Super User

Nemport in Turkey orders fleet of Konecranes Noell RTGs to handle growing demand

NEMPORT LÌMAN ÌŞLETMELERI (Nemport) in Izmir, Turkey, has ordered 10 Konecranes Noell Rubber-Tired Gantry (RTG) cranes to handle growing container traffic. The order was booked in July and the cranes will be delivered in October 2022.

Nemport said: “Nemport is experiencing growing container traffic. We are building a new container yard and a new berth for mega container vessels, and the new RTGs will be fundamental to its productivity. As usual, Konecranes was very proactive in providing the solution, carefully evaluated by Nemport. We are confident that the Konecranes Noell RTGs will give us the performance and reliability we need. From the beginning, we have been operating Konecranes RTGs and Konecranes Gottwald Mobile Harbor Cranes with great success.”

Nemport terminal

Nemport terminal

Adel Issa, Sales Manager Region EMEA, Konecranes Port Cranes, said: “Konecranes is committed to meeting Nemport’s needs in every way. We are a good fit with Nemport’s entrepreneurial spirit. The Konecranes Noell RTGs on order will help Nemport to expertly serve its customers as the growing trade gateway of the Aegean region.”

A strong focus on customers and commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2020, Group sales totaled EUR 3.2 billion. The Group has around 16,500 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

Metso Outotec to deliver grinding mills and thickeners to a nickel plant in Indonesia

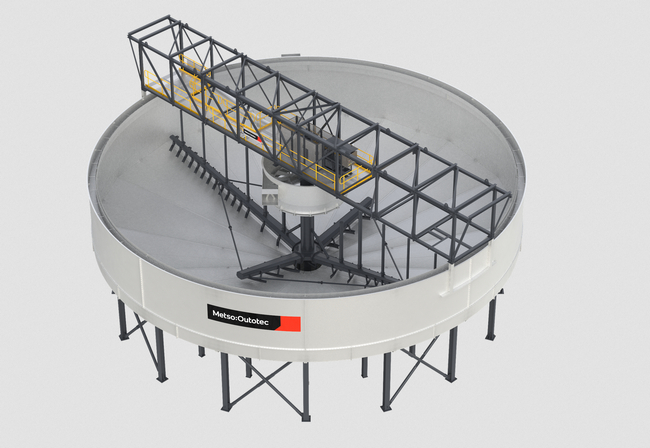

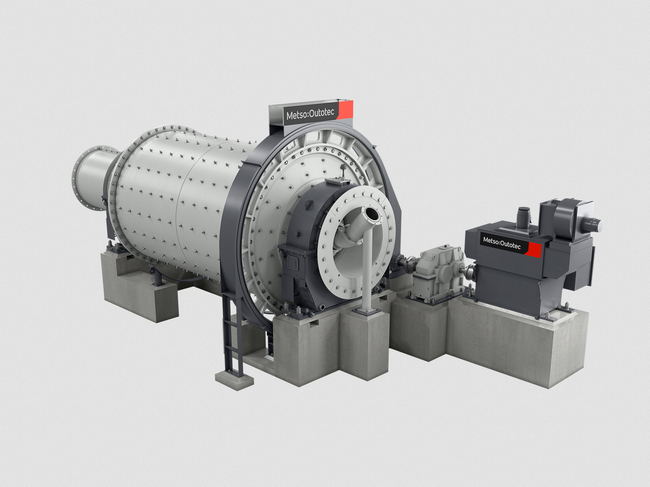

Metso Outotec has been awarded a contract for the delivery of several horizontal grinding mills and thickeners to a greenfield nickel project in Indonesia.The value of the order is approximately EUR 24 million, and it has been booked in Minerals’ Q3/2021 orders received.

