Super User

Let's not waste time and energy: How the operational management of photovoltaic power plants succeed at the first attempt

The climate crisis requires urgent action as we need to significantly reduce our CO2 emissions to curb climate change and limit the average temperature increase to about 1.5°C. Here, Austrian ORF meteorologist, Marcus Wadsack writes: We are the first generation to feel climate change and the last to do something about it. We have the technology and the money, it would be negligent if we do nothing.

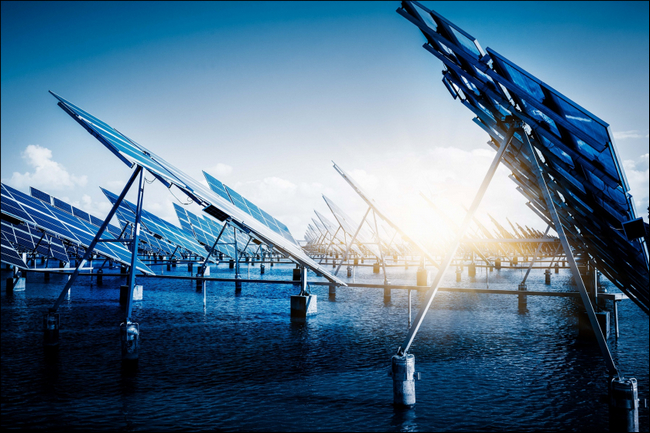

Nature itself provides climate-neutral energy in abundance. Year after year, the sun alone supplies more than 10,000 times the annual energy demand of the entire human race. The task of photovoltaic power plants is to convert the sun's rays into electricity. But the optimal management of the huge number of components like PV panels, converters or switchgear requires advanced techniques and methods.

Using the sun's energy with automation

Whether small solar PV systems with an electrical output of 1MW or large ones with well over 100MW, they should all be operated as close as possible to the optimum and must therefore be monitored. In addition, when such large outputs are fed into the power grid, they must be continuously reported to the entity responsible for the grid. The feeding point is usually a substation with special features in terms of switching reliability and remote monitoring. But not only online monitoring and control is important, retrospective monitoring of key indicators should also be possible. After all, the operator wants to know what return his investment is delivering or where there is a need for optimization.

To meet all these requirements, COPA-DATA has developed the Solar PV Application Set based on its zenon software platform. An Application Set is an application template that helps integrators and operators alike to create a specific process visualization quickly and easily.

For solar PV systems, the Application Set offers the ideal overview, summarizes all relevant components such as PV modules and strings, combiner boxes and inverters and clearly displays their operating status. In a solar heat map, the service engineer can immediately see which parts of the system are shaded or dirty or have other deviations or errors. This allows continuous maintenance work to be carried out in a simple and targeted manner, but also with foresight.

Another great advantage lies in the integrated reporting functions of zenon. Meaningful statistics can be created based on value archives of any duration and pre-compression. Thus, for example, causes of alarms can be analyzed, or yield figures and benchmarks — for example, according to IEC 61724 — can be formed. The possibility of uncomplicated reporting in zenon, based on an integrated database, means an invaluable advantage in the strategic optimization of system operation.

Accurate forecasting and balancing of the yields in real time is another important aspect of the automation of solar power plants. Corresponding outputs or surpluses must be precisely coordinated with the grid operator. On the other hand, specifications must be received from the grid operators. The data exchange required for this can take place via various industry protocols such as IE C 60870, DNP3 or OPC-UA as well as via REST or MQTT-based web protocols (XML, JSON) and must in any case fulfill a sufficient degree of robustness as well as cyber security.

Switchgear or substations form the bridge between the local power plant and the next higher network level. Here, expensive high-voltage components must be reliably orchestrated and monitored. Several specialized switching and protection systems from different manufacturers are typically used here. Here, zenon provides a comprehensive overview by means of the topological real-time representation of the networks. Powerful functions for the safe execution, but also recording and playback of complex switching operations can be easily used with the zenon software platform.

The possibilities of modern solar PV operation management

The consistent use of renewable energies for the purpose of mitigating the negative consequences of climate change must be made a top priority, especially in view of the effects that are already being clearly felt. Photovoltaic power plants are a supporting pillar for a carbon neutral energy economy. Intelligent automation helps to fully exploit the potential of photovoltaic power plants and to optimize yields over many years. The zenon software platform covers a unique spectrum of tasks for the operational management of photovoltaic power plants as well as surrounding switchgear or substations. The Solar PV Application Set in zenon effectively combines important functions and thus creates the ideal prerequisite for the perfect use of the valuable energy that our sun offers us.

