Super User

Asset health in the palm of your hand

~ How on-site oil analysis could give control back to industry decision-makers ~

When it comes to minimising disruptive maintenance work and lowering costs, prevention is better than a cure. Using oil condition monitoring as a predictive maintenance solutions can provide a deep insight into ongoing system health, reducing the risk of equipment damage caused by unknown contaminants in the system. Here, Dr Tom Knott, product manager at petrochemical lab equipment supplier SciMed, discusses the benefits of oil condition monitoring (OCM) analysis and offers some advice on the best equipment for the job.

Keeping an eye on the quality and integrity of your oil is nothing new to most industries that rely on lubrication, hydraulic or coolant fluids. Almost 70% of industry respondents to a Spectro Scientific® survey had some form of reliability monitoring programme in place. It’s safe to say that most decision-makers are aware that tracking the status of machine lubricant to enable predictive maintenance action is an essential practice.

Predictive maintenance is the sweet spot where facility managers can make decisions based on timely data about the health of their critical machinery assets. This is more cost-effective than preventative maintenance, where oil replacements are carried out based on a routine schedule, and far more economical than reactive maintenance, when components break and shut down production until the problem is fixed.

Predictive maintenance is the sweet spot where facility managers can make decisions based on timely data about the health of their critical machinery assets. This is more cost-effective than preventative maintenance, where oil replacements are carried out based on a routine schedule, and far more economical than reactive maintenance, when components break and shut down production until the problem is fixed.

This predictive strategy is especially important in those industries where replacing worn bearings or overheated components is particularly difficult, such as off-shore power generation and remote materials processing sites.

In 2023, most OCM programmes involve sending samples to professional laboratories. While providing the peace of mind that analysis is executed by experts, this outsourcing practice can limit businesses in a number of ways.

For one, the timeframe of sending a sample to the lab and waiting for the report is usually multiple weeks. With each passing day, maintenance managers could be running out of time to intervene in the mechanical decline of a vital asset.

Another issue with outsourcing the OCM process is the rising cost. The UK’s industrial services have been universally inflated by the COVID-19 pandemic and supply chain issues from China. The necessary increase in cost constrains testing volume: if you can only test six samples per month instead of ten, the likelihood that you miss a burgeoning problem increases.

These same geopolitical factors that are prompting quality managers to seek more cost-effective alternatives to outsourcing their oil condition monitoring needs also compound the potentially ruinous costs of a reactive maintenance policy. If your machine breaks and halts business, you might be waiting weeks, not days, for a replacement part.

Solving the fluid analysis conundrum

On-site fluid analysis instruments can significantly boost testing volume, improve sustainability and provide immediate results to give maintenance managers the best platform from which to make decisions and keep business running smoothly.

In the first implementation year of an on-site OCM programme that only tracked one parameter of oil quality, an industrial manufacturer of animal feed cut their unplanned maintenance downtime by 50%. Furthermore, the company saved almost $1 million (~£810,000) in lost production time and gear failures.

It’s true that the short-term investment costs of in-house OCM can deter facility managers from pursuing this as a cost-saving avenue. Additionally, it’s natural for engineers and machine operators without a chemical background to feel unprepared to take on the role of oil analyser.

Although understandable, these concerns can easily be assuaged.

OCM instruments are often sold as modules, each responsible for analysing different properties of the classic oil condition tri-vector; Wear, Contamination, and Chemistry & Viscosity. This is true of the Minilab series from Spectro Scientific®, a central docking station with multiple portable analysers. Maintenance managers can select the instrument most relevant to their business without investing in the whole selection.

One helpful device in this endeavour is a common software feature that allows the operator to schedule tests, collate and trend results, set alarm/action limits and track how much money has been saved on lubricant purchases, unplanned downtime and labour costs.

Indeed, the benefit to maintenance budgets is something worth highlighting. While the initial cost of investment might appear significant, the savings produced from predictive oil condition monitoring can be lucrative. An American city saved $2 million (~£1.62 million) in one year by extending the interval periods between oil changes in a large municipal fleet of city vehicles.

Uncertainty about the rapidity of oil degradation had pressured the city into spending millions on a preventative maintenance strategy and servicing their vehicles before it was necessary.

The popularity of on-site oil condition monitoring is set to sky-rocket in the coming years, as maintenance managers seek to optimise processes to protect their business against rising costs and increasingly drastic consequences for inadequate instrumentation management.

To find out more about how you can implement on-site oil condition monitoring into your workflow, visit Scimed’s product page.

About SciMed:

Since its founding in 1979, Scientific & Medical Products (SciMed) has been a highly successful distributor of laboratory and process equipment. It exclusively represents a number of leading manufacturers in the UK and Ireland and has recently been appointed the distributor for several companies in France and other selected regions around Europe. The company’s focus is on the promotion, sales, service and support of innovative and world-class products to customers in industry and academia.

Sulzer to establish new clean technology research and development center in Singapore for Asia Pacific

Sulzer has signed an agreement with JTC Corporation, the master planner and developer of Singapore’s industrial infrastructure, to build and operate a new research center for its separation technology solutions. The new facility will be located at the Jurong Innovation District’s CleanTech Park, Singapore’s first eco-business park specifically designed to support clean and sustainable manufacturing and urban solutions. Sulzer will focus its research activities on chemical separation processes for circular operations such as polymer recycling and bio-based fuel and polymer production.

Sulzer and JTC Corporation signed a tenancy agreement last week at the site location in CleanTech Park to mark the start of construction. Designed as a self-sustaining ecosystem, CleanTech Park supports the growth of clean technologies and advanced manufacturing by offering large-scale ‘living laboratories’ to test new solutions in real-world conditions. The new Sulzer Chemtech facility will focus on driving development of innovative separation solutions for customer applications in the Asia Pacific region. The test center will start commissioning in Q4/2023 and will be fully operational in Q2/2024.

Executive Chairwoman of Sulzer Suzanne Thoma said: “This investment in a new research and development center for Asia Pacific is a significant expansion to Sulzer’s global footprint and supports our strategic goals of progress, and the development of sustainable solutions. It also shows our commitment to innovation through continuous, significant spending in R&D.”

Executive Chairwoman of Sulzer Suzanne Thoma said: “This investment in a new research and development center for Asia Pacific is a significant expansion to Sulzer’s global footprint and supports our strategic goals of progress, and the development of sustainable solutions. It also shows our commitment to innovation through continuous, significant spending in R&D.”

Uwe Boltersdorf, Sulzer Chemtech division president, added: “Several Sulzer Chemtech separation technologies are enabling the transition towards more eco-conscious, circular operations. With our clean technology R&D center in Singapore we continue to anticipate and address market needs and enable sustainable manufacturing in the region.”

Lim Junwei, Director of Urban Solutions & Construction Cluster, JTC, said: "We welcome Sulzer to the growing ecosystem for advanced manufacturing, clean technologies and urban solutions at CleanTech Park. Sulzer's investment in CleanTech 3 to develop sustainable separation technologies dovetails with JTC’s vision of pushing the boundary for green manufacturing at CleanTech Park and the larger Jurong Innovation District. CleanTech Park provides a conducive environment for Sulzer’s research into new and sustainable separation solutions and we look forward to growing our partnership."

Sulzer is a global leader in fluid engineering and chemical processing applications. We specialize in energy-efficient pumping, agitation, mixing, separation, purification, crystallization and polymerization technologies for fluids of all types. Our solutions enable carbon emission reductions, development of polymers from biological sources, recycling of plastic waste and textiles, and efficient power storage. Our customers benefit from our commitment to innovation, performance and quality through our responsive network of 180 world-class manufacturing facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2022, our 12’900 employees delivered revenues of CHF 3.2 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN). www.sulzer.com

Anritsu Company Extends Frequency Range of Field Master™ MS2080A Up to 6 GHz to Support 5G FR1

Anritsu Company expands its Field Master™ MS2080A, a multi-functional spectrum analyzer that combines nine instruments into a single solution, to operate up to 6 GHz. With extended frequency coverage, the MS2080A addresses growing congestion in the 6 GHz spectrum caused by rapid growth in satellite services; cellular, commercial and LMR networks; radio location services; and industrial scientific and medical networks. The compact and portable spectrum analyzer provides insights into interference and intermodulation that degrade network performance through its best-in-class performance and features, bringing distinct benefits to base station installation and maintenance (I&M) applications.

— Multi-functional Spectrum Analyzer Brings Unprecedented Performance and Measurement Capability to Interference Hunting and Network Verification Applications —

At 6 GHz, the MS2080A features fast sweep speed of 45 GHz/s for greater insight over wider spans. It also has advanced user features, such as AM/FM audio demodulation, and best-in-class RF performance, including +/- 1 dB amplitude accuracy. Additionally, it supports a cable and antenna analyzer, power meter, and 5G/LTE analysis to make it an ideal general-purpose instrument that addresses measurement requirements for legacy and emerging wireless networks.

Options Expand Measurement Capability

Simultaneous with the launch of the MS2080A 6 GHz frequency model, Anritsu announces a new AM/FM modulation quality measurement option for all instruments in the Field Master family. The option enables full characterization of broadcast transmitters, as required by national regulators and transmitter owners. It provides a single screen display of RF spectrum, audio spectrum, and audio oscilloscope, alongside modulation quality and distortion values.

Simultaneous with the launch of the MS2080A 6 GHz frequency model, Anritsu announces a new AM/FM modulation quality measurement option for all instruments in the Field Master family. The option enables full characterization of broadcast transmitters, as required by national regulators and transmitter owners. It provides a single screen display of RF spectrum, audio spectrum, and audio oscilloscope, alongside modulation quality and distortion values.

An optional real time spectrum analyzer (RTSA) provides real-time spectrum analysis with 2 µs probability of intercept (POI). The RTSA has up to 40 MHz analysis bandwidth and DANL of <-150 dBm, making it well-suited for capturing intermittent and digitally modulated signals that can be hard to identify. Spectrograms allow irregular and drifting signals to be captured, recorded, and displayed.

The MS2080A conducts a full range of measurements for 5G FR1 radios to support I&M of 5G New Radio (NR) and LTE base stations. Gated sweep analysis for transmitter quality measurements to accurately verify FR1 carriers with 100 MHz bandwidth is provided. The MS2080A offers full-channel, power-based, and 5G/LTE modulation quality measurement-based coverage mapping for accurate Over-the-Air (OTA) testing.

Rugged Design for Any Environment

The MS2080A is a highly durable analyzer that performs in the most challenging environments. It is the only instrument in its class to provide 5 watts of continuous RF input overload protection, preventing costly damage to the instrument’s front-end when used close to high power transmitters or in high signal level environment.

A large 10-inch 1280 x 800 resolution display meets the demanding IK08 specification for direct knocks and drops. Common functions are always accessible from the MS2080A display, and side menus collapse to maximize graphical results.

A soft case provides IP52 environmental protection to safeguard the instrument during transport or rain. Weighing less than 4 kg, the MS2080A is small, compact, and easy to carry.

About Anritsu

Anritsu Corporation (www.anritsu.com), a global provider of innovative communications test and measurement solutions for 128 years. Anritsu’s philosophy engages customers as true partners to help develop wireless, optical, microwave/RF, and digital solutions for R&D, manufacturing, installation, and maintenance applications, as well as multidimensional service assurance solutions for network monitoring and optimization. Anritsu also provides precision microwave/RF components, optical devices, and high-speed electrical devices for communication products and systems. The company develops advanced solutions for 5G, M2M, IoT, as well as other emerging and legacy wireline and wireless communication markets. With offices throughout the world, Anritsu has approximately 4,000 employees in over 90 countries.

#GLAD2023 Turns to Individuals, End Users

Global Lifting Awareness Day—#GLAD2023—has arrived at the point of use, as 13 July draws nearer.

Driven by the Lifting Equipment Engineers Association (LEEA), #GLAD2023 will again bring together all industry stakeholders, including manufacturers and suppliers, but end users are a prime target as the concept strives to promote safe and high quality load lifting.

Now in its fourth year, #GLAD2023 harnesses the power of social media to promote videos, articles, and in-person activity, while pointing people to a dedicated website—www.globalliftingawarenessday.com—where information about apprenticeships, military recruitment, diversity, sustainability, and technology has been posted since the concept’s 2020 launch.

Ross Moloney, CEO at LEEA, said: “Ultimately, we’re trying to change behaviour, so pivoting towards owners, inspectors, examiners, and end users is key to achieving that. Social media postings are important, and we know that they are effective in giving people reason to pause, but this isn’t a movement confined to the virtual world; we need to do more to help people along their journey of conversion.”

Ross Moloney, CEO at LEEA, said: “Ultimately, we’re trying to change behaviour, so pivoting towards owners, inspectors, examiners, and end users is key to achieving that. Social media postings are important, and we know that they are effective in giving people reason to pause, but this isn’t a movement confined to the virtual world; we need to do more to help people along their journey of conversion.”

He added: “Most of us in the industry know where to look for guidance, and where to go for advice, but users that have only a passing understanding of lifting—they might only rent, or buy, or use it occasionally—likely need more support to understand the risks and how to mitigate them better. This is a demographic continuously prone to accidents if we don’t position our safety messages where they’re needed most.”

Taking ownership

LEEA has already invited stakeholders to show support by participating on social media and holding events that serve as hubs from where the concept can grow in future years, which is a message to individuals as well as wider marketing teams. From the C-suite of the largest corporations to the crane cab of the smallest rental company, #GLAD2023 is for everyone. Literally anybody with an interest in lifting and working at height can contribute.

Moloney said: “Our industry is owned by the individuals who work in it, so while we love that companies are getting involved, there’s no reason why individuals can’t post themselves, and we actively encourage both. In fact, a newcomer to the sector or somebody that has tools in their hands will find kindred spirits in those applying lifting equipment at the point of use.”

Also aligning to power #GLAD2023 are a collection of authorities and trade bodies, in addition to industry press, equipment manufacturers, and influencers. All are bound by a commitment to share material that promotes safe and high quality load lifting and are actively encouraging memberships, readerships, peers, etc. to support the cause. If you are an engineer, crane operator, rigger, signalperson, trainer, or apprentice, social media is the place to start.

Celebrate the lifting industry on Thursday 13 July—include the #GLAD2023 hashtag.

Guinea’s Winning Logistics bolsters its bauxite handling fleet with two more Konecranes barge cranes

In Q1 2023, Konecranes won an order for two Konecranes Gottwald Cranes on Barge from Winning Logistics in Guinea. After on-site commissioning in Q3 2024, Winning will operate a total of ten Konecranes Gottwald Cranes on Barge, loading ships with bauxite off the West African coast.

Konecranes Gottwald Cranes on Barge are specially designed and built to ensure uninterrupted material flow on water, even under demanding marine conditions. They can operate in winds of up to 24 m/s and at maximum wave heights of 2.5 m, and are built according to Lloyd’s Register Code for Lifting Appliances in a Marine Environment.

“Winning International Group takes Environmental, Social, Governance compliance seriously in terms of sourcing products and services that are safe, reliable and efficient. We know that Konecranes Gottwald mobile harbor cranes are reliable products for harsh environments. Their high productivity backed by quality service consistently creates added value for us. These cranes play a critical role in our unique offshore transshipment operation that has proven to be efficient, cost-effective and environmentally friendly. We are happy to be able to partner with suppliers, like Konecranes, who share our belief in sustainability beyond shipping and mining,” says Mr. Sun Zhijun, Vice President of Winning International Group.

“Winning International Group takes Environmental, Social, Governance compliance seriously in terms of sourcing products and services that are safe, reliable and efficient. We know that Konecranes Gottwald mobile harbor cranes are reliable products for harsh environments. Their high productivity backed by quality service consistently creates added value for us. These cranes play a critical role in our unique offshore transshipment operation that has proven to be efficient, cost-effective and environmentally friendly. We are happy to be able to partner with suppliers, like Konecranes, who share our belief in sustainability beyond shipping and mining,” says Mr. Sun Zhijun, Vice President of Winning International Group.

“Our barge cranes are thoroughly modern cargo handling machines that can operate mid-stream and on the open sea. Winning’s continuing trust in our expertise in this area, which reaches back over 20 years, confirms our leadership in this market,” says Holger Wagner, Regional Sales Manager, Port Solutions, Konecranes.

A strong focus on customers and commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.

For a concise overview of Konecranes’ business, please click here. More on Konecranes Gottwald cranes on barge can be found here. For a useful glossary of crane and lifting terms, please click here.

Further information:

Robert Vennemann, Marketing Manager, Mobile Harbor Cranes, Port Solutions, Konecranes

Email: This email address is being protected from spambots. You need JavaScript enabled to view it. or phone: +49 211 7102 3119

Konecranes is a world-leading group of Lifting Businesses, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2022, Group sales totaled EUR 3.4 billion. The Group has approximately 16,500 employees in around 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

Industry players to seize ample opportunities at ISH China & CIHE 2023

China’s HVAC market is well placed to thrive with plentiful business opportunities. Manufacturers have been actively developing energy-efficient HVAC solutions, in response to the Chinese government’s initiatives on sustainable development. With the presence of leading global and domestic brands featuring their innovative solutions and products, the line-up of international pavilions and specialised areas will act as the highlight of ISH China & CIHE 2023.

Organised by Messe Frankfurt (Shanghai) Co Ltd and CIEC GL events (Beijing) International Exhibition Co Ltd, ISH China & CIHE – China’s leading international trade fair for heating, ventilation, air-conditioning, sanitation & home comfort systems is set to open from 11 – 13 May 2023 at the China International Exhibition Center (Shunyi Hall) in Beijing. Focusing on three major themes: Energy, Water and Life, which are in line with China’s green initiatives and energy infrastructure optimisation targets, more than 1,300 exhibitors will showcase the latest HVAC, plumbing, smart heating and home comfort technologies and products across 106,800 sqm of exhibition space.

As China’s latest national policies underline the green economy, the accelerating growth of the HVAC market sees new business opportunities for industry players, who are prepared to showcase their latest products and innovations to professional buyers. A number of leading companies and brands worldwide have confirmed their participation at the 2023 edition, which include:

AMA&HIEN, Amitime, Amnesty, ARODD, BDR, Beigao, CALEFFI, DA, Danfoss, Devotion, Electrolux, Fangkuai, GMICÖU, GONGDA KEYA, GREE, Grundfos, Gude, Haier, Hailin, Hnbwrn, Hongyue, Huadehuamei, Huamei, Inovisen, JESDY, Kaaniche, Kenuo, Kingfore, Kiturami, Leo, Lonpend, Mayair, MICOE, Midea, Naturaquell, Nedfon, New Energy, Nobana, NORITZ, OUTES, PHILIPS, PHNIX, POWERWORLD, Resideo, Rinnai, RUIGE, RUNA, Shengxu , Shimge, Shinco, Shiteng, SHUANGLIANG, SIEMENS, Snowman, Solerad, ST.LAWRENCE, Suming, Tasan, Tongfang Smart Energy Saving, Tongli, Towngas Smart Energy, UNBEATABLE, Vanward, Walker, WDK, Wellhausen, Westone, WILO, Xinhuaxing, Xinxing, YORO, YUQ and more.

Strong line-up of pavilions and specialised display areas to showcase the latest innovations and technologies

This year, the German Pavilion, Canada Pavilion, Overseas Area, Zhejiang Pavilion, Water Pump Area and Clean Energy District Heating Area will be the major highlights of ISH China & CIHE. Supported by the Federal Ministry of Economic Affairs and Climate Action (BMWK), the German Pavilion will continue to be the key feature of the fair. The new Canada Pavilion will present the latest Canadian advanced manufacturing technologies and applications to meet the specific demands of the Chinese winter. Furthermore, following its success in the 2021 edition with over 100 domestic exhibitors spanning 10,000 sqm of exhibition space, the Zhejiang Pavilion will once again feature this year with product showcases including HVAC, sanitation and plumbing products.

Located in halls E1 and W2, the Overseas Area has already gathered a number of international brands, including AYVAZ, Broen, CALEFFI, EMS, Fondital, Heatmiser, KMC, Nuova Imas, Polidoro, Rima, Sermeta, Vernet, Vexve and Zero. The area will also introduce the new Minibox Service Area, which will allow international exhibitors who cannot attend the fair in-person to showcase their products and explore business opportunities online.

Being one of the key components for green heating and cooling, water pumps are again one of the highlighted products at ISH China & CIHE. The Water Pump Area will feature a number of prominent brands within the plumbing industry, including DAB, DAFU, Dooch, Goodpump, Grundfos, HOMA, Hydroo, Kaiquan, Leo, Lingxiao, Minamoto, Nanyuan, Pentax, RHEKEN, SFA, TQ GROUP, Westone, WILO and more.

