Super User

Danfoss Power Solutions’ Thorx™ cam lobe motors deliver better performance in a compact package

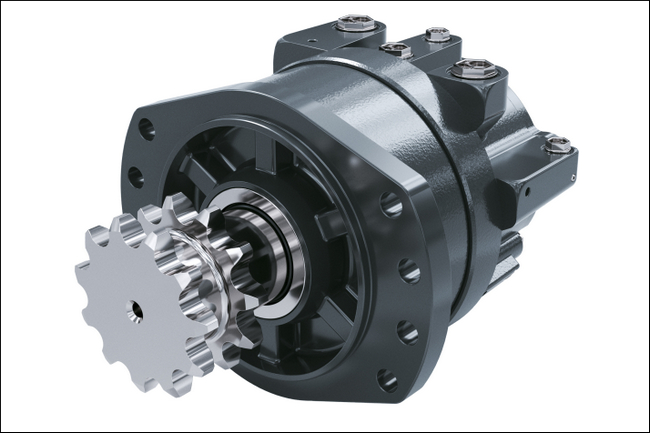

Danfoss Power Solutions, a leading global supplier of mobile and industrial hydraulics as well as electric powertrain systems, today announced the launch of its Thorx family of cam lobe motors. The first product, the CLM 8 S motor, is now available. Designed for construction machinery with chain drives, such as skid steer loaders, the compact motor offers better performance, higher efficiency, and longer lifetime than other cam lobe motors.

- With integral parking brake, Thorx motor is 33% shorter in length than other cam lobe motors, reducing space requirements

- Motor reduces shock at speed changeover by 70%, improving machine handling and operator comfort

- Optimized brake technology lasts 20 to 25 times longer than competitive motors, extending motor service life

The Thorx motor features newly developed two-speed technology, which offers 70% shock reduction when shifting speeds compared to other cam lobe motors. The technology delivers smoother speed changeover with a consistent, quick response time, even at low temperatures, resulting in superior machine handling and better operator comfort. The motor also produces less noise when shifting, further improving comfort.

“We developed our Thorx cam lobe motors in close collaboration with our customers,” said Chris Shrive, head of Cam Lobe Motors, Danfoss Power Solutions. “The first thing they told us to do was reduce shock at speed changeover. We didn’t just meet their expectations; we set a new standard for smooth, predictable, fast changeover, regardless of oil temperature.”

Compact construction is another considerable advantage of the Thorx CLM 8 S motor. By integrating the parking brake rather than bolting it to the rear, the motor is 33% shorter in length than similar products, creating the most compact drive solution in its class. The smaller size results in easier integration and assembly while enabling the use of larger, longer-lasting chains.

The integral parking brake is the toughest on the market, offering a longer service life. Thorx motors utilize a proven brake design that has been optimized to withstand 100 dynamic emergency stops throughout a machine’s lifetime, which is 20 to 25 times more than competitive cam lobe motors.

The Thorx CLM 8 S motor offers 5% higher efficiency than other cam lobe motors, with better starting efficiency and performance at low rotations per minute, plus improved mechanical efficiency at high speed. Operators can achieve faster travel speeds or use less power at the same speed while wasting less energy in the form of excess heat.

“Danfoss Thorx motors have reinvented cam lobe technology,” Shrive continued. “This is the most efficient, most power dense two-speed technology on the market. Our CLM 8 S motor for skid steer loaders is just the beginning.”

For more information, visit the Danfoss Thorx cam lobe motors webpage.

About Danfoss

Danfoss engineers solutions that increase machine productivity, reduce emissions, lower energy consumption and enable electrification. Our solutions are used in such areas as refrigeration, air conditioning, heating, power conversion, motor control, industrial machinery, automotive, marine, and off- and on-highway equipment. We also provide solutions for renewable energy, such as solar and wind power, as well as district-energy infrastructure for cities. Our innovative engineering dates back to 1933. Danfoss is family-owned, employing more than 40,000 people, and serving customers in more than 100 countries through a global footprint of 95 factories.