Visit the COPA-DATA website for more product information, or click here to contact directly.

About COPA-DATA

COPA-DATA is an independent software manufacturer that specializes in digitalization for the manufacturing industry and energy sector. Its zenon® software platform enables users worldwide to automate, manage, monitor, integrate and optimize machines, equipment, buildings and power grids. COPA-DATA combines decades of experience in automation with the potential of digital transformation. In this way, the company supports its customers to achieve their objectives more easily, faster and more efficiently.

The family-owned business was founded by Thomas Punzenberger in 1987 in Salzburg, Austria. In 2020, with more than 300 employees worldwide, it generated revenue of EUR 54 million.

Emerson to Provide Advanced Automation Technologies for Revolutionary Plastics Recycling Plant

Digital solutions will enable ReNew ELP to safely operate first-of-its-kind plastics recycling process

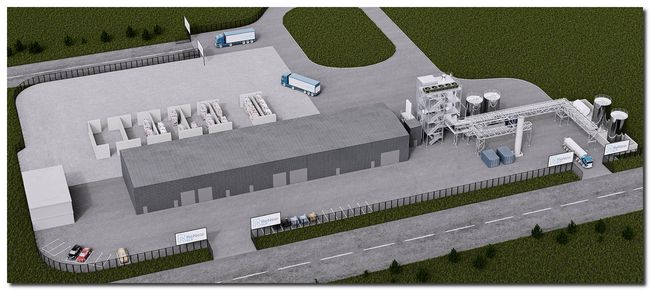

ReNew ELP, a UK-based advanced recycling company, has selected Emerson (NYSE:EMR) as its digital automation partner for its new plastics recycling plant in Teesside, north-east England. Emerson’s advanced automation technology and software will help achieve safe, efficient operation of an innovative hydrothermal process to convert end-of-life plastics back into their original feedstock to produce new plastic products, reducing waste and pollution.

Currently, many post-consumer plastics, including flexible and multi-layer plastic packaging items, such as films, pots, tubs and trays, are considered ‘unrecyclable’ via traditional mechanical recycling methods and are instead sent to landfill or incinerated. After a short first-use cycle, 95% of plastic packaging material value, or $80-120 billion annually, is lost to the economy, according to the World Economic Forum.

“By converting end-of-life plastics into fossil-replacement feedstocks, ReNew ELP has the potential to eliminate unnecessary single-use plastic and make the raw ingredients for a circular plastics economy, creating value instead of waste,” said Richard Daley, managing director, ReNew ELP. “Pivotal to achieving these goals is the construction of this first commercial-scale plant using a unique hydrothermal platform, and in Emerson we have found a valuable, long-term partner to create an advanced automation model for further plants planned across Europe.”

The ReNew ELP plant will utilise a ground-breaking advanced recycling process called HydroPRS™ (Hydrothermal Plastic Recycling System), that uses supercritical steam (high pressure and temperature) to convert waste plastics into the valuable chemicals and oils from which they were originally made. These products can then be used to manufacture new plastics and other materials.

Emerson’s advanced automation technology and software will help achieve safe, efficient operation of the ReNew ELP plastics recycling plant in Teesside, north-east United Kingdom.

Emerson’s advanced automation technology and software will help achieve safe, efficient operation of the ReNew ELP plastics recycling plant in Teesside, north-east United Kingdom.

“The HydroPRS process is currently undergoing a Life Cycle Assessment by Warwick Manufacturing Group to understand both its environmental impacts and Global Warming Potential (GWP), alongside the CO2 savings from diverting plastic waste away from incineration and into advanced recycling,” said Daley. “Initial findings indicate a significantly reduced GWP when compared to energy from waste (incineration) and a favourable comparison to fossil naphtha, supporting the ambition of a viable pathway to net zero.”

As the main automation contractor, Emerson will be responsible for developing a complete automation and control solution to ensure safe, efficient operation of the demanding production process with minimum operator intervention. Emerson’s Project Certainty methodology, which digitalises project execution, will help deliver the plant on budget and on schedule, while its Operational Certainty methodologies will help ReNew ELP realise maximum operational performance and profitability over the lifecycle of the facility.

