operating 13 multi-functional manufacturing sites and 13 Research & Innovation centers around the globe. Elkem Silicones offers a full range of silicone technologies for diverse specialty markets including aerospace, automotive, construction, consumer goods, energy, healthcare, paper, personal care and textiles. Elkem Silicones is committed to create new, innovative and green solutions and business models that promote a sustainable future. To learn more, please visit Elkem Silicones Website

About Elkem

Elkem is one of the world's leading providers of advanced material solutions shaping a better and more sustainable future. The company develops silicones, silicon products and carbon solutions by combining natural raw materials, renewable energy and human ingenuity. Elkem helps its customers create and improve essential innovations like electric mobility, digital communications, health and personal care as well as smarter and more sustainable cities. With a strong track record since 1904, its global team of more than 6,800 people has a joint commitment to stakeholders: Delivering your potential. In 2020, Elkem was rated among the world's top 5% on climate and achieved an operating income of NOK 24.7 billion. Elkem is listed on the Oslo Stock Exchange (ticker: ELK). www.elkem.com

Caldwell Provides Beam for Balancing Rolls

The Caldwell Group has provided a 1,500-lb. capacity roll lifting beam and leveling system for a company that manufactures various types of hygienic wipes. A major advantage is that one operator can now complete the application instead of two.

These substrate rolls must be lifted into place during an important phase of the production process.The beam, which is 86 in. between the j-style hooks and 95.75 in. from end-to-end, is designed for unbalanced loads. In the end user’s application, it is common for a roll to be slightly off-center and the operator would previously have to handle the load or below-the-hook equipment to straighten it.

These substrate rolls must be lifted into place during an important phase of the production process.The beam, which is 86 in. between the j-style hooks and 95.75 in. from end-to-end, is designed for unbalanced loads. In the end user’s application, it is common for a roll to be slightly off-center and the operator would previously have to handle the load or below-the-hook equipment to straighten it.

These substrate rolls must be lifted into place during an important phase of the production process. The method employed by this end user is unique, not because of its utilization of the beam, but in its incorporation of Caldwell’s load leveler product. The concept, which balances the roll before a worker performs the next operation, is operated by two pendant push-buttons.

Caldwell was initially given the nature of the material handling problem, in addition to the weight, width, height of rolls, and distance between the cradle support. Based on this, it was decided that a combination roll lifting beam and leveler would best suit the user’s requirements. The attachment works beneath the hook of Harrington Hoists’ equipment, to which it is attached by a hook and latch system. The lifter’s bottom hooks are not designed for side-loading, but they can pivot laterally. These j-hooks extend approx. 50 in. in length and are designed to handle a specific mandrel diameter.

Darrin Noe, director of sales at Caldwell, said: “A red / green indicator light notifies the operator that the leveler has engaged and which direction the bail is adjusting to accommodate for the load’s center of gravity location. The leveler can be used to adjust the lifter bail as needed to find the center of gravity. Once the leveler indicates a level lift, the operator can continue to move, rotate, and position the load as needed.”

Caldwell’s leveler, originally used strictly for the Posi-Turner product, is now used in multiple applications where it is beneficial to have a control system that senses when a load is out of level and automatically activates the leveling adjustment on the lifter to level the load. Besides added speed and efficiency, the leveling option brings added safety to many types of lifting requirements by allowing the operator to stand a safe distance from the suspended load.”

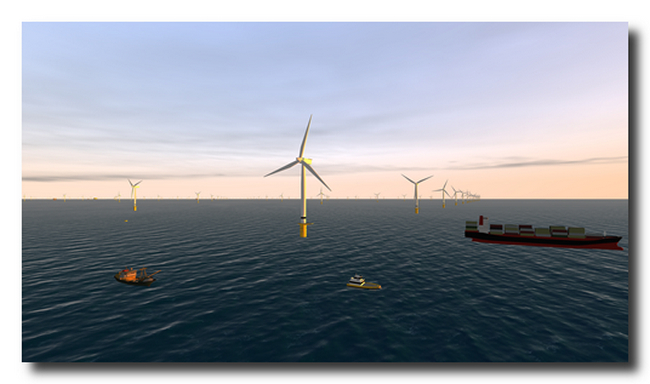

RWE awards RINA with contract for Sofia Offshore Wind Farm in the North Sea

RINA has been awarded a contract by RWE for the Sofia Offshore Wind Farm, to provide Cable Verification Services & OCP (Offshore Converter Platform) construction site quality services. The full scope of work for the Sofia project will be managed from RINA’s Sunderland office and is expected to bring extensive opportunities to the UK supply base.

