Super User

Chevron Sanctions Ballymore Project in Deepwater U.S. Gulf of Mexico

Chevron Corporation (NYSE: CVX) announced today it has sanctioned the Ballymore project in the deepwater U.S. Gulf of Mexico. The project, with a design capacity of 75,000 barrels of crude oil per day, will be developed as a three-mile subsea tieback to the existing Chevron-operated Blind Faith platform.

“Chevron’s U.S. Gulf of Mexico production is some of the lowest carbon intensity production in our portfolio at around 6 kg CO2 equivalent per barrel of oil equivalent and is a fraction of the global industry average,” said Steve Green, president of Chevron North America Exploration and Production. “Once complete, Ballymore is expected to add a reliable supply of U.S.-produced energy to help meet global demand. The project is designed to lower development costs by using a subsea tieback approach, standardized equipment and repeatable engineering solutions – leveraging existing operated infrastructure.”

“Chevron’s U.S. Gulf of Mexico production is some of the lowest carbon intensity production in our portfolio at around 6 kg CO2 equivalent per barrel of oil equivalent and is a fraction of the global industry average,” said Steve Green, president of Chevron North America Exploration and Production. “Once complete, Ballymore is expected to add a reliable supply of U.S.-produced energy to help meet global demand. The project is designed to lower development costs by using a subsea tieback approach, standardized equipment and repeatable engineering solutions – leveraging existing operated infrastructure.”

Ballymore will be Chevron’s first development in the Norphlet trend of the U.S. gulf. The project will be in the Mississippi Canyon area in around 6,600 feet (2,000 m) of water, about 160 miles (260 km) southeast of New Orleans. Potentially recoverable oil-equivalent resources for Ballymore are estimated at more than 150 million barrels.

The project, which involves three production wells tied back via one flowline to the nearby Blind Faith facility, will require an investment of approximately $1.6 billion. Oil and natural gas production will be transported via existing infrastructure. First oil is expected in 2025.

Chevron subsidiary Chevron U.S.A. Inc. is the operator of the Ballymore project with a 60 percent working interest. Co-owner TotalEnergies E&P USA, Inc. has a 40 percent interest.

About Chevron

Chevron is one of the world’s leading integrated energy companies. We believe affordable, reliable and ever-cleaner energy is essential to achieving a more prosperous and sustainable world. Chevron produces crude oil and natural gas; manufactures transportation fuels, lubricants, petrochemicals and additives; and develops technologies that enhance our business and the industry. We are focused on lowering the carbon intensity in our operations and seeking to grow lower carbon businesses along with our traditional business lines. More information about Chevron is available at www.chevron.com.

Solenis Recognizes Contact Energy as Winner of a 2021 Sustainability Award for Project That Significantly Offset Carbon Dioxide Emissions

Solenis LLC, a leading global producer of specialty chemicals, is proud to announce that Contact Energy Limited is a winner of a 2021 Solenis Sustainability Award. Contact Energy’s Wairakei geothermal power plant in Taupō, New Zealand, has received recognition for a project that offset carbon dioxide emissions by around 57,000 tons of CO2 equivalent (tCO2e, which includes methane) over one year, compared to coal.

Contact Energy’s project was focused on returning an 8-megawatt geothermal well to full production capacity. Buildup of minerals, mostly in the channels through the rocks underground near the well (formation scale), reduced the flow of steam so severely that the well could no longer contribute to the electricity output of the plant.

Any shortfall in low-carbon geothermal electricity generation in New Zealand is made up by fossil fuels, increasing the country’s carbon footprint. Abandoning the well and drilling a new one would cost up to $10 million, which was not a satisfactory option. Cleaning the well with harsh chemicals, such as hydrofluoric acid, was also unattractive because of its cost, aggressive nature, risks to operators and short-term effectiveness, especially on the silica formation scale seen at Wairakei.

Contact Energy needed a solution and partnered with Solenis field professionals and technical specialists to work on the problem. Solenis recommended a new method of cleaning the rock formation that combined advanced concepts from reservoir engineering, geology and pumping dynamics. The solution used low concentrations of chemicals, high pressure, high flow rates and carefully controlled flow to allow cleaning chemicals to penetrate the fissures in the rock formation and dissolve the scale buildup.

Trials showed it was so effective that a well’s output capabilities could not only be recovered but expanded. The expansion is attributed to stimulation of the formation near the wellbore by dissolution of rock minerals, creating slightly larger pathways for flow. In addition to the method’s effectiveness, the chemical portfolio developed by the Solenis team performed exceptionally well in geothermal conditions, had a significantly improved safety profile and was far more cost-effective than conventional methods.