“Emerson has the ability to support the environmental sustainability goals of industrial companies through greater efficiency, expanded use of cleaner energy sources, emissions capture and improved management of waste materials,” said Roel Van Doren, group president of global sales at Emerson. “Through collaborative project engineering, advanced digital solutions and lifecycle services, Emerson will help ReNew ELP create a solution that supports sustainable practices and helps advance our goals to preserve resources.”

As part of the automation solution, Emerson will provide an integrated control and safety system, incorporating its DeltaV™ distributed control system and DeltaV safety instrumented system for process and emergency shutdown, plus fire and gas detection. Emerson’s Plantweb™ digital ecosystem, incorporating wired and wireless networks that support clusters of advanced measurement instrumentation, will provide visibility to process performance and actionable data about equipment health. The automation system will feature a broad range of severe service and general-purpose control valves, on/off valves and pressure control technology. A range of asset management solutions will be deployed to enhance equipment reliability and increase process availability and throughput, while minimising the time operators spend in the field performing manual inspections.

The plant is expected to become operational in late 2022, with the first phase including one of four recycling lines, each able to process 20,000 tonnes of plastic waste per year.

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and engineering company providing innovative solutions for customers in industrial, commercial, and residential markets. Our Automation Solutions business helps process, hybrid, and discrete manufacturers maximise production, protect personnel and the environment while optimising their energy and operating costs. Our Commercial & Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency, and create sustainable infrastructure. For more information visit Emerson.com.

About ReNew ELP

ReNew ELP, based at Wilton Centre, Teesside, is an advanced recycling company using hydrothermal upgrading to recycle all forms of plastic waste, including that which is currently considered unrecyclable, such as flexible films, pots, tubs and trays. For more information, visit www.renewelp.co.uk

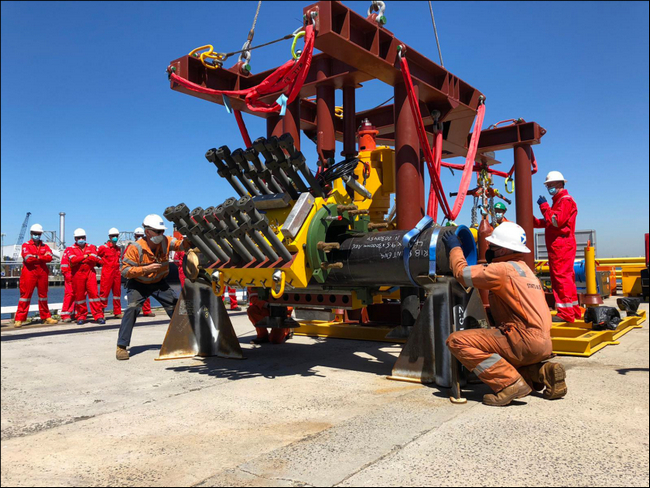

STATS Group invest £1 million to tap into Australian pipeline market

STATS Group has established a new Australian entity and will invest up to $AUD 2 million (£1 million) in workshop facilities and intervention equipment to support its drive in the country’s pipeline integrity market.

The pipeline technology specialist has been successful in the last five years in securing a range of strategic contracts in the oil and gas and LNG sectors and is now consolidating its presence in-country.

As part of the group’s broader localisation strategy, a workshop and storage facility close to Perth, Western Australia, has been secured and the Aberdeenshire-headquartered business is recruiting local field and workshop technicians and a lead project engineer to support an increase in demand for the group’s services.

Already in 2021, on behalf of major Operators, STATS has completed two 12” BISEP (double block & bleed isolation) intervention projects in Darwin, Northern Territory; four 14” BISEP workscopes in Perth; and in Victoria’s Bass Strait provided an 18” Subsea Hot Tap Clamp with 12” branch and subsea hot tapping services, and a 20” Remote Tecno Plug isolation on an offshore platform.

The new Perth base will act as STATS’ intervention hub for Asia Pacific (APAC) clients, making it easier to ship equipment between key markets, minimising freight costs and importantly reducing the company’s carbon footprint.

STATS Group’s regional manager for APAC, Gareth Campbell, said Australia was a commercially attractive market which offered regular year-on-year opportunities with clients who were receptive to new and innovative technology, which is at the core of STATS’ offering.