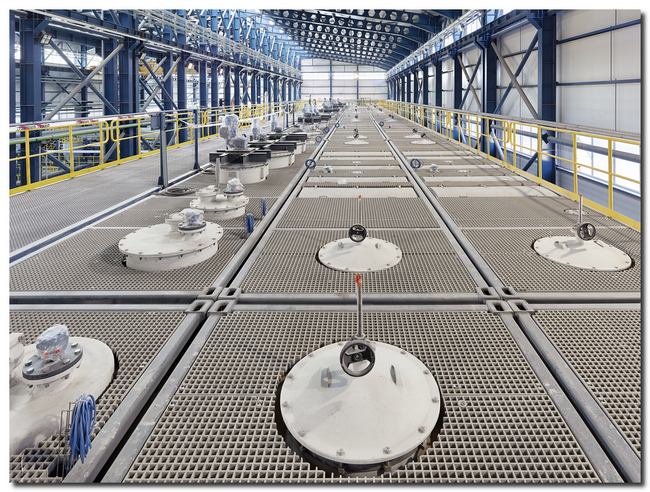

Metso Outotec’s scope of delivery includes five grinding mills with a total installed power of 10.6MW, as well as 13 HCT high-compression thickeners, which are part of the company’s Planet Positive offering.

Metso Outotec HCT thickner

Metso Outotec HCT thickner

“We are pleased to have been chosen as the supplier of this key equipment for this major project. A diligent verification process with the customer confirmed that Metso Outotec grinding mills and thickeners will provide significant added value to their process. The customer selected our grinding mills based on robust, proven technology, and industry leading availability. The HCT thickeners are proven to provide the best washing efficiency, thus reducing the loss of nickel metal in leaching residue,” says Markku Teräsvasara, President, Minerals and Deputy CEO of Metso Outotec.

Discover more about Metso Outotec thickening and clarification solutions here. For more information about our grinding mills, please visit the related product pages on our website.

Metso Outotec Select mill

Metso Outotec Select mill

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

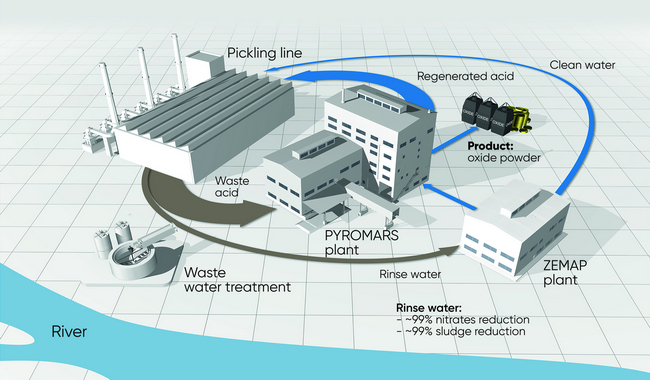

ANDRITZ to supply two new mixed acid recovery systems (Pyromars) to Walsin Lihwa

International technology group ANDRITZ has received an order from Walsin Lihwa, Taiwan, to supply two Pyromars plants with capacities of 4,500 l/h and 6,500 l/h for their wire rod production sites in Yantai, China, and Yenshui, Taiwan.

Start-up of the plants is scheduled for the first quarter of 2023.

ANDRITZ Pyromars plant © ANDRITZ

ANDRITZ Pyromars plant © ANDRITZ

The ANDRITZ scope of supply includes the mechanical and electrical equipment as well as supervision of erection work and commissioning.

The ANDRITZ mixed acid recovery systems will significantly reduce the nitrates in the wastewater and enable nitric and hydrofluoric acids to be recovered, thus saving consumption of fresh acid in Walsin Lihwa’s wire rod pickling plants. In addition, this investment in sustainable operation will strongly reduce the amounts of wastewater and sludge produced.

Walsin Lihwa is a strong business partner of ANDRITZ and is already operating a Pyromars plant and two ZEMAP systems that ANDRITZ has supplied.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.

ANDRITZ METALS

ANDRITZ Metals is – via the Schuler Group – one of the world’s leading suppliers of technologies, plants and digital solutions in metal forming. The product portfolio also includes automation and software solutions, process know-how and service.

In the metals processing segment, the business area offers innovative and market-leading solutions for the production and processing of flat products, for welding systems and furnaces, as well as services for the metals processing industry.

91% of HGV drivers in UK feel undervalued, survey shows

More needs to be done to keep experienced truck drivers behind the wheel and help address the current shortage – with more respect and improved conditions top of the list.

Initial findings from a survey which commenced in August for Pertemps Driving Division, part of the Pertemps Network Group, showed 91 per cent of truckers believe they do not get enough respect for the job they do.

Many qualified and experienced drivers have left or are planning to leave their roles because they are fed up with the way they are treated, often at point of drop-off for customers and the general public.

Samantha Leleu, General Manager at Pertemps Driving Division, which has been offering free LGV training to entice new people into the sector, believes it is only by treating experienced drivers with more respect that the brakes can be put on the skills drain and the economy can begin to get back on the right road.

