Super User

Semcon awarded new digital product information project for Volvo Cars

In a new project with Volvo Cars, Semcon develops the digital workshop information for an upcoming electric vehicle model. The project involves diagnostic, service and spare parts information, and is planned to run through September 2023.

Making sure that workshop technicians always have access to accurate diagnostic information for troubleshooting, as well as service and spare parts information, means that they can more quickly and easily do their jobs – servicing and repairing vehicles. With deep technical expertise and experience in digital information solutions, Semcon’s experts ensure that Volvo Cars technicians have the right conditions for their work.

“Our long experience as a partner to Volvo Cars and several other major clients in the automotive industry makes us a reliable choice for this type of complex delivery. We look forward to supporting Volvo Cars in this new project and in the ongoing transition to fully electrified model programmes,” says David Sondén, General Manager Product Information Sweden at Semcon.

Semcon is contributing a broad mix of expertise to the project, which will continue until September 2023. Up to about 30 people are expected to be part of the international team, which will be comprised of employees in Sweden, China and Hungary, and include skills such as diagnostic engineers, method developers, spare parts service engineers and illustrators.

Digital product information customised for the target group creates important competitive advantages for companies when it comes to strengthening relationships with customers through, for example, increased uptime, more efficient service and maintenance, and a better user experience. Read more about Semcon’s complete offering of services in aftermarket solutions.

Semcon is an international technology company. We turn technology into excellent user experiences by combining digital edge and engineering expertise. With diverse multi-disciplinary teams we add new perspectives creating sustainable and competitive businesses. Regardless if you aim to recharge a current product or service, reinvent new technology or reimagine future needs, our focus is always on human needs and behaviour in order to develop solutions with the clearest benefits to people and our planet. By combining our 40 years of advanced engineering, strategic innovation, digital services and product information solutions, we drive transformation in a wide range of industries with more than 2,000 dedicated employees based in seven different countries. Read more on www.semcon.com

Metso Outotec collaborates with Malvern Panalytical on Planet Positive offering for bulk ore sorting

Metso Outotec and Malvern Panalytical have signed a collaboration agreement to provide sensor-based bulk ore sorting solutions for the mining industry. The combination of the companies’ expertise in crushing and bulk material handling solutions and ore analyzers enables the parties to offer an industry-leading portfolio of solutions for bulk ore sorting. With this offering, mining customers can substantially improve head grade by preconcentrating the ore at the crushing stage and thereby reduce their energy consumption and related environmental footprint in the comminution stage.

”Sustainability is a top priority for our entire industry. Collaboration with partners like Malvern Panalytical will allow us to meet the industry’s increasing sustainability and resource efficiency needs in an enhanced way in the early comminution stage. Sensor-based bulk ore sorting and data-driven analysis upgrades low-grade or waste stockpiles, making them economical and far less energy-intensive to treat,” says Rashmi Kasat, Vice President, Digital Technologies at Metso Outotec.

Bulk ore sorting with Metso Outotec and Malvern Panalytical

Bulk ore sorting with Metso Outotec and Malvern Panalytical

“Malvern Panalytical’s cross-belt analyzers provide high-frequency online data for cost-efficient bulk material analysis of major commodities. This collaboration enables customers to benefit from the in-depth know-how of both companies,” says Jarmo Lohilahti, Sales Manager at Malvern Panalytical.

“Bulk ore sorting allows waste rock elimination early in the process, and when combined with Metso Outotec’s complementary crushing and bulk material handing solutions portfolio, it provides more sustainable flowsheets for our customers. Enhanced bulk ore sorting will contribute to Metso Outotec’s Planet Positive portfolio,” says Renato Verdejo, Business Development Lead for Bulk Ore Sorting at Metso Outotec.

Discover more about Metso Outotec’s solutions for ore sorting on our website.