He said: “Our BISEP double block and bleed isolation technology is a strong differentiator for Australian clients who are looking for solutions, particularly for high pressure systems.

“In addition to day-to-day business with the leading gas operators working in the gas distribution and transmission space, there is also continued large scale investment by the Majors in new fields, tie backs and other projects, offering us the opportunity to get involved in large isolation projects and subsequent growth potential.

“We are well established in the Australian energy sector and have an extensive track record of completed projects, so the next natural step was to strengthen our physical presence, and establishing a formal entity along with this significant investment is being widely welcomed by our customers and suppliers.

“Our well established policy is to invest in local infrastructure – both human and equipment and facilities – and if Covid-19 taught us anything, it was the value of being in-country and to be able to respond quickly to the crisis. This is what clients are looking for and expect, and this new facility and local expertise can only improve further our response times.”

Based in Kintore, near Aberdeen, STATS principal activity is the provision of pressurised pipeline isolation, hot tapping and plugging services to the global oil, gas and petrochemical industries.

STATS Group provides specialist engineering services for the maintenance, integrity and repair of oil, gas and petrochemical installations and infrastructure.

STATS have gained an excellent reputation for providing a responsive, client-centred approach combined with expertise and innovative products which enhance safety and environmental performance, reduce system or plant downtime, improve asset performance, and support decommissioning and abandonment.

The group operates from its headquarters in Kintore, Aberdeenshire in the UK; Edmonton, Canada; Houston, USA; Abu Dhabi, Oman and Qatar in the Middle East; and Kuala Lumpur in Malaysia.

Website: www.statsgroup.com

Strong Commitment to Climate Protection

The Schwarz Group’s climate targets validated by the Science Based Targets initiative

Climate change poses enormous challenges for our society and demands action at all levels. In virtue of their group-wide climate strategy, the Schwarz Group supports the Paris Agreement. As such, already in August 2020, the retailer officially joined the Science Based Targets initiative (SBTi). Therefore, the Schwarz Group analyzed its carbon footprint, compiled a complete climate impact assessment, defined climate targets in line with the SBTi climate target methodology and set a variety of measures. These scientifically based targets have now been validated and approved by the SBTi.

With the aim of reducing its operational emissions (Scope 1 and 2) by 55 percent by 2030 compared to 2019 levels, the Schwarz Group is making a measurable contribution to limiting global warming to 1.5 degrees Celsius. In order to achieve this, the Schwarz Group intends to obtain 100 percent of its electricity from renewable energy sources from 2022 onwards. All PreZero sites will also follow this target in 2022. Already today, the retail group produces its own green electricity, for example, from photovoltaic systems on the roofs of more than 1,300 stores, logistics centers and office buildings worldwide. The retail divisions are going one step further and use carbon offset projects to set their operational emissions (Scope 1 and 2) climate neutral – Lidl as of 2022, Kaufland by 2025 at the latest.

Food production and manufacturing within the upstream value chain are responsible for the majority of the Schwarz Group’s carbon footprint. For this reason, the corporate group would like to provide its suppliers with incentives to reduce emissions themselves, and obligates those suppliers who are responsible for 78 percent of the product-related Scope 3 emissions to set themselves climate targets in accordance with the SBTi criteria by 2026. The Schwarz Group is supporting and accompanying its suppliers in this process.

Further information on the Schwarz Group Sustainability Strategy can be found here www.responsibility.schwarz.

Autonomous robot delivers packages to residents in Helsinki

No queuing at busy pick-up points – starting from November, an electric robot will be operating in Hyväntoivonpuisto in Jätkäsaari, Helsinki, providing an easy way for residents to pick up their packages.

The increase in the population of the Jätkäsaari district of Helsinki, Finland creates additional needs for urban logistics. With the growth of e-commerce, logistics companies are also in need of new solutions for easier deliveries. The delivery of DB Schenker packages to customers will be tested in the Hyväntoivonpuisto area of Jätkäsaari with the help of an autonomously moving, electric delivery robot. This pilot will start in Jätkäsaari on the 2nd of November, 2021 and continue until the 10th of December, 2021.

“Last mile deliveries in particular can be challenging in cities. The pilot is based on the desire to determine how an autonomous delivery robot could help with this challenge,” says Project Planner Matias Oikari from Forum Virium Helsinki.

