Super User

Pfannenberg USA Highlights Liquid Cooling Solutions for Industrial Electronics

Sealed enclosure cooling solutions ideal for extreme indoor or outdoor environments

Pfannenberg, Inc., a leading global manufacturer of thermal management and signaling technologies, highlights its high-efficiency liquid cooling solutions for industrial electronics. Pfannenberg EB 2.0 Large Packaged Chillers and PWS Series Air to Water Heat Exchangers provide contaminant-free, cost-effective component cooling without adding heat to the local environment.

Closed-loop liquid cooling efficiently and economically improves performance for advanced manufacturing processes and electronics in hot, dirty environments using field-proven water circulation technology. Designed to guarantee full separation of water lines and airflow paths, Pfannenberg liquid cooling systems feature integrated electronic thermostats and flow control components for accurate temperature control and superior energy efficiency. Liquid cooling offers an ideal cooling solution for spindle motors and automation drives in automotive manufacturing, power plant electronics and solar inverters in energy production, and oven controls and product coolers/dryers in pharmaceutical production, as well as for paper & printing, plastic manufacturing, ozone sanitization, and water/wastewater applications.

EB 2.0 Large Packaged Chillers

Compact Pfannenberg EB 2.0 Large Packaged Chillers allow maximum cooling capacity in the smallest possible footprint. Heavy-duty finned-tube condensers deliver high efficiency and long service life in hot, corrosive, or dirty ambient environments.

Models range up to 30 Tons, so proper capacity is available for most applications, while all units are ready to use after simple installation—requiring only piping and power. Remote start/stop capability and insulated vented polypropylene reservoir tanks for rapid heat load changes provide reliable and flexible operation.

For more information watch our video: https://www.youtube.com/watch?v=T7h3XHAu-38

PWS Air to Water Heat Exchangers

Pfannenberg PWS Air to Water Heat Exchangers deliver energy efficiency and high cooling capacity with a maintenance-free design for indoor and outdoor applications. Featuring a closed-loop design, PWS Air to Water Heat Exchangers seal contaminants out by isolating ambient air from the internal air circuit.

These units are utilized in a variety of applications including extreme environments such as plant washdown areas, and areas with high amounts of particulate, high ambient temperatures, or an oily or aggressive atmosphere. PWS Air to Water Heat Exchangers maintain a UL Tested NEMA Type 12/3R/4 seal against enclosure, and a stainless-steel option offers NEMA Type 4X protection. This NEMA 4/4x protection makes the units ideal for wastewater processing and ozone sanitization control cabinet applications where protection from corrosion is paramount.

If a water source is not available on site, facilities can combine Pfannenberg PWS Air to Water Heat Exchangers with Pfannenberg EB 2.0 Large Packaged Chillers for an efficient closed cooling solution.

Visit the EB 2.0 Large Packaged Chillers page and the Air to Water Heat Exchangers page to learn more.

About Pfannenberg

Established in 1954 by Otto Pfannenberg in Hamburg Germany, Pfannenberg is recognized as a leading global manufacturer of thermal management technologies within the Electro-technology Industry. In 1958 we invented the Filterfan®, which continues to be recognized worldwide as a leading product to help manage the temperature in electrical enclosures. Our business philosophy: Protecting Man, Machine and the Environment.

Nouryon expands technical capabilities of Application Development Centers in Europe and North America

Nouryon, a global specialty chemicals leader, have just announced the expansion of the company’s Application Development Centers in Deventer, the Netherlands and Chattanooga, Tennessee, US, to offer advanced technical service capabilities dedicated to cleaning in Europe and North America. The expansion accelerates meaningful and sustainable innovation to meet the evolving needs of the cleaning market, while supporting the company’s existing global network of Application Development Centers.

Nouryon’s advanced technical service capabilities offer advanced performance-in-use testing for hard surface cleaning, dishwashing, and laundry applications, with the ability to evaluate processes under household, industrial, and institutional conditions. These capabilities will also support advanced analytical competencies, ecotoxicity development, and regulatory compliance.

“Collaboration with our customers is critical for accelerating the development of novel, high-efficiency, and more sustainable cleaning solutions,” said Suzanne Carroll, Senior Vice President of Nouryon’s Home and Personal Care Business. “Our investment marks an expansion in resources, equipment, and technical competency allowing us to enhance our essential solutions and deliver more robust value to our customers.”

“Collaboration with our customers is critical for accelerating the development of novel, high-efficiency, and more sustainable cleaning solutions,” said Suzanne Carroll, Senior Vice President of Nouryon’s Home and Personal Care Business. “Our investment marks an expansion in resources, equipment, and technical competency allowing us to enhance our essential solutions and deliver more robust value to our customers.”

Nouryon offers a portfolio of innovative, high-performance sustainable surfactants, hybrid polymers and solutions developed to address major cleaning formulation challenges and is a leading producer of high-performing, biodegradable chelates worldwide.