“There is a known driver shortage, and the noise has mostly been about attracting new talent to the sector – but what about those experienced drivers who have just had enough of difficult working conditions, and disrespect from customers and the public? They deserve better and it is the least we, as employers, can do to try and help as the UK seeks to address a shortage of 100,000 HGV drivers,” said Samantha.

“We have surveyed more than 2,500 drivers in the last couple of months and the initial results show that 91 per cent of existing lorry drivers feel they are treated with disrespect. In addition, 69 per cent do not think working conditions are good – and it is the more experienced truckers more likely to be disillusioned with their roles.

“Some people may point to the fact that pay rates have gone up significantly recently, but that does not compensate for years of being underpaid a decent going rate and treated ‘like a nuisance’ when making deliveries.

“We, the great British public, have to get a handle on this to keep these good people in the sector as everything we touch has been delivered on the back of a lorry, while we get the talent pipeline moving again for those looking to train to be lorry drivers.

“Things need to change and with the spotlight currently firmly on the sector, and people starting to see the importance of our lorry drivers to their everyday lives, we hope both customers and the general public will better consider how they treat these essential workers.”

Pertemps Driving Division has had to temporarily close its free training offer to new applications after more than 10,000 people applied in six weeks. The business is now working its way through the candidates to take forward all those that it can. However, tests are ultimately carried out at a pace set by the DVSA and a lack of test availability means there is lengthy tailback of waiting applicants.

Once qualified, the drivers are found roles with clients across the UK through Warwickshire-based Pertemps Network Group, one of the country’s leading specialist driver recruitment businesses.

Initial top line finds from two questions in survey of more than 2,500 truck drivers in the UK during August and September 2021:

“General public don’t respect the role of truckers enough”

- 91% agree (69% agree strongly)

- Most likely to agree strongly – drivers with the longest experience (over 20 years – 74%), and 75% of those who think it unlikely they’ll still be driving in 3 years’ time

“Working conditions in the industry are good”

- Just 17% agree; 69% disagree (37% disagree strongly)

- Most likely to disagree strongly – 11+ years’ experience (41%), owner drivers (43%) and directly employed (37%) vs 33% of agency drivers, 56% of those unlikely still to be driving in 3 years’ time

Full survey results will be published at a later date.

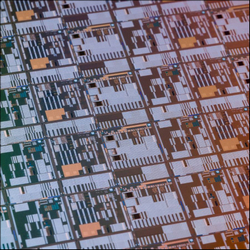

The role of nanomaterials in electronics

The late twentieth to early twenty-first century is known as the silicon age, and the impact of silicon on the electronics industry is almost too large to quantify. But, silicon electronics are close to their physical limits in terms of efficiency and performance. Research initiative the Graphene Flagship is working on the solution — nanomaterials like graphene and graphene related materials (GRMS). In this article, Sanna Arpiainen, deputy division leader for the 2D Experimental Pilot Line (2D-EPL), explains how layered materials will unveil a new generation of electronics, promising new functionalities and applications.

Wonder material graphene is a single carbon atom thick and can therefore be classed as a nanomaterial — a material with at least one external dimension measuring less than 100nm. Despite a small size, nanomaterials promise a whole world of potential for the future of electronics, creating faster, smaller and more powerful devices.

It is thanks to their physical properties that nanomaterials like graphene hold such promise for the electronics industry. Using their unique characteristics, nanomaterials can result in smaller, more lightweight electronics that use fewer resources to build and improve the accuracy of circuit construction down to an atomic level. Nanomaterials have the potential to stretch the boundaries of what we currently think electronics should do or be.

But the properties of each nanomaterial differ, so what about graphene, specifically?

Wafer production is already ongoing in 2D-EPL partner imec’s cleanroom. Credit: imec

Wafer production is already ongoing in 2D-EPL partner imec’s cleanroom. Credit: imec

Hot properties

Graphene is the strongest known material, harder than diamond and lighter than aluminium. Most importantly for electronics applications though, graphene is incredible conductive —13 times more so than copper. It is also mechanically flexible, chemically stable and disperses heat.

Electronics applications include detectors, modulators, imagers, sensors and transceivers — all have which have been investigated by the research institutions and partner companies within the Graphene Flagship.