Solenis recognized Contact Energy’s Wairakei geothermal power plant with a 2021 Solenis Sustainability Award for a project that reduced scale and improved power generation, saving around 57,000 tons of CO2 equivalent over one year compared to coal.

Solenis recognized Contact Energy’s Wairakei geothermal power plant with a 2021 Solenis Sustainability Award for a project that reduced scale and improved power generation, saving around 57,000 tons of CO2 equivalent over one year compared to coal.

The solution developed by Contact Energy and Solenis produced outstanding results. With the wellbore cleaned of scale, output peaked at 130 percent of the well’s expected recoverable capacity, which translated to an increased power generation of around 50,000 megawatt-hours over the year following the clean.

Because this geothermal energy source is very low carbon, it has a positive effect on carbon emissions. Estimated emissions from this geothermal generation over that one year are 1,080 tCO2e, significantly less than fossil fuel alternatives. Generating the same power from coal would produce around 58,600 tCO2e, or 23,900 tCO2e from combined-cycle gas.

Contact Energy was very pleased with the outcome of the project. John Clark, Chief Generation Officer at Contact Energy, said, “Our company strategy is to lead New Zealand’s decarbonization journey, and our renewable generation capacity has a critical role to play. To be able to take our existing operations and continuously improve and deliver better outcomes for the whole of New Zealand is incredibly exciting. We will continue to invest our time and resources to build a better New Zealand for future generations.”

Solenis was equally pleased by the partnership. Andrew Dine, the New Zealand commercial lead at Solenis, said, “Our company values collaboration. We try to be present with advice for our customers in their water-intensive tasks or long-term strategies. Wherever these goals and sustainability intersect, we’ll be there.”

The Solenis Sustainability Awards program reviews customer projects completed over the previous 12 months and chooses those delivering high value and high impact. The awards recognize projects in five sustainability categories, including reduced water use, reduced energy use, improved carbon footprint, reduced waste and optimized raw material utilization. To learn more about Solenis and sustainability, visit the Solenis website at: www.solenis.com/en/sustainability/strategic-vision

About Solenis

Solenis is a leading global producer of specialty chemicals, focused on delivering sustainable solutions for water-intensive industries, including the pulp, packaging paper and board, tissue and towel, oil and gas, petroleum refining, chemical processing, mining, biorefining, power, municipal, and pool and spa markets. The company’s product portfolio includes a broad array of water treatment chemistries, process aids and functional additives, as well as state-of-the-art monitoring and control systems. These technologies are used by customers to improve operational efficiencies, enhance product quality, protect plant assets, minimize environmental impact and maintain healthy water. Headquartered in Wilmington, Delaware, the company has 47 manufacturing facilities strategically located around the globe and employs a team of over 6,000 professionals in 120 countries across five continents. Solenis is a 2022 US Best Managed Company.

For additional information about Solenis, please visit solenis.com

About Contact Energy

Contact Energy is one of New Zealand’s largest energy retailers and generators. The company generated 8.4 terawatt hours of electricity from hydro, geothermal and gas last year and managed more than 550,000 customer connections. Contact Energy’s vision is to build a better New Zealand and play a leading role in the decarbonization of the energy sector and wider economy.

Bacton Gas Terminal secures coupling reliability with Bibby Turboflex

The Bacton Gas Terminal supplies up to a third of the UK’s total gas demand, whilst also exporting gas to Europe 1. Now more than ever, the reliability of the nation’s energy supply is paramount, making the Bacton complex one of the UK’s most crucial energy infrastructure assets. To support continued reliability at one of the six gas terminals making up the complex, Bibby Turboflex recently refurbished a critical gas compressor coupling which had been operational for two decades.

Located on the Norfolk coast, the Bacton Gas Terminal can process up to 58 million cubic metres of gas per day 2, most of which is extracted from North Sea oilfields, delivering it via pipeline to homes and businesses across the UK. The UK Government estimates gas constituted 41.9% of all inland energy consumption in 2020,3therefore ensuring reliability at sites like Bacton Gas Terminal is essential for supporting the UK’s energy needs. Generally, it is recommended that plant operators hold critical spares, such as power transmission products, to maximise operational efficiency and minimise breakdowns and downtime.

Bibby Turboflex high performance 305S Torquemeter disc coupling.