“We are excited to expand our technical capabilities to enable our teams to work even more closely with our global customers, furthering the development of collaborations that will advance sustainable innovation,” said Brad Pearson, Nouryon Business Director for Cleaning Goods.

In 2022, Nouryon also announced that it had commissioned a biodegradable chelates production facility in the Netherlands to meet growing consumer demand for eco-friendly auto dishwashing and liquid laundry products, complementing the company’s existing plants in Ningbo, China and Lima, Ohio, US.

Nouryon has application development centers for the cleaning end-market in Deventer, the Netherlands, Stenungsund, Sweden, as well as in Bridgewater, New Jersey and Chattanooga, Tennessee, US.

Nouryon was awarded an EcoVadis Platinum rating for its sustainability performance in 2022. Visit Nouryon.com to learn more about its sustainable solutions for a variety of cleaning applications.

About Nouryon

Nouryon is a global, specialty chemicals leader. Markets and consumers worldwide rely on our essential solutions to manufacture everyday products, such as personal care, cleaning goods, paints and coatings, agriculture and food, pharmaceuticals, and building products. Furthermore, the dedication of more than 7,650 employees with a shared commitment to our customers, business growth, safety, sustainability and innovation has resulted in a consistently strong financial performance. We operate in over 80 countries around the world with a portfolio of industry-leading brands. Visit our website

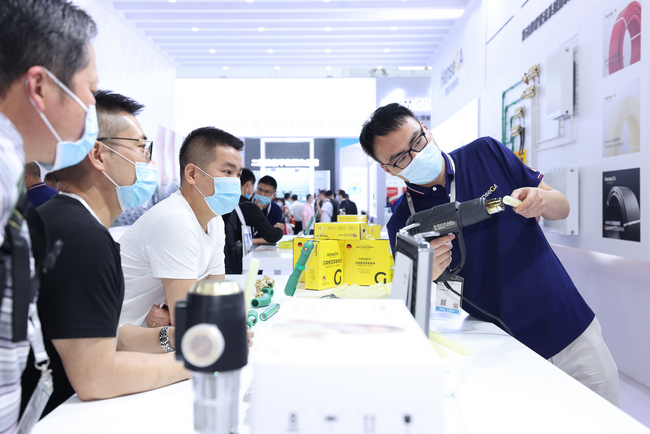

ISH China & CIHE to return in May 2023 with restructured product zones supporting industry growth

ISH China & CIHE – China’s leading international trade fair for Heating, Ventilation, Air-Conditioning, Sanitation & Home Comfort Systems has confirmed the dates and venue for its 2023 edition, taking place from 11 – 13 May at the China International Exhibition Center (Shunyi Hall) in Beijing. Organised by Messe Frankfurt (Shanghai) Co Ltd and CIEC GL events (Beijing) International Exhibition Co Ltd, the show will once again present fairgoers with trend-setting HVAC, plumbing, smart heating and home comfort technologies and products in the Chinese and wider Asian markets. The upcoming edition will continue to hone in on the “Energy”, “Water” and “Life” themes, which are in line with China’s national development strategies. In total, the fair is expected to welcome over 1,300 exhibitors across 106,800 sqm of exhibition space.

The ‘carbon peak’ and ‘carbon neutrality’ policies highlighted in the Chinese government’s 14th Five-Year Plan underlines a commitment by the country to generate energy through reform and innovation. These new reforms offer strong prospects not only to China’s renewable energy and energy storage markets but also inherently changes China’s modern energy systems while bringing new opportunities to the HVAC industry, particularly for the heat pumps market. To adhere to the government’s initiatives and energy infrastructure optimisation targets, manufacturers are actively developing energy-efficient HVAC solutions, specifically refining heat pumps and revolutionary energy storage technologies to meet the stringent carbon emission regulations. By recognising the benefits in the efficiency and flexibility of heat pump technologies, paired with the central government’s goal to strengthen domestic capabilities in all core energy storage technologies, intelligent and green HVAC technologies will continue to be key development focuses for manufacturers.

Apart from the booming heat pump market in China, according to the 2022 China Heat Pump Industry Development Report by the Heat Pump Committee of China Energy Conservation Association, China is currently the largest heat pump exporter in the world. In the first seven months of 2022, China’s exports of air source heat pumps increased by 63.7% year-on-year[1]. A recent report titled the Future of Heat Pumps by International Energy Agency estimated by 2030, total sales of heat pumps in the EU will reach 7 million units[2]. With lucrative opportunities for domestic and overseas markets, renowned brands worldwide require an effective platform to spark new business opportunities. Brands to participate in ISH China & CIHE 2023 include A.O Smith, ARCIO, BDR, Beiming Tianshi, DAB, Danfoss, Devotion, Dooch, GREE, Grundofs, Haier, Hailin, Kiturami, Koate, Leo, Micoe, Midea, New Energy, NORTIZ, OUTES, PHILIPS, Phnix, Ploumeter, Rinnai, Shengneng, Shiteng, Siemens, Tongfang, Unbeatable, Vanward, Wilo and others.

Specialised display areas, zones and pavilions to be a major highlight at ISH China & CIHE

For over two decades, the fair’s thematic zones have become the key component to its success. The 2023 edition will again highlight the returning German Pavilion, Overseas Area, Water Pump Zone, Floor Heating and Cooling System Area and Clean Energy District Heating Area. This year’s fair will also feature the new Minibox Service Area located in the Overseas Area. It is a business matching platform at ISH China & CIHE, which aims to bridge domestic suppliers with overseas buyers who cannot physically attend the fair. Running throughout the full duration of the fair, the Minibox Service Area serves as a marketing tool for local suppliers to promote their latest innovations and technologies abroad.

With ISH China & CIHE’s mission to showcase some of the world’s most energy efficient HVAC solutions, the organisers are bringing this to the fore through their cooperation with Trade Commissioner Service (TCS) of the Embassy of Canada to China. Canada is renowned for their harsh winters, with many regions reaching subarctic climates. To combat the extreme climate, not too dissimilar to the winters in China, Canadian HVAC manufacturers will showcase the latest additive manufacturing technologies and applications in Canada. The Trade Commissioner Service (TCS) of the Embassy of Canada to China will group their members in a pavilion to expand their overseas market, and to boost the development for companies in the Chinese HVAC industry.

Concurrent events highlight opportunities for growth and innovation

As an integral part of ISH China & CIHE, a series of concurrent events will be held during the fair with many well-known HVAC industry experts present to exchange ideas and introduce technologies that will drive the industry forward. Responding to a series of national policy goals, specifically on peak carbon dioxide emissions and carbon neutrality, ISH China & CIHE will offer various summits, seminars and conferences, focusing on the fair’s three core themes: “Energy” (the latest heating solutions paired with renewable energy sources), “Water” (water pumps, valves and fittings) and “Life” (home comfort products and solutions). These events will create a comprehensive platform for fairgoers to expand their knowledge through learning more about the latest industry trends. Some of the highlighted topics featured at the fair include:

- The China International HVAC Congress (iHVAC)

- China Innovative Heating Products and Technologies

- Fresh Air Systems

- Home Comfort Intelligent Development Forum

- Air Source Heat Pump Heating Technologies

- FCH Cooling & Heating System Technology Forum

ISH China & CIHE will take place from 11 – 13 May 2023, once again at the China International Exhibition Center (Shunyi Hall) in Beijing. A further ISH event in China, ISH Shanghai & CIHE, will be held in Autumn of 2023 at the Shanghai New International Expo Centre. For more information about ISH China & CIHE and ISH Shanghai & CIHE, please visit www.ishc-cihe.hk.messefrankfurt.com.

ISH China & CIHE is organised by Messe Frankfurt (Shanghai) Co Ltd and CIEC GL events (Beijing) International Exhibition Co Ltd. It is headed by the biennial ISH event in Frankfurt, Germany, the world’s leading trade fair for HVAC + Water which will next take place from 13 – 17 March 2023. For more information, please visit www.ish.messefrankfurt.com.

TotalEnergies EP Canada acquiert une participation additionnelle dans Fort Hills, en vue de son spin-off

In the context of its future spin-off, TotalEnergies EP Canada Ltd announces that it has exercised its preemption right to acquire an additional 6.65% interest in the Fort Hills Energy Limited Partnership and associated sales and logistics agreements from Teck Resources Limited, for a consideration of 312 million Canadian Dollars.

Fort Hills is located 90 kilometers North of Fort McMurray in the Province of Alberta. Prior to the transaction, TotalEnergies EP Canada held a working interest of 24.58% in the Fort Hills project, and after the transaction it will hold 31.23%. TotalEnergies EP Canada also holds a 50% working interest in the Surmont project located in the region.

Fort Hills is located 90 kilometers North of Fort McMurray in the Province of Alberta. Prior to the transaction, TotalEnergies EP Canada held a working interest of 24.58% in the Fort Hills project, and after the transaction it will hold 31.23%. TotalEnergies EP Canada also holds a 50% working interest in the Surmont project located in the region.

In line with its low-carbon strategy, TotalEnergies announced in September 2022 its intention to exit Canadian oil sands by spinning off TotalEnergies EP Canada in 2023. Through the acquisition of an additional interest in Fort Hills, TotalEnergies EP Canada is building the future for the spin-off entity in an asset with long-term growth potential. The spin-off is planned to be submitted to vote at TotalEnergies’ annual Shareholders’ Meeting in May 2023.

“By seizing this opportunity to grow its business under attractive conditions, TotalEnergies EP Canada will deliver value to the future shareholders of the spin-off entity”, said Jean-Pierre Sbraire, CFO of TotalEnergies.

About TotalEnergies

TotalEnergies is a global multi-energy company that produces and markets energies: oil and biofuels, natural gas and green gases, renewables and electricity. Our 100,000 employees are committed to energy that is ever more affordable, cleaner, more reliable and accessible to as many people as possible. Active in more than 130 countries, TotalEnergies puts sustainable development in all its dimensions at the heart of its projects and operations to contribute to the well-being of people.

Fugro’s Geo-data supports development of UK’s first flexible power station with carbon capture technology

Fugro has been awarded a ground investigation contract for SSE Thermal and Equinor’s planned Keadby 3 Carbon Capture Power Station in North Lincolnshire. When complete, Keadby 3 could become the UK’s first flexible power station equipped with carbon capture technology, capable of capturing up to 1.5 million tonnes of carbon annually. The acquired Geo-data will enable stakeholders to understand ground conditions and make informed decisions during the engineering, design and construction phases of this project.

With fieldwork underway, Fugro is performing a range of in-depth geotechnical assessments as well as in situ testing to deliver a comprehensive set of factual ground data at the Keadby 3 site. Fugro will further support the development of Keadby 3 with interpretative reporting for site specific engineering, allowing design and ground engineering specialists to solve or avoid engineering challenges, manage ground related risk, and associated project costs.

With a generating capacity of up to 910 MW, Keadby 3 will use natural gas as its fuel and will be fitted with a carbon capture plant to remove the CO2 from its emissions. In December 2022, it became the first power carbon capture and storage (CCS) project in the UK to receive planning permission.

Fugro engineers on site at Keadby 3

Fugro engineers on site at Keadby 3

Matthew Chappell, Fugro’s Service Line Director of Site Investigation said: “We’re proud to play a part in the development of what could be the UK’s first flexible power station. CCS plays a key role in realising the UK’s emission reduction targets aligning directly with Fugro’s purpose of working together to create a safe and liveable world. With our Geo-data, ground characteristics and behaviours can be confidently determined, and potential hazards identified, allowing solutions to be modelled and managed. We look forward to continuing to support the UK’s energy transition and assist SSE Thermal and Equinor as they prepare for future developmental phases of this critical project.”

About Fugro

Fugro is the world’s leading Geo-data specialist, collecting and analysing comprehensive information about the Earth and the structures built upon it. Adopting an integrated approach that incorporates acquisition and analysis of Geo-data and related advice, Fugro provides solutions. With expertise in site characterisation and asset integrity, clients are supported in the safe, sustainable and efficient design, construction and operation of their assets throughout the full lifecycle.

Employing approximately 9000 talented people in 59 countries, Fugro serves clients around the globe, predominantly in the energy, infrastructure and water industries, both offshore and onshore. In 2021, revenue amounted to EUR 1.5 billion. Fugro is listed on Euronext Amsterdam.

Jebens: The perfect wave

Flame-cut parts for wave power plants based on the pumping principle of the human heart

Image 1: Before flame cutting in several levels, the 270 millimetre thick fine grained S690 QL1 structural steel was preheatedGenerating power from renewable energies has a crucial role to play in curbing global warming and reducing climate-damaging carbon dioxide (CO2). The use of wave energy to generate electricity can sustainably support the mix of 100 per cent renewable energies. Inspired by the pumping principle of the human heart, the Swedish company CorPower Ocean AB has been working intensively for more than ten years on the development of wave power plants for commercially viable generation of electricity. For the construction of the full-scale prototype, the researchers from Stockholm relied on the integrated expertise of Jebens GmbH, a specialist in bespoke steel work based in Korntal-Münchingen.

Image 1: Before flame cutting in several levels, the 270 millimetre thick fine grained S690 QL1 structural steel was preheatedGenerating power from renewable energies has a crucial role to play in curbing global warming and reducing climate-damaging carbon dioxide (CO2). The use of wave energy to generate electricity can sustainably support the mix of 100 per cent renewable energies. Inspired by the pumping principle of the human heart, the Swedish company CorPower Ocean AB has been working intensively for more than ten years on the development of wave power plants for commercially viable generation of electricity. For the construction of the full-scale prototype, the researchers from Stockholm relied on the integrated expertise of Jebens GmbH, a specialist in bespoke steel work based in Korntal-Münchingen.