Graphene can also be used for photonic and optical electronic devices. Graphene absorbs a broad range of optical wavelengths — from ultraviolet to the far infrared — enabling ultra-broadband communications way beyond the capabilities of 5G. Plus, when used in optical devices, graphene transforms almost all the light it receives into electric signals. This characteristic results in devices that consume less power and work more efficiently.

Graphene will also play a role in the rise of wearable, flexible electronics. The nanomaterial’s extreme thinness, strength and elasticity make it ideal for this kind of device.

The Graphene Flagship Flexible Electronics Work Package, a research and innovation group within the flagship project, is currently working on conductive textiles, stretchable electronics for smart patches, and electronics for paper-based, disposable smart products — like smart packaging — all using graphene and other layered materials.

Integrating graphene and related materials into silicon wafers could revolutionise the electronics industry. Credit: imecGraphene on the market

Integrating graphene and related materials into silicon wafers could revolutionise the electronics industry. Credit: imecGraphene on the market

So, electronics using nanomaterials, including graphene, sound great in theory, but when will they reach the market? The Graphene Flagship aims to bring graphene out of academic laboratories and into society within ten years. To this end, it has already developed numerous successful technologies — over 90 products and 15 spin off companies emerging since the Flagship’s inception in 2013, and each year these numbers grow.

However, to reach the market, many electronics applications rely on the wafer scale integration of graphene on a commercial level. In the next five years, products that don’t rely on wafer scale integration, such as flexible sensors and smart packaging, are expected to appear on the market. For those that do, pilot production is expected in 2025 in the earliest. The 2D Experimental Pilot Line (EPL) has been created to speed up this process.

A foundry for the future

At the start of 2021, the European Commission launched the 2D-EPL, a new €20 million collaborative project to pioneer the fabrication of new electronics, photonic devices and sensors that integrate graphene and layered materials. The 2D-EPL is a graphene foundry, or factory, that offers comprehensive prototyping services to companies, research centres and academics, so they can develop and test their innovative technologies based on 2D materials.

The ultimate goal of the 2D-EPL is to industrialize the production of innovative graphene and layered material-based devices that are integrated with traditional semiconductors. In addition to providing the low and medium volume processing services to advance the component production and integration, the 2D-EPL develops automated high-volume tools and tailored process chemicals compatible with semiconductor industry standards. It will be the first graphene foundry in the world to do so. The 2D-EPL will keep Europe at the forefront of technological innovation, while helping to create the next generation of electronics and semiconductors.

Though silicon has shaped the twenty-first century electronics industry — and in fact wider society too — so far, combining it with graphene and other layered or nanomaterials will push the capabilities of electronic devices much further. A lack of infrastructure has made integrating layered materials with silicon on a large scale a challenge. But, thanks to the 2D-EPL this will change, commercialising graphene and layered material-based electronic technologies.

For more information on the role of nanomaterial graphene in electronics or the 2D-EPL, go to www.graphene-flagship.eu.

The Graphene Flagship is research, innovation and collaboration.

Funded by the European Commission, the Graphene Flagship aims to secure a major role for Europe in the ongoing technological revolution, helping to bring graphene innovation out of the lab and into commercial applications. The Graphene Flagship gathers nearly 170 academic and industrial partners from 21 countries, all exploring different aspects of graphene and related materials. Bringing diverse competencies together, the Graphene Flagship facilitates cooperation between its partners, accelerating the timeline for industry acceptance of graphene technologies. The European Commission’s FET Flagships enable research projects on an unprecedented scale. With €1 billion budgets, the Graphene Flagship, Human Brain Project and Quantum Flagship serve as technology accelerators, helping Europe to compete with other global markets in research and innovation.

Keep up with the latest from the Flagship here: https://graphene-flagship.eu/news

Moxa’s New All-in-one Industrial Secure Router for Safeguarding Industrial Applications

Moxa Inc., a leader in industrial communications and networking with a focus on securing industrial networks, has introduced the new EDR-G9010 Series.

These industry-certified all-in-one firewall/NAT/VPN/switch/routers act as a robust first line of defense for industrial networks in diverse applications such as smart manufacturing and critical infrastructure. Moxa’s EDR-G9010 Series industrial secure routers offer 10-port GbE performance and defense-in-depth security capabilities to fulfill the needs of bandwidth-hungry applications that require field-proven reliability and multi-layered security.