The 1.4 GW Sofia Offshore Wind Farm, situated in the central North Sea area known as Dogger Bank, will be one of the world’s largest offshore wind farms, undertaken by one of the world’s leading renewable energy companies RWE. RINA will be providing expert third party surveillance to support the supply of quality assurance services required to verify the cable design, the manufacturing cycle by inspection, the project specific type test and final acceptance testing (FAT) along with reviewing cable handling and load out procedures.

The project includes a 220 km 320kV high voltage DC offshore cables, running from the landfall area to the OCP as well as a shorter 7km onshore cable to connect from the landfall area to the onshore converter station. The reliability of these cables is crucial to the project. RINA has extensive industry experience in the cables consultancy and inspection field, having worked with RWE on the Triton Knoll project and having supported numerous wind farm operators, cable industry R&D projects, and cable manufacturers with verification, design consultancy and testing services, including forensic investigations.

Sofia’s Transmission System Senior Package Manager, Mark Carter of RWE, said, “We selected RINA because of its local expertise and pioneering work in supporting improved subsea cable. We have previously employed RINA’s cable expert team for cable consultancy on the Triton Knoll project.”

Steve Cullen, Head of Project Procurement Solutions for Northern Europe at RINA, said, “RINA is delighted to have been selected by RWE to provide a broad range of services to such a prestigious project, which showcases the breadth and depth of RINA’s capabilities. The project committed to bringing extensive opportunities to the UK supply base, and this has been realised with our work award. Our work includes cables consultancy verification, factory inspections, along with site QA/QC services, and a digital offering with the Kiber smart helmet system. Supporting the supply of enough green power to meet the needs of so many UK households is an exciting prospect.”

RINA provides a wide range of services across the Energy, Marine, Certification, Transport & Infrastructure and Industry sectors. With net revenues in 2020 of 495 million Euros, over 4,000 employees and 200 offices in 70 countries worldwide, RINA is a member of key international organizations and an important contributor to the development of new legislative standards. www.rina.org

Filtermist introduces new five-year warranty for all its oil mist collectors

Filtermist International Limited is looking to offset supply chain uncertainty by giving customers additional peace of mind with its oil mist collectors.

The Telford-based company has introduced a new five-year warranty that is totally free of charge, with the package covering key non-consumable components, including the motor.

The new extended warranty was officially unveiled at the EMO Trade show in Milan and is valid on all units purchased after October 1st 2021.

Filtermist International CEO James Stansfield commented: “We have manufactured our compact, centrifugal oil mist filters for more than 50 years and, in that time, we have perfected our manufacturing processes.

“If our units are properly serviced and maintained there is no reason why they cannot last for a substantial number of years – for example, we have Filtermists operational in the field that are more than 30 years-old! This is a really important factor in why we are so successful globally, especially given the current conversations around sustainability and the environment.

All Filtermist oil mist collectors now come with a free five-year warranty

All Filtermist oil mist collectors now come with a free five-year warranty

“Our oil mist filters have been developed and improved since 1969 to become the globally recognised products that they are today. This has been achieved through the guidance of our skilled and experienced team, many of whom have been with us for more than 20 years.

“We are putting our money where our mouth is by offering a free five-year warranty to all of our customers as we know our units are designed to keep working for the long haul.”

Filtermist’s ethos is to protect people by ensuring cleaner, safer, more productive workshops.

Established in the UK in 1969, the company manufactures a range of compact, quiet and efficient oil mist collectors which are trusted by world leading manufacturers to effectively remove oil and coolant mist, fume and steam from workshop air.