With the latest innovations and clean-energy technology showcases adhering to carbon emission regulations, the Clean Energy District Heating Area organised by the China District Heating Association will be housed in hall W3 with renowned companies, including Desource, Diehl, GMSDIP, Gongda Keya, GREEN ENERGY ALLIANC, HDCHIP, Heighten, Huameng, Huizhong, HYTC, JHRJ, Jumo, Kingfore, Lcarbo, Nanjing Jiangu, Nuanliu, Ploumeter, POER, Precise, Revoheat, RUNA, Shuanghe, SHUOREN TIMES, THT, TigerIOT, TOKYO, TSCC, Wukexing, Xingbang, Xinxing Pipes, Younai and others.

ISH Shanghai & CIHE is another ISH event in China. For more information about ISH China & CIHE and ISH Shanghai & CIHE, please visit www.ishc-cihe.hk.messefrankfurt.com or email This email address is being protected from spambots. You need JavaScript enabled to view it..

ISH China & CIHE is organised by Messe Frankfurt (Shanghai) Co Ltd and CIEC GL events (Beijing) International Exhibition Co Ltd. It is headed by the biennial ISH event in Frankfurt, Germany, the world’s leading trade fair for HVAC + Water which will next take place from 17 – 21 March 2025. For more information, please visit www.ish.messefrankfurt.com.

Fischer Connectors enhances IIoT connectivity with ultra-rugged solutions using Single Pair Ethernet and USB 3.2 protocols

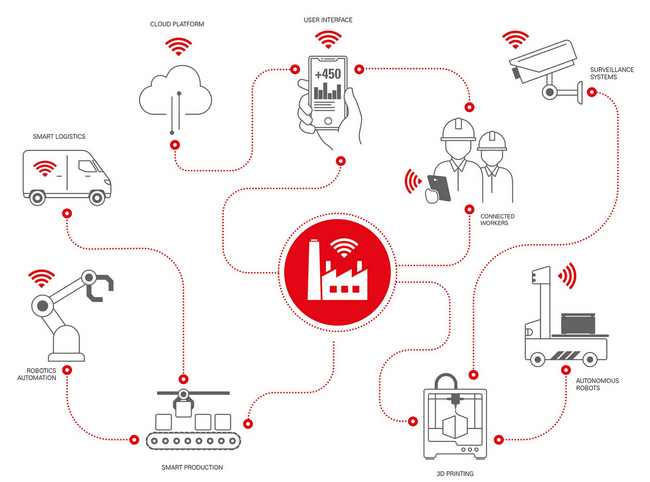

Fischer Connectors, the Swiss-based global leader in high-performance connectivity, releases ultra-robust Single Pair Ethernet (SPE) and USB 3.2 Gen 2 connectivity solutions to meet the specific requirements of Industrial Internet of Things (IIoT) applications in rugged environments.

With the increase in sensor density, actuators and controllers in Industry 4.0 and IIoT operational settings, high power levels and massive amounts of data must be securely and efficiently managed through ultra-fast transmission lines with cables running over long distances. Miniature connectors and cables are needed to interconnect smaller and smaller devices and sensors in areas that are sometimes confined and hard to access. And connectivity must be ruggedized to resist shock, vibration, extreme temperatures, water and corrosion when exposed to demanding environmental and chemical conditions, both indoors and outdoors.

To address these challenges, Fischer Connectors has developed new high-speed data and power connectivity solutions combining Single Pair Ethernet and USB 3.2 Gen 2 high-speed protocols with the rugged, high-density and miniature features of its flagship product lines. They enable space-saving and cost-efficient integration in industrial automation and robotics, chemical plants, food processing, automotive production lines, outdoor sensing and unmanned systems.

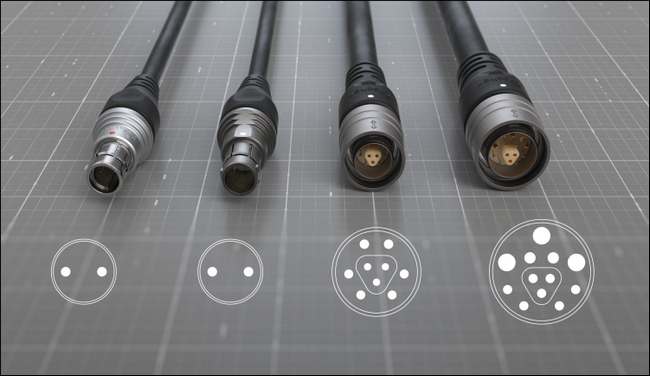

Fischer Connectors’ new Single Pair Ethernet (SPE) and USB 3.2 products include (from left to right): Fischer Core Series in size 102 with SPE 1 Gbit/s; Fischer UltiMate™ Series in size 07 with SPE 1 Gbit/s; Fischer MiniMax™ Series in size 08 with USB 3.2 Gen 1 for 5 Gbit/s, Gen 2 for 10 Gbit/s; Fischer MiniMax™ Series in size 10 with power and USB 3.2 Gen 1 for 5 Gbit/s, Gen 2 for 10 Gbit/s.

Fischer Connectors’ new Single Pair Ethernet (SPE) and USB 3.2 products include (from left to right): Fischer Core Series in size 102 with SPE 1 Gbit/s; Fischer UltiMate™ Series in size 07 with SPE 1 Gbit/s; Fischer MiniMax™ Series in size 08 with USB 3.2 Gen 1 for 5 Gbit/s, Gen 2 for 10 Gbit/s; Fischer MiniMax™ Series in size 10 with power and USB 3.2 Gen 1 for 5 Gbit/s, Gen 2 for 10 Gbit/s.