Bibby Turboflex high performance 305S Torquemeter disc coupling.

Installed between a gas turbine and a high-speed compressor, the Bibby Turboflex high performance 305S Torquemeter disc coupling operated at peak performance for more than 20 years. With a torque rating up to 100 kNm and a max speed of 7700 RPM, this unique coupling features an integrated torque meter that measures asset efficiency ensuring maximum gas output. Due to its length in service, plant operators decided to install the site’s spare coupling and return the original operational coupling back to Bibby for a health check and any necessary refurbishments.

A leading brand of Altra Industrial Motion Corp., Bibby Turboflex is a market leader in the design and manufacture of high performance engineered couplings specifically designed for turbomachinery applications.

The coupling was returned to Altra’s Bedford facility. Within two weeks, the coupling was disassembled and removed from the bearing casing. All components were cleaned, de-greased and checked, with major components then shot blasted. Utilising a coordinate measuring machine (CMM), the critical dimensions of all parts were checked against the original coupling drawings. A thorough magnetic particle inspection (MPI) was performed and a written detailed inspection report, including photos of any defects, sent to the customer.

Now more than ever, the reliability of the nation’s energy supply is paramount. (AdobeStock_248615217)

Now more than ever, the reliability of the nation’s energy supply is paramount. (AdobeStock_248615217)

Subsequently, Bibby replaced all flexible elements and hardware. The coupling was then re-phosphated, re-assembled and dynamically balanced back to original specification prior to shipping back. The complete overhaul returned the coupling to its original production condition. The coupling was delivered back to the customer with a full 1-year warranty.

The local engineering capabilities offered by Bibby meant that the coupling could be returned to an optimal condition quickly. The plant maintained operation efficiency by holding a critical spare coupling in stock, therefore allowing the operational coupling to be sent back for repair. Furthermore, refurbishment provided increased value compared to supplying an all-new custom coupling. In addition to the significant cost reduction and time saving repair offers over purchasing new, repairing the coupling had a much lower carbon impact on the environment.

With securing energy supply an ever more pressing issue, operators choosing reliable power transmission components backed by responsive OEM maintenance support can help maximise operational efficiency by minimising downtime and failures. As a result, homes and businesses can be sure of reliable power and heating all year round. The next time you turn on the lights, heating or water think about the quality rotating equipment which supports those everyday utilities.

Sources:

1:https://www.shell.co.uk/about-us/what-we-do/bacton-gas-plant/about-bacton-gas-plant.html

2:https://www.fluxys.com/en/company/interconnector-uk/infrastructure

3:https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/1032260/UK_Energy_in_Brief_2021.pdf

About Bibby Turboflex

Since 1917, with the introduction of the resilient grid coupling, Bibby Turboflex has been recognised as a global leader in the design and manufacture of highly-engineered industrial couplings. Bibby develops reliable and safe power transmission solutions that eliminate downtime and optimise efficiency.

World-class Bibby Turboflex product lines include grid, gear and pin & bush couplings, high performance Torsiflex and Transmissions disc couplings plus a wide range of torque limiters and torque limiting modules.

Bibby Turboflex solutions can be found hard at work in a variety of key markets including power generation, metals, oil & gas and food & beverage on applications such as pumps, conveyors, gearboxes, fans & blowers, compressors, printing presses, gas & steam turbines, generators, ball mills, extruders and marine/offshore platforms.

Konecranes named best Finnish Large Cap company on furthering diversity

At its annual gala, the Finnish Foundation for Share Promotion (Pörssisäätiö), a foundation promoting securities investment and the securities market, rewarded Konecranes as the best Finnish Large Cap company on furthering diversity. Diversity and inclusion are cornerstones of Konecranes’ culture and business, propelling its performance and organization.

With the award, Konecranes was praised for its all-company diversity trainings, set targets, activities and processes. Konecranes has placed special focus on key topics such as inclusive recruitment and accountability.

“Diversity and inclusion are key for our culture and performance as a company. We are humbled to receive this award, with big thanks to our people who made our progress a reality through their participation and commitment”, Konecranes Interim CEO Teo Ottola says.

Konecranes has made diversity and inclusion a top priority, with an ambition to reshape both the company and industry. In 2019, the company established the position of Chief Diversity & Inclusion Officer and embarked on a multi-year roadmap. Diversity brings a wide range of benefits: improving innovation and performance, enabling employees to have equal opportunities and being close to customers by representing the societies the company operates in.