More information about Malvern Panalytical’s solutions is available on their website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2021 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Valmet to start personnel negotiations on temporary layoffs at its valve factory in Finland

The geopolitical situation caused by the crisis in Ukraine and the intensified COVID-19 restrictions in China have reduced the orders at the valve factory in Helsinki, Finland, during spring. The exceptional situation has particularly impacted the factory’s oil and gas projects. The impact of the COVID-19 pandemic in China also continues to cause challenges related to component availability and logistics.

To adjust production capacity to match the reduced workload at the valve factory in Helsinki, Valmet is initiating personnel negotiations on potential temporary layoffs on May 25, 2022.

The employees within the scope of the negotiations are those in the Flow Control business line’s valve production and related operations in Helsinki, excluding the positioner production unit. The layoffs will be temporary and are estimated to last a maximum of 90 days. The negotiations involve around 340 employees.

The employees within the scope of the negotiations are those in the Flow Control business line’s valve production and related operations in Helsinki, excluding the positioner production unit. The layoffs will be temporary and are estimated to last a maximum of 90 days. The negotiations involve around 340 employees.

Valmet employs about 6,200 people in Finland, about 830 of the employees are in the Flow Control business line.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Baseload Capital Sweden AB Secures €25 Million Debt Facility to Finance Geothermal Projects

The Facility will be used to re-finance Baseload’s operational assets and assets in construction or late-stage development as well as to finance future pipeline projects. The Facility can be utilized during the availability period and has a 10-year tenor after each draw down. The funding is eligible when the bond is redeemed.

Alexander Helling, the CEO of Baseload Capital says, “We’re extremely excited because this Facility enables Baseload to roll out projects faster and provide project financing to assets under development and construction. It is optimally structured for a company like Baseload with a portfolio of geothermal assets in various development phases. SEEIT is an esteemed investment company listed on the London Stock Exchange and a constituent of the FTSE 250 with a strong focus on sustainability and ESG. We are very happy to have SDCL as our important financing partner.”

SEEIT was launched to facilitate investment into environmental infrastructure markets. It has always focused on investing in projects that are good for the environment, good for people and commercially sustainable.

Commenting further on the investments, Purvi Sapre, Fund Manager of SEEIT, said: “The Baseload Capital investment provides heat and power generated locally from geothermal sources and is a great example of high efficiency renewable district energy generation. The investment generates income straight away and, as such, contributes to meeting both SEEIT's yield and total return targets.”

About SDCL Energy Efficiency Income Trust PLC

SDCL Energy Efficiency Income Trust plc is a constituent of the FTSE 250 index. It was the first UK listed company of its kind to invest exclusively in the energy efficiency sector. Its projects are primarily located in the UK, Europe and North America and include, inter alia, a portfolio of cogeneration assets in Spain, a portfolio of commercial and industrial solar and storage projects in the United States, a regulated gas distribution network in Sweden and a district energy system providing essential and efficient utility services on one of the largest business parks in the United States.

The Company aims to deliver shareholders value through its investment in a diversified portfolio of energy efficiency projects which are driven by the opportunity to deliver lower cost, cleaner and more reliable energy solutions to end users of energy.

For more information, please contact:

Alexander Helling CEO of Baseload Capital

This email address is being protected from spambots. You need JavaScript enabled to view it.

About Us

Baseload Capital is a specialized investment entity that funds the deployment of heat power worldwide. Our portfolio of companies in Iceland, Japan, Taiwan and the U.S. work with local communities and power companies to permit, build and commission heat power plants.

Heat power is an affordable form of renewable energy that can be harnessed from either geothermal resources or waste heat. By applying innovative financing structures to help our local operators build and run the heat power plants, Baseload Capital can help nations quickly transition away from fossil fuels and toward energy independence. The result will lead to more resilient societies and a planet in balance.

The German Clean Tech Startup BIO-LUTIONS and PulPac, the Dry Molded Fiber pioneer, are natural allies in their objective to replace single-use plastics globally.