The Single Pair Ethernet solutions from the Fischer Core and Fischer UltiMate™ Series allow for 1 Gbit/s data transfer per IEEE 802.3bp - 1000Base-T1. Exceptionally rugged by any market standards, they outperform other suppliers’ SPE solutions in terms of security, durability, as well as environmental and mechanical performance. Fischer SPE is compliant with MIL-STD norms (through Fischer UltiMate™) and offers 10,000 mating cycles, three locking mechanisms (push-pull, screw, quick-release), and hermetic sealing in addition to IP68/ IP69 ratings. SPE is also featured in the ultra-miniature Fischer MiniMax™ connector in ‘size 06’ (Ø 10 mm receptacle).

The demand for USB 3.0+ protocol is high in Industry 4.0 operations, as it offers high data transfer rates with low latency for IIoT control applications, nearly twice the power output than USB 2.0 (900 mA vs. 500 mA), better power efficiency due to lower consumption in idle state, and larger bandwidth. Fischer MiniMax™ connectors with USB 3.2 Gen 2 allow for 10 Gbit/s data transfer, offer additional power contacts up to 8 A, and are half the size of some competitor connectors with similar speed but no power.

To accompany its product release, Fischer Connectors has published a trend paper entitled “The Connectivity Challenge – Connecting Industry 4.0”. It describes three challenges facing OEM engineers designing IIoT applications, as well as three innovation practices addressing cybersecurity, global logistics and Edge/Cloud infrastructure.

With billions of smart sensors, computers and machines connected and operating across the Internet, the market of the Industrial Internet of Things (IIoT) is expected to grow by more than 20% annually, reaching CHF 1.5 trillion by 2030.

With billions of smart sensors, computers and machines connected and operating across the Internet, the market of the Industrial Internet of Things (IIoT) is expected to grow by more than 20% annually, reaching CHF 1.5 trillion by 2030.

The innovation-driven IIoT market is growing exponentially. With billions of smart sensors, computers and machines connected and operating across the Internet, experts expect an annual increase of over 20%, reaching CHF 1.5 trillion by 2030.

About Fischer Connectors

Founded in 1954, Fischer Connectors designs, develops and deploys end-to-end interconnect solutions for ecosystems requiring local transfer and management of data, signals and power. Its tailored electronic solutions, connectors and cable assemblies are trusted globally for their reliability, durability and faultless precision in demanding environments such as test & measurement, industrial IoT, robotics, medical, defense and security.

Fischer Connectors is part of Conextivity Group, a global technology group offering high-performance connectivity solutions that manage power and data flows seamlessly from sensors and devices to the cloud and AI, enabling the emergence of new transverse and scalable ecosystems. With nearly 600 people worldwide, four R&D centers and six manufacturing sites, the Swiss-headquartered group is a full-service connectivity partner comprising two core businesses: Fischer Connectors and Wearin’, which creates IoT wearable solutions enhancing the safety and efficiency of connected humans.

New IDEC Safety Commander Improves HMI Tablet Usability for Industrial and Safety Applications

The newest IDEC HT4P Safety Commander accepts more device sizes than ever before, and it adds networking and operator interface options for using modern tablet interfaces with industrial equipment.

IDEC Corporation has developed the new HT4P Safety Commander, building on the success of the HT3P by incorporating end user feature requests for additional networking and operator interface functionality. The HT4P Safety Commander is an ergonomic device enabling users to securely hold and protect a human-machine interface (HMI) tablet, while providing power, networking, and hardwired emergency stop (e-stop) and other operator interface devices. OEMs and automation designers can now provide flexible and safety-rated operator interface options for equipment, robotics, collaborative robots, automated guided vehicles (AGVs), autonomous mobile robots (AMRs), and other manufacturing system applications.

Bringing tablets to the factory floor

Industrial operations personnel have long been constrained to using specialized HMIs mounted on fixed control panels, or dedicated teaching pendants. Modern consumer-grade tablets offer a better visualization solution, especially for data-intensive industrial internet of things (IIoT) applications, and they can also offer instant viewing of drawings and manuals, videoconferencing, and reports. But they simply are not made to withstand industrial conditions.

Now, the Safety Commander family of devices provides a ruggedized way of deploying HMI tablets to deliver many convenience and productivity benefits, in an arrangement designed for use on the factory floor.

Enhanced HMI options

The original HT3P Safety Commander provided a lockable, ergonomic, and sturdy way to secure HMI tablets. It included charging provisions, along with a hardwired e-stop and a 3-position hold-to-run enabling switch, so designs could integrate tablets in compliance with ISO/IEC safety standards and requirements. Many OEMs and end users have used this device to great advantage, and some have requested even more features to expand its usefulness for their applications.

The new HT4P Safety Commander builds on these capabilities and has been enhanced with:

Larger size: The HT4P can now hold tablets ranging from 10-inch all the way up to a 13-inch (whereas the HT3P accepts 8- to 11-inch tablets) using adjustable grippers, so users can take advantage of more display real-estate and greater CPU processing speeds. In most cases, the larger the tablet screen size, the greater the price advantage compared to using a traditional fixed-mounted touch panel.