Progress is monitored through a set of key metrics, including gender balance as well as representation of nationalities and geographies. To ensure everyone’s involvement, trainings on diversity and inclusion are mandatory for the entire company.

“I’m proud of our progress. Inclusion is underpinning our culture and we have made improvements in our gender representation and diversity is being advanced on all levels and sectors of the company. Still, there is much to achieve for both us and the industry and we are determined to be pioneers in that work”, Konecranes Chief Diversity & Inclusion Officer Mara Zavagno says.

For more information on Konecranes work on diversity and inclusion, please see the 2021 Sustainability Report.

Further information:

Mara Zavagno, Chief Diversity & Inclusion Officer, Konecranes

Email: This email address is being protected from spambots. You need JavaScript enabled to view it. or phone: +491722030543

Konecranes is a world-leading group of Lifting Businesses, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2021, Group sales totaled EUR 3.2 billion. The Group has around 16,600 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

TotalEnergies pursues its development in floating offshore wind with the start of construction of a first farm in France

TotalEnergies is pleased to announce the start of construction of the Eolmed project, operated by Qair and in which TotalEnergies has a 20% stake. This 30 MW project is located more than 18 km off the coast of Gruissan and Port la Nouvelle (Occitan region). The start of production is expected by 2024.

The wind farm will consist of three 10 MW wind turbines mounted on steel floats and connected to the French Electricity Transmission Network (RTE) by an underwater cable.

The project meets the objectives of the partners to ensure its good environmental integration and to promote the know-how of the Occitanie Region thanks to the involvement of all the stakeholders. Eolmed is part of the Occitanie Region's strategy to relocate industrial production: the consortium has chosen a joint venture formed by Matière and Ponticelli to produce the floats in Bagnac-sur-Célé (Lot) and Port-la-Nouvelle (Aude). This joint venture will benefit from the port's new infrastructure and will mobilize more than 600,000 man-hours of work across Occitania.

This project is part of TotalEnergies’ strategy to develop floating wind energy, which allows access to deeper sites, further from the coast, and to take advantage of greater wind resources. The Company is developing this technology in France and abroad through several projects at different stages of development:

- In France, In addition to the Eolmed project in the Mediterranean Sea, the Company is participating in a tender in Brittany to develop a floating wind farm with Green Investment Group and Qair,

- In South Korea, TotalEnergies is developing a portfolio of over 2 GW of floating offshore wind with Green Investment Group,

- In the UK, TotalEnergies is developing the 96 MW Erebus project in the Celtic Sea with its partner Simply Blue Energy,

- In the United States, TotalEnergies launched the TotalEnergies SBE US joint venture with Simply Blue Group to contribute to the growth of floating wind in the country.

“We are proud to contribute through Eolmed to France’s development in floating offshore wind, a very promising segment in which TotalEnergies notably brings its extensive experience in offshore projects. Together with our partners, we will mobilize our know-how and our best resources to meet the technological and industrial challenges of this project, which meets the dual objective of developing local content while providing renewable energy,” said Olivier Terneaud, VP Offshore Wind at TotalEnergies.

TotalEnergies and offshore wind

TotalEnergies is already developing a portfolio of offshore wind projects with a total capacity of more than 11 GW, of which 2/3 are bottom-fixed and 1/3 are floating. These projects are located in the United Kingdom (Seagreen project, Outer Dowsing, Erebus, ScotWind), South Korea (Bada project), Taiwan (Yunlin project), France (Eolmed project) and the United States (New York Bight project, North Carolina project). The Company has also been qualified to participate in competitive tenders in the US, UK and France, and will also participate in tenders in Norway, in Poland and Netherlands.

TotalEnergies and renewables electricity

As part of its ambition to get to net zero by 2050, TotalEnergies is building a portfolio of activities in renewables and electricity. At the end of September 2021, TotalEnergies' gross renewable electricity generation capacity is 10 GW. TotalEnergies will continue to expand this business to reach 35 GW of gross production capacity from renewable sources and storage by 2025, and then 100 GW by 2030 with the objective of being among the world's top 5 producers of electricity from wind and solar energy.

About TotalEnergies

TotalEnergies is a global multi-energy company that produces and markets energies: oil and biofuels, natural gas and green gases, renewables and electricity. Our more than 100,000 employees are committed to energy that is ever more affordable, cleaner, more reliable and accessible to as many people as possible. Active in more than 130 countries, TotalEnergies puts sustainable development in all its dimensions at the heart of its projects and operations to contribute to the well-being of people.