All manufacturing is accredited to ISO9001:2015 and ISO14001:2015, with its oil mist collectors CE marked. The motors used are CE and CSA/UL certified.

“As an ISO accredited company, we follow documented procedures to ensure all of our products are manufactured to the highest standards,” continued James.

“Every single Filtermist unit undertakes rigorous Quality Assurance checks during the assembly process to ensure it is in perfect condition and ready for dispatch. Our dedicated Quality Assurance Manager is constantly monitoring our production - this all helps us to check standards are continuously maintained.”

The five-year warranty must be activated via Filtermist’s global website: www.filtermist.com – where full Terms and Conditions can also be downloaded.

Filtermist’s ethos is to protect people by ensuring cleaner, safer, more productive workshops.

Established in the UK in 1969, Filtermist manufactures a range of compact, quiet and efficient oil mist collectors which are trusted by world leading manufacturers to effectively remove oil and coolant mist, fume and steam from workshop air.

Oil mist is created by machine tools spraying high pressure oils and coolants onto metal components to keep them cool during manufacturing operations including milling, drilling, turning and grinding. Exposure to airborne oil mist particles can cause a number of occupational diseases including skin conditions, respiratory problems and even cancer. It can also pose a fire and slip risk, and can damage sensitive electrical equipment if left in the atmosphere.

Filtermist oil mist collectors use centrifugal force to separate oil mist particles from the air – clean oil drains back to the machine for re-use or collection, and clean air is returned to the workshop.

Filtermist offers local support in more than 60 countries worldwide through a network of approved distributors and Absolent Air Care Group sales operations in Europe, UK and Ireland, APAC and EMEA.

Visit www.filtermist.com for more details

ADC Energy identifies upgrade to reduce rig emissions by almost 5,000 tonnes per year

ADC Energy, a specialist provider of integrated rig inspections, has completed a project with a major rig owner which identified that an upgrade to Dynamically Positioned (DP) rigs power systems can reduce carbon emissions by almost 5,000 tonnes per year.

- Upgrade to power management systems can deliver fuel savings of $620,000 per year and reduce engine running hours by 20%

Typical DP drilling units operate in HV split-bus, or open-bus, configuration with the power management switchboards operating in silos, using an independent island philosophy. However, this mode from a redundancy perspective requires more engines to be online than may be required for the total operational loads, creating a potentially greater emission output.

Typical DP drilling units operate in HV split-bus, or open-bus, configuration with the power management switchboards operating in silos, using an independent island philosophy. However, this mode from a redundancy perspective requires more engines to be online than may be required for the total operational loads, creating a potentially greater emission output.

By upgrading existing rig power management systems to allow for closed-bus mode, which ties the switchboards together, this allows the power plant to run with less engines and optimal loads, therefore delivering a more efficient power source.

ADC’s recent project highlighted that DP rigs operating in closed-bus configuration can successfully reduce annual CO2 emissions by 4,800 tonnes per year – delivering a fuel saving of $620,000 per year - while reducing engine running hours by 20%.

With the number of engines required to be online at one time lowered, the enhancement also provides operators with greater maintenance schedule flexibility, which can create potential maintenance savings of up to $150,000 per annum.

Austin Hay, Director at ADC Energy said: “There is significant pressure on the oil and gas industry to decarbonise current assets and the findings of our recent project effectively highlight how upgrades to existing systems can actively reduce the carbon footprint of operations.

“We recognise this enhancement requires considerable investment from rig owners and operators but as the sector continues its efforts to deliver more sustainable operations, this capital is essential to support net zero goals. Existing rigs and vessel are critical components in the energy transition, and we are already working with a number of clients to advise them through this process to ensure that assets continue to operate safely and efficiently with minimal environmental impact.”

ADC Energy currently employs 76 specialist personnel across its strategic bases located in Aberdeen, UK; Houston, Texas; Jakarta, Indonesia and Kuala Lumpur, Malaysia.