Wired networking: While designers may still choose to use Wi-Fi for their tablet, there are many applications where electrical noise or other conditions make wireless unsuitable. Now, designers have the option with the HT4P to use an on-board wired LAN combined with a USB-PD connection, providing stable communications and 30W power charging simultaneously. A USB/RS232C/RS422 converter option is also available. External shielded cables with connectors are available for the HT4P in lengths of 5m, 10m, 15m, and 20m, making them suitable for almost any application.

Hardwired non-safety switches: The HT4P now has three on-board mounting positions capable of providing standard or custom arrangements of hardwired pushbuttons, illuminated pushbuttons, and selector switches. In addition, a guard is available to protect against inadvertent operation of the e-stop button.

The HT4P maintains other key features, such as the ability for the tablet to be used in vertical/portrait or horizontal/landscape orientations, by both left- and right-handed users, with a hand or shoulder strap to minimize fatigue. A wall-mountable bracket is available, and the device can also be placed on a desk for easy viewing. The device has been tested for drop resistance up to 1.2m, and it offers IP54 protection from water splashes, dust, and dirt. It operates in temperatures ranging from -10DegC up to +35DegC or more, depending on configuration. Clean room compatible parts are also available.

Adding industrial-grade safety to tablets

The IDEC HT4P Safety Commander lets OEMs and equipment designers take advantage of modern and familiar tablets acting as HMIs located close to machinery, and it eliminates the need to develop or use dedicated and less flexible devices.

As with all its products, IDEC offers free tech support for the HT4P Safety Commander, with no service or support contract required. For complete specifications or additional information, please contact IDEC Corporation at 800-262-IDEC (4332), or visit us online at https://lp.idec.com/HT4p-Safety-Commander-US.html .

About IDEC: IDEC Corporation is a global supplier that has provided innovative and reliable industrial automation and control products since 1945. Covering a broad range of market needs, these feature-rich and value-driven products include PLCs, human machine interfaces (HMIs), safety products and other industrial automation components. By delivering world-class products backed by personalized service and highly-rated technical support, IDEC enables design engineers to create lean, cost-effective and safe solutions to optimize their automation applications. With the recent acquisition of APEM, one of the world's leading manufacturers of operator interface panels and related components, IDEC continues to enhance our customers’ ability to create high-quality solutions. For additional information, visit www.IDEC.com/usa

Ecolab survey reveals high expectations for water conservation

New data from a global survey conducted and commissioned by Ecolab, a global sustainability leader offering water, hygiene and infection prevention solutions and services, has revealed high consumer expectations for the role of companies in water access and conservation.

The Water, Sustainability and Climate Change survey consulted thousands of consumers across eight countries. The survey revealed:

- 74% of consumers believe businesses should make conserving water a high or essential priority;

- Just 25% of consumers believe companies are taking the right amount of action to conserve water; and

- More than 60% of consumers said they or a family member had trouble accessing drinking water.

Ecolab Senior Vice-President and Market Head for Southeast Asia, Gregory Lukasik said, “We recognize the necessity of tackling water scarcity, especially in regions such as Asia, where 1.9 billion people lack access to drinking water and basic sanitation – with the global demand for water expected to increase by 40% by 2030. Accelerated solutions are as crucial as ever, and we must continue prioritizing water stewardship to keep up with consumer demands. Our progress at Ecolab sets the foundation to push further and work hard with our customers and communities to improve the efficiency of all our water supplies.”

A ‘Year in Water’ Recaps the Company’s Progress on World Water Day

A ‘Year in Water’ Recaps the Company’s Progress on World Water Day

Each year on March 22, World Water Day elevates water and sanitation issues. The theme for 2023 is “Accelerating Change” and urges continued progress towards U.N. Sustainable Development Goal 6. Ecolab highlighted the company’s leadership role across a full year of change and progress to mark the occasion.

Highlights from the company’s Year in Water include:

- Ecolab helped our customers conserve 215 billion gallons of water in 2022, equivalent to the drinking water needs of nearly 730 million people. By 2030, Ecolab aims to help customers conserve 300 billion gallons of water each year, equivalent to the annual drinking water needs of 1 billion people.

- Ecolab joined DuPont, Gap, Inc., Reckitt, Starbucks and the U.S. International Development Finance Corporation to provide $139.9 million in investments in WaterEquity’s Global Access Fund IV to help improve water access, sanitation and hygiene for up to 5 million people in water-scarce regions including Southeast Asia.

- Ecolab launched the Ecolab Water for Climate program to help companies respond to the intensifying impacts of the energy crisis, climate change and water scarcity. The program is designed to address these challenges by providing holistic solutions including auditing, consulting, engineering, advanced chemistries and digital technologies that help support reduce, re-use and recycle water strategies across an enterprise.

Accelerating change through the power of water is core to Ecolab’s purpose to improve the health of people, the planet and businesses worldwide. The company shares its expertise in smart water use with customers to help them reduce, reuse and recycle water in their operations. In addition to supporting effective water use, Ecolab’s solutions help customers use energy more efficiently, reduce waste and cut greenhouse gas emissions to advance a more sustainable future.