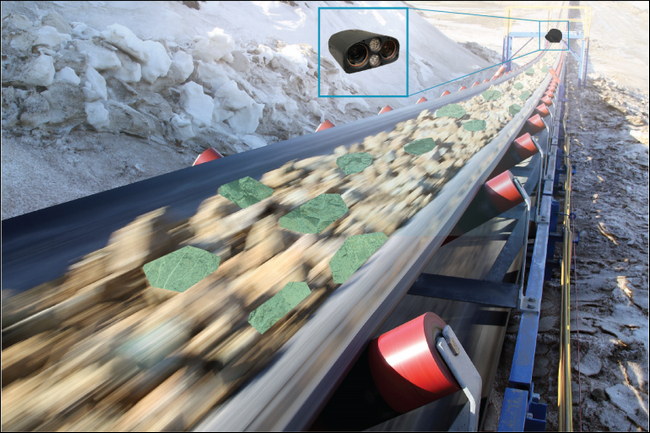

Hexagon introduces 3D camera for complete production material monitoring

Hexagon’s Mining division has just strengthened its leadership in production material monitoring and measurement by introducing HxGN MineMeasure Detect, a 3D camera hardware, software and data solution. MineMeasure Detect enables real-time optimization for plant production with automated digital-image analysis offering continuous, accurate and rapid measurement of oversize, volume, rock fragmentation and color analysis.

Mines demand consistent, predictable, high-volume production with plants intended to operate 24/7. Changing geologic mineral and structural conditions within mining benches can sometimes mean oversize particles block crushers, chutes and conveyors. Blockages can halt operations, in severe cases resulting in lost operational revenues worth millions of dollars.

MineMeasure Detect minimizes production interruptions and costly downtime with oversize detection of large particles. It enhances production efficiencies and reconciliation by calculating volume, density and tonnage. Advanced detection reveals an aggregate of previously unmeasured ancillary variables, such as material density and hardness, which is essential to throughput maximization and ore liberation.

The solution’s fragmentation analysis capabilities enable continuous monitoring and improvement of production throughput while managing costs. Industry-leading research and proven algorithms for direct measurements of particle identification and fines identification set MineMeasure Detect apart for its measurement accuracy in mineral processing. It includes the largest set of data availability applied across the international mining industry. Color-analysis data for ore detection empowers operators with additional opportunities to adjust material handling, material blending, clay detection and ore treatment recipes.

“MineMeasure Detect is built on more than 25 years’ experience partnering with international mining operations, allowing systems to be fully integrated with customer technologies,” said James Dampney, VP-MineMeasure, Hexagon’s Mining division. “Combined with our fragmentation tools, the solution’s immediate detection capabilities offer a critical early warning for operators to avoid catastrophic production stoppages.

“With its image-analysis techniques ensuring that fragmentation is managed and optimized, MineMeasure Detect fits seamlessly in the MineMeasure portfolio, which delivers scrutiny and transparency in every step of the ore extraction journey.”

To see HxGN MineMeasure Detect in action at Capstone Copper’s Pinto Valley Mine, click here.

Hexagon is a global leader in digital reality solutions, combining sensor, software and autonomous technologies. We are putting data to work to boost efficiency, productivity, quality and safety across industrial, manufacturing, infrastructure, public sector, and mobility applications.

Our technologies are shaping production and people-related ecosystems to become increasingly connected and autonomous — ensuring a scalable, sustainable future.

Hexagon’s Mining division solves surface and underground mine challenges with proven technologies for planning, operations and safety.

Hexagon (Nasdaq Stockholm: HEXA B) has approximately 22,000 employees in 50 countries and net sales of approximately 5.1bn USD. Learn more at hexagon.com and follow us @HexagonAB.

Emerson’s New Emergency Shutdown Discrete Valve Controller Improves Safety, Uptime in Hazardous Applications

TopWorx DX Partial Stroke Test with HART 7 provides detailed valve assembly data and diagnostics, enabling predictive maintenance and reliable operation.

Emerson has just introduced the TopWorxTM DX PST with HART® 7. Units provide valuable valve data and diagnostic information, enabling the digital transformation of process applications. The new DX PST integrates seamlessly with existing valves and control systems, giving operators access to critical valve data, trends, and diagnostics that can be used to predict and schedule maintenance.