The human heart uses stored hydraulic pressure to generate force for recoil. This means that the heart muscles only have to pump the blood in one direction. CorPower Ocean relies on this principle for its wave energy converters (WEC), which use wave pressure to generate energy in two directions. WECs are buoy-shaped point absorbers that are pulled down by a pre-tensioning system. An upward wave surge pushes the buoy upwards and the resulting stored pressure pushes it down again. The mechanical energy of the waves is first converted into linear movement along the buoy axis and then - through a cascade reducer comparable to a planetary gear - into rotary movement. A drive train inside the buoy, known as the Power Take Off (PTO), converts this movement into electricity. The oscillating movement of the buoy, which is optimally attuned to each wave, ensures even energy production in both directions.

According to CorPower Ocean, the amount of energy generated per tonne is five times higher than with previously known wave technologies. Several WECs are concentrated into grid-connected wave farms in so-called CorPack wave clusters. Despite having only a minor visual impact on the ocean scenery, the Swedish company claims they can deliver up to three times as much electricity per area of ocean compared to typical offshore wind farms. Generators and power electronics correspond to the standard components used by the wind industry and can therefore be connected to the existing grid infrastructure. The joint use allows complementary energy generation from wind and wave power. System prototypes have been trialled by CorPower Ocean on an increasingly large scale in extensive test series in the laboratory and during operations on the high seas to determine their reliability and performance capability.

Flame-cut parts for full-scale prototypes

Image 4: Jebens manufactured three different flame cut parts for the prototype of the C4 wave energy converter from 270 millimetre thick S690 QL1 fine grain structural steel, including this componentFor the C4 wave energy converter - the first full-scale prototype - the researchers relied on the integrated expertise of Jebens, a specialist in large, heavy flame-cut parts, mechanical machining and complex welding assemblies. A first assignment for the system provider of precision steel work was to find a suitable corrosion-resistant coating. The size of the component was a particular challenge in view of the limited bath sizes. However, the proven experts in Jebens' purchasing department found a supplier with a suitably large bath that was able to implement the 50-micron-thick nickel plating. Jebens also undertook the entire project management associated with this coating. A short time later, Jebens received another urgent order from the Swedish developers: the production of three large flame-cut parts with complex geometry made of high-strength fine-grained S690 QL1 structural steel in the exceptional plate thickness of 270 millimetres. This also involved the task of testing four material samples from this steel for possible structural changes. As Jebens’ warehouse is one of the largest in Europe for thick, large plates, the company also had this exceptional thickness in stock in the required quality and size. This ensured the rapid completion of the order, as the supply of such a plate would have meant a delay of many months.

Image 4: Jebens manufactured three different flame cut parts for the prototype of the C4 wave energy converter from 270 millimetre thick S690 QL1 fine grain structural steel, including this componentFor the C4 wave energy converter - the first full-scale prototype - the researchers relied on the integrated expertise of Jebens, a specialist in large, heavy flame-cut parts, mechanical machining and complex welding assemblies. A first assignment for the system provider of precision steel work was to find a suitable corrosion-resistant coating. The size of the component was a particular challenge in view of the limited bath sizes. However, the proven experts in Jebens' purchasing department found a supplier with a suitably large bath that was able to implement the 50-micron-thick nickel plating. Jebens also undertook the entire project management associated with this coating. A short time later, Jebens received another urgent order from the Swedish developers: the production of three large flame-cut parts with complex geometry made of high-strength fine-grained S690 QL1 structural steel in the exceptional plate thickness of 270 millimetres. This also involved the task of testing four material samples from this steel for possible structural changes. As Jebens’ warehouse is one of the largest in Europe for thick, large plates, the company also had this exceptional thickness in stock in the required quality and size. This ensured the rapid completion of the order, as the supply of such a plate would have meant a delay of many months.

The Swedish company could also count on Jebens' expertise in material analysis. The required flame-cut parts - one which was 270 millimetres thick, 555 millimetres wide and 1,020 millimetres long and two others of the same thickness but only 310 millimetres wide and 725 millimetres long - had to be cut in several levels for the specified structure. This required cutting in several levels with frequent turning - a speciality of the experts at Jebens. In view of the large plate thickness, they first pre-drilled the material with a particularly powerful drilling device. The channels created ensured that the flame passed through exactly as intended. The Swedish customer was highly satisfied with the implementation of the complete package of material supply, manufacturing, sophisticated mechanical processing, coating and dimensional specification. Two further orders and various new enquiries were therefore not long in coming.

Jebens GmbH

As a leading specialist for heavy flame-cut components, mechanical processing and welded structures with weights of up to 160 tonnes per item, Jebens GmbH regularly sets standards in its locations in Korntal-Münchingen and Nördlingen. With seven-stage manufacture of products from eight to 1,400 mm, widths up to 5,000 mm and lengths up to 20,000 mm Jebens stands for precision steelwork. As a subsidiary of the most important heavy plate manufacturer worldwide, Dillinger, Jebens has access to technologically pioneering steel know-how at all times. Leading technology, the most modern machines and systems, as well as the largest annealing furnace in Southern Germany, make Jebens the experts for demanding jobs.

Midtherm lasers in on growth after £1.2m machine investment

A specialist sub-contract laser cutting and forming specialist is reaping the operational and environmental benefits of a £1.2m machine investment.

Midtherm Laser, which employs 45 people at its factory on Peartree Lane in Dudley, has increased its capacity and speed of processing thanks to the installation of a new Bystronic Bystar Fiber 12kW laser with part automation.

One of the largest purchases in its 23-year history introduces the next level of power in fiber laser cutting and will help the company deliver high cutting dynamics and thin to thick cutting capabilities to a customer base that spans aerospace, automotive and decorative work to food processing, agricultural and conveyors.

It has also made a massive difference to the firm’s environmental performance, with the Bystronic model replacing two older CO2 machines and is already delivering a 50% energy saving – the equivalent of powering 2100 average homes every month.

“Our expertise in laser cutting and metal forming is respected throughout our sector and has led to us increasing sales by a further 6% last year, a great achievement considering the volatility of the market,” explained Mark Hannon, Director of Midtherm Laser.

“The knowledge of our experienced people is one of our greatest strengths and we like to complement this with a sustained investment programme that incorporates the latest technology into our production processes.”

He went on to add: “The 12kW Bystar Fiber is a class leading machine that can cut from 0.5mm to 30mm in mild steel, aluminium, and a host of other materials. It gives us more capacity to target new opportunities and, importantly, means three quarters of our machines are now fiber technology instead of gas.

“With this in mind, and when you consider we have also invested in LED lighting, sensor switches and electric vehicles and charging for our staff on the road, it’s not difficult to see how we have managed to cut our energy usage in half since 2018.”

Midtherm was originally established in 1968 by Ray Andrews and operated through sister companies offering powder coating, enamelling and UV flues.

There was a laser cutting machine that was occasionally being used at one of the factories and the decision was taken in 2000 to put it to better use by creating a ‘laser’ business that initially employed just three people.

With orders starting to take off, Ray’s son Richard Andrews moved the business to its current 20,000 sq ft factory on Peartree Lane in Dudley in 2004, with the next big milestone taking place in 2018 when Mark Hannon replaced Dean Cockayne as Director and took over the operation alongside Richard and Kate Birt.

Today, Midtherm Laser works with more than 500 companies across 20 different sectors, cutting or forming various sheet metal from 0.5mm to 30mm to a +/- 0.25mm tolerance.

It is also the only sub-contract laser provider that can offer the cutting of non-ferrous materials without the risk of cross contamination for industries, including food processing and chemical manufacture.

Richard Andrews, Director at Midtherm Laser, concluded: “There has been a lot of investment recently, with the new laser following the installation of automated warehousing and the rebrand to form the Midtherm Group.

“Embracing new technology is a must for our business, but the company still thrives on the same values my father started it on in 1968, which are quality, service and technical knowledge.”

For further information, please visit www.midthermlaser.co.uk

New R&S PVT360A one box solution for FR1 base station, small cell, and RF component characterization and production test

For high-speed, high-throughput testing of all forms of 5G FR1 base stations and small cells as well as for RF components characterization or production, Rohde & Schwarz introduces the new R&S PVT360A performance vector tester. Within a minimal footprint, the compact single box instrument provides maximum performance with its signal generation and analysis capabilities. Demanding requirements of the test environment such as minimum Error Vector Magnitude (EVM) in test signals and high test throughput are all fulfilled. The optional second generator and analyzer support multiport component tests, true MIMO testing or simply double the test capacity.

Rohde & Schwarz introduces the new R&S PVT360A performance vector tester, a VSG/VSA single box tester optimized for FR1 base station, small cell and RF component testing in production and characterization environments. It meets the increasingly demanding requirements for 5G NR FR1 base station and small cell tests, resulting from additions to the original 3GPP Release 15 specification in Releases 16 and 17. The instrument’s frequency range from 400 MHz to 8 GHz covers not just all 5G FR1 requirements, but also the extension to unlicensed frequency bands in the USA to 7.125 GHz. The 500 MHz maximum signal bandwidth far exceeds the 5G FR1 maximum of 100 MHz, supporting out of band and adjacent channel leakage ratio (ACLR) measurements.

For maximum test throughput, two independent signal generators and analyzers enable fast parallel measurements; the twin channels each support eight parallel full-duplex test ports. For each channel, the output test signal can be broadcast to all eight ports. For input, ports are fast-switched in less than 10 microseconds for sequential analysis of either parallel or multiport devices. Transmit¬ter and receiver tests can be carried out in parallel; the R&S PVT360A optimizes test sequences to minimize any idle time between result processing. With the second channel installed, users can run True MIMO 2x2 tests with the signal paths tested in parallel, not sequentially. The optional smart channel mode divides the R&S PVT360A in up to eight separate virtual instruments, each with independent output signals and input measurements. The generator and analyzer are shared across the virtual instru-ments, with optimized resource scheduling for all calculations and processing.