Delta Joins Dutch PV Association Holland Solar

Delta Electronics EMEA announced it is now an official member of Holland Solar, the highly respected industry association for the Dutch solar energy sector. Since 1983, Holland Solar has been working together with its members to inspire, inform, connect and further professionalise the Dutch solar industry.

Being accepted a member of Holland Solar signifies that the association recognises Delta as a reliable and leading Photovoltaic (PV) inverter manufacturer, and that Delta has agreed to comply with Holland Solar’s rules of conduct for members. In return, Delta will share its knowledge and expertise of both PV technology and installation techniques, adding to the existing talent pool, knowledge skills and professional understanding among the Holland Solar community.

Being accepted a member of Holland Solar signifies that the association recognises Delta as a reliable and leading Photovoltaic (PV) inverter manufacturer, and that Delta has agreed to comply with Holland Solar’s rules of conduct for members. In return, Delta will share its knowledge and expertise of both PV technology and installation techniques, adding to the existing talent pool, knowledge skills and professional understanding among the Holland Solar community.

In addition to the association’s positive reputation among the Dutch PV sector - where it has an influence on decision-making - it also has an established relationship with the Dutch government, to whom it provides substantive information about the sector and market developments. As such, Holland Solar has an advisory role during the creation of new policies, while also driving the agenda on future legislation and subsidies. Therefore, the membership of Holland Solar presents Delta with excellent opportunities to further progress the deployment of its PV solutions across the region.

“For more than 50 years, Delta has been at the heart of initiatives that drive energy efficiency and sustainability. As such, it is a great honour to join Holland Solar, an association that shares our values and goals. It has a proud history of its own, supporting the Photovoltaic industry and influencing government policy to help accelerate the uptake of PV solutions for almost 40 years.” said Michiel Klees, PVI BU Sales Manager Benelux, UK & Ireland, Delta Electronics EMEA region.

Commenting on Delta’s membership, Wijnand van Hooff, General Manager, Holland Solar said: “Delta is well respected across the global PV community, so we welcome its membership and the valuable contribution we know it will make to the association and its members. Delta joins at a time of increasingly strict Environmental, Social en Governance (ESG) goals, and a heightened awareness among citizens and corporates of the need to be more energy efficient. Delta’s reputation as an industry pioneer brings further credibility to Holland Solar and supports its objective of making PV even more popular as a sustainable energy solution.”

Pfannenberg Celebrates 25th Anniversary of North American Manufacturing

Growth built on high-quality products, skilled employees, and reputation as a trusted advisor

Pfannenberg, Inc., a leading global manufacturer of thermal management, signaling technologies and packaged process chillers, announces the 25th anniversary of its United States manufacturing operations. A celebratory event will be held on November 9th, 2022, from 12-5 p.m. at the company’s facility at 68 Ward Road, Lancaster, NY. The event will feature a buffet meal, factory tours, and presentations by Andreas Pfannenberg, Owner - Pfannenberg Group, Tobias Merle, CEO - Pfannenberg Group, Earl Rogalski, President - Pfannenberg Sales America, and Ronald Ruffino, Lancaster Town Supervisor.

In announcing the celebration, Andreas Pfannenberg paid special tribute to the resources available in the Western New York Region that he says is a major contributor to the company’s success. “When we decided in the late 1990s to expand into North America from our roots in Germany, we understood that, to successfully grow the business, products for North America needed to be designed and manufactured in North America.” He added, “The Buffalo area’s long and storied manufacturing history and reputation for a strong work ethic fits our needs and supports Pfannenberg’s high quality reputation. Our North American growth is largely due to the willingness of the two cultures to work together in the spirit of learning.”

In announcing the celebration, Andreas Pfannenberg paid special tribute to the resources available in the Western New York Region that he says is a major contributor to the company’s success. “When we decided in the late 1990s to expand into North America from our roots in Germany, we understood that, to successfully grow the business, products for North America needed to be designed and manufactured in North America.” He added, “The Buffalo area’s long and storied manufacturing history and reputation for a strong work ethic fits our needs and supports Pfannenberg’s high quality reputation. Our North American growth is largely due to the willingness of the two cultures to work together in the spirit of learning.”