The DX PST’s partial stroke test ensures the system’s reliable function without shutting down the process. A safety feature that confirms the valve will fully close and stop the process if an emergency is detected, and the test is activated by simply pressing the local PST button — no additional equipment is required. To prevent critical failure in upset conditions, the unit will override testing to perform an emergency shutdown (ESD).

Certified for operation in harsh and hazardous applications, the adaptive DX PST is designed to ensure the integrity of valves, improving overall safety and facility uptime in oil and gas, refinery, chemical, industrial energy and mining applications.

TopWorx DX PST with HART 7 monitors and tests valve assemblies, providing detailed data and diagnostics and enabling the digital transformation of process applications.

TopWorx DX PST with HART 7 monitors and tests valve assemblies, providing detailed data and diagnostics and enabling the digital transformation of process applications.

“The digital transformation of the process industry continues to make operations safer and more productive,” said Prayag Vatsraj, Global Product Manager of Emerson’s Switchbox. “The DX PST with HART 7 supports digital transformation by providing reliable data that delivers valuable insight into the condition of valve assemblies that ensures the integrity of the system without shutting down the process.”

The HART® protocol, the specifications of which are owned by the FieldComm Group, builds another layer of information that ensures data, trends and diagnostics are monitored and tied into the Industrial Internet of Things. This information can be used to effectively predict and schedule maintenance.

Capable of Safety Integrity Level 3 (SIL 3), the DX PST is available with an integrated 2oo2 or 2oo3 solenoid valve redundancy when paired with ASCOTM Series Advanced Redundant Control System (ARCS) to further enhance safety and open terminals that allow an additional pressure transmitter along with two pressure switches. The discrete valve controller offers simple local and remote calibration.

Additional resources:

• Join the Emerson Exchange 365 Community

• Connect with Emerson via Twitter Facebook LinkedIn YouTube

• Learn more about the TopWorxTM DX PST with HART® 7

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and engineering company providing innovative solutions for customers in industrial, commercial, and residential markets. Our Automation Solutions business helps process, hybrid, and discrete manufacturers maximize production, protect personnel and the environment while optimizing their energy and operating costs. Our Commercial and Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency, and create sustainable infrastructure. For more information visit Emerson.com.

Emerson Automation Solutions | AVENTICS GmbH | Ulmer Straße 4 | 30880 Laatzen | Germany

Ayhan Ronai

Phone : T +49 511 2136 ext 862

This email address is being protected from spambots. You need JavaScript enabled to view it.

Cepsa Quimica introduces chemical products based on recycled raw materials and biomass

London-based leading global chemicals business Cepsa Quimica has introduced the first two products in a new line of sustainable chemicals: NextLAB and NextPhenol.

- NextLAB and NextPhenol: first products in a new line of sustainable chemicals

Cepsa Quimica, a market leader in sales of solvents in the UK, has tanks in Tees and Dagenham and distributes its products from those two terminals.

NextLAB and NextPhenol, which are used primarily for the production of cleaning agents and engineering plastics, are now made from renewable and recycled raw materials.

The introduction of the new product lines is not only part of Cepsa Química’s ambitions to make its own business activities fossil-free in the long term, but it also helps Cepsa customers to make their products and production processes more sustainable.

The introduction of the new product lines is not only part of Cepsa Química’s ambitions to make its own business activities fossil-free in the long term, but it also helps Cepsa customers to make their products and production processes more sustainable.

Cepsa Quimica is one of the world's leading producers of LAB (linear alkylbenzene) and phenol. LAB is mainly used in the production of biodegradable, household laundry and cleaning products. Phenol is used in the automotive, construction and pharmaceutical industries among others as a raw material for the production of engineering plastics, nylon, polycarbonate, methyl methacrylate (MMA) and coatings.

“Cepsa Quimica has formulated clear objectives to make the company sustainable and fossil-free in the long term,” explains Jose Maria Cuadro, Head of Cepsa Química’s division for Feedstocks, ESG & HSEQ. “To achieve this, we not only look at our own production processes, energy consumption and the supply chain, but above all we also look at the origin of the raw materials, replacing traditional fossil sources for renewable feedstocks and wastes.

Product specifications

“Although the new range of products, marketed under the NextLAB and NextPhenol brands, contains at least 68% of sustainable (or alternative) carbon sources using the mass balance approach, we are ultimately still supplying the same molecules,” explains Jose María Cuadro. “The only difference is that we no longer get them from fossil sources, but from waste and biomass. The product specifications, performance and applications of the new products are basically the same and the REACH perspective does not change either. We do have to adapt our production processes, because renewable and recycled raw materials need additional treatment.