The R&S PVT360A combines ideal functions for e.g. 5G base station production test with a minimum footprint and maximum performance

The R&S PVT360A combines ideal functions for e.g. 5G base station production test with a minimum footprint and maximum performance

For most production test requirements, standard compliant waveforms for 5G NR release 15, 16 and 17 (plus WLAN standards up to 8 GHz) support all typical base station transmitter and receiver tests such as EVM, output power or frequency error. In particular for component characterization applications, with developers searching for the highest possible performance, the low EVM of the R&S PVT360A signal generator provides high precision test signals for minimal measurement uncertainty. If additional signals are required, customized waveforms may be created using WinIQSIM2, the PC-based waveform creation program. For additional analysis the R&S VSE Vector Signal Explorer PC-based signal analyzer software is utilized.

To cover the full range of requirements in the extremely price-sensitive market for production test with a single instrument, the R&S PVT360A option concept supports setups from a single generator and analyzer with eight test ports for frequencies from 400 MHz to 6 GHz and a bandwidth of 250 MHz, up to the complete twin channel configuration each with the full frequency and bandwidth ranges of 8 GHz and 500 MHz. All updates are by keycode, and can be installed instantly.

The new R&S PVT360A performance vector tester is now available from Rohde & Schwarz. For more information go to: https://www.rohde-schwarz.com/product/pvt360a

www.press.rohde-schwarz.com.

The Rohde & Schwarz technology group is among the trailblazers when it comes to paving the way for a safer and connected world with its leading solutions in test & measurement, technology systems, and networks & cybersecurity. Founded more than 85 years ago, the group is a reliable partner for industry and government customers around the globe. On June 30, 2021, Rohde & Schwarz had around 13,000 employees worldwide. The independent group achieved a net revenue of EUR 2.34 billion in the 2020/2021 fiscal year (July to June). The company is headquartered in Munich, Germany.

R&S® is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

Sulzer gains 2023 Top Employer recognition in multiple countries

Sulzer has been named a 2023 Top Employer in Brazil, China, Switzerland, the UK and the USA, demonstrating its commitment to best HR policy and people practices globally. The Top Employers Institute surveyed five key countries for Sulzer, also rating and independently auditing them against an international standard. Sulzer scored an average of 85% across the board, with an exemplary 95% in Sustainability.

Designed to positively impact the global employee experience at work, Top Employers Institute rates applicant companies in a number of HR domains. These cover topics such as People Strategy, Work Environment, Learning, Wellbeing, Sustainability, Diversity & Inclusion and more. Following extensive assessments, Sulzer achieved a remarkable average score of 85% across its five certified country locations. In the area of Sustainability, the company’s strategic commitment to enabling sustainable practices is notably reflected in its exemplary score of 95%.

“We strive to make a difference at Sulzer, and we empower our employees to do so,” said Executive President Suzanne Thoma. “We are committed to do everything we can to offer our employees a safe, inclusive and meaningful work environment in which we can thrive.”

“We strive to make a difference at Sulzer, and we empower our employees to do so,” said Executive President Suzanne Thoma. “We are committed to do everything we can to offer our employees a safe, inclusive and meaningful work environment in which we can thrive.”

Issued by the Top Employers Institute, Top Employer recipients are surveyed, rated and independently audited against an international standard. Sulzer scored an average of 85% across the board, with an exemplary 95% in Sustainability.

Top Employers Institute CEO David Plink says: “This year’s Top Employers have shown that they care for the development and well-being of their people. By doing so, they collectively enrich the world of work. We are proud to announce and celebrate this year’s group of leading people-oriented employers: the Top Employers 2023.”

Sulzer is a global leader in fluid engineering and chemical processing applications. We specialize in pumping, agitation, mixing, separation, purification, crystallization and polymerization technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of over 180 world-class manufacturing facilities, engineering and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2021, our 13’800 employees delivered revenues of CHF 3.2 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN). www.sulzer.com

Are drones in the pipeline?

~ The buzz around drones in the oil industry ~

A bee can travel over five miles and then remember its way home, despite possessing a brain the size of a pinhead. Scientists have been putting them in virtual reality simulators to help improve unmanned aerial vehicle (UAV) or drone technology. While the honey bee currently has the edge, drone technology is catching up. Here, Chris Johnson, managing director at miniature bearings specialist SMB Bearings, explains the challenges and opportunities when using drones to monitor and inspect oil and gas pipelines.

Drones are being employed in a wider range of sectors and for myriad purposes. The further growth and adoption of this technology will be encouraged by consumer market growth, spill overs from the military sector and the possibilities opened up by 5G. The potential for drones to revolutionise the world of maintenance is clear. They certainly pass the ‘D test’: tasks that are dirty, dangerous and dull could all be left to drones.

BP, Shell and Exxon have already begun using drones for asset inspection and other tasks. Following an incident in 2008, where Exxon’s use of sonar technology was implicated in the deaths of 100 whales near Madagascar, the company recently used drones to help monitor the locations of whales off the coast of Santa Barbara.[i] But what about the benefits for pipelines?

Opportunity in the pipelines

From Alaska to the Niger Delta, oil pipelines are often located in inhospitable or even dangerous environments. In addition to their vast size, this fact makes maintenance through visual inspection a dangerous task. By handing the task of visual inspection over to drones, human workers are no longer in harm’s way.

Making the task of maintenance safer is not the only incentive. Early investors in the technology are seeing significant cost savings. Although it is difficult to quantify the precise saving, research by Roland Berger, has estimated that drone-based inspection of oil and gas rigs leads to cost savings of around 90 percent. The same research estimated that the use of drones has cut maintenance times from eight weeks to five days. The bottom line is that drones will provide a more cost-effective alternative to traditional asset inspection methods such as helicopters and ground vehicles.

However, drones are not simply replacing existing methods. Their agility allows them to offer visualisation and data analysis that existing methods cannot compete with. For example, satellites are limited by their orbit and weather can disrupt the accuracy of the images they provide. An engineer would have to assemble scaffolding to physically access a potential problem.

Scientists now claim that sophisticated sensors are developed enough and small enough to be mounted on UAV systems. As well as capturing high resolution visual data, drones can be equipped with other sensors to monitor pipelines, such as thermal imaging or ultrasound inspection.

Challenges for take off

Companies wanting to adopt this technology must also make sure they understand the evolving regulatory environment. Those that already use aviation, for example with helicopters, are probably in a better position to confront this hurdle due to their existing knowledge of aviation regulation.

Beyond visual line of sight (BVLOS) is among the most discussed things in the drone industry. This refers to where a drone is operating beyond the pilot’s line of sight. BVLOS activity will be necessary to enjoy the full benefits this technology could offer for asset inspection of pipelines, but in some countries it is not permitted.

In the United States, for smaller drones flying below 400 above ground level (AGL), BVLOS is currently not permitted without the necessary authorisation from the Federal Aviation Administration (FAA). To navigate around this restriction an FAA waiver is required. According to Geospatial World, 99 percent of waiver applications fail.

The restrictions are different when you enter different airspace classifications (those above 400 AGL). For pipelines that traverse national boundaries, these regulatory issues become even more complex.

Another consideration many businesses must make is what business model to adopt. In its guidance for the industry, the American Petroleum Industry outlines three alternative models.

Although the technology is constantly improving, there are limitations that are relevant to their potential for surveying pipelines. The limitations of the batteries that power the vehicles gives rise to range anxiety, a problem that is more significant for pipelines that cover significant distances. It is likely the industry will focus on using drones for inspection of oil rigs and other infrastructure before taking on the challenge of vast pipelines.

Something to bear in mind

If maintenance engineers are to exploit the benefits of UAV technology, keeping the drones in tip-top condition will be essential. Understanding the maintenance needs of these vehicles will be important for those companies who adopt the internal model referred to above. Engineers will need to be quick to acquire fresh expertise in this area.

Maintaining and replacing the bearings in drones will be an essential part of this. Many oil installations face significant risks from corrosion. Bearings too, need protection from corrosion. If your drone is operating in an environment where this risk exists, speak to a reputable supplier like SMB Bearings for the best information on bearing choice for your application.

The buzz surrounding drones is only set to grow and their use in monitoring and maintaining oil installations will allow the oil industry to improve worker safety, reduce the time taken to complete key maintenance tasks and realise substantial cost savings. If you are thinking of adopting an unmanned aerial vehicle program to monitor your assets, consider the benefits of partnering with a reliable supplier of high-quality precision bearings to help keep your drones in the air.

SMB Bearings is a specialist supplier of miniature bearings. To find out more visit smbbearings.com

[i] Stephanie Roker (2016), ‘Exxon Mobil using drones to track whales,’ 13 July, available at: https://www.worldpipelines.com/equipment-and-safety/13072016/exxon-mobil-using-drones-to-track-whales/

About SMB Bearings: SMB Bearings originally specialised in miniature bearings, thin-section bearings and stainless steel bearings. By natural progression, the company expanded the range to include other corrosion resistant bearings such as plastic bearings, 316 stainless bearings and ceramic bearings.

Remaining a specialist business, SMB Bearings provide a high level of product knowledge, providing bearing and lubrication solutions to existing or potential customers, whether individuals or large corporations. SMB Bearings does not just sell bearings, but helps to solve your problems.

For further information please visit http://www.smbbearings.com/