Top tips for avoiding food contamination

All parties involved in the food processing chain have a responsibility to ensure that food reaching consumers does not become contaminated. While manufacturers already take steps to prevent the main causes of contamination, thermal fluid could be a hidden contaminator. Here Clive Jones, managing director of heat transfer fluid specialist Global Heat Transfer, explains how thermal fluid choice and maintenance can prevent cross-contamination being a problem.

Cross contamination can occur at any stage of the food production chain, so food processing facilities have processes and procedures in place to remove any risk of product mishandling. These are built on an understanding of how cross-contamination occurs — food handling is one of the main causes of cross contamination. For example, a worker may handle raw meat without gloves and then touch other food products without washing their hands. Food residue left on equipment can also provide opportunities for contamination, as well as the harmful bacteria often found on raw products, for example if blood from raw meat drips onto uncovered products.

Food processing applications, such as brewing, baking or freezing, often require indirect heating or cooling generated from a heat exchanger and transported using thermal fluid. The fluid may absorb excess heat energy and take it away from the product, or transfer heat energy to the product.

Thermal fluid contamination

Heat transfer fluid is transported around a facility in pipes, meaning that it is unlikely to come into direct contact with a product. However, if any issues occur in the system that leads to leaks or breakages, the fluid could contaminate the product. If food and beverage manufacturers use a standard heat transfer fluid and there is incidental contact with the product, the whole batch must be scrapped to avoid any contaminated food reaching consumers, damaging their health and the company’s reputation.

Food grade fluid

In any environment where thermal fluid may come into contact with a consumable product, manufacturers should consider using a food grade thermal fluid. Food grade thermal fluids must carry a HT-1 certificate, granted by the US Food and Drug Administration (FDA) or the NSF International, to be approved for use in food processing. They are typically colourless, non-toxic, non-irritating and non-fouling, so if they do come into contact with food and therefore consumers, they lead to lower recall rates.

Food and beverage processing reactions take place at very specific temperatures, so manufacturers require a fluid with precise temperature control. Global Heat Transfer's Globaltherm™ FG, for example, can operate and maintain temperatures ranging from -20 to 326 degrees Celsius. It has outstanding thermal oxidation stability and a lower viscosity than standard mineral oils, so it is easier to pump around the system. This thermal fluid has HT-1 certification and is accredited for use in Kosher and Halal applications.

Fluid maintenance

While incidental contact between the HT-1 certified fluid and the food product will not pose a risk to consumers, manufacturers should still do everything possible to prevent any maintenance issues that could lead to the fluid impacting production.

Thermal fluids degrade over time, especially when operating at high temperatures for long periods of time. Fluid degradation can cause a build-up of carbon and other by-products in pipes, reducing heat transfer efficiency and causing products to be cooked inconsistently. If the fluid is properly maintained, manufacturers can slow down the degradation process and reduce the risk of unplanned downtime.

To achieve this, manufacturers can implement a preventative maintenance programme. This should include regular visual walk-round checks, as well as quarterly fluid sampling to determine the condition of the fluid. Engineers can samples taken from a live, hot and circulating system to a laboratory for fluid analysis, using the results to plan preventative actions to maintain or expand fluid lifespan.

The food processing sector must uphold the highest standards to ensure food safety and prevent cross-contaminated products from reaching consumers. By selecting a food grade thermal fluid and carrying out regular fluid analysis and maintenance checks, plant managers can ensure that their products are manufactured safely and efficiently.

For more advice on choosing and maintaining thermal fluids, visit www.globalhtf.com.

About Global Heat Transfer: Global Heat Transfer is a thermal fluid specialist, providing heat transfer engineering assistance and thermal fluid supplies. Services offered include sampling and analysis, 24 hour delivery of premium quality thermal fluids, system drain down / cleaning / waste management, planned maintenance programs and a broad portfolio of affiliated system design and installation services. It is part of the Global Group of companies.