The German Clean Tech Startup BIO-LUTIONS and PulPac, the Dry Molded Fiber pioneer, are natural allies in their objective to replace single-use plastics globally. Together with machine suppliers they have developed a Dry Molded Fiber production line, set to start production in the new BIO-LUTIONS factory in Schwedt/Oder, Germany by the summer of 2022.

BIO-LUTIONS mechanically converts agricultural residues into unique, self-binding, durable fibcro® natural fibers. This patented method eliminates the need for binding agents or chemical cellulose isolation, as the whole fiber is used. From these fibers together with the dry moulding technology, BIO-LUTIONS will produce a variety of sustainable single-use disposable products such as service food items (cutlery and tableware) as well as protein, fruit and vegetable packaging. By introducing the new dry moulding technology provided by PulPac, production can now benefit from the unique cost and quality advantages compared to existing cellulose forming solutions.

The cooperation with PulPac opens the door to an additional production technology for fibre moulding, allowing for technology diversification as well as optimisation of dry moulding processes. The Dry Molded Fiber technology saves significant amounts of valuable water resources and energy, resulting in up to 80% lower CO2 footprint compared to alternatives. The process is extremely fast and more efficient than conventional fiber forming methods. While Dry Molded Fiber technology will not be used for all BIO-LUTIONS’ products, it does offer significant production advantages for a large variety of single use products.

“Each company brings something unique and valuable to the table. Being able to create partnerships that prioritize creating real solutions to the plastic age, rather than trying to build walls is what will make true change possible. That is why we are very excited to include dry moulding from PulPac as a second core production technique” Eduardo Gordillo, CEO BIO-LUTIONS.

The new factory in Germany will be up and running this summer and brings together two unique innovations, BIO-LUTIONS’s fibcro® natural fibers and PulPac’s Dry Molded Fiber technology – delivering truly sustainable and competitive fiber-based packaging to the world.

The new factory in Germany will be up and running this summer and brings together two unique innovations, BIO-LUTIONS’s fibcro® natural fibers and PulPac’s Dry Molded Fiber technology – delivering truly sustainable and competitive fiber-based packaging to the world.

“BIO-LUTIONS is an innovative and fast-moving partner. We share a doer attitude and a clear-cut commitment to replace single-use plastics at scale. Having products on the market already this year will take the concept of sustainable packaging a big leap forward. We look forward to a long-term partnership where we can share know-how and expertise to leverage the full potential of dry moulding within BIO-LUTIONS’ operations and customer network.” says Linus Larsson, CEO, PulPac AB.

About PulPac

PulPac provides the packaging industry with a groundbreaking manufacturing technology for low-cost, high-performance fiber-based packaging and single-use products. By pioneering the technology of cellulose molding PulPac enables their customers to replace single-use plastics with a sustainable and cost competitive alternative globally.

For additional information about PulPac, please visit www.pulpac.com or follow us on social media.

About BIO-LUTIONS

BIO-LUTIONS is a Hamburg-based green tech start-up that has developed its own innovative natural fibre technology, used to produce sustainable packaging and disposable tableware. The production process gives a second life to currently unused agricultural residuals as raw material to replace con-ventional plastic and paper products. BIO-LUTIONS was founded in 2017 and is currently expanding in Asia and Europe. With the purely mechanical process BIO-LUTIONS creates stable structures and products without additional binding agents. The application of this innovative fibre technology was

developed in Germany, at their technical centre in Schwedt, Brandenburg. The first factory was opened in Bangalore, India and now follows the new production facility in Schwedt, Germany. As part of the Innovation Campus Schwedt, BIO-LUTIONS is a part of the new hub for innovative technology in Brandenburg.

For more information, please visit: www.bio-lutions.com

About Dry Molded Fiber

Dry Molded Fiber, invented and patented by PulPac, is a manufacturing technology designed for the circular economy. It leverages globally available, affordable, and renewable cellulose fibers to produce high performance fiber-based packaging and single-use products with highly competitive unit economics. Dry Molded Fiber also saves significant amounts of valuable water resources and energy, resulting in up to 80% lower CO2 footprint compared to alternatives. The process is up to ten times as efficient as conventional fiber molding invented over 100 years ago.