Tobias Merle added, “As a German family business, we are proud to develop and produce our thermal management products in Lancaster, NY. Known for offering unique value and the highest standards, our product solutions and services are trusted by some of the largest, well-known companies from around the world. Our success for the last 25 years is based on a long-term vision of growth built around high-quality products manufactured in America, our skilled employees, and our reputation as a trusted advisor to our customers. As we look forward, we welcome anyone who wants to be part of this journey for the next 25 years.”

Earl Rogalski, noted that it is an honor to be working alongside his Pfannenberg colleagues in the United States and around the world. “What makes this milestone achievement so special,” said Rogalski, “Is knowing the positive impact our colleagues are making and the solutions our products are providing – from critical life-saving infrastructure to clean drinking water. Few companies get an opportunity to celebrate 10-years, let alone 25-years. This is a fantastic achievement made possible by our dedicated and highly talented team.”

About Pfannenberg

Pfannenberg, Inc. is recognized as a leading global manufacturer of Thermal Management, Liquid Cooling Solutions and Signaling Technologies. In 1958 we invented the Filterfan®, which continues to be recognized worldwide as a leading product to help manage the temperature in electrical enclosures. Our business philosophy: Protecting People, Machine, and the Environment.

Bison Announces PowerSTAR® High-Efficiency Right Angle Gearmotor Celebrating 10 Years of Product Excellence

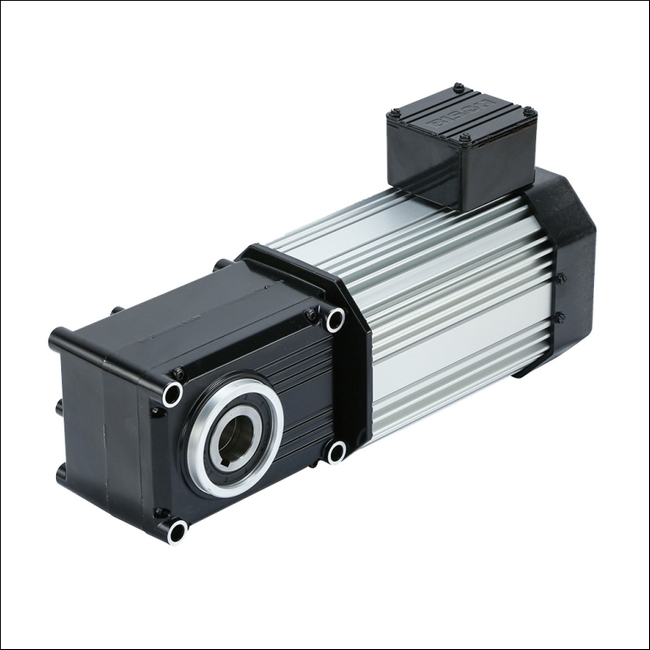

Bison Gear & Engineering Corp., a leader in the power transmission industry, announces its proven PowerSTAR® high-efficiency right angle gearmotor is celebrating 10 years of industry-leading product excellence.

Featuring advanced hypoid gearing technology for improved energy efficiency over traditional right angle worm gearmotors, PowerSTAR® offers maximum power density in a compact profile that does not compromise performance. Its sleek design offers easy mounting in several orientations, ground gearing for low noise, and a variety of frame sizes to fit numerous design specifications.

Ground gearing provides whisper-quiet operation and low backlash precision, while larger diameter pinions offer more surface area contact. With multiple tooth contact that handles larger loads at better efficiency, PowerSTAR® offset gears transmit higher torque output in a smaller profile along with high energy efficiency sustained throughout all standard gear ratios.

For more information about the Bison PowerSTAR® high-efficiency right angle gearmotor, visit www.bisongear.com.

About Bison Gear & Engineering Corp.

Bison Gear and Engineering began in 1960 by designing problem-solving gearboxes and gear motors for their customers. Today, the company has grown into an industry leader for fractional and low integral horsepower electric motor, gearmotor and gear reducer products by implementing innovative lean manufacturing processes, world class engineering and customer support teams driven by their Robusticity® design philosophy; allowing Bison to consistently expand its product line with new motion control and power transmission solutions. For more information on Bison or their products, please visit www.bisongear.com, or contact Bison directly at 1-800-AT-BISON (1-800-282-4766).