“From a production point of view the customer however will not notice any difference between the traditional and new products. In addition to increased efficiency in the processing systems, the biggest benefit is that the customer will be able to increase the sustainability of its products and production processes thanks to our sustainable raw materials and thus reduce their ecological footprint. Buyers and consumers are increasingly demanding this.”

ISSC+ certification

The new NextLAB and NextPhenol product lines are currently being produced at factories of Cepsa Quimica in the Spanish provinces of Cádiz and Huelva, but also in Shanghai. These plants have been certified according to the ISCC Plus standard, which focuses on the sustainability and traceability of recycled materials, waste products and biomass for the production of recyclable plastics and chemical raw materials. The ISCC Plus certificate proves that a company meets globally recognised requirements for ecology and sustainability, voluntary reduction of greenhouse gases and traceability. ISCC Plus certifications are also in the pipeline for the production of LAB and LABSA at the plants in Detén (Brazil) and Bécancour (Canada).

Next steps

Cepsa's portfolio of sustainable raw materials and sustainable products will be expanded in the coming years. The development of the new product lines is a logical result of the continuous focus of the company on innovation and sustainability of both products and production processes as Cepsa Química, together with Universal Oil Products (UOP) developed the Detal technology, the most modern and environmentally friendly production process currently available for the manufacture of LAB

About Cepsa Quimica

Cepsa Química is a world leader in its sector and is leading the shift towards sustainable chemistry, with a clear commitment to the fight against climate change and the transition to a circular, non-fossil economy. The company leads the worldwide production of LAB, the main raw material used in biodegradable detergents, where Cepsa Química is a pioneer player. It is also number one in the production of cumene, an intermediate product used in the production of phenol and acetone, which are the main raw materials for the manufacture of engineering plastics and of which it is the world's second largest producer. Cepsa Química currently employs more than 1.000 people and has plants in seven countries around the world (Spain, Germany, Brazil, Canada, China, Indonesia and Nigeria).

Valmet to deliver a BioPower heat and power plant and a pretreatment BioTrac system to ORLEN Poludnie S.A. in Poland

Valmet will deliver key technology areas for ORLEN Poludnie’s S.A. planned second generation bioethanol (B2G) plant in Jedlicze, Poland. The engineering, procurement, and construction (EPC) delivery includes a pretreatment BioTrac system with a capacity to process approximately 400 tons of dry straw per day, a BioPower 48 MWth lignin fired combined heat and power (CHP) plant and a Valmet DNA Automation system.

The order was included in Valmet’s orders received of the first quarter 2022. The value of the order will not be disclosed.

The plant will start its operation in 2024. Through this project ORLEN Południe S.A. will increase its share in the biofuels market. In addition, the project will support ORLEN’s ambition to reach the EU target for bio-additives in the liquid fuels market. Bioethanol will be produced from non-food agricultural feedstocks (predominantly cereal straw) sourced mainly from Polish farmers.

Ethanol process byproduct, lignin, is used as fuel in the BioPower CHP plant, producing all steam for the ethanol plant and power.

Ethanol process byproduct, lignin, is used as fuel in the BioPower CHP plant, producing all steam for the ethanol plant and power.

“Valmet has a natural role to support its customers in the global transition from fossil fuels to renewable resources. The second-generation bioethanol is a very good example of Valmet utilizing the decades of experience in biomass processing for developing solutions that can be used for other applications outside its traditional pulp, paper and energy field. We see great potential in this field and are very happy to have been selected by ORLEN Południe S.A. as a key technology partner in this very important project”, says Bertel Karlstedt, Business Line President, Pulp and Energy, Valmet.

Technical information about the delivery

The delivery includes a Valmet Pretreatment BioTrac system and a Valmet BioPower heat and power plant. Both installations are controlled by a Valmet DNA automation system with embedded information management and cyber security solutions. The BioTrac pretreatment enables an annual production capacity of 25 000 tons of bioethanol.

Valmet BioPower plant is based on proven bubbling fluidized bed (BFB) combustion technology and flue gas cleaning combined with factory manufactured modules enabling faster project implementation, shorter site time and completion with better quality and lower implementation risks. The fuel capacity of the plant is 48 MWth.