To learn more about how Ecolab works with customers to help solve the world’s most complex problems amid a changing landscape, visit www.ecolab.com/expertise-and-innovation/people-planet-business-health

|

About Ecolab and Nalco Water, an Ecolab Company |

|

A trusted partner for millions of customers, Ecolab (NYSE:ECL) is a global sustainability leader offering water, hygiene and infection prevention solutions and services that protect people and the resources vital to life. Building on a century of innovation, Ecolab has annual sales of $14 billion, employs more than 47,000 associates and operates in more than 170 countries around the world. The company delivers comprehensive science-based solutions, data-driven insights and world-class service to advance food safety, maintain clean and safe environments, and optimize water and energy use. Ecolab’s innovative solutions improve operational efficiencies and sustainability for customers in the food, healthcare, life sciences, hospitality and industrial markets. www.ecolab.com |

Anritsu Partners with VDI to Introduce Frequency Extender Modules to Bring Best-in-Class Performance to Sub-THz Applications

- New Modules for Anritsu Rubidium™ Signal Generators Create Solution that Provides Industry’s Broadest Frequency Coverage and Best Signal Purity, Output Power -

Anritsu Company introduces frequency extender modules for its Rubidium™ line of signal generators, in partnership with Virginia Diodes, Inc. (VDI). Covering 50 GHz to 1100 GHz, the modules complement Rubidium’s best-in-class performance by providing the industry’s broadest frequency coverage and best output power to create a sub-THz signal generator solution for emerging scientific, wireless communications systems, and body and material scanner applications.

The integrated solution brings significant signal purity and output power benefits to sub-THz design environments. Rubidium outperforms all other signal generators in its class in phase noise and harmonic/spurious by a substantial margin. The performance advantages are preserved at sub-THz frequencies.

When the VDI frequency extender modules are used with Rubidium signal generators, engineers realize the industry’s highest output power at THz frequencies. The VDI modules offer high test port power, voltage-controlled RF attenuation, and TTL controlled ON/OFF modulation rates to a few kHz as standard.

Each frequency extender module has two multipliers, which can be configured to allow input signals in two frequency bands. One multiplier has low frequency input for < 20 GHz and 10 dBm input level and the other has high frequency input for < 50 GHz and 0 dBm input level.

Each frequency extender module has two multipliers, which can be configured to allow input signals in two frequency bands. One multiplier has low frequency input for < 20 GHz and 10 dBm input level and the other has high frequency input for < 50 GHz and 0 dBm input level.

The Rubidium-VDI signal generation solution meets the growing demand for emerging sub-THz radio spectrum designs. It can be used during development of satellite services, radio astronomy, earth exploration, and meteorology applications.

Wireless communication systems focusing on the W band (90 GHz to 120 GHz) and D band (130 GHz to 170 GHz), as well as intersatellite links operating at 220 GHz to 330 GHz, are also applications for which the solution is designed.

“VDI strives to produce the highest quality test and measurement solutions for the mmWave, sub-THz and THz frequency ranges through frequency extension of existing microwave test infrastructure. Achieving this requires continual innovation and development to integrate leading-edge active devices with our in-house Schottky diode technology to meet tomorrow’s measurement challenges,” said Cliff Rowland V.P. Business Development, VDI. “VDI is exited to work with Anritsu to combine our high-frequency SGX extension modules with its new signal generation capability to bring high-performance solutions to the market.”

Rubidium Delivers New Level of Performance

The Rubidium signal generator family delivers outstanding signal purity and frequency stability, even at high output power levels, across a broad frequency range of 9 kHz to 43.5 GHz. Coupled with built-in, easy-to-use, at-location frequency and power calibration capability, Rubidium offers exceptional overall utility and long-term value in a broad range of commercial, scientific, and military/aerospace measurement applications.

Rubidium offers an order of magnitude with better frequency stability compared to other signal generators that use an OCXO-based reference. The signal generators offer groundbreaking low single sideband (SSB) phase noise of -136 dBc/Hz (typical) and -140 dBc/Hz (measured) at 10 GHz and 10 kHz offset that is unmatched in the industry. Coupled with best-in-class harmonic and spurious performance, Rubidium signal generators enable customers to make highly accurate measurements.

About VDI

VDI’s mission is to make the terahertz region of the electromagnetic spectrum as useful for scientific, military and commercial applications as the microwave and infrared bands are today. VDI manufactures state-of-the-art test and measurement equipment for mm-wave and THz applications. These products include Vector Network Analyzer, Spectrum Analyzer and Signal Generator Extension Modules that extend the capability of high performance microwave measurement tools to higher frequencies. VDI's component products include detectors, mixers, frequency multipliers and custom systems for reliable operation at frequencies between 50 GHz and 3 THz. All VDI components include in-house fabricated GaAs Schottky diodes and microelectronic filter structures.

About Anritsu

Anritsu Corporation (www.anritsu.com), a global provider of innovative communications test and measurement solutions for 125 years. Anritsu’s philosophy engages customers as true partners to help develop wireless, optical, microwave/RF, and digital solutions for R&D, manufacturing, installation, and maintenance applications, as well as multidimensional service assurance solutions for network monitoring and optimization. Anritsu also provides precision microwave/RF components, optical devices, and high-speed electrical devices for communication products and systems. The company develops advanced solutions for 5G, M2M, IoT, as well as other emerging and legacy wireline and wireless communication markets. With offices throughout the world, Anritsu has approximately 4,000 employees in over 90 countries.