Endress+Hauser redefines the 4-20mA RTD temperature transmitter with the iTEMP TMT31

This RTD head transmitter for Pt100/Pt1000 sensors provides high measurement accuracy, flexible use, and safe operation in a multitude of process industries.

The newly developed iTEMP TMT31 temperature transmitter for analog 4-20mA signals is characterized by its long-term stability, high accuracy, and ease of use, making it an important pillar for reliable temperature measurement.

Temperature transmitters are an important link between temperature sensors in the field and higher levels of automation and analysis in the process industries.

The iTEMP TMT31 improves upon its RTD transmitter predecessors with better connection technology, available in two optimized formats. The first incorporates push-in terminals, enabling tool-free, secure field wiring in a matter of seconds. It is also available in the classic screw terminal format, with an optimized design that makes wire terminations in the connection head easier. Corrosion-free contacts ensure maximum reliability of measured value transmission for both connection variants.

For fast commissioning, users have the option to receive the TMT31 transmitter conveniently pre-configured from the factory, or to apply custom parameterization on site with free configuration software, such as Endress+Hauser FieldCare or DeviceCare. These software packages run conveniently on a host of operating systems, both on laptops and tablets. The USB configuration kits required for this, such as TXU10 or Commubox FXA291, are also available from Endress+Hauser as accessories.

Robust ratings and high reliability

The TMT31 is approved for safe operation in Zone 2 / Div. 2 hazardous areas (non-sparking) in accordance with ATEX and CSA C/US standards, along with Pt100 and Pt1000 sensors. Additionally, the sensor adjustment parameter in the head transmitter can be modified according to Callendar-Van Dusen equations (CvD) to match the connected RTD sensor characteristics, further refining the temperature measurement accuracy of the entire system.

For more information, check out the iTEMP TMT31 temperature transmitter on the web.

About Endress+Hauser

Endress+Hauser is a global leader in measurement and automation technology for process and laboratory applications. The family company, headquartered in Reinach, Switzerland, achieved net sales of approximately 2.9 billion euros (3.3 billion U.S. dollars) in 2021 with a total workforce of more than 15,000 worldwide. Endress+Hauser devices, solutions and services are at home in many industries. Customers thus use them to gain valuable knowledge from their applications. This enables them to improve their products, work economically and at the same time protect people and the environment. For further information, please visit www.endress.com.

IFF Launches SUPRO® TEX, a Breakthrough Innovation in Whole-Muscle Pieces of Plant Protein Meat Alternatives

IFF’s versatile extruded protein in an easy-to-use format features whole muscle meat texture that consumers crave, expanding plant-based food opportunities.

IFF (NYSE: IFF) have just announced the global launch of its next generation plant-based protein – SUPRO® TEX – to accelerate growth in the meat alternative category beyond ground meat burgers. This new solution unlocks the door for rapid innovation in the meat alternative space because of its unique texture and versatility. SUPRO® TEX provides a very similar texture to chunky pieces of whole muscle animal protein in an easy-to-use format that does not require major capital investment for manufacturers to begin production. Made in irregularly shaped, the new 80 percent protein SUPRO® TEX is based on soy protein, a complete, high-quality protein, comparable in quality to animal protein. As a dry product, it eliminates the need for a cold supply chain, simplifying and reducing shipping costs and storage.

“What makes SUPRO® TEX stand out in the plant-based space is – for the first time, meat alternative manufacturers can make tender, plant-based protein, whole muscle pieces or chunks without the need for major capital investments or a refrigerated supply chain,” said Michel Mellema, global innovation director of IFF’s RE-IMAGINE PROTEIN® program. “This is the latest from IFF’s RE-IMAGINE PROTEIN® program, where we accelerate the development of breakthrough ingredients and technologies to meet the needs of our customers and consumers. By combining science and creativity, we’re developing an end-to-end portfolio of plant-based solutions that pushes past traditional boundaries to change the way people eat.”