With more and more cybersecurity incidents occurring in operational technology (OT) systems, enhancing industrial network security becomes a key priority for business owners and chief security officers. However, in OT environments, network requirements are not just concerned with security, but also focus on keeping operations functioning smoothly.

“With the launch of the new EDR-G9010 Series, Moxa brings a tailor-made network security solution for OT environments”, says Kevin Huang, Product Manager at Moxa Networking. “We recommend our customers to use the EDR-G9010 Series industrial secure routers to segment their networks as a first line of defense and prevent threats from propagating to the rest of the network. Furthermore, users can leverage its advanced OT Deep Packet Inspection (DPI) technology, firewall, NAT, and VPN features to achieve multi-layered security. Last but not least, the 10-port Gigabit performance, faster boot time, and Layer 2/Layer 3 redundancy help ensure the availability of industrial networks. The EDR-G9010 Series combines all these powerful functions into a single compact, rugged, industry-certified industrial secure router. Overall, the EDR-G9010 series will be Moxa’s future proof secure routing platform, with additional capabilities being added over time.”

The EDR-G9010 Series industrial secure routers offer:

Advanced Network Protection with Network Segmentation and Advanced DPI

Within one field site, the EDR-G9010 Series industrial secure routers can help build a security boundary by segmenting OT and IT networks and feature advanced DPI technology to give users more granular control over network traffic by filtering industrial protocols* based on the requirements of the application. Moxa will continuously extend the DPI protocol coverage. Starting with Modbus TCP/UDP and DNP3 Moxa will add specifically power market related protocols in 2022.

When remote connections across multiple sites are needed, the EDR-G9010 Series’ embedded IPsec VPN ensures safe industrial network communication channels when accessing the private network from the public Internet.

Future-proof platform for OT Intrusion Prevention

The superb computing power of the EDR-G9010 platform enables it to run an Intrusion Prevention Module, which will safely block ransomware, malware, viruses and other cybersecurity threats in OT networks. This signature-based scanning technology will move traffic filtering and asset visibility in OT networks to an unprecedented level.

This module is licensed on demand and will be available by mid of 2022.

Better Performance with High Bandwidth and Faster Boot Times

With the number of connected devices constantly growing, the EDR-G9010 Series is capable of achieving high throughput while providing robust security, perfect for bandwidth-hungry applications. Meanwhile, the faster boot time helps reduce system downtime during regular maintenance or in the event of an emergency recovery situation.

More Versatility

The EDR-G9010 Series caters to the needs of different networks, whether it is the need for a firewall, network address translation (NAT), remote VPN communications, switching, or routing. These secure routers are also certified for IEC 61850-3/IEEE 1613, NEMA TS2, ATEX Zone 2, and Class I Division 2. The accessible and versatile all-in-one design makes these devices ideal for securing industrial applications such as in power substations, intelligent transportation systems, oil and gas, and smart manufacturing.

EC-62443 hardened

Secure routers play a pyramidal role in security architecture and need to be security hardened. Hence EDR-G9010 hardware and software has been developed with Moxa’s IEC-62443-4-1 certified process and is ready to meet the IEC-62443-4-2 requirements up to Security Level 2.

EDR-G9010 Series 10-port Gigabit Industrial Secure Router Highlights

• All-in-one firewall/NAT/VPN/switch/router

• 8-port TX GbE and 2-port SFP GbE

• Comprehensive redundancy mechanisms, including Turbo Ring and VRRP

• Wide -40 to 75°C operating temperature (-T model)

• Advanced Deep Packet Inspection (DPI) for Modbus TCP/UDP and DNP3 traffic and 104 and MMS (available in Q1, 2022).

• Certified for IEC 61850-3, NEMA TS2, ATEX Zone 2, Class I Division 2, EN 50121-4, DNV, IEC-62443-4-2 SL 2 (available in Q4 2022).

To enhance network security visibility, the EDR-G9010 Series is also compatible with Moxa’s MXview network management software. With MXview, users can e.g., visualize the achieved security level of IEC-62443 ready Moxa devices, perform regular configurations backups, and have an at-a-glance overview of the network’s performance.

With the launch of the EDR-G9010 Series industrial secure routers, Moxa has expanded its secure network infrastructure portfolio to cover a broader range of industrial applications and introduced more granular control over industrial networks to fulfill its ongoing commitment to protect the connectivity of industrial environments.

