Super User

PA Consulting and PulPac launch new Collective to bring Dry Molded Fiber tablet blister packs to market

PA Consulting and PulPac are calling upon pharma, consumer health and FMCG industries to join the Blister Pack Collective to bring the world’s first Dry Molded Fiber tablet pack to market - minimising the use of plastics for over-the-counter and prescription drugs and vitamins.

With 100,000 tonnes of plastic produced globally for medicine packaging every year, PulPac, the Swedish R&D and IP company behind Dry Molded Fiber, and PA Consulting (PA), the consultancy that’s bringing ingenuity to life, have launched a Blister Pack Collective to use PulPac’s technology to provide a recyclable and sustainable fiber alternative with minimal use of plastic to traditional non-recyclable PVC (Polyvinyl Chloride) blister packs.

Dry Molded Fiber uses renewable pulp and cellulose resources to produce low-cost, high-performance fibre-based packaging. The proprietary manufacturing process uses less CO2 and almost no water to create highly versatile tablet arrays that match the design and tablet count of commodity PVC, providing a like-for-like, scalable solution for pharma and consumer healthcare companies to use.

Philip Fawcus, Dry Molded Fiber Technical Lead and Sustainable Materials Expert at PA Consulting, commented: “PulPac’s Dry Molded Fiber technology combined with the ingenious PA team has allowed the shapes, functions and features of current plastic blister packs to be translated into cellulose – a huge step for the industry as they seek sustainable packaging options.”

PulPac's revolutionary fiberforming technology, Dry Molded Fiber, presents a competitive packaging alternative for brands seeking to do the shift away from single-use plastics.

PulPac's revolutionary fiberforming technology, Dry Molded Fiber, presents a competitive packaging alternative for brands seeking to do the shift away from single-use plastics.

With an initial proof of concept to demonstrate viability, industry collaboration is now required to accelerate development.

Sanna Fager, Chief Commercial Officer at PulPac, commented: “The innovative tablet blister packs designed by the PA team demonstrates a viable fiber-based concept of a circular solution in cellulose that can solve a global challenge. Leveraging the benefits of our Dry Molded Fiber technology – instead of single-use PVC – these packs would be circular in paper-streams and still be functional, scalable, but most importantly affordable. Industry players that seek to be a force for sustainable change in the packaging industry are very welcome to join the collective in support of this transition to sustainability with rapid adoption and global impact.”

Jamie Stone, Dry Molded Fiber Design Lead and Sustainability Design Expert at PA Consulting, said: “It will take innovation and collaboration to tackle the climate crisis, and our partnership with PulPac epitomises this. Using our collective strengths, we have found a solution to tackle one of the huge plastic waste issues across industries reliant on tablet blister packs. We now need industry to join us and help accelerate the development of this ingenious solution and help remove tonnes of problem plastic waste from the planet.”

Organisations interested in pioneering the world’s first fiber-based blister pack and accelerating the industry transition from PVC should sign up here.

About PulPac

PulPac provides the packaging industry with a groundbreaking manufacturing technology for low-cost, high-performance fiber-based packaging and single-use products. By pioneering the technology of cellulose molding PulPac enables their customers to replace single-use plastics with a sustainable and cost competitive alternative globally. For additional information about PulPac, please visit www.pulpac.com or follow us on social media.

About PA

We believe in the power of ingenuity to build a positive human future. As strategies, technologies and innovation collide, we create opportunity from complexity. Our diverse teams of experts combine innovative thinking and breakthrough use of technologies to progress further, faster. Our clients adapt and transform, and together we achieve enduring results. An innovation and transformation consultancy, we are over 4000 specialists in consumer and manufacturing, defence and security, energy and utilities, financial services, government and public services, health and life sciences, and transport. Our people are strategists, innovators, designers, consultants, digital experts, scientists, engineers and technologists. We operate globally from offices across the UK, US, Netherlands and Nordics. Discover more at paconsulting.com and connect with PA on LinkedIn and Twitter

Dry Molded Fiber

Dry Molded Fiber, invented and patented by PulPac, is a manufacturing technology designed for the circular economy – using renewable pulp and cellulose resources to produce low cost, high performance, fiber-based packaging, and single-use products. Dry Molded Fiber gives up to 80% lower CO2 footprint at similar cost as plastic. It is up to ten times as efficient as conventional fiber molding invented over 100 years ago. The dry process also saves massive amounts of valuable water resources. In addition, energy savings are significant - as the molded products need no drying.