The participants in the pilot include the startup company LMAD, which is in charge of operating the delivery robot; GIM Robotics; the City of Helsinki’s innovation company Forum Virium Helsinki; and DB Schenker, which will use the delivery robot as its pick-up point.

A delivery robot can serve as an additional solution in urban areas

“DB Schenker is actively involved in the innovation of the logistics industry. In Finland, we have developed package pick-up points in particular to facilitate smooth flows of goods to various residential environments. We study the use of delivery robots as one pick-up point solution for densely populated urban areas,” says Antti Jarva, who is in charge of DB Schenker’s package business in Finland.

The startup company LMAD is in charge of operating the robot. “For us, this is an excellent opportunity to test an autonomous delivery service with the residents of Jätkäsaari. We want to learn how our solution brings additional value to both residents and our partner, DB Schenker. Our aim is to offer a service that is a convenient, flexible and environmentally friendly option while simultaneously reducing logistics costs,” says Co-founder, Product Lead Gergely Horváth from LMAD.

The Jätkäsaari delivery robot pilot is a part of the Last Mile Autonomous Delivery innovation project funded by EIT Digital. This project aims to develop and bring to the market a software platform for controlling, managing and optimising autonomously moving delivery robots. LMAD is the spin-off company created in the project to commercialise the results and operate the platform and the robots.

Safety is taken into account

The delivery robot stops at several locations in Hyväntoivonpuisto for the pickup of packages. The robot moves at walking speed along pavements. During the pilot, it is accompanied by an operator who monitors the robot and simultaneously ensures safe mobility. The robot is equipped with sensors implemented with lidar technology, which continuously observe the surroundings. The robot stops immediately when there is an obstacle in its path.

Picking up a package from the delivery robot resembles picking up a package from the parcel lockers found in public spaces: the pin code needed to open the locker is sent to the recipient by text message, and the recipient enters it into the robot.

The robot is roughly 1.5 metres tall and features 13 lockers, the smallest of which is 10 cm x 44 cm x 53 cm in size, while the largest lockers are roughly the size of a carry-on bag. The robot delivers packages once a day in the Hyväntoivonpuisto area.

How to pick up a package from the delivery robot in Hyväntoivonpuisto:

- When placing an order, select delivery by DB Schenker and the LMAD robot from the list of options.

- Shortly before delivery, you will receive a link that allows you to select the exact place and time of delivery.

- You will receive a notification when the robot is in the selected location at the time agreed upon. The robot will stop at the location for at least 30 minutes. If you miss this time window, you can still easily pick up your package, as the locations at which the robot stops in the Hyväntoivonpuisto area during the pilot are located near each other. If you do not pick up your package from the robot, you can pick it up later at the R-kioski on Välimerenkatu.

- The notification sent to you will include a pin code for opening the locker and picking up your package from inside the robot.

Further information:

Matias Oikari

Project Planner

Forum Virium Helsinki

tel. +358 40 664 8877, This email address is being protected from spambots. You need JavaScript enabled to view it.

Tony Koljonen

Development Manager, e-Com

DB Schenker

tel. +358 50 406 5760, This email address is being protected from spambots. You need JavaScript enabled to view it.

Gergely Horváth

Co-founder, Product Lead

LMAD - Last Mile Autonomous Delivery

tel. +358 50 338 4244, This email address is being protected from spambots. You need JavaScript enabled to view it.

Metso Outotec launches innovative Concorde Cell flotation technology for fine and ultra-fine particle recovery

Metso Outotec is launching groundbreaking Concorde Cell™ flotation technology for efficient fine and ultra-fine particle recovery. This innovative Planet Positive technology sets a new benchmark in high-intensity pneumatic flotation, reducing plant operation costs and contributing to sustainability of operations through minimized energy and water consumption per tons of metal produced.

The patented Metso Outotec Concorde Cell™ technology is the first fine and ultra-fine flotation solution for more finely disseminated and complex orebodies that have previously been inaccessible.

“The need to process more finely disseminated and complex ore grades, as well as the declining ore grades and the demand for improved flotation selectivity, all bring new challenges to minerals processing flowsheets. The new Concorde Cell™ technology helps flotation circuits overcome these challenges and recover the previously unachievable ore value,” says Antti Rinne, Vice President, Flotation at Metso Outotec.

Metso Outotec Concorde Cell

Metso Outotec Concorde Cell

The Concorde Cell™ forced-air Blast Tubes treat 100% of fresh feed combined with tailings recycling for improved performance, allowing finer grinding to get extra liberation without the risk of valuable particles lost into tailings.

“Combining the well-proven TankCell® technology with Concorde Cells is a low-risk and high-benefit approach for minerals processing flowsheets. The cell produces very high shear and extremely fine bubbles, which increases recovery in particles under 20 microns,” explains Rinne.

Benefits of the Concorde Cell™ flotation technology:

- Superior recovery of fine and ultra-fine particles

- Very high shear environment with increased bubble surface area flux for faster flotation kinetics

- Optimized froth recovery and improved selectivity

- Forced air allowing wider process control and stability for further flotation optimization

The offering also includes Blast Tube retrofit kits for upgrading the metallurgical performance of self-aspirated pneumatic flotation cells to the Concorde Cell™ technology. In addition, Metso Outotec can provide a complete slurry handling package for the Concorde Cell, including pumps, spare parts, as well as optimization and maintenance services.

Discover more about the innovative Metso Outotec Concorde Cell™ technology on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki.

Peru requires private investors to ramp up natural gas production and accelerate transition towards cleaner energy, says GlobalData

Peru has signed the Paris Agreement and committed to develop policies to increase the share of renewable energy sources from current 5.5% to at least 20% by 2040. However, the country needs significant capital investments to ramp up its natural gas production and increase the share of low-carbon energy sources in the overall mix, says GlobalData, a leading data and analytics company.

Svetlana Doh, Oil & Gas Analyst at GlobalData, comments: “While electricity generation in the country is considered more or less clean, as it is sourced from natural gas and hydropower primarily, oil consumption by all the sectors altogether is high and roughly accounts for 50%. So, until other renewables sources could contribute the required amount of energy, growing natural gas production still stays very important in this transition period as its consumption could grow and partially replace oil utilization in industrial use, residential sector and power generation.”

The newly elected president of Peru, Pedro Castillo, appears strongly committed to support the involvement of private sector in energy projects. As per Peru’s National Energy Plan 2010-2040, the country has been establishing the legal framework that is aimed to promote and protect private investment in the sector.

The newly elected president of Peru, Pedro Castillo, appears strongly committed to support the involvement of private sector in energy projects. As per Peru’s National Energy Plan 2010-2040, the country has been establishing the legal framework that is aimed to promote and protect private investment in the sector.

Ms. Doh concludes: “When it comes to current projections regarding natural gas production in Peru, it is expected to grow by 3.4% next year from 1.16 billion cubic feet of gas (bcfd) to 1.20 bcfd in 2022. But, in 2023, production is expected to start declining at an average of 2.1% annually and reach 1.16 bcfd in 2025. Based on the National Energy Plan, the demand for natural gas will grow from approximately 1.6 bcfd in 2021 to at least 2.4 bcfd in 2025.

“Currently, gas is used in about 22% of the energy market in the country, and in order to get that share growing, under-explored gas areas in Peru need to be developed sooner rather than later. More aggressive exploration work needs to be conducted as there have been no significant discoveries in Peru since 2014, and offshore blocks are significantly under-explored.”

- Quotes provided by Svetlana Doh, Oil & Gas Analyst at GlobalData

- This press release was written using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

2021 and Advanced Textiles Conference

New fabric designs provide inspiration for innovative products and components

New fabric designs provide inspiration for innovative products and components

Bally Ribbon Mills (BRM), an industry leader in the design, development, and manufacture of highly specialized engineered woven fabrics, will be highlighting custom weave designs and high-performance fibers at IFAI Expo 2021 and the Advance Textiles Conference, to be held November 1-4, 2021, at Music City Center, Nashville TN, Booth # A925.

On display will be new fabrics that utilize custom weave designs and high-performance fibers or combinations of fibers with patterns specific to end-use applications. Visitors to the booth can see examples and discuss creation of innovative patterns for new applications that may be on their drawing boards.

Visit the booth to view:

- E-WEBBINGS® – woven fabrics of traditional fibers in conjunction with functional elements, including conductivity, light transmission, and sensors.

- Composites – fabrics that contain more than one unique fiber for the purpose of utilizing different and inherent properties of each component fiber.