For more information about the EDR-G9010 Series, please visit the product page

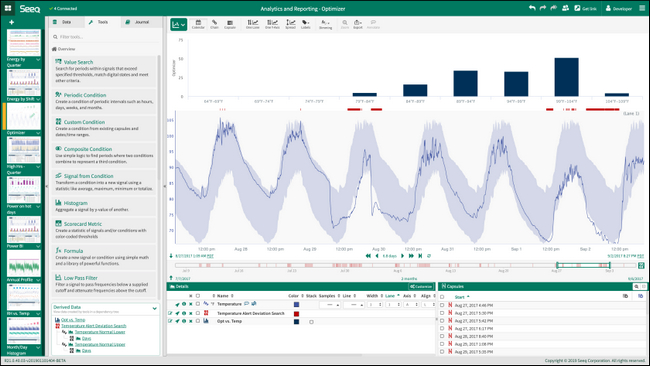

Seeq Expands Machine Learning Support to Democratize Data Science Innovation

New initiative facilitates the integration of machine learning algorithms from open source, third party, and customer data science teams into Seeq applications.

Seeq Corporation, a leader in manufacturing and Industrial Internet of Things (IIoT) advanced analytics software, announces the expansion of its efforts to integrate machine learning algorithms into Seeq applications. These improvements will enable organizations to operationalize their data science investments, and their open source and third-party machine learning algorithms, for easy access by front-line employees.

Seeq customers include companies in the oil & gas, pharmaceutical, chemical, energy, mining, food and beverage, and other process industries. Investors in Seeq, which has raised over $100M to date, include Insight Ventures, Saudi Aramco Energy Ventures, Altira Group, Chevron Technology Ventures, and Cisco Investments.

Seeq’s strategy for enabling machine learning innovation provides end user access to algorithms from a variety of sources, rather than forcing users to rely on a single machine learning vendor or platform. This addresses the diversity and types of algorithms available to organizations, including:

- Open sources algorithms and other public resources. For example, this week Seeq will publish two Seeq Add-ons to GitHub, including algorithms and workflows, for correlation and clustering analytics, which users can modify and improve based on their needs.

- Customer-developed algorithms in Seeq Data Lab—or machine learning operations platforms such as Microsoft Azure Machine Learning, Amazon SageMaker, Anaconda, and others—as part of data science or digital transformation initiatives.

- Third-party algorithms provided by software vendors, partners, and academic institutions. AWS’s Lookout for Equipment, Microsoft Azure AutoML, BKO Services’ Pump Prediction, and Brigham Young University’s open-source offerings are examples of the emerging marketplace for industry and vertical market specific algorithms.

The Seeq initiative also address the critical ‘last mile’ challenge of scaling and deploying algorithms in manufacturing organization by putting data science innovation in the hands of plant employees in easy-to-use applications: Seeq Workbench for advanced analytics, Organizer for publishing insights, and Seeq Data Lab for ad hoc Python scripting.

This is in addition to Seeq support for the foundational elements of success with machine learning. This includes access to all manufacturing data sources—historian, contextual, and manufacturing applications—for data cleansing and modeling, support for employee collaboration and knowledge capture, quick iteration, and performance-based continuous improvement workflows.

“Data science innovation in manufacturing organizations has the potential to deliver a step change in plant sustainability, productivity, and availability metrics,” says Kevin Prouty, VP Industrials, IDC Corporation. “But to land this opportunity, companies must be able to deploy data science innovation to frontline engineers with the expertise, data, and plant context to make decisions on insights provided by these new algorithms.”

Examples of customers using Seeq applications to access and integrate data science innovation include an oil & gas company deploying a deep-learning-based emissions prediction algorithm, a pharmaceutical company using an unsupervised learning algorithm to proactively detect sensor drift in sensitive batch processes, and a chemical company using pattern learning to identify root causes of process instability and extend cycle time.

“Seeq provides a bridge between data science teams and their algorithms to front-line employees in hundreds of plants around the world,” says Brian Parsonnet, CTO at Seeq Corporation. “Deploying algorithms is now as simple as registering them in Seeq, and then defining which employees have access to each algorithm in their Seeq applications.”