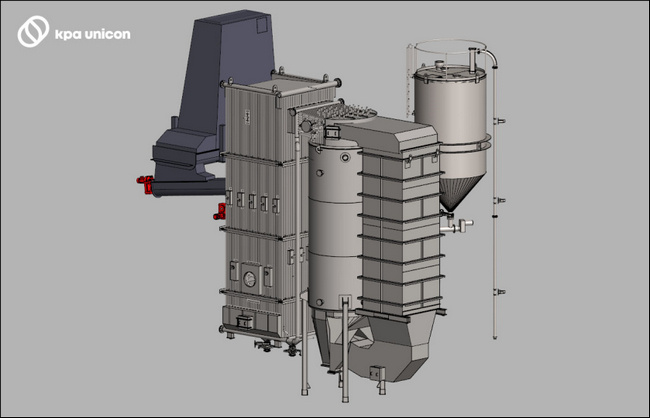

KPA UNICON AND KEITELE ENERGY HAVE AGREED ON MODERNIZATION OF THE KEITELE PRODUCTION FACILITY

KPA Unicon and Keitele Energy have agreed to modernize the existing boiler plant at the Keitele Timber sawmill, which is located in Keitele, Northern Savonia, Finland. This is a large-scale modernization project, which will invest in cleaner energy production and modernize the plant's automation and other systems.

“The solution delivered to Keitele consists of intelligent and environmentally friendly clean energy solutions. The investment helps our partner to operate efficiently, effectively and responsibly. For KPA Unicon, this is the ninth plant delivery to Keitele Group”, says Jukka-Pekka Kovanen, Managing Director of KPA Unicon.

“With the investment, we will enable us to increase the production capacity of the Keitele sawmill in 2022. We constantly want to invest in efficient and modern technology that enables energy-efficient operations and reduces the environmental impact of our operations”, says Ilkka Kylävainio, Managing Director, Keitele Energy Oy.

The new energy system is based on Unicon Renefluid fluidized bed boiler technology, which combines the highest efficiency on the market, low operating costs, a very wide range of fuels and fast load change capability. It replaces the 7.5 MW fluidized bed boiler installed in 1994. As part of the energy system, KPA Unicon will supply the 15 MW boiler, auxiliary equipment and a Unicon Bag filter flue gas cleaning system. The Unicon Bag filter is an effective way to filter out hazardous particles from the breathing air. In addition, KPA Unicon is responsible for the recycling and modification of the existing equipment and modernization of the control and automation system as part of the overall delivery.

“The system will be connected to KPA Unicon’s comprehensive PlantSys digital platform, which allows remote control of the energy production. The platform provides digitalization of maintenance reporting and the automatic data collection, which improve the plant's efficiency and usability”, says Kovanen.

Delivery and implementation in 2022

Keitele mainly produces pine and spruce sawn timber, with exports accounting for 94% of production in 2020. The heat generated by the new energy system will be used to dry the timber produced by the sawmill. As a fuel the plant will utilize the by-products of the sawmill, such as sawdust and cutter chips, as well as bark, wood chips and milled peat.

The modernization project will be implemented during 2022.

KPA Unicon

KPA Unicon is a Finnish company that has been an advocate of clean, renewable energy since 1990. KPA Unicon creates and implements new clean energy solutions around the world. It will also reform existing production systems with renewable energy technologies and equip energy producers with innovative digital tools. The company aims to lead the discussion in favour of clean energy and to provide added value to its partners. The company is head office in Pieksämäki, Finland and employs 210 energy professionals in eight different countries.

KPA Unicon is part of Partnera business group that creates shareholder value and a more sustainable future through its operations. Partnera Corporation is listed on Nasdaq First North Growth Market Finland.

Keitele Energy Oy

Keitele Energy is a part of Keitele Group, which is a family run business founded in 1981. The company has grown into one of Finland’s largest mechanical wood processing companies. Keitele log procurement areas are located close to the production units in Keitele in Eastern Finland, Alajärvi in Ostrobothnia, and Kemijärvi in Lapland.

Keitele Group's core operations are responsible wood procurement from Finnish forest owners as well as wood sawing and further processing. Keitele Group consists of three independent companies: the parent company Keitele Forest Oy, which is also responsible for wood procurement, the sawmill company Keitele Timber Oy and the wood products manufacturer Keitele Wood Products Oy.