Metso Outotec wins order for large iron ore pellet plant in Oman

Metso Outotec has signed an agreement for the delivery of engineering and key equipment for an iron ore Grate Kiln pellet plant to Vulcan Pelletizing LLC. The plant is located in the industrial port of Sohar, the Sultanate of Oman. The value of the order is approximately EUR 33 million, and it has been booked in Metals’ Q2/2022 orders received. The pellet plant will supply pellets to Jindal Shadeed Iron & Steel LLC, Oman.

Metso Outotec’s scope of delivery consists of the supply of core pelletizing plant equipment, including the traveling grate, rotary kiln, and annular cooler. The design is based on the Grate Kiln plants that Metso Outotec is currently supplying for a customer in India. The plant, which is planned to produce six million tons of high-quality iron ore pellets per year, is scheduled to be operational by the end of 2023.

Metso Outotec’s scope of delivery consists of the supply of core pelletizing plant equipment, including the traveling grate, rotary kiln, and annular cooler. The design is based on the Grate Kiln plants that Metso Outotec is currently supplying for a customer in India. The plant, which is planned to produce six million tons of high-quality iron ore pellets per year, is scheduled to be operational by the end of 2023.

“This is the third order for a 6 mtpa Grate-Kiln pelletizing plant within the last 16 months. Metso Outotec is proud to be the Vulcan group’s selected partner in iron ore pelletizing, and we look forward to propelling the Vulcan group to be a global leader with world-class pellet products,” says Chris Urban, Vice President, Heat Transfer Products at Metso Outotec.

Metso Outotec is the world’s leading supplier of Grate Kiln pellet plants, with more than 50 installations globally totaling over 130 mtpa of production. The Metso Outotec technology produces superior-quality pellets while minimizing overall plant operational expenses.

Discover more about our pelletizing technologies and the Grate Kiln system on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2021 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Wärtsilä successfully completes delivery of 15 groundbreaking LPG fuel supply systems

The technology group Wärtsilä has successfully completed delivery of its LPG Fuel Supply System (LFSS) to 15 Very Large Gas Carrier (VLGC) vessels owned and operated by BW LPG. The Oslo-listed company is a world leader in liquefied petroleum gas (LPG) shipping, and has the world’s largest fleet of VLGC vessels.

BW LPG ordered the first four of these 15 systems in 2018, immediately following Wärtsilä’s full-scale testing of a full-sized 2-stroke marine engine operating with LPG fuel. This was the world’s first such testing protocol, and the performance attained was seen as exceeding expectations. Orders for a further 11 systems were placed in 2020.

The Wärtsilä LFSS is a key enabler for the use of LPG as an environmentally sustainable marine fuel. It meets IMO emission limits without the need for exhaust scrubber systems. Compared to heavy fuel oil (HFO), LPG reduces sulphur oxide (SOx) emissions by 97 percent, nitrous oxide (NOx) emissions by approximately 20 percent, greenhouse gas emissions by approximately 24 percent, and particulate matter emissions by 90 percent.

BW Malacca, the last vessels in the series of 15 Very Large Gas Carriers (VLGC’s) retrofitted with Wärtsilä LPG Fuel Supply System © BW LPG

BW Malacca, the last vessels in the series of 15 Very Large Gas Carriers (VLGC’s) retrofitted with Wärtsilä LPG Fuel Supply System © BW LPG

“The successful introduction of the LFSS is testament to Wärtsilä’s commitment to working towards the decarbonisation of shipping We were very quick to adopt this system in support of our own decarbonisation ambitions, and we have enjoyed collaborating with them in this important and groundbreaking project,” commented Pontus Berg, Executive Vice President, Technical and Operation, at BW LPG.

“It has been a pleasure cooperating with BW LPG in the introduction of the LFSS to 15 of their vessels. We fully support their ambitions towards enhancing the sustainability of their operations, and are proud to bring the widespread use of LPG fuel closer to reality, thanks to the Wärtsilä LFSS.” says Walter Reggente, Vice President, Wärtsilä Gas Solutions.

In the retrofitting of these 15 vessels, Wärtsilä has had system integrator responsibilities. This has involved not only the installation of the LFSS, but also the required ship design modifications. The Wärtsilä LPG Fuel Supply System is available as a stand-alone solution, or as an integrated element within the LPG cargo handling system.

Wärtsilä Gas Solutions is a market leader with innovative systems and lifecycle solutions for the gas value chain. Our main focus areas are handling of gas in seaborne transport (storage, fuel, transfer and BOG management), gas to power, liquefaction and biogas solutions. We help our customers on the journey towards a sustainable future through focus on lifecycle, innovation and digitalization.

Wärtsilä Marine Systems in brief:

Wärtsilä Marine Systems supports customers with high quality products and lifecycle services related to the gas value chain, exhaust treatment, shaft line, underwater repair and electrical integrations. We are committed to providing the latest and most efficient solutions, in line with Wärtsilä’s vision for a safe and sustainable future for our customers, our communities and our planet.

www.wartsila.com/marine

Wärtsilä in brief:

Wärtsilä is a global leader in innovative technologies and lifecycle solutions for the marine and energy markets. We emphasise innovation in sustainable technology and services to help our customers continuously improve their environmental and economic performance. Our dedicated and passionate team of 17,000 professionals in more than 200 locations in 68 countries shape the decarbonisation transformation of our industries across the globe. In 2021, Wärtsilä’s net sales totalled EUR 4.8 billion. Wärtsilä is listed on Nasdaq Helsinki.

www.wartsila.com

Sunlight Group to showcase diversified and integrated portfolio of energy storage and IoT technologies at LogiMAT 2022

The company will be attending the international trade show for intralogistics solutions in Stuttgart, Germany to present its product portfolio, designed to accelerate the transition toward an all-electric future

Sunlight Group Energy Storage Systems, the global technology company and producer of integrated and innovative energy storage solutions, announces its attendance of LogiMAT 2022, held from May 31 to June 2 in Stuttgart, Germany. At booth 10 A75, Sunlight Group will demonstrate its innovative, integrated and diversified energy storage and IoT solutions, including the newly launched semi-traction battery, Sunlight ElectroLiFe, smart Battery Monitoring System, Sunlight KnoWi, and portfolio of chargers, Sunlight PowerBox.

- From 31 May to 2 June, Sunlight Group will be attending the LogiMAT Trade Show to showcase the company’s extensive portfolio of lithium-ion and lead-acid energy storage solutions

- Featured products include the company’s newest semi-traction lithium-ion battery, Sunlight ElectroLiFe, smart Battery Monitoring System (BMS), Sunlight KnoWi, and complete range of chargers, Sunlight PowerBox

- Sunlight Group CEO, Lampros Bisalas, will be in attendance to discuss the company’s €560m five-year business plan under implementation, aimed at strengthening the European clean energy sector

The Sunlight PowerBox range includes low- and high-frequency chargers for both lithium-ion and lead-acid products. The range has been enriched with the addition of PBM S.R.L to the Sunlight family. PBM is an established global leader in the production of battery chargers and industrial devices, and its acquisition brings the Sunlight Group another step closer to a sustainable, efficient, and complete batteries value chain – a critical aspect of the transition to an all-electric future.

Sunlight ElectroLiFe is Sunlight Group’s range of semi-traction lithium-ion batteries. Its innovative lightweight yet robust design is built to suit evolving customer needs and allows for tool-less, plug & play installation in golf carts and other recreational and light commercial or manufacturing vehicles, industrial or material handling equipment, as well as leisure marine applications.

Sunlight KnoWi is the market’s most advanced Battery Monitoring System (BMS) for motive power lead-acid batteries. It’s designed to help improve the management and performance of both batteries and the forklifts they power.

Both lithium-ion and lead-acid Sunlight products offer remote connectivity to the company’s smart cloud-based platform Sunlight GLocal. GLocal uses artificial intelligence (AI) to record, in real-time, key parameters about the operation of the battery. It also allows for remote monitoring and preventive maintenance, protecting the equipment, maximizing battery service life, and reducing costs.

At LogiMAT, an experienced team from Sunlight Group –led by CEO, Lampros Bisalas– will be presenting the company’s full range of lithium-ion and lead-acid solutions. These include the lithium-ion motive power battery, Sunlight Li.ON FORCE, semi-traction battery, Sunlight ElectroLiFe, and reserve power energy storage system, Sunlight Li.ON ESS.

The company will also discuss its plans to further strengthen the European energy storage market through a five-year €560m business plan, currently under implementation. The plan aims to expand the company’s production capacity in lead-acid and lithium-ion batteries and energy storage systems, as well as secure and grow its supply chain and sales network. To that effect, Sunlight invests millions in equipment, automated production and assembly lines, Research & Development, human resources, as well as Mergers & Acquisitions, across its facilities in Greece and abroad.

Commenting on the company’s participation at the exhibition, Sunlight Group CEO, Lampros Bisalas said: “Following our establishment in the US and Italy with manufacturing and sales facilities, we are excited to attend LogiMAT and establish ourselves further in a market in which we’ve been operating for over three decades. Thanks to our growing international team of experts, each of whom has strong expertise and knowledge of the energy storage market, and the robust steer of our BoD and Executive Committee, we’ve made significant additions to our product range that better serve our customers. And as we proceed with the implementation of our five-year €560m business plan, and our support to the global goal of transition to a more sustainable future, the next few years will see the continued expansion of Sunlight Group across key markets.”

To find out more about Sunlight Group Energy Storage Systems, please visit: www.systems-sunlight.com

About Sunlight Group Energy Storage Systems

Sunlight Group is a Greece-based technology company with a global reach, member of the Olympia investment Group. It has 30+ years of experience in energy storage, specializes in integrated and innovative solutions, invests in capacity expansion and R&D, and offers a solid portfolio of lithium-ion and lead-acid products for various applications. This includes the new range of lithium-powered motive (Sunlight LiON FORCE), semi-traction (Sunlight ElectroLiFe) and reserve (Sunlight Li.ON ESS) batteries, as well Sunlight’s cloud-based platform, Sunlight GLocal, smart Battery Monitoring System, Sunlight KnoWi, and complete range of chargers, Sunlight PowerBox. Sunlight’s industrial batteries and energy storage systems are exported to 100+ countries. The company runs state-of-the-art production plants and facilities in Greece, Italy, and the USA.

For additional information from the Sunlight Group or to arrange an interview, please contact Gong Communications, This email address is being protected from spambots. You need JavaScript enabled to view it.; +44 20 7935 4800

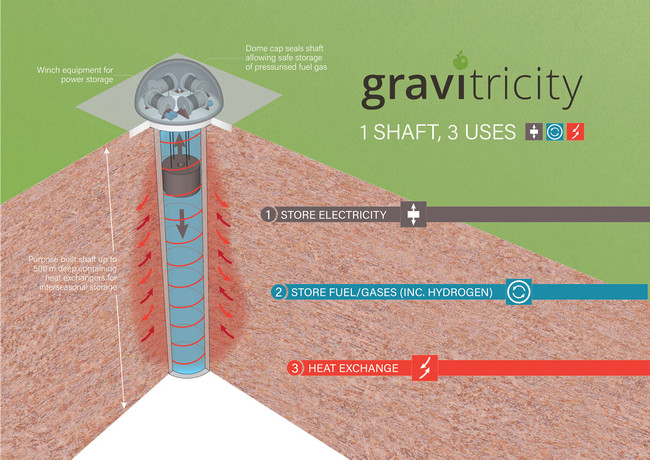

Gravitricity and Arup secure £300k BEIS HySupply 2 grant to develop below ground hydrogen storage

The towns and cities of the future may be able to rely on green hydrogen stored below ground, if a newly funded UK project succeeds.

- Purpose-built shafts could store large quantities of hydrogen

- Feasibility study could lead to first of a kind UK project

- Potential to build hydrogen stores wherever required

Gravitricity and Arup have together secured £300,000 from the Department of Business Energy & Industrial Strategy (BEIS) to study the feasibility of storing hydrogen in purpose-built underground shafts.

Edinburgh-based energy storage specialists Gravitricity and global built environment consultancy Arup will collaborate to deliver a complete system design and commercial feasibility report for the novel idea, as well as identifying a potential site for their underground hydrogen store. The design will also include integration with gravity energy storage and inter-seasonal heat.

The parties been awarded £299,985 in Phase 1 of the BEIS Low Carbon Hydrogen Supply 2 [HySupply 2] Competition which aims to support innovation in the supply of hydrogen, reducing the costs of supplying hydrogen, bringing new solutions to the market, and ensuring that the UK continues to develop world leading hydrogen technologies for a future hydrogen economy.

If successful, the project could be selected to enter Phase 2, where the partners would build a £multi-million scale demonstrator in the UK.

This would involve sinking a purpose-built concrete lined vertical underground shaft with a domed cap, to create a demonstration pressurised hydrogen storage vessel. [Pictured.]

Commenting on the project, Gravitricity’s Hydrogen and Thermal Storage Lead, Sally Molyneux says:

“If green hydrogen is to become a mass market fuel of the future – for example for providing heat to industry or powering heavy vehicles – then we need to find ways to store it safely and in large quantities close to where it is needed.

“Storing hydrogen in underground shafts is intrinsically safer and less obtrusive than above ground options and is a solution that does not require unique geology such as salt caverns. We believe Gravitricity’s innovation is a scalable storage method which is cost effective, extremely durable, and can be implemented everywhere.”

Gravitricity Managing Director Charlie Blair adds:

“Our partnership with Arup creates a combined team with all of the expertise and experience required to build and deliver Gravitricity underground energy stores.

“In the past, our cities relied on huge gasometers to store the gas they required. In the future, our towns can look to purpose-built shafts to safely store the green hydrogen they will need.”

Mark Neller, Arup’s Energy Leader for the UK, India, Middle East and Africa, said:

“Working with Gravitricity and BEIS on this innovative approach to hydrogen storage has the potential to play an important role in the future of the UK’s energy systems. This project will draw on Arup’s extensive skills and experience, as part of our wider efforts to help the UK meet its ambitious target of reaching net-zero by 2050.”

UK Energy Minister Greg Hands said:

“The UK is truly leading the world in hydrogen innovation thanks to the exciting efforts of companies like Gravitricity. The government support which they have received today will help to boost the development of hydrogen as the clean, affordable, homegrown superfuel of the future.”

Longer term, the partners believe the shafts can also be used for fast response electricity storage, using Gravitricity’s solid weight technology which raises and lowers heavy weights in a shaft.

In addition, the shaft’s gastight lining will in future incorporate heat exchangers for inter-seasonal heat storage. Adding heat exchangers to the shaft lining, at marginal cost, creates a very large ground source capable of feeding a network of heat pumps in the surrounding area.

This sharing of infrastructure means the cost per unit of energy stored (as electricity, heat and hydrogen) will be very competitive.

Last summer Gravitricity successfully commissioned and operated a grid-connected 250kW demonstrator in Leith, Edinburgh, and now plan to build a full-scale project in a decommissioned mine shaft in mainland Europe.

About Gravitricity

Gravitricity uses heavy weights – totalling up to 12,000 tonnes – suspended in a deep shaft by cables attached to winches.

When there is excess electricity, for example on a windy day, the weight is winched to the top of the shaft ready to generate power. This weight can then be released when required – in less than a second – and the winches become generators, producing either a large burst of electricity quickly, or releasing it more slowly depending on what is needed.

Unlike batteries, the Gravitricity system can operate for decades without any reduction in performance.

See a short (30 second) explainer animation here.

Gravitricity has applied for seven patents in total, with five granted and two pending.

The idea of using gravity to store energy is not new. Britain already relies on a number of pumped storage hydro schemes, such as Ben Cruachan, where water is pumped uphill to be released when required.

About Arup

Arup is a world class firm of more than 16,000 designers, planners, engineers, architects, consultants and technical specialists, working in 140 countries across the world on every aspect of today's built environment. For more information, see: https://www.arup.com/our-firm.

SecurityHQ Partners with SentinelOne to Enhance Global Cyber Security Offerings

Global Managed Security Services Provider (MSSP), SecurityHQ, have announced their partnership with leading cyber security solutions provider, SentinelOne.

How the Partnership Benefits Cyber Security for Clients Across the Globe

There has been a substantial growth of highly sophisticated Advanced Persistent Threats (APT’s), around the world, which has led to a demand for a next-gen endpoint security solution, coupled with skilled analysts to proactively detect and respond to those risks.

SecurityHQ's Managed Endpoint Security Service leverages the power of their global Security Operation Centers, combined with SentinelOne’s best technology for detecting known signature-based and unknown behavioural-based threats, across all known MITRE ATT&CK TTPs.

Armed with a U.S. patent technology, Windows compatible remediation feature, to roll-back any alteration, deletion or encryption to sensitive documents or data volumes, as a result of a successful breach or ransomware attack.

Pete Carfrae, UK Channel Manager for SentinelOne, states that ‘We are delighted to announce our partnership with SecurityHQ. As an independent managed security service partner, they bring a lot of expertise in solving customers challenges and we are very happy they have chosen to work with us to provide their clients with managed detection & response services.’

Islam Rashad, MSSP Solutions Presales Lead for SecurityHQ, adds that ‘SecurityHQ’s 24/7 SOC Managed Endpoint service, powered by SentinelOne, is delivered through a single agent, that tracks code in real time, while Active EDR, applies ML-based behavioural scoring to all events, to track the root cause. Deep investigation of the storyline saves time for analysts, as well as reduces dwell-time without fine-tuning, to promptly understand the full chain of a detected threat. This empowers a proactive response to threats, to effectively suppress the spread of any infiltration, and place control at the source of compromise.’

‘SentinelOne is committed to working with the right profile of partner and that is why we are happy to announce our partnership with SecurityHQ. They have the right blend of technical capabilities, coupled with an understanding of their customers challenges. They are well placed to take SentinelOne’s XDR messaging to the market.’ - Matt Percival, Northern Europe Channel Director, SentinelOne

In response, SecurityHQ’s CEO, Feras Tappuni declared that ‘The way we deliver, requires best of breed technology, but it also requires a partner. SentinelOne delivers on both counts.’

About SentinelOne

SentinelOne's cybersecurity solution encompasses Al-powered prevention, detection, response and hunting across endpoints, containers, cloud workloads, and loT devices in a single autonomous XDR platform.

About SecurityHQ

SecurityHQ is a Global MSSP, that detects, and responds to threats, instantly. As your security partner, we alert and act on threats for you. Gain access to an army of analysts that work with you, as an extension of your team, 24/7, 365 days a year. Receive tailored advice and full visibility to ensure peace of mind, with our Global Security Operation Centres, and utilize our award-winning security solutions, knowledge, people, and process capabilities, to accelerate business and reduce risk and overall security costs.