Seeq first shipped machine learning features in 2017 in Seeq Workbench, and then in 2020 introduced Seeq Data Lab for Python scripting and access to any machine learning algorithm. This support for multiple audiences—with point-and-click features for process engineers, low code scripting, and a programming environment for data scientists engaged in feature engineering and data reduction efforts—delivers an end-to-end solution for organizations with all levels of analytics sophistication.

Seeq is available worldwide through a global partner network of system integrators, which provides training and resale support for Seeq in over 40 countries, in addition to its direct sales organization in North America and Europe.

To learn more about Seeq visit seeq.com

About Seeq Corporation

Founded in 2013, Seeq publishes software applications for manufacturing organizations to rapidly find and share data insights. Oil & gas, pharmaceutical, specialty chemical, utility, renewable energy and numerous other vertical industries rely on Seeq to improve production outcomes, including yield, margins, quality, and safety. Headquartered in Seattle, Seeq is a privately held virtual company with employees across the United States and sales representation in Asia, Canada, Europe, and South America.

Brenntag forms distribution agreement with biobased solvents experts NXTLEVVEL Biochem

Brenntag, the global market leader in chemicals and ingredients distribution, forms a distribution agreement with NXTLEVVEL Biochem to expand its growing Household, Industrial, & Institution (HI&I) portfolio in providing sustainable biobased solvents in North America.

This current agreement covers a new product line including the below product names and consists of levulinates and levulinate ketals. These products are all biobased solvents offering high performance and improved safety and sustainability:

- NXT SOLV 100

- NXT SOLV 200

- NXT SOLV 300

- NXT SOLV 400

Brenntag forms distribution agreement with biobased solvents experts NXTLEVVEL Biochem. Image: Brenntag

Brenntag forms distribution agreement with biobased solvents experts NXTLEVVEL Biochem. Image: Brenntag

“We are excited to have the opportunity to bring a new innovative solution to our customers from NXTLEVVEL. Having a sustainable alternative solvent will allow our customers to better meet the increasing consumer demands for sustainable cleaning products,” said Jeffrey M. Carey, Ph.D. Vice President HI&I Americas.

These biobased products can reduce dependence on fossil fuels and play a role in reducing carbon emissions. They are used in applications such as hard surface cleaners, floor cleaners, and laundry detergents.

“I’m very excited that NXTLEVVEL and Brenntag are embarking on a relationship to promote our range of biobased solvents in the HI&I industry by leveraging the strength of our technology along with Brenntag’s market-leading position,” commented Aris de Rijke, CEO of NXTLEVVEL Biochem. “NXTLEVVEL’s technology is highly innovative, proprietary and, for the first time, allows the production of levulinate derivatives at industrial scale. The cornerstone is the patented biomass-derived levulinic acid technology and its esters enabling the affordable production of biobased solvents and other biobased chemicals,” de Rijke notes.

About Brenntag:

Brenntag is the global market leader in chemicals and ingredients distribution. The company holds a central role in connecting customers and suppliers of the chemical industry. Headquartered in Essen, Germany, Brenntag has more than 17,000 employees worldwide and operates a network of more than 670 sites in 77 countries. In 2020, Brenntag generated sales of around 11.8 billion EUR. The two global divisions, Brenntag Essentials and Brenntag Specialties, provide a full-line portfolio of industrial and specialty chemicals and ingredients as well as tailor-made application, marketing and supply chain solutions, technical and formulation support, comprehensive regulatory know-how, and digital solutions for a wide range of industries. In the field of sustainability, Brenntag pursues specific goals and is committed to sustainable solutions in its own sector and the industries served. Brenntag shares have been listed at the Frankfurt Stock Exchange since 2010, initially in the MDAX and since September 2021 in the DAX. In addition, the Brenntag SE shares are listed in the DAX 50 ESG and DAX 50 ESG Target. For more information, visit www.brenntag.com.

About NXTLEVVEL:

A privately held company headquartered in The Netherlands, NXTLEVVEL is a commercial scale manufacturer of next generation biomass-derived chemicals. As a joint venture formed in 2018, NXTLEVVEL brings together the industrial expertise of the Towell Engineering Group (Sultanate of Oman) with advanced technology developed by GFBiochemicals. GFBiochemicals was founded in 2008 and holds 200 patents for its world leading proprietary technology in bio-solvents, polyols, and plasticizers based on levulinic acid. Levulinic acid is considered a key biobased building block that enables the production of an extensive portfolio of derivatives. For more information, visit www.nxtlevvel.com

Metso Outotec to deliver modular cobalt solvent extraction technology to Canada

Metso Outotec has signed an agreement with the Canadian battery materials company First Cobalt Corporation to deliver Planet Positive solvent extraction technology to their cobalt refinery expansion in Ontario. The value of the order is approximately EUR 10 million, and it has been booked into Metals’ Q4/2021 orders received.

Metso Outotec’s scope of delivery includes the engineering and supply of a modular VSF®X solvent extraction plant. First Cobalt aims at producing 25,000 tonnes of traceable, high-quality, battery-grade cobalt sulfate annually. Their refinery in Ontario is currently the only permitted producer of battery-grade cobalt for the North American electric vehicle market.

“We are happy to be moving forward with Metso Outotec, an industry-leading business partner. Metso Outotec was selected based on its competitive pricing and technically superior bid. The contracted solution involves the latest advancements in solvent extraction in terms of modular design, process control, and ease of installation and start up,” explains Trent Mell, President & CEO of First Cobalt.

Metso Outotec VSF x solvent extraction lines

Metso Outotec VSF x solvent extraction lines

“We are excited to start working on this ambitious project with First Cobalt. To date, we have sold almost 50 solvent extraction plants worldwide, 11 of which represent the proven modular VSF®X technology. This will be our first VSF®X solvent extraction plant in Canada,” says Mikko Rantaharju, Vice President, Hydrometallurgy, at Metso Outotec.

Read more about our solvent extraction technologies on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

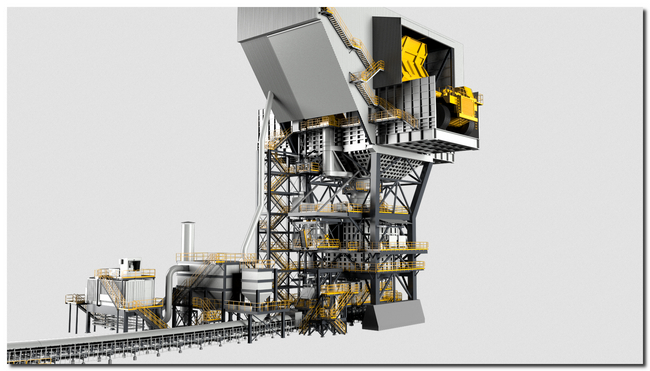

Metso Outotec wins order for Foresight™ semi-mobile primary gyratory crushing plant at Codelco’s Radomiro Tomic operation

Metso Outotec has signed an agreement with Codelco in Chile to design and supply a Foresight™ semi-mobile primary gyratory (SMPG) crushing plant for Codelco’s Radomiro Tomic operation. The value of the order is not disclosed. It has been booked in Minerals’ Q3/2021 orders received.

Equipped with a Superior™ MKIII 60-110 primary gyratory crusher, apron feeder discharge and dust collection, the Foresight™ SMPG meets the highest demands in productivity and sustainability. It is part of Metso Outotec’s in-pit crush and convey solutions (IPCC) portfolio.

“We have extended our Planet Positive offering in June of this year, launching our IPCC solutions, combining the right team, technology, and services to redefine productivity in this space. We highly appreciate Codelco’s continued trust in us to deliver significant crush and convey infrastructure to meet Codelco’s demanding operational and sustainability goals,” says Markku Teräsvasara, President, Minerals.

Foresight™ semi-mobile primary gyratory crushing plant

Foresight™ semi-mobile primary gyratory crushing plant

“We are honored Codelco has chosen us to deliver this significant project in Radomiro Tomic and extend the fleet of Superior™ primary gyratory crushers at that site. With more than 1,300 employees and integrated fabrication of wear materials in Chile, we service our fleet of crushers wholistically and look forward to supporting this plant as well,” says Eduardo Nilo, President, South America Market Area.

Metso Outotec’s integrated modular in-pit crush and convey solutions consist of crushing, conveying, and stacking equipment combined with IPCC planning and life cycle services. The offering is designed to ensure the highest productivity, energy efficiency, and maintainability. Metso Outotec IPCC solutions with their improved energy efficiency are part of the company’s Planet Positive portfolio. In-pit crush and convey operations also reduce haulage related energy consumption and CO2 emissions.

Discover more about in-pit crush and convey technology at mogroup.com/ipcc

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com