By 2035, market researchers predict that one in 10 portions of protein is likely to be plant-based1. Today, consumers of plant-based meat alternatives are primarily motivated by their health and wellbeing, yet sustainability and ethical concerns are becoming increasingly important to them. Because more than 40 percent of global consumers2 are highly interested in meat alternatives with the same taste and texture as animal-origin meat, SUPRO® TEX was designed specifically to deliver a similar meat-eating experience that consumers crave.

“This is a paradigm shift,” said Mellema. “We are expanding our offerings to more meat alternative players. Today, we have solutions and technical knowledge to support customers who use High Moisture Extrusion technology (HME), which is an excellent technology, but not necessarily suitable for all meat alternative players. That´s why we developed SUPRO® TEX – a single, easy-to-use product that can deliver similar texture to what HME products provide, but without major capital investments.”

SUPRO® TEX offers endless product design and formulation opportunities with its high-process tolerance, neutral flavor, and color. Manufacturers can easily reproduce pieces of differently textured meats just by adjusting hydration levels and custom flavor systems—imagine a tender beef bourguignon, chicken stir fry or pork fajitas—but all 100 percent plant-based.

“In a patent-pending process, soy protein is combined with other texturants to improve the firmness of the protein pieces after hydration,” explained Ulrik Madsen, culinary designer, IFF. “Due to their unique composition, SUPRO® TEX chunks retain their texture throughout manufacturing—without breaking apart when in a tumbler or simmering—as compared to typical low-moisture extruded products.”

Flavors and colors are added during the product hydration process, so they become evenly distributed and better absorbed among pieces. SUPRO® TEX pieces are gluten free and require no animal products, such as eggs, to be added to the end products to achieve optimal performance.

For more information about the SUPRO® TEX, visit here.

1. BCG Food for Thought, The Protein Transformation, 2021

2. Protein Report, Health Focus International, 2021

About IFF’s Nourish

At IFF, we’re united by a common goal: to apply science and creativity for a better world. Across our business divisions, we’re on a mission to Do More Good for our people, customers, and communities.

To us, “nourish” means “to feed with purpose” — and we’re here to redefine the industry by nourishing people, products, and our planet. Every day, our teams are boldly reimagining and pioneering the next generation of food and beverage experiences. We’re leveraging our industry-leading product portfolio, unmatched innovation capabilities, and customer-centric approach to become the partner for essential solutions. Let’s nourish the future, together.

Welcome to IFF

At IFF (NYSE: IFF), an industry leader in food, beverage, health, biosciences and scent, science and creativity meet to create essential solutions for a better world – from global icons to unexpected innovations and experiences. With the beauty of art and the precision of science, we are an international collective of thinkers who partners with customers to bring scents, tastes, experiences, ingredients and solutions for products the world craves. Together, we will do more good for people and planet. Learn more at iff.com

Kongsberg Digital launches a new application to optimize drilling and well operations in real time

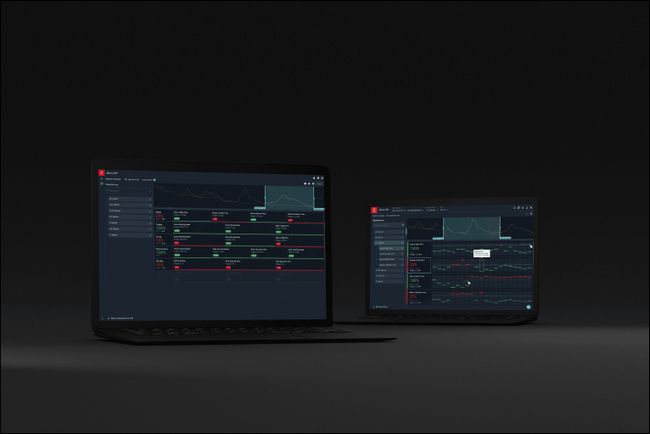

Kongsberg Digital has launched a new application at ADIPEC, which will enable operators in the energy sector to follow their key performance indicator (KPI) progress on drilling and well operations in real time.

Invisible lost time (ILT) – the difference between actual operational duration and a best practice target - is a known challenge when delivering wells. Without effective measurement, it is impossible to optimize best practice processes. KPIs are a proven method of increasing well delivery time efficiency and reducing costs through target-driven metrics. By using a proprietary algorithm, real time data and conditions-based logic can be integrated, analysed, and applied to track bespoke KPIs and identify further areas for efficiencies across teams, processes, and technology.