About the customer

ORLEN Południe S.A. is a member of the Capital Group of PKN ORLEN S.A. The business activity of ORLEN Południe focuses on the primary product segments related to the production and sales of biofuels and biocomponents, paraffin and solvents. Consistently developed technologies, emphasis on the development of know-how and a series of optimization initiatives are the foundations of the company’s development towards a bio-refinery. ORLEN is an integrated, multi-utility company operating in Central Europe and Canada. It provides energy and fuel to over 100 million Europeans, and the products are sold to over 90 countries across six continents. ORLEN is a regional leader in energy transition by implementing clean and sustainable technologies as well as power generation based on low- and zero-emission sources. Their strategic goal is to reach emission neutrality by 2050.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

TotalEnergies and Ørsted partner to participate in Dutch offshore wind tenders

TotalEnergies and Ørsted have joined forces to jointly submit bids for the two Dutch offshore wind tenders “Holland Coast West” with the aim to achieve net positive impact on biodiversity and the Dutch energy system. The Holland Coast West wind farms are located approximately 53 km off the Dutch coast and have a combined capacity of nearly 1.5 gigawatts (GW).

As world-class leaders in renewable energy and offshore wind, Ørsted and TotalEnergies will combine their strengths in these tenders with a view to contribute to the Netherlands’ objective of developing more than 70 GW of offshore wind capacity by 2050 for power generation associated with large scale hydrogen production.

As the largest offshore wind farm developer in the world, Ørsted has industry-leading experience in developing and constructing offshore wind farms in the most sustainable and ecologically friendly manner. Ørsted aims for a net-positive biodiversity impact by 2030. Furthermore, Ørsted has significant, global experience in supplying large-scale green energy to communities and industries. The successful realisation - on time and on budget during a worldwide pandemic - of the Borssele 1&2 wind farm demonstrates that Ørsted is a reliable partner for the green transformation of the Netherlands.

TotalEnergies, on its side, will leverage its proven expertise in offshore operations, and its unique position as an integrated energy company in the Netherlands, through an ambitious investment program of green energy and hydrogen production to decarbonize its industrial activities in the Zeeland province. TotalEnergies will also ensure the stability of the Dutch power grid while putting sustainable development in all its dimensions at the heart of its projects and operations to contribute to the well-being of people.

Olivier Terneaud, VP Offshore Wind at TotalEnergies, says: “The energy transition brings new challenges, both in terms of environmental impact and integration of green energy into the power system. It’s precisely to meet these challenges that we’re participating in these tenders, together with Ørsted, to support the energy transition in the Netherlands, where we draw on more than half a century of Dutch offshore operational experience to be a reliable energy partner. As a global multi-energy company that places sustainable development at the heart of its strategy, we’d be delighted to realise these innovative projects.”

Rasmus Errboe, Head of Region Continental Europe at Ørsted, says: “We are very pleased with our partnership with TotalEnergies for the upcoming Dutch tenders. With our joint bids we want to ensure the Netherlands can accelerate its offshore wind build-out towards 2030 and beyond, in a state-of-the-art ecologically friendly manner and as part of an integrated energy system. Ørsted looks forward to making a significant contribution to the energy transition in the Netherlands, together with TotalEnergies.”

The HKW VI tender proposal will change how wind farms relate to ecology. With its measures, unprecedented monitoring program, and strong cooperation with companies, institutes, universities and NGOs it focuses on working with all parties, both international and local, to build the knowledge needed to have wind farms strengthen nature by default.

Zeeland is the largest hydrogen cluster in the Netherlands. With 600 MW of electrolysis capacity, the largest green hydrogen cluster in the world will be made possible by 2027, powered solely by the Holland Coast West wind farm. Supplemented with, among other things, electric transport, batteries and direct electrification of the industry, we will achieve maximum system integration.

The winners of the tenders are expected to be announced by the Dutch government in Autumn 2022.

TotalEnergies and offshore wind

TotalEnergies is already developing a portfolio of offshore wind projects with a total capacity of more than 11 GW, of which 2/3 are bottom-fixed and 1/3 are floating. These projects are located in the United Kingdom (Seagreen project, Outer Dowsing, Erebus, ScotWind), South Korea (Bada project), Taiwan (Yunlin project), France (Eolmed project) and the United States (New York Bight project, North Carolina project). The Company has also been qualified to participate in competitive tenders in the US, UK and France, and will also participate in tenders in Norway, in Poland and Netherlands.

TotalEnergies and renewables electricity

As part of its ambition to get to net zero by 2050, TotalEnergies is building a portfolio of activities in renewables and electricity. At the end of September 2021, TotalEnergies' gross renewable electricity generation capacity is 10 GