Super User

Estal presents Corkcoal, its innovative and sustainable cork and activated charcoal stopper

Estal, the leading company in the development of premium packaging presents the Corkcoal stopper, which is distinguished by its innovation in materials, its commitment to sustainability and its careful design, worldwide and within the framework of the ProWein fair.

Complex industrial processes are used in the manufacture of traditional micro granulated cork stoppers, with the consequent use of water, energy and chemical agents. All this with the aim of eliminating unwanted properties (taste, odour, colour, etc.) of the cork. Corkcoal combines two materials; cork and activated charcoal. The latter naturally neutralises and traps unwanted substances in the cork, as well as accepting and integrating variations in colour and size of the micro granulate.

Corkcoal is unique, therefore, in terms of sustainability because it reduces rejects and raw material waste without sacrificing quality; because the industrial cork washing processes are reduced and chemical bleaches are not used, and, therefore, its carbon footprint is lower. In addition, the active charcoal accelerates the biodegradation process of the stopper. Compared to other stoppers, thanks to its materials, Corkcoal offers a lower transfer of flavours to the product, and being neutral it also has better organoleptic properties.

The Corkcoal collection consists of three models: Sharp, Barrel and Cornice, with two sizes available 21.5 mm and 18.5 mm. Their design makes them perfect for spirits. Charcoal is a key element in the wine and spirit making process and the use of a stopper with this material gives these bottles authenticity. The material and appearance of Corkcoal prevail, highlighting its natural qualities of charcoal from renewable sources.

Adding a new innovation to the Wild world

The launch of Corkcoal expands the innovations that make up the Wild world, already consisting of Wild Glass and Wildly Crafted bottles. Wild Glass uses up to 100% recycled glass in the production process and embraces the flaw through a unique design language that translates into a unique new range of coloured glass. It has two distinctive collections, the Rude Collection for spirits and the Prima Collection for wines. Corkcoal stoppers are the perfect complement to Rude bottle designs, especially those with super short necks like Choker. Corkcoal models with a short stem of only 15 mm guarantee a watertight seal and are ideal for bottles with a reduced expansion chamber.

Corkcoal also brings authenticity and naturalness to the bottles in the Wildly Crafted collection, intended for manufacturers seeking a beautiful but imperfect look and an industrial production that respects sustainability. Wildly Crafted bottles, unique thanks to their labelable textures, come in 5 different shapes (Primal, Natural, Brave, Bobber and Bobber Jr) and two types of mouths, Bocachata and Chocker, which stand out for their clean and clear finish, typical of manual manufacturing processes. The organic, rough and handcrafted design is absolutely complemented by the Corkcoal stopper models. Coherence and consistency in all the innovations developed by Estal.

About Estal

Estal was created in 1994 as a specialist in the world of packaging, offering a wide variety of premium packaging solutions for wine, distillery, beer, water and other beverages, gourmet products, perfumery, cosmetics and home fragrances. Basing its philosophy on a commitment to innovation and industrial excellence, the company is a market leader thanks to its work in customising packaging, developing unique models with the most advanced technical innovations and design. Estal has a new e-commerce platform, https://shop.estal.com/, which represents another step in the digitization of its services and adds benefits to the shopping experience it offers its customers.

NSK roller guides increase uptime of blow moulding machines

A manufacturer of PET (polyethylene terephthalate) bottles frequently had to replace the linear guides on its blow moulding machines. However, after switching to NSK’s RA series roller guides, there have been no failures for over a year, producing annual cost savings in maintenance, spare parts and downtime of €60,000.

Dissatisfied with the number of linear guide failures on its blow moulding machines, the manufacturer invited NSK to investigate several faulty guides. Expert analysis identified the cause to be end cap damage, which was occurring due to the combination of short stroke movements, short cycle times, frequent start-stop operation and increased displacement force during start-up.

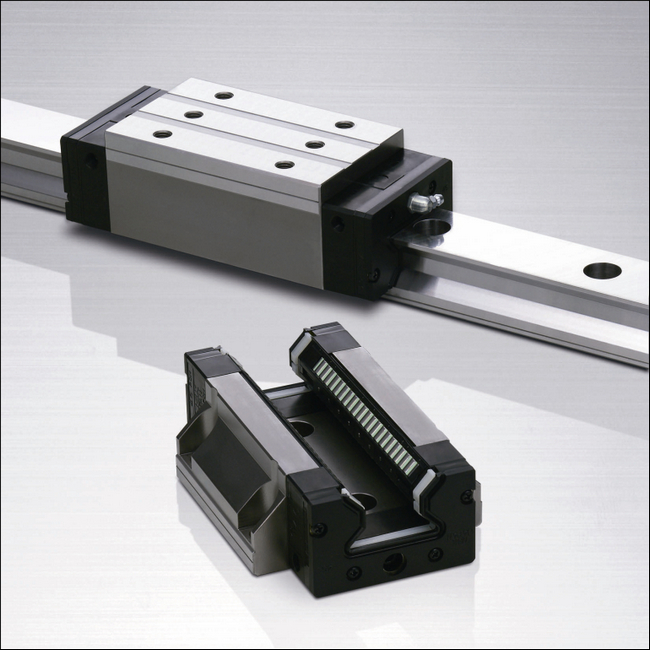

A manufacturer of PET bottles is benefitting from NSK RA series roller guides on its blow moulding machines. Photo: Shutterstock

A manufacturer of PET bottles is benefitting from NSK RA series roller guides on its blow moulding machines. Photo: Shutterstock

Given this application profile and the damage that was taking place, NSK recommended that the plastics processor installed RA series roller guides. These guides offer, among other things, very high load-carrying capacity and motion accuracy, extreme rigidity, smooth running, and long service life under conditions of short cycle rates and high loads.

A principal design feature of the RA series are its spacers, which perform a restraining function between each of the rollers. These spacers reduce roller skew and ensure smooth running, as well as lower displacement force during start-up.

The user followed the recommendation and, on a trial basis, equipped one of its blow moulding machines with NSK RA series roller guides. This machine ran for more than a year without any problems or breakdowns, reducing production downtime costs to zero. NSK's cost savings analysis showed that the retrofit of this one machine alone resulted in a saving of €59,500.

NSK RA series roller guides offer high load capacity and rigidity to meet the needs of a wide range of applications. Photo: NSK

NSK RA series roller guides offer high load capacity and rigidity to meet the needs of a wide range of applications. Photo: NSK

In the light of this outcome, the PET bottle manufacturer had no hesitation in upgrading its other blow moulding machines.

About NSK Europe

NSK Europe Ltd. is the European organisation of the Tokyo-based bearing manufacturer NSK, which was founded in Japan in 1916 and today employs nearly 30,400 people in its worldwide operations. The products and solutions provided by the industrial and automotive supplier can be found wherever things move. In addition to nearly all types of rolling bearings, the company’s portfolio includes housed bearings, linear technology, wheel bearing units, transmission and engine bearings and steering systems. The company is oriented to perfection in all of its business activities. Its aim is quality leadership in its industry, which it strives for through a continuous process of improvement, excellent product development, optimised production processes and customer-oriented service processes. In fiscal year 2020, the more than 4,350 employees of NSK Europe Ltd. generated sales of over € 792 million.

www.nskeurope.com

Solving thermal system complexity

Thermal solutions are a part of almost every industry, from chip manufacturing and medical devices to oil and gas operations. What these diverse industries have in common is a need to design simple, yet responsive systems that can monitor and maintain the precise application of heat. However, this need means that engineers must contend with various complexities. Here, Brandy Phillips, engineering manager at industrial electric heating element manufacturer Watlow, explains how adaptive thermal solutions (ATS) can provide an answer to common heat processing challenges.

Any device or process with a heater needs some degree of thermal control, with some devices or processes needing more precise control than others. That precision is traditionally achieved by adding sensors and controllers to heaters. The more precision needed, the more complex the control apparatus and the wiring becomes.

ATS, which combines sensing, heating and control technologies, represent a different and more innovative approach to controlling thermal performance for complex systems. However, adding the complexity is not always an option, which is where challenges present themselves.

Complex systems in small spaces

A surface that needs to be heated to within a certain temperature range requires not only several heating elements, but also sensors that can detect the temperature of the surface at various points. Those sensors then deliver that feedback to a controller that then responds by adjusting the power sent to the heaters. If the temperature of the surface fluctuates, the sensors and controller should be able to respond in tandem to maintain the desirable temperature range.