This holistic, target driven performance analysis across multiple operations, covering various rigs and wellbores, quickly removes human bias and monitors real time performance, providing a high level, easy to interpret view of project status.

As an industrial software company, Kongsberg Digital provides SaaS solutions to enable asset-to-cloud data infrastructure, automatic contextualization, capturing and aggregating quality data cost-effectively and securely.

The KPI application will be offered as part of the company’s innovative SiteCom platform, utilizing its Industrial Work Surface to provide a complete ecosystem for safer and reliable drilling and wells operations, leveraging decades of experience and complex data to enable effective and efficient decision-making.

By combining crew information and operational reporting, Kongsberg Digital KPI application benefits from an additional layer of qualification and testing.

Pedro Alcântara Nunes Neto, Senior Vice President at Kongsberg Digital, said: “Providing the industry with a joint Industrial Work Surface to optimize workflows and operations is how digitalization really proves its value. Our new KPI application proactively conceptualizes holistic solutions to provide real-time data, predictive tools, processes, and expertise to our customers’ fingertips, ensuring workers are able to translate real-time data on performance indicators into appropriate actions, across the world.

“ADIPEC is an important and strategic event for Kongsberg Digital. The UAE and the wider region are vitally important to ensure global energy security, and one in which we want to extend our geographic footprint.”

Kongsberg Digital is exhibiting on stand 9110 at ADIPEC as part of the Innovation Norway delegation.

KONGSBERG DIGITAL

Kongsberg Digital is a provider of next-generation software and digital solutions to customers within maritime, oil and gas, and renewables and utilities. The company consists of more than 1000 software experts with leading competence within the internet of things, smart data, artificial intelligence, maritime simulation, automation, and autonomous operations.

Follow us on: www.kongsberg.com/digital

West of Orkney Windfarm successfully completes offshore and nearshore survey campaign

The developer of the West of Orkney Windfarm has completed its 2022 offshore surveys for the project area, located around 25km north of the Sutherland coast.

The 2 GW project is a joint venture comprising Corio Generation, TotalEnergies and Renewable Infrastructure Development Group (RIDG) and is scheduled to be generating electricity by 2029.

This milestone achievement covered geophysical and benthic surveys of the seabed across the 657km2 offshore option agreement area, with the objective of establishing the project ground model and habitats map. In addition, nearshore geophysical and geotechnical surveys were completed along the offshore cable corridors.

“We are delighted the seabed survey work has been completed safely, on schedule and within budget, with no lost time incidents. This leaves the project ideally placed to advance our windfarm design and progress with our consent applications next year as planned,” said Stephen Kerr, Project Director of the West of Orkney Windfarm.

“The offshore geophysical survey work covered an area of leased seabed 1.5 times the size of Edinburgh and, during the six-month programme, the main survey vessel travelled more than 17,000 kilometres – equivalent to the distance between London and Sydney. The geotechnical campaign included 50 cone penetration tests and 50 vibrocores along the cable route. The nearshore survey vessels covered over 500km in total.

“I’d like to thank the survey management team at TotalEnergies UK Offshore Wind Hub, our advisers OWC, and survey contractors Ocean Infinity and Spectrum, who worked diligently through a long campaign to deliver excellent results. I would also like to thank the licencing team at Marine Scotland for their support, Crown Estate Scotland and the local fishers, who have engaged positively with us throughout,” added Stephen.

The offshore seabed surveys commenced in early April 2022, with seabed survey specialists Ocean Infinity using their vessels MV Relume and MV Geo-Ranger, operating out of Scrabster Harbour. Ocean Infinity was also responsible for the shallow geotechnical work on the cable corridor whilst the nearshore geophysical survey was completed by Spectrum using the vessels Spectrum 1 and Spectrum Nyquist and a photogrammetry aerial drone.

The information collected, alongside three seasons of bird and marine mammal surveys which were completed in September, keeps the West of Orkney team on track to submit onshore and offshore consent applications next summer.