- Tapes and webbing with superior properties – materials with high strength to weight ratio, chemical resistance, low elongation, and many more properties.

- Engineered fibers and fabrics utilized in space for mission success and to keep our astronauts and pilots safe – samples of materials used by NASA, ESA, and commercial near and deep space contractors providing materials on Planet Mars.

For more information on BRM’s products, go to www.ballyribbon.com.

About Bally Ribbon Mills

Bally Ribbon Mills (BRM) designs, develops, and manufactures highly specialized engineered woven webbing, tapes, specialty fabrics, woven preforms, and two dimensional and three dimensional structural fabrics. With more than 95 years of textile manufacturing experience, BRM has earned a reputation for meeting new advanced design challenges. Working in aerospace, defense, medical, safety, automotive, commercial, and industrial applications, BRM offers ingenuity, technical know-how, extensive weaving capabilities, and rigorous quality assurance systems. For more information, visit www.ballyribbon.com or call 610-845-2211.

KHK USA Inc. Announces Extensive Line of Metric Screw Gears

Large Selection includes Stainless Steel, Aluminum Bronze and Nylon

KHK USA Inc., distributor of the market leading KHK® brand of metric gears, announces its extensive line of metric screw gears, manufactured to the highest quality standards by Kohara Gear Industry Co., of Japan. KHK’s large selection of screw gears are suitable for a very wide range of applications, including conveyors with light loads and are offered in many materials, modules and numbers of teeth.

KHK stock screw gears are available in economical S45C carbon steel, as well as rust-resistant SUS303 stainless steel suitable for food machinery. Corrosion-resistant and wear-resistant CAC702 (formerly AlBC2) aluminum bronze are also available.

KHK stock screw gears are available in economical S45C carbon steel, as well as rust-resistant SUS303 stainless steel suitable for food machinery. Corrosion-resistant and wear-resistant CAC702 (formerly AlBC2) aluminum bronze are also available.

The KHK catalogue of stock screw gears also includes light-weight MC Nylon screw gears that can be used without lubrication. Other plastic materials are available, including Ultra High Molecular Weight Polyethylene (UHMW-PE), which has excellent abrasion resistance. A single piece order is acceptable and will be produced as a custom-made gear.

Screw gears are crossed helical gears with helix angles of 45 degrees. As such, they are the only helical gear pairing that can be used in either a left hand - left hand combination or a left hand - right hand combination. When used in a left hand - left hand combination, the gears operate with non-parallel and non-intersecting axes. In this fashion they operate in a similar manner to miter or bevel gears. When used in a left hand - right hand combination, they act like traditional helical gear pairs.

All KHK screw gears allow for secondary operations such as opening the bore, adding of keyways, adding of tapped holes, and the reduction of the hub diameter to be performed. The catalogue includes products which have already had some of these secondary operations completed. These products are identified by a "J" in their part number and they are available within 10 calendar days.

For more information on KHK Bevel Gears, please visit: www.khkgears.us/products/screw-gears.

About KHK USA Inc.

KHK USA, based in Mineola, New York, is a wholly owned subsidiary of Kohara Gear Industry. KHK USA is a factory direct, full-service distributor of KHK gears with a large selection of product available off-the-shelf to meet your gearing needs. On staff application engineers assist customers with a wide selection of gears for their design and can produce customer gear quotations.

NETZSCH exhibits at ADIPEC: The long service life of NOTOS® multi screw pumps convinces on the oil field

NETZSCH Pumps & Systems will be exhibiting at ADIPEC in Abu Dhabi. At this trade fair, NETZSCH will present NOTOS® multi screw pumps. These pumps are designed for the oil and gas sector to handle difficult media. Due to their high suction power, they are suitable for a wide range of applications in this sector.

NOTOS® multiple screw pumps offer high suction power of up to 8 m.a.s.l. They are pumping safely and continuously low to high lubricant fluids, low to high viscosity, shear sensitive, or chemically aggressive media. Therefore they are suitable, for example, for tank emptying.

Besides that, these pumps show a very low-maintenance effort. They are hydraulically balanced, with low axial force and enable continuous flow without pulsation or turbulence over the long service life. They work quietly and need only a small space for installation.

The NOTOS® Multiple Screw Pumps are available as two screw-, three screw- and four screw pumps. If you have any questions, the NETZSCH team at booth 8850 is looking forward to advising customers.