Traditionally, the approach to getting such fine control of the heating surface has been to increase the zone count, which requires the addition of independent sensors, wires and controllers. As the system scales, the complexity grows, but the overall space in which this needs to happen does not. In many manufacturing scenarios, precise control is needed in a confined space, and additional wiring and equipment is not feasible.

Control system challenges

Manufacturers may experience disconnection between their control systems. Different banks of sensors at different points in a process are often connected to separate controllers, which might not be networked in such a way that their activity can be coordinated easily, which results in unresponsive systems.

The above challenge often results in adding an element of unpredictability to the system. The added complexity of additional sensors and controllers will, for some applications, either compromise adaptability or prevent the system from achieving desired thermal uniformity. These, in turn, lead to excess waste and variable material quality.

Unlocking these challenges

Precision and tunability of a thermal system is traditionally achieved by adding sensors and controllers to the system. But there are plenty of applications where this is not a viable option, including semiconductor manufacturing, analytical devices and home medical devices. ATS makes possible a greater degree of control in systems where piling on more components is simply not an option.

Every application is unique, and some can take advantage of many ATS technologies at once while others might use just one. In semiconductor manufacturing, deposition pedestal heaters must reach certain temperatures during the chipmaking process, and temperature uniformity is critical to quality control. The pedestal itself allows little room for extra wires. With high TCR materials and multi-loop control and sensing, individual heaters can be made into sensors, and the number of heating zones can be more than doubled. These zones can be independently controlled, in real time, adjusting heater output to achieve a more uniform surface temperature.

Furthermore, existing medical and analytical equipment often have to meet new agency requirements, like safety specifications for allowed temperatures. Having heaters that can sense their own temperature, when then adjusts power levels via power conversion, helps to keep

temperatures within safe limits.

Watlow, which manufactures industrial heating technology, has decades of experience with thermal systems to help engineers and designers to incorporate ATS technology into a variety of industrial processes and products.

The beauty of ATS is that it is not one solution, but a suite of solutions that can be tailored to specific engineering challenges. Unlocking the benefits of this technology requires a deep understanding of the product or process in question, including the thermal and power requirements of the system.

For more information about ATS, visit watlow.com

About Watlow:

Watlow is a global industrial technology company that uses its world-class engineering expertise, advanced thermal systems and manufacturing excellence to enrich everyday life. Many of the world’s leading companies leverage our technology in vital applications such as semiconductor processing, environmentally-friendly energy solutions and lifesaving medical and clinical equipment, to name a few. Founded in 1922, Watlow’s culture is driven by our purpose of “Enriching Lives Through Inspired Innovation,” enabling us to deliver high-impact solutions that improve our customers’ competitive advantage.

The NETZSCH NOTOS® 3NS multiple screw pump is the next generation in LACT pipeline booster pump technology

Unique cartridge design provides high reliability, small footprint, and easy serviceability

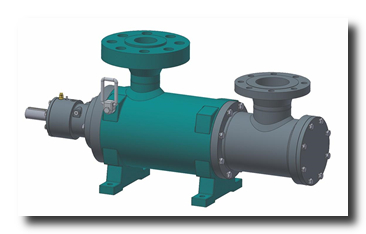

NETZSCH Pumps North America, LLC, experts in solutions designed specifically for complex fluid handling pumping applications, announces the new NETZSCH NOTOS® 3NS multiple screw pump, the next generation in Lease Automatic Custody Transfer (LACT) pipeline booster pump technology. The efficient operation, low noise, small footprint, high reliability, and easy serviceability of this technology makes it ideal for pipeline booster pump service, whether in a LACT building for cold weather duty or sustaining the summer heat of the hot climate areas.

The NOTOS® 3NS stretches the boundaries with increased flow and pressure capability with greater reliability. The cartridge design makes servicing in the field an efficient, time saving operation. With the compact design and ability to cover 6,000 bpd and 750 psi, the NOTOS® 3NS provides flexibility unrivaled by other manufacturers.

Due to the optimization by means of the High Efficiency Unique Design (HEUD) concept, three screw pumps provides constant flow at any pressure in the pipeline. The state-of-the-art technology, precise tolerances and optimized screw profile guarantees that the noise level of the pump is lower than the motor.

Due to the optimization by means of the High Efficiency Unique Design (HEUD) concept, three screw pumps provides constant flow at any pressure in the pipeline. The state-of-the-art technology, precise tolerances and optimized screw profile guarantees that the noise level of the pump is lower than the motor.

In addition to a drive screw that transmits torque via a thin hydrodynamic film, 3NS three screw pumps have two rotating, intermeshing driven screws. The design of the 3NS meets the oil standards including the American Petroleum Institute (API) standards with minimal changes.

These pumps are versatile and can be used in a wide variety of applications because they can be made from a wide range of materials and support different viscosities and temperatures. They are available in carbon steel and other alloys. The HEUD design, state-of-the-art manufacturing, an exclusive patented design and cartridge assembly ensure low maintenance and low life cycle costs.

About NETZSCH Pumps & Systems

NETZSCH Pumps & Systems has served markets worldwide for more than 60 years, providing customized, sophisticated solutions for applications in every industry type. Experts in solutions designed specifically for difficult pumping applications, NETZSCH supplies NEMO® progressing cavity pumps, TORNADO® rotary lobe pumps, and NOTOS® multi screw pumps, new PERIPRO™ peristaltic pumps as well as N.Mac® twin shaft grinders, macerators, barrel emptying units, metering technology and accessories. With a workforce of more than 2,200, NETZSCH Pumps & Systems is the largest business unit in the NETZSCH Group, with annual sales of more than 300 million Euros.

Coval covers all industry needs with its range of vacuum grippers

Coval, the French leader in vacuum gripping, offers vacuum grippers for automated applications, from gripping single parts to complete layers. The range equally suited to equipping either cobots or robots, offering a catalogue of modular, standard products, designed to meet the customers' needs.

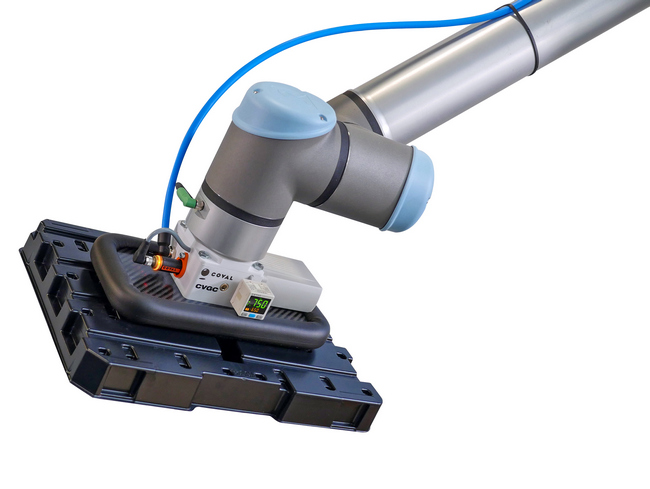

Coval, with its complete range of vacuum grippers, can be applied at various points along the whole production line, from the manipulation of individual objects to palletizing a full layer of product at the end of the line. The range includes 3 complementary series, starting with the ultra-compact CVGC models, designed from carbon specifically for cobots. Further in the range is the CVGL series of compact and lightweight end effectors for robots. At the top end is the MVG modular series, which is fully configurable.

The CVGC, the carbon vacuum gripper for cobots

The CVGC carbon vacuum gripper is not just an adaptation of an existing product, but a plug and play product designed 100% for the various cobot models, The lightness of the CVGC due to its carbon material (the smallest model weighs less than 1 kg) facilitates the optimum use of collaborative robots and preserves their lifting capacity. The vacuum generator, control cartridge, vacuum switch, and silencer are grouped together in a compact function block. The CVGCs are versatile, with a foam grip interface suitable for many materials and available in three sizes: 150 x 150 mm, 240 x 120 mm and 320 x 160 mm. In addition, Stéphane Garcia, Marketing and Communication Manager at Coval, points out: "the attachment Interfaces and connectivity are adapted to the particular cobot model in each case, which means that the CVGC fits on all types of cobots. "

CVGL, the lightweight vacuum gripper for robots

The dimensions and weight of the CVGL vacuum grippers make them one of the lightest and most compact ranges on the market. By reducing the weight and size of its vacuum grippers, COVAL enables integrators and manufacturers to integrate them into low-power robot manipulators. This translates into savings in terms of investment and operating costs.

To match the application requirements perfectly, the CVGL range of vacuum grippers is available in 3 standard lengths (424, 624, and 824 mm) or a custom length, and a fixed width of 120 mm, with 3 gripping interface technologies (foam, suction cups, or the gel-like COVAL-flex), 3 suction powers, and an integrated or remote generator. They offer a vacuum handling solution suited to parts of various sizes, weights, and materials.

MVG Modular Vacuum Grippers: customization as standard

The MVG modular vacuum gripper, which is mainly used for heavy payload robots and palletizers, offers the possibility of configuring a gripper that is perfectly adapted to each application, for loads of several hundred kg. To achieve this result, major developments have been carried out and patented.

The first choice the user has to make is the size, because MVGs are custom-made to the desired size from 150x150 to 1200x1000 mm. To ensure that the vacuum gripper is perfectly adapted to the specific requirements the user can also configure the vacuum generator and the gripping interfaces such as foams and suction cups. "The MVG grippers are equipped with gripping interfaces, either by means of suction cups, foam, or Coval-flex. These solutions ensure an optimal grip regardless of the size or material of the object to be gripped (cardboard, metal, plastic, glass, concrete/stone, composites, wood, etc.)," explains Stéphane Garcia. "High performance, flexible and robust, the MVG grippers can be multi-zone, i.e. equipped with several independent gripping zones, which makes it possible to ensure staggered or multiple pick-up and drop-off, guaranteeing optimized vacuum management as well as a reduction in leaks and consumption," he emphasizes.

Precise vacuum management with multizoning is particularly useful for staggered pick and place, managing different formats to be handled, or optimizing palletizing layers.

Stéphane Garcia adds: "Coval has been recognized for over 35 years as one of the world's specialists in systems and components for vacuum gripping. Our products are renowned for their quality and reliability. Our added value also lies in our teams of specialists who support our customers in the technical definition of the solution that precisely meets their needs and constraints. "

Coval supports manufacturers in various sectors: automotive, aeronautics, packaging, agri-food, plastics, and more.

Innovative Stabilizer™ LFG Well Caps from QED Environmental Systems

Unique support ring feature molded directly into the cap aligns and stabilizes the wellhead

The innovative Stabilizer™ landfill gas (LFG) well cap, from Q.E.D. Environmental Systems, features a unique, patented support ring molded directly into the cap that aligns and stabilizes the LFG wellhead and reduces leaks. The Stabilizer LFG well cap’s durable, heavy-walled polyethylene construction makes it ideal for any climate.

The Stabilizer is the first engineered gas well cap that allows liquid level readings without removing the wellhead. Easy access for liquid level reading is faster, safer, and results in less system disruption. There is no air introduction or gas release, no need to shut down the well for level measurements, and no need to rebalance the wellfield afterwards.

The cap’s innovative support ring design takes pressure off the flexible coupling and the flex hose and, along with watertight threads, reduces the potential for leaks at the wellhead. The caps are molded in QED’s distinctive yellow that is designed to help identify and protect the entire well from damage and ensures users are receiving genuine QED well caps.

The Stabilizer LFG well caps are designed to work with 6-inch and 8-inch diameter wells with 2-inch or 3-inch gas wellheads. An economy model is available for 6-inch gas-only wells. All well caps feature direct access ports compatible with several existing landfill products, including the QED Easy Level™ for monitoring and measuring liquid levels and a portable water level meter that provides light and sound indication when a probe touches water. Available pump fitting kits allow conversion of gas recovery caps to dual extraction wells.

About Q.E.D Environmental Systems, Inc.

Q.E.D. Environmental Systems, a subsidiary of Graco Inc., is a leading manufacturer of innovative environmental pumping systems, landfill products, landfill gas products, and air strippers for use at landfills, mines, oil refineries and other industrial sites, as well as hazardous waste cleanup sites. Our products are used around the world for a wide range of environmental applications, including groundwater sampling, groundwater remediation pumping, landfill leachate and condensate pumping, landfill gas collection and control, landfill and biogas analysis, air stripping and VOC removal, and wireless data acquisition. Based in Dexter, MI, QED serves customers from support centers in Michigan and California. For more information, call 734-995-2547 or contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

Metso Outotec signs partnership agreement with CSIRO for providing SwirlFlow® technology to Alumina refineries

Metso Outotec and Australia’s national science agency, CSIRO, have signed a global exclusive cooperation agreement on the delivery of SwirlFlow® agitation technology for the Bauxite and Alumina sector outside of China.

The combination of the companies’ leading expertise in their respective fields will allow the parties to create the strongest offering to the market for the use of SwirlFlow® technology in the refinery precipitation tanks.

Metso Outotec Swirlflow

Metso Outotec Swirlflow

“Sustainability is a top priority for Metso Outotec. In addition to our own investments to develop technology for sustainable alumina processing, we are pleased to be able to announce our cooperation with CSIRO. This will allow us to meet our customers’ growing demand such as lower capital installation, reduced spare parts costs and increase in precipitation tank availability,” says Dr. Alessio Scarsella, Director of Light Metals at Metso Outotec.

”CSIRO’s leading technology in SwirlFlow® agitation has been pioneered at a tier one refinery precipitation tanks, leading to significantly reduced maintenance costs and improved operational time between descaling events,” says Andrew Jenkin, Research Program Director for Processing at CSIRO.

Discover more about Metso Outotec solutions for alumina processing on our website.

More information about CSIRO on their website.

Further information, please contact:

Dr. Alessio Scarsella, Director Light Metals, Metals, Metso Outotec, tel. +49 172 688 0 333, email: alessio.scarsella(at)mogroup.com

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2021 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

The need for a secure web gateway Cybersecurity measures

The 2021 Global Threat Intelligence Report (GTIR) revealed that there was a 300 per cent increase in cyberattacks during 2020. The growing cyber threat puts energy grids more at risk than ever before, yet some of the cyber security protocols in this sector are often lacking in sophistication. Here, Reinhard Mayr, head of information security and research operations at automation software supplier, COPA-DATA, explains why a secure internet gateway is crucial for industry to combat rising cyber threats.

A secure internet gateway is an essential component when building a safe entry point into a critical infrastructure. It helps to protect OT infrastructure from online threats by filtering internet bound traffic and is therefore embedded in security standards. All security related standards, such as the IEC 62443, the BSI or the NIST SP 800 series, demand access to critical operational technology (OT) infrastructure is secure.

These standards do not only suggest a secure web gateway or connection, but for a company to implement a demilitarized zone (DMZ) for more OT protection. Simply put, a DMZ is a physical or logical component that separates a local area network (LAN) from other untrusted networks, acting as a buffer zone between the public internet and the private network. All inbound network packets are screened using a firewall, or other security appliance, before they arrive at the servers hosted in the DMZ.

Operators require appropriate software to follow these cybersecurity measures — but where do they start?

Revamping existing systems

A secure internet gateway can be implemented without negatively impacting existing systems, such as human machine interfaces (HMIs) and supervisory control and data acquisition (SCADA). This is particularly relevant to users in a brownfield environment, where they need to implement new software to existing — and often ageing — infrastructure without causing interference.

A web gateway, such an DMZ, also needs to support other commonly accepted security standards, like transport layer security (TLS) encryption, and digital authentication methods. It also must be integrated seamlessly into the existing infrastructure, while also being able to support different ways of deployments, from a native local installation to a containerizes option.

Containerization simplifies administration and is another step to making systems secure. Here, containerization implements tools and policies to ensure that container infrastructure, apps and other container components are protected. Applications run in isolated user spaces, called containers, using the same shared operating system (OS).

With software like COPA-DATA’s zenon Service Grid, it is easy to implement on brownfield applications. Its design allows access to data without impacting existing infrastructure. This is particularly crucial for energy grids and infrastructures that contain legacy equipment.

This method can help to prevent any unwanted denial of service (DoS) blocking an operator’s path, access information systems, devices or other network resources due to a malicious cyber threat.

Up to the standard

Scenarios like this are recognized in the security industry standards and must be supported by software.

Continuing with our aforementioned example, COPA-DATA’s zenon Service Grid communicates using certificate-based TLS connections, ensuring secure transmission of information, even over public networks. Here, the software’s Identity Service handles data flows and access rights over the web, which is crucial for a secure web gateway.

The Identity Services does this by providing high project specific security standards and checking all connection requests from all Service Grid connections. This service also includes a web bases interface to configure access clients, user roles and access rights.

Greater protection and a higher level of sophistication is a necessity in cybersecurity measures for the energy sector. And with the right software, adhering to industry standards and providing a more secure internet gateway, users can protect their critical OT infrastructure to significantly reduce the number of cyber security attacks.

About COPA-DATA

COPA-DATA is an independent software manufacturer that specializes in digitalization for the manufacturing industry and energy sector. Its zenon® software platform enables users worldwide to automate, manage, monitor, integrate and optimize machines, equipment, buildings and power grids. COPA-DATA combines decades of experience in automation with the potential of digital transformation. In this way, the company supports its customers to achieve their objectives more easily, faster and more efficiently. The family-owned business was founded by Thomas Punzenberger in 1987 in Salzburg, Austria. In 2021, with more than 300 employees worldwide, it generated revenue of EUR 64 million.

Amara Raja, leading Indian battery manufacturer joins global research organization

Supporting advanced lead battery research and innovation, the Consortium for Battery Innovation (CBI) has welcomed its newest member - and largest Indian battery manufacturer in membership - Amara Raja.

Headquarted in Tirupati, Andhra Pradesh, India, Amara Raja Batteries Limited (ARBL) is a technology leader that has been instrumental in the development and production of advanced lead battery technologies since it’s establishment in 1985.

Working in both the automotive and industrial sectors, Amara Raja is a leading supplier for industries including OEM, UPS, telecoms and solar energy storage in India as well as countries in the Indian Ocean rim. Demand is on the rise for batteries in India, forecast to grow to 260 GWh annually by 2030.

Partnering with industry, research institutes and universities across the globe, CBI drives pre-competitive research to deliver the next generation of advanced lead batteries with enhanced performance to meet future market demand.

Partnering with industry, research institutes and universities across the globe, CBI drives pre-competitive research to deliver the next generation of advanced lead batteries with enhanced performance to meet future market demand.

Ambitious targets are underway in India’s renewable energy storage sector, with goals of adding 300 GW of renewables by 2030. The need for high-performing, sustainable and innovative lead batteries is more critical than ever to support this clean energy transition which will represent a 20% year-over-year growth in solar and wind capacity.

CBI’s Director, Dr Alistair Davidson, said: “We are excited to have Amara Raja on board as our newest and largest Indian lead battery manufacturer. This regional market is extremely important for lead batteries, particularly in energy storage, and we’re looking forward to working with them to really drive innovation in the technology.

ARBL Chief Technology Officer, Mr. Jagadish M, said, “We are excited to be part of this consortium. We look forward to leveraging this opportunity to dominate the energy sector with innovative products. By working together, we can improve our technical capabilities and explore many energy-related applications.”

ARBL Executive Director, Mr. Harshavardhana Gourineni, said: “We are honored to be a part of this consortium, which brings together, and shares innovations and cutting-edge technology. We continue to be delighted to engage with businesses that complement our strengths and help generate value in our growth areas. This relationship will provide us with space for new generation energy storage and global corporate expansions.”

CBI organizes high-impact technical workshops for its membership throughout the year in North America, Europe, China and, for the first time this year, India. These events bring together leading global battery experts to stimulate technical discussion about the latest research and developments in the technology. The meetings also identify key innovation pathways for future advanced batteries to delve into the significant untapped potential of lead battery technology.

About the Consortium for Battery Innovation

The Consortium for Battery Innovation is the world’s only global pre-competitive research organization funding research into lead batteries for energy storage, motive and automotive applications. For more than 25 years, with its global membership of battery manufacturers, industry suppliers, research institutes and universities, CBI has delivered cutting-edge research pushing the boundaries of innovation in lead battery technology, setting the standard for advanced lead batteries and the next generation of energy storage. For more information, visit our website: www.batteryinnovation.org

About Amara Raja

Amara Raja Batteries Limited is an Energy and Mobility enterprise and one of the largest manufacturers of energy storage products for both industrial and automotive applications in the Indian battery industry.

In India, Amara Raja is the preferred supplier to major telecom service providers, Telecom equipment manufacturers, the UPS sector (OEM & Replacement), Indian Railways and to the Power, Oil & Gas, among other industry segments. Amara Raja’s industrial battery brands comprise PowerStack®, AmaronVolt® and Quanta®. The Company is a leading manufacturer of automotive batteries under the brands Amaron® and PowerzoneTM, which are distributed through a large Pan-India sales & service retail network.

The Company supplies automotive batteries under OE relationships to Ashok Leyland, Ford India, Honda, Hyundai, Mahindra & Mahindra, Maruti Suzuki, and Tata Motors. The Company’s Industrial and Automotive Batteries are exported to countries in the Indian Ocean Rim.

Intelligent instruments for optimizing mining operations: introducing Metso Outotec Sense series

Metso Outotec has grouped its portfolio of intelligent instruments under the Sense series. The portfolio is designed to solve specific process challenges and enable optimization for minerals and hydrometallurgical processes. The market’s most comprehensive portfolio of intelligent instruments is part of Metso Outotec’s Planet Positive offering. Covering the entire flowsheet, Sense series instruments are suited for both new and existing operations.

“Metso Outotec Sense series includes specialized instruments that provide data for analytics and a better understanding of processes. They utilize the latest technologies, such as artificial intelligence (AI) and neural networks for extra insight. These additional tools for process problem solving and data mining can significantly help improve production within customer operations,” explains Veli-Matti Järvinen, Vice President, Automation product group at Metso Outotec.

The latest additions to the portfolio bring improved value

- Metso Outotec FrothSense+™ takes flotation optimization to the next level with the latest technology and capabilities. It has completely new and redesigned software and hardware. It includes the best features from two legacy systems, FrothSense™ and VisioFroth™, and adds new capabilities such as froth height measurement, history analysis and artificial intelligence with deep learning algorithms to detect flotation properties.

- The new Metso Outotec RockSense™ product family will take comminution optimization to the next level with better knowledge of particle size distribution (PSD) on the belt. RockSense consists of a renewed, two-level offering: RockSense 3D and RockSense 2D, formerly known as VisioRock™. They enable online, continuous on-belt coarse particle size distribution. RockSense 3D also adds new capabilities with artificial intelligence and deep learning algorithms to detect oversized lumps and foreign objects, for example.

- Metso Outotec MillSense™ provides online volumetric charge analysis by direct measurement of charge position. It is now available, together with SmartEar™, as a bundle. SmartEar™ uses sound to give an additional measurement of charge impacts and liner wear. The bundle fuses acoustic, vibration and force sensor information for improved online analytics of mill operations. This enables new ways of optimizing grinding performance.

In total, Metso Outotec intelligent instruments include more than 10 technologies to optimize the mining process:

- RockSense™ 2D: An online particle size analyzer system for rocks moving on a conveyor belt that uses 2D imaging technology.

- RockSense™ 3D: Accurate, continuous on belt coarse particle size distribution and volume flow using 3D imaging.

- MillSense™: Analysis of toe and shoulder position and total volume of the charge. Enables load control and mill optimization.

- FrothSense+™: New system with best features and capabilities for froth flotation analysis. It adds AI neural network, multiple regions of interest and froth height measurement.

- CycloneSense™: An online measurement of hydrocyclone air core data enables measuring and visualization of their performance.

- LevelSense™: Utilizing electrical impedance tomography (EIT), LevelSense improves the slurry level measurement of flotation cells.

- CarbonSense™: An online measurement of carbon concentration in carbon-in-pulp and carbon-in-leach applications.

- CellSense™: Tankhouse monitoring system that automatically measures electrolyte temperature and voltage in individual cells.

- SmartEar™: Online impact analyzer uses sound to provide additional measurements of charge impacts and lifter/liner wear.

- VisioTruck™: Advanced vision technology for estimating rock size distribution of mine truck loads.

- SmartTag™: An innovative system for open pit and underground mines to track ore from the mine to the processing plant, and beyond.

- VisioPellet™: A pellet size-control system that measures the size of green pellets using proven camera technology installed in a pelletizing disc or drum.

Sustained results with Metso Outotec’s automation and digital solutions

Metso Outotec’s automation and digital solutions are designed to provide performance improvements for our customers. These results can be sustained and improved through the support of additional Expert Services or a long-term Metso Outotec Life Cycle Services (LCS) contract.

More information about the Metso Outotec Sense series is available on our website.

Get the big picture of Metso Outotec automation here.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2021 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com