The bird and marine mammal surveys were carried out by HiDef Aerial Surveying Limited using high-resolution digital cameras mounted on aircraft. This high-definition information gives the project confidence they are recording and identifying all of the different species that which might be found at the offshore windfarm site.

In January 2022 the West of Orkney Windfarm secured the rights to an area of seabed from the Crown Estate Scotland in the highly competitive ScotWind process.

About RIDG

RIDG – Renewable Infrastructure Development Group – is an independent, specialised offshore wind project development company with the knowledge and experience to identify and deliver high quality consented assets for strategic partners to build and operate.

RIDG presents a simpler, leaner and more flexible approach to project development, one that draws upon the strengths of both established and emerging suppliers to deliver projects safely, efficiently and cost effectively.

About Corio Generation

Corio Generation is a specialist offshore wind business, dedicated to harnessing renewable energy worldwide. With a unique blend of sector-leading expertise and deep access to long-term capital, we work closely with our partners in the creation and management of projects from origination, development and construction, and into operations.

Our 20+ GW offshore wind development portfolio is one of the largest in the world, spanning established and emerging markets, as well as floating and traditional fixed-bottom technologies. These next generation offshore wind projects will help form the backbone of the net-zero global energy system while meeting the energy needs of communities and corporate offtakers sustainably, reliably, safely and responsibly.

Corio Generation is a Green Investment Group (GIG) portfolio company, operating on a standalone basis. GIG is a specialist green investor within Macquarie Asset Management, part of Macquarie Group.

About TotalEnergies

TotalEnergies is a global multi-energy company that produces and markets energies: oil and biofuels, natural gas and green gases, renewables and electricity. Our more than 100,000 employees are committed to energy that is ever more affordable, cleaner, more reliable and accessible to as many people as possible. Active in more than 130 countries, TotalEnergies puts sustainable development in all its dimensions at the heart of its projects and operations to contribute to the well-being of people.

Silver Fox targets growth after coordinated investment drive

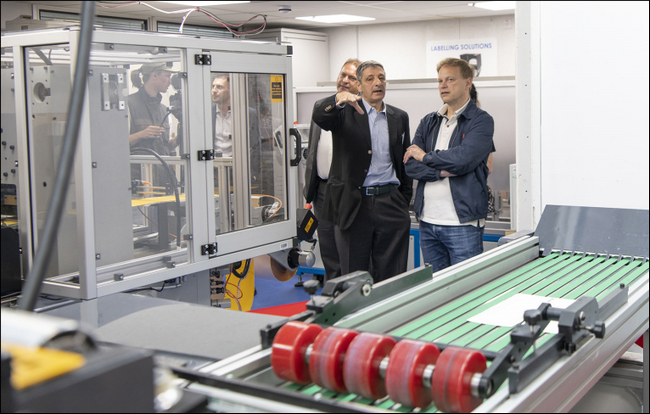

A Hertfordshire manufacturer that supplies its labelling solutions to companies such as ABB, London Underground, Mitsubishi, Network Rail and Vodafone is looking to expand after tapping into expert support.

Silver Fox Ltd has continued to invest in new plants and machinery throughout Covid-19 and, when combined with specialist external assistance, this has helped it grow considerably over the last twelve months.

The family-run business has benefitted from accessing industry knowledge through the Manufacturing Growth Programme (MGP), an initiative designed for SMEs, funded by the European Regional Development Fund and delivered by Oxford Innovation Advice.

“We design, develop and manufacture highly durable labelling solutions, particularly for the electrical instrumentation, data, and telecoms sectors. We’re also seeing growing success in the process sector,” explained Nick Michaelson, Director at Silver Fox Ltd.

“One of our innovations is an industry-leading product called the Fox-in-a-Box®, which means clients can print our entire range of thermal labels all from one software, one printer and one ribbon.”

He continued: “This includes the highly durable Fox-Flo® tie-on cable label, which is both UV-stable and Low-Smoke Zero-Halogen. This makes it ideal for use trackside on Network Rail, in tunnels with the London Underground and across oil and gas, pharmaceuticals, data centres, public buildings and the rapidly expanding renewables sectors.”