Watson-Marlow Highlights Qdos Chemical Metering Pumps

Watson-Marlow Fluid Technology Solutions (WMFTS) highlights its range of Qdos chemical metering pumps for chemical processing and OEM applications.

- Pumps are ideal for chemical processing and OEM applications

The Qdos range features a simple drop-in installation that eliminates the ancillary equipment required by diaphragm pump alternatives while maintaining accurate, linear, and repeatable metering for all chemical processing conditions.

Qdos peristaltic chemical metering pumps have flow rates ranging from 0.001 to 32 USGPH at up to 100 psi with +/- 1% accuracy. An intuitive menu offers advanced control features including fluid level monitoring, line priming, fluid recovery, leak detection, and flow calibration.

Qdos pumps are available with either 110V AC or 12-24V DC. The 12-24V DC power option increases the range of Qdos applications involving remote applications where 110V AC power supply is not available.

Qdos pumps offer long maintenance intervals, and have no valves or seals to clog, leak or corrode. Furthermore, the pumps feature no-tools maintenance with quick and easy pump head replacement, reducing the impact of process downtime and lowering the total cost of ownership.

Built for simplicity in installation, operation, and maintenance the Qdos range of pumps are adaptable to fit all chemical processing and OEM applications.

To learn more about Qdos, visit: https://www.wmfts.com/en-us/watson-marlow-pumps/cased-pumps/qdos-metering-pump/.

About Watson-Marlow Fluid Technology Solutions

Watson-Marlow Fluid Technology Solutions is an award-winning, global leader in fluid management technology and for over 60 years has engineered components and systems for customers in the food processing and handling, pharmaceutical and industrial markets. The company is part of Spirax-Sarco Engineering plc, a FTSE 100 company. Learn more at www.wmfts.com

KROHNE Offers Full Instrumentation Portfolio for Produced Water

KROHNE, a world-leading manufacturer and supplier of solutions in industrial process instrumentation, highlights its market-leading instrumentation portfolio for managing produced water. Throughout the water management process, from collection to transportation and injection, KROHNE’s OPTIFLUX electromagnetic flowmeters cut costs while providing peak levels of performance for operators.

- Reduce pump costs throughout the process of produced water management

KROHNE's products facilitate accurate, reliable measurement, provide instrument diagnostics, and reduce cost to help operators overcome challenges that arise while managing produced water during oil and gas production. OPTIFLUX electromagnetic flowmeters avoid moving parts entirely to avoid wear and measurement inaccuracy due to drifting. These flowmeters are full bore and do not require flow conditioners or strainers. OPTIFLUX flowmeters work free-of-charge alongside KROHNE’s OPTICHECK verification software, which provides easy on site meter verification without requiring the meter to be removed from service. This combination of instrumentation and software provides real time diagnostic information, flow rates and totals, and conductivity information, which are all made available via Modbus.

OPTIFLUX electromagnetic flowmeters are available in multiple models. The OPTIFLUX 2050 is designed for basic water and wastewater applications such as flow and conductivity measurement. It has multiple outputs and a choice of liners including hard rubber. The OPTIFLUX 4300 serves advanced process and custody transfer (CT) applications. A market leader for water injection applications, this model has achieved pressure ratings up to 2500 pounds. It supports all types of connections, from RF and FF to RTJ and Clamp, and more. With robust, fully welded construction, this model is approved for hazardous areas and well suited for demanding environments due to its corrosion resistant materials.

KROHNE’s product portfolio has a long standing track record in industries such as oil and gas and water and wastewater treatment. Its factory inventory of standard meter configurations are available for fast delivery, and its team stands ready at all hours to provide technical support over mail or phone free of charge.

Contact us for special pricing information at This email address is being protected from spambots. You need JavaScript enabled to view it..

About KROHNE

KROHNE is a worldwide technological leader in the development, manufacture and distribution of accurate, reliable and cost-effective measuring instruments for the process industries. KROHNE focuses on forming partnerships with its customers to provide them with the most reliable and innovative solutions available in the marketplace. For more information about KROHNE’s complete line of measuring instrumentation for the process industries, contact KROHNE at 1-800-FLOWING (978-535-6060 in MA); fax: (978) 535-1720, email: This email address is being protected from spambots. You need JavaScript enabled to view it. or visit www.us.krohne.com

Emerson’s New Analytics Software Automates Utilities Monitoring and Reporting for Clean-in-Place Applications

Technology replaces error-prone manual record keeping and monitors energy and utilities parameters, improving efficiency and productivity.

Emerson has just announced the release of its new Clean In Place (CIP) Utilities and Automated Reporting Analytics package delivered via PACEdge™ and Movicon™ platforms on an industrial edge control device. The software aids in digitally transforming manual and semi-automated systems by optimizing utilities consumption, benchmarking against known cycles and generating automated reports that can be used to reduce energy consumption and improve productivity in a single system or throughout a facility.

The CIP Utilities & Automated Reporting Analytics package combines Emerson’s deep application expertise and industry knowledge with advanced technology to convert process and utilities data into actionable insights for the food and beverage industries and other environments that use clean- and steam-in-place operations.

Equipped with the data and analytics provided by the software, plant managers, operators and maintenance personnel can view the information on a dashboard and share the insights with sustainability officers and other stakeholders to optimize their CIP cycles. The software package can be customized and layered into an existing system, or Emerson can provide a turn-key solution of hardware, instrumentation, valves and analytics.

The CIP Utilities & Automated Reporting Analytics allows plant managers, operators and maintenance personnel to convert process and utilities data into actionable insights for industries and environments that use clean- and steam-in-place operations.

The CIP Utilities & Automated Reporting Analytics allows plant managers, operators and maintenance personnel to convert process and utilities data into actionable insights for industries and environments that use clean- and steam-in-place operations.

Central to food and beverage production, clean-in-place systems clean and sanitize internal piping, tanks and machines between product batches to help facilities meet government regulations and guarantee product quality and safety. CIP skids that don’t have sensors and analytics software in place require manual reporting, which can be time-consuming and susceptible to errors, especially when data is transferred by hand into reports. These skids may also run at unnecessarily long preset cycles and use more time and resources than required for effective cleaning.

Digitally transformed and optimized CIP processes, in comparison, only use the time, media, water, energy and labor required for effective cleaning, significantly reducing waste and increasing production time.

“Food and beverage manufacturers typically spend about 30% of utility costs on clean-in-place operations. They also lose time between changeovers and spend between 20 to 40 thousand dollars in labor costs for manual reporting,” said Amit Patel, director digital transformation for discrete and industrial at Emerson. “Emerson’s new CIP Utilities and Automated Reporting Analytics software package collects and analyzes data in real time and presents it as a report, equipping plant managers, CIP operators, maintenance personnel and sustainability officers with the actionable insights to optimize wash cycle settings, including duration and media use, for maximum efficiency and productivity.”

The CIP Utilities & Automated Reporting Analytics software package can help CIP operators better understand and forecast energy use, water consumption and resource needs. Generated reports can be used to satisfy regulation compliance, plan system maintenance, schedule downtime and order media supplies, and deeper analytics can be used to identify insights and trends that support predictive maintenance schedules and facilitate standardization of CIP processes across production facilities.

The agnostic software is compatible with any CIP equipment, which empowers manufacturers to control the digitization of their systems no matter what stage of the digital transformation journey they are in and to integrate any or all Emerson components and customize the solution for their needs.

● Join the Emerson Exchange 365 Community

● Connect with Emerson’s Automation Solutions business via Twitter Facebook LinkedIn YouTube

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and engineering company providing innovative solutions for customers in industrial, commercial, and residential markets. Our Automation Solutions business helps process, hybrid, and discrete manufacturers maximize production, protect personnel and the environment while optimizing their energy and operating costs. Our Commercial and Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency, and create sustainable infrastructure. For more information visit Emerson.com.

Innodisk Proves AI Prowess with Launch of FPGA Machine Vision Platform

Innodisk, a leading global provider of industrial-grade flash storage, DRAM memory and embedded peripherals, has announced its latest step into the AI market, with the launch of EXMU-X261, an FPGA Machine Vision Platform. Powered by AMD’s Xilinx Kria K26 SOM, which was designed to enable smart city and smart factory applications, Innodisk’s FPGA Machine Vision Platform is set to lead the way for industrial system integrators looking to develop machine vision applications.

Automated defect inspection, a key machine vision application, is an essential technology in modern manufacturing. Automated visual inspection guarantees that the product works as expected and meets specifications. In these cases, it is vital that a fast and highly accurate inspection system is used. Without AI, operators must manually inspect each product, taking an average of three seconds per item. Now, with the help of AI solutions such as Innodisk’s FPGA Machine Vision Platform, product inspection in factories can be automated, and the end result is not only faster and cheaper, but can be completely free of human error.

Innodisk’s FPGA Machine Vision Platform comes with 1GbE LAN, 4 USB 3.1 Gen1 ports, 2 M.2 slots, and a series of other expansion and connectivity options. Thanks to the platform’s 0° to 70 °C operational temperature support, and optional industrial temperature support from -40° to +85°C, EXMU-X261 is tough enough for the harshest of industrial environments. In addition, EXMU-X261 features support for Innodisk’s InnoAgent out-of-band remote management module, allowing the platform to be remotely managed from anywhere, even during a system crash or an in-band network failure. This is important for any automated system, as it allows for it to be completely unmanned, which further reduces manpower and maintenance costs.

Customers can take advantage of AMD’s Xilinx Kria K26 SOM’s ability to quickly get applications to market thanks to EXMU-X261’s full support for Innodisk’s AI Suite SDK. The suite includes an FPGA Model Zoo, as well as Innodisk’s in-house software solutions, such as iCAP (Innodisk Cloud Administration Platform), and iVIT (Innodisk Vision Intelligence Toolkit). iVIT for example, provides a deep learning environment for efficient development and deployment of “no-code-operation” solutions.

Valmet to supply flue gas condensing process to Vantaa Energy in Finland

Valmet will supply a flue gas condensing process to Vantaa Energy’s new high-temperature incineration plant in Vantaa, Finland. The plant is designed to process household and industry waste that is classified as hazardous and not suitable for recycling.

The order is included in Valmet’s orders received of the fourth quarter 2022. Its value will not be disclosed, but such an order is typically worth over EUR 15 million. The project will start in 2022 and the plant is scheduled for completion in 2025.

The flue gas condensing equipment recovers heat from the incineration process. The waste heat produced will be utilized in the heating of properties in Vantaa. The waste heat obtained from the plant will reduce the need for using natural gas and fossil fuels and supports the transition to clean energy production.

“The high-temperature incineration plant treating non-recyclable hazardous waste continues Vantaa Energy’s investment programme to phase out the use of fossil fuels in the company’s energy production as soon as possible and to continue towards carbon-negative energy production in 2030. Energy utilization of waste and carbon capture and processing into new products play a key role in our strategy. For Vantaa Energy the high safety level of the technology and design solutions used, implementation of the investment projects according to stringent targets and the high degree of availability of the plants are extremely important. We are delighted to have Valmet as our partner in the high temperature incineration plant project,” says Vantaa Energy’s CEO Jukka Toivonen.

“The project is an excellent example of Valmet’s ambition to provide sustainable emission reduction solutions to our customers, and we are happy to share the journey toward a carbon negative future with Vantaa Energy,” says Lari-Matti Kuvaja, Manager, Sales & Technology, Environmental Systems, Pulp and Energy, Valmet.

Technical information about the delivery

The delivery will include a complete flue gas cleaning process consisting of an evaporative cooler, a baghouse filter with conditioned dry sorption (semi-dry), a condensing flue gas scrubber with heat recovery and condensate treatment, and a Selective Catalytic Reduction (SCR) for removal of nitrogen oxides (NOx).

About the customer

Vantaa Energy Ltd is one of Finland’s largest city energy companies, producing heat, electricity and energy efficiency services. The company enables a smooth everyday life for its customers by producing constantly developing services in a climate-friendly way. The energy sector plays a significant role in the mitigation of climate change. Vantaa Energy Ltd wants to be part of the solution by being a growing circular economy energy company that invests in finding carbon-neutral energy solutions. The company will phase out fossil fuels by 2026 and is progressing towards carbon negativity by 2030.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 were approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

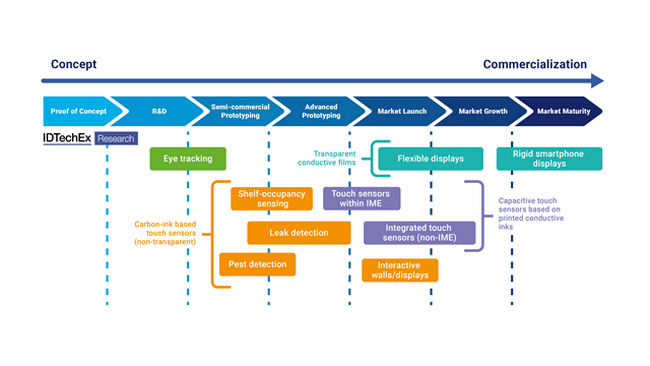

IDTechEx Asks If There Is Untapped Potential for Capacitive Sensors

Ever wondered how a touch-sensitive screen works? The answer is capacitive sensing, which can detect the presence of your finger through the protective glass sheet and doesn’t require any pressure. However, this perhaps under-appreciated technology is not limited to touch-sensitive displays: it is increasingly being utilized for many other established and emerging applications, ranging from automotive controls to leak sensing and even eye tracking.

How Does Capacitive Sensing Work?

Understanding the operating mechanism of capacitive sensors is key to understanding the applications to which they are well suited. Briefly, the sensors work via capacitive coupling to detect objects that have dielectric properties substantially different from air – fingers, being mainly water, work well. Since electric fields can travel through dielectric materials such as air or glass, there is no requirement for electrical contact. However, depending on sensitivity and readout methodology, the object being sensed often needs to be close to the patterned conductive layer, which is why it’s often difficult to use touchscreens or other capacitive controls while wearing gloves.

Opaque Touch Sensing

Although capacitive sensing is widely associated with touch-sensitive displays, it is also increasingly used on opaque surfaces. These include car steering wheel controls and touch panels – the conductive material used to make the capacitive sensor is sometimes a transparent metal mesh so that the controls can be backlit. Capacitive touch sensing is also an essential feature of in-mold electronics, in which conductive traces and LEDs are first printed/mounted on a flat substrate, then thermoformed, and finally, injection molded.

Moving from conventional mechanical switches to capacitive switches brings multiple benefits: fewer components, a reduction in materials used, an interface that can be wiped clean (since there are no grooves between buttons), and a sleek modern aesthetic. However, some drivers have expressed concerns that capacitive sensors are less tactile and hence more difficult to use while driving – integrating haptic feedback is a possible solution.

Leak Sensing

As anyone who has tried to operate their smartphone in the rain will attest, capacitive sensors are extremely sensitive to water due to its high dielectric constant. While this might be undesirable on a touch-sensitive display, it does enable capacitive sensors to be used for leak detection.

By utilizing low-cost materials such as carbon inks printed onto plastic using conventional methods, it is possible to produce rolls of printed/flexible sensors for just a few dollars. These can then be placed around plumbing, under kitchen appliances, and even along pipes – a small control unit housing a circuit board with a micro-controller and batteries measures the changing capacitance. If a leak occurs, a change in capacitance is detected, and a signal is sent to an app to provide a notification. This capability is proving compelling to insurance companies since limited capital investment would substantially limit the property damage caused by any leak.

Eye-Tracking

Perhaps the most surprising emerging application of capacitive sensors is an early-stage technology that provides eye-tracking for virtual/augmented reality glasses. Based on multiwalled carbon nanotubes (MWCNTs) embedded within paper to produce a conductive material with a very large surface area and hence high sensitivity to changes in the dielectric environment. Utilizing three sensors enables projected capacitance, in which the relative response of each sensor enables the location of the change in dielectric properties of the target object to be determined via triangulation. Compared to competing approaches such as machine vision, capacitive sensing promises a much shorter processing time and hence a more responsive system.

Emerging Printed & Flexible Sensor Technologies

IDTechEx’s report “Printed and Flexible Sensors 2022-2032: Technologies, Players, Markets” assesses the technologies and market landscape across 9 distinct printed sensor technologies: piezoresistive sensors, piezoelectric sensors, printed photodetectors, temperature sensors, strain sensors, capacitive touch sensors, gas sensors, biological sensors, wearable electrodes. The report draws on detailed profiles of over 50 companies, the majority based on interviews, to evaluate each of these printed sensor categories in considerable detail, evaluating the different technologies and the challenges to adoption. IDTechEx develop 10-year market forecasts for each technology and application sector, resulting in 33 individual forecast segments delineated by revenue and printed sensor area.

About IDTechEx

IDTechEx guides your strategic business decisions through its Research, Subscription and Consultancy products, helping you profit from emerging technologies. For more information, contact This email address is being protected from spambots. You need JavaScript enabled to view it. or visit www.IDTechEx.com.

Outokumpu is the first stainless steel producer to provide a product-specific carbon footprint based on continuous production data

Outokumpu is committed to help its customers to reduce their climate emissions. As part of its continuous development efforts in sustainability, Outokumpu is the first stainless steel producer to provide a product-specific carbon footprint on its stainless steel products. This will both help customers in their emission-reduction goals and support Outokumpu’s long-term climate targets* and sustainability strategy.

“As the global leader in sustainable stainless steel, we are the frontrunner to push the whole industry forward. At the same time when customers are paying more attention to cutting down emissions, they are asking more specific information about the carbon footprint for each product and solution. We are happy to be the first stainless steel producer to provide the information for products produced in our mills in Europe. Now customers can utilize the data to calculate the product carbon footprints of their products and provide more sustainable solutions to the market”, says Stefan Erdmann, Chief Technology Officer & Group Sustainability at Outokumpu.

The distinct feature of the calculation model Outokumpu is using is based on continuous follow-up of production data.

“In addition to customer value, the product-specific carbon footprint brings full transparency to the sustainability work Outokumpu is executing”, Erdmann continues.

Coil in quality control

Coil in quality control

Transport industry shows an example of urgent need for emission-reduction actions

One of the industries benefiting from product-specific carbon footprint is transport. Transport accounts for 21% of global carbon emissions and the emissions from the transport sector are expected to grow by 20% by 2050**. Biofuels and electric vehicle solutions are already in use to cut emissions from heavy road traffic, but we need to use other solutions too. The reduction of emissions from a new vehicle is also affected by, for example, the steel material used in the manufacture of the vehicle and its carbon footprint.

“Road transportation, especially buses and coaches, is an area where stainless steel can have a very significant impact in helping to achieve carbon neutral mobility. Companies in the industry have ambitious climate targets and the end-customers’ demands, as well as requirements coming from all major Original Equipment Manufacturers, guide the climate work forward. With this new feature, it is also interesting to see how the customers would now be able to design CO2-emission optimized products for the upcoming application generations – for example next-generation vehicles”, says Markus Buckner, Head of Mobility & Transport at Outokumpu.

“Today, many companies are calculating and reporting direct and indirect emissions, but there is a growing need to reduce all other indirect emissions from a company’s value chain. To calculate the complete CO2 emissions down the supply chain it is essential to know the CO2 impact of the pre-material – and that’s why the product-specific information is needed. Outokumpu is in a great position to support the steel industry with the knowledge of being the only stainless steel producer to report emissions from all three scopes and to have the leading role in using recycled material for over 90% globally”, Buckner continues.

*) Outokumpu’s climate target is to reduce carbon dioxide emissions by 42% by 2030 from the base year of 2016. This translates to an emission reduction of 14% by the end of 2025 from the 2021 levels, in accordance with the Science-Based Targets initiative’s 1.5 climate target. Outokumpu is the only producer of stainless steel with a climate target approved by the initiative.

**) https://www.weforum.org/agenda/2021/11/global-transport-carbon-emissions-decarbonise/

For more information:

Product carbon footprint | Outokumpu

Outokumpu is the global leader in stainless steel. The foundation of our business is our ability to tailor stainless steel into any form and for almost any purpose. Stainless steel is sustainable, durable and designed to last forever. Our customers use it to create civilization’s basic structures and its most famous landmarks as well as products for households and various industries. Outokumpu employs some 9,000 professionals in more than 30 countries, with headquarters in Helsinki, Finland and shares listed in Nasdaq Helsinki. www.outokumpu.com

Renaissance Textile successfully starts up the first textile recycling line in France delivered by ANDRITZ

Sustainable textile technology from ANDRITZ Laroche enables to carry out a breakthrough project based on the circular economy

Renaissance Textile in Laval, France has successfully started up a complete textile recycling line, delivered, installed, and commissioned by ANDRITZ Laroche, part of the international technology group ANDRITZ.

The state-of-the-art ANDRITZ textile recycling equipment enabled Renaissance Textile to become the first French recycling platform dedicated to industrial end-of-life textiles. The project aims to produce new fibers from the collected post-consumer apparel, which will be used to weave new recycled fabrics in the end.

The new 12,000 m² plant is equipped with a complete tearing line whose unique design is the result of close collaboration between R&D specialists from ANDRITZ Laroche and Renaissance Textile, as well as customized trials carried out jointly by the two parties at the ANDRITZ technical center in Cours, France.

Tearing line by ANDRITZ in operation at the Renaissance Textile plant © Robin Inizan - Lucas Pavy Production

Tearing line by ANDRITZ in operation at the Renaissance Textile plant © Robin Inizan - Lucas Pavy Production

The new clothing produced based on this type of circular economy model thus reflects the social and sustainability commitments of Renaissance Textile in terms of decarbonizing the textile industry, the fight against global warming, autonomy in raw material sourcing, and promotion of local staffing, particularly for people who have been unemployed for a long time or are seeking to enter the labor market for the first time. It is the first milestone of a pioneering project that ANDRITZ is proud to actively support. By 2025, for example, Renaissance Textile plans to create no less than 110 direct jobs.

Nicolas Nojac, director of Renaissance Textile, comments: “Our first recycling line is dedicated to white polycotton textiles that mainly come from the healthcare and food processing industries. This equipment enables us to recycle 3,000 tons of textiles every year, representing 10 million items of clothing. We also plan to install two additional lines by the end of 2023 and 2025, respectively, to enlarge the range of recycled textiles by adding different colors and fibers”.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for many different industries and end-markets. ANDRITZ ranks among the global market leaders in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence, and sustainability are the main pillars of the company’s business strategy for achieving long-term growth. The publicly listed group has around 27,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Pertamina, Keppel Infrastructure, and Chevron Sign Agreement to Explore Development of Green Hydrogen and Ammonia Projects in Indonesia

Pertamina Power Indonesia (Pertamina NRE), Keppel Infrastructure, through Keppel New Energy Pte. Ltd., and Chevron Corporation (NYSE: CVX), through Chevron New Energies International Pte. Ltd. (Chevron New Energies), have signed a Joint Study Agreement (JSA) to explore the development of selected green hydrogen and green ammonia projects using renewable energy located primarily in Sumatera, Indonesia.

The signing of the JSA took place at the Business 20 (B20) Investment Forum held in conjunction with the B20 Summit in Bali. B20 is an official G20 engagement group that represents the global business community. Signing the JSA were CEO of Pertamina NRE, Dannif Danusaputro; Director of Keppel New Energy Pte., Ltd., Chua Yong Hwee, and Director of Chevron New Energies International, Pte. Ltd., Andrew S. Mingst. The signing was witnessed by the Coordinating Minister for Maritime Affairs and Investment, Luhut Pandjaitan; Minister of Investment of Indonesia & Head of BKPM, Bahlil Lahadalia; President Director & CEO, PT Pertamina (Persero), Nicke Widyawati; and Chief Executive Officer, Keppel Infrastructure, Cindy Lim.

The JSA intends to explore the feasibility of developing a green hydrogen facility, with a production capacity of at least 40,000 tonnes per annum, powered by 250-400 megawatts of geothermal energy in the initial phase. The hydrogen production facility could have the potential to scale up to 80,000-160,000 tonnes per annum, depending on the availability of geothermal energy as well as market demands.

The JSA aims to draw on the complementary strengths of Pertamina, the largest energy company in Indonesia; Keppel Infrastructure, a leading Singapore-based energy infrastructure solutions provider with a strong track record of developing and operating large scale energy and environmental infrastructure projects; and Chevron, a multinational energy corporation committed to providing affordable, reliable, ever-cleaner energy.

According to an International Energy Agency report, Indonesia, the world’s fourth most populous country, has a viable path to reaching its target of net zero emissions by 2060.1 Hydrogen and ammonia are expected to be important lower carbon fuels as part of this roadmap. Ammonia can also be used to transport hydrogen and potentially be used to replace bunker fuels as a lower carbon solution in the global maritime industry.

From Left: Director of Chevron New Energies International, Pte. Ltd., Andrew S. Mingst; CEO of Pertamina NRE, Dannif Danusaputro; Director of Keppel New Energy Pte., Ltd., Chua Yong Hwee. (Photo: Business Wire)

From Left: Director of Chevron New Energies International, Pte. Ltd., Andrew S. Mingst; CEO of Pertamina NRE, Dannif Danusaputro; Director of Keppel New Energy Pte., Ltd., Chua Yong Hwee. (Photo: Business Wire)

Indonesia accounts for approximately 40 percent of global geothermal resources, providing opportunities to utilize geothermal energy as a reliable and stable energy source to produce green ammonia or hydrogen.

Dannif Danusaputro, CEO of Pertamina NRE, said, “The development of green hydrogen and green ammonia holds a significant role in Indonesia’s Net Zero Emissions roadmap. And with its potential, we believe that Indonesia will also play a key role in green hydrogen production in Asia. We are very excited with this strategic collaboration as we know that Keppel and Chevron are reputable companies and have the same vision in energy transition as we do.”

Ms. Cindy Lim, CEO of Keppel Infrastructure, said, “Indonesia is a country with vast resources and enormous potential for renewable and low carbon energy. We are happy to partner with industry leaders, Pertamina and Chevron, to explore the first of its kind use of geothermal and other renewable energy to develop green hydrogen and green ammonia projects and support Indonesia’s energy transition efforts, as well as catalyze investments in green energy supply chain in the regions. In line with Keppel’s Vision 2030, which places sustainability at the core of its strategy, this collaboration will broaden Keppel Infrastructure’s geographical footprints to create and capture more value arising from the global commitment to net zero and its energy transition.”

Austin Knight, vice president of Hydrogen, Chevron New Energies, said, “We have a long history of working in Indonesia and with Pertamina, and a growing relationship with Keppel Infrastructure. We look forward to leveraging our collective strengths to study and evaluate lower carbon opportunities for the region. Chevron’s strength has always been solving big, complex energy challenges, and creating a lower carbon future is the opportunity that motivates us. As part of this effort, we must work together to identify new, innovative ways of producing and delivering ever-cleaner energy to a growing world.”

Keppel Corporation Limited, the parent company of Keppel Infrastructure, does not expect the abovementioned development to have any material impact on Keppel Corporation’s earnings per share and net tangible asset per share for the current financial year.

1 https://www.iea.org/news/indonesia-s-push-to-reach-net-zero-emissions-can-help-power-a-new-phase-in-its-economic-development

About Pertamina NRE

PT Pertamina Power Indonesia (Pertamina NRE) is member of PT Pertamina (Persero), Indonesia’s largest energy company, comprised of four business entities: PT Pertamina Geothermal Energy (subsidiary), PT Jawa Satu Power (affiliate), PT Jawa Satu Regas (affiliate), and PT Industri Baterai Indonesia. Its business focuses on clean energy development. It is highly committed to support Indonesia’s net zero emission 2060 through energy transition and to implement ESG.

About Keppel Infrastructure

Keppel Infrastructure (KI) is a wholly-owned subsidiary of Keppel Corporation, a Singapore flagship multinational company providing solutions for sustainable urbanisation. KI provides solutions for some of the world’s most pressing challenges through its power & gas, environment and new energy businesses by leveraging its proprietary technology, strong technical expertise and proven operating capabilities.

KI has a track record of developing energy and environmental infrastructure end-to-end, including power generation assets, waste-to-energy (WTE) facilities, large-scale district cooling systems, as well as NEWater and desalination plants. In Singapore, it operates a 1,300-megawatt high efficiency gas-fired combined cycle power plant and a utility pipe rack and pipeline network in Jurong Island. It is also Singapore’s leading electricity retailer, and the first and largest district cooling systems developer and service provider. Globally, through Keppel Seghers, it is one of the leading WTE technology providers with more than 100 project references in 20 countries.

KI is expanding its presence, in Singapore and overseas, in areas such as power generation, waste management, district cooling, renewables and energy storage, electric vehicle charging infrastructure and other clean energy opportunities.

For more information, please visit www.kepinfra.com.

About Chevron

Chevron is one of the world’s leading integrated energy companies. We believe affordable, reliable, and ever-cleaner energy is essential to achieving a more prosperous and sustainable world. Chevron produces crude oil and natural gas; manufactures transportation fuels, lubricants, petrochemicals and additives; and develops technologies that enhance our business and the industry. We are focused on lowering the carbon intensity in our operations and growing lower carbon businesses along with our traditional business lines. For more information, please visit www.chevron.com.