Silver Fox, which was the first manufacturer in Hertfordshire to become carbon-negative in 2020, is a strong advocate of MGP and the specialist support it has provided.

It is urging other SMEs to tap into the remaining grants available for business improvement projects and is calling on management teams to throw their support behind the initiative as the new funding landscape is being formed.

“Industry really needs to make the most of the Manufacturing Growth Programme whilst it is here and, importantly, ensure that it is still around when the new support packages are announced,” added Nick.

“It is a helpful service, and it makes the process so easy. The impact is immediate, and we’ve also looked at using the specialist support to complement our own long-term solutions for our business.”

Amanda Freeland, MGP’s Manufacturing Growth Manager for Hertfordshire, concluded: “The company is a great example of a specialist firm that has really served its marketplace, formed strong connections with very large clients by making products that are world-beating.

“In addition, it is a carbon-negative company that builds sustainability into everything it does, from investment in energy savings and process improvements, to reductions in plastic waste and choosing biodegradable materials in its packaging for example.”

As the business grows during these challenging times, it is likely that Silver Fox will also be looking to expand its workforce in the months to come.

For further information, please visit www.manufacturinggrowthprogramme.co.uk or www.silverfox.co.uk

Brenntag acquires Tech Management (dba), building one of the largest platforms for energy business solutions in North America

Brenntag the global market leader in chemicals and ingredients distribution, has just announced the acquisition of Tech Management (dba), a leading solutions provider for proprietary formulations and on-site services directly to operators in the energy sector in the Permian Basin. This is the largest energy producing region in North America, fostering Brenntag’s resilience in this market against the background of shifts on the global energy market and will accelerate the creation of a dedicated energy service platform.

Steven Terwindt, Member of the Management Board of Brenntag Group and COO Brenntag Essentials: “I look forward to welcoming our new colleagues from Tech Management (dba) to the Brenntag family. The company’s formulation expertise and state of the art laboratory facilities are a welcome addition to Brenntag’s Energy Services business in North America, providing a further pillar to our resilient market offerings in the energy sector and filling a vital support role in a region critical to global energy security.”

Steven Terwindt, Member of the Management Board of Brenntag Group and COO Brenntag Essentials: “I look forward to welcoming our new colleagues from Tech Management (dba) to the Brenntag family. The company’s formulation expertise and state of the art laboratory facilities are a welcome addition to Brenntag’s Energy Services business in North America, providing a further pillar to our resilient market offerings in the energy sector and filling a vital support role in a region critical to global energy security.”

Founded as Hughes Chemical in 2009, Globe Chemical, LLC d/b/a Tech Management has its headquarters and blending facility located in Odessa, TX, with ten additional operating facilities in West Texas, New Mexico and Oklahoma.

Scott Leibowitz, Regional President Brenntag Essentials highlights: “The acquisition represents a strategic opportunity to complement our leadership position in the US while helping our customers produce energy in an efficient and safe manner. Tech Management’s research and support colleagues will provide another center of excellence for innovation for Brenntag.”

The acquired business had sales of USD 85 million in the financial year 2021. Signing and closing of the transaction took place simultaneously.

About Brenntag:

Brenntag is the global market leader in chemicals and ingredients distribution. The company holds a central role in connecting customers and suppliers of the chemical industry. Headquartered in Essen, Germany, Brenntag has more than 17,000 employees worldwide and operates a network of about 700 sites in 78 countries. In 2021, Brenntag generated sales of around 14.4 billion EUR. The two global divisions, Brenntag Essentials and Brenntag Specialties, provide a full-line portfolio of industrial and specialty chemicals and ingredients as well as tailor-made application, marketing and supply chain solutions, technical and formulation support, comprehensive regulatory know-how, and digital solutions for a wide range of industries. In the field of sustainability, Brenntag pursues specific goals and is committed to sustainable solutions in its own sector and the industries served. Brenntag shares have been listed at the Frankfurt Stock Exchange since 2010, initially in the MDAX and since September 2021 in the DAX. In addition, the Brenntag SE shares are listed in the DAX 50 ESG and DAX ESG Target. For more information, visit www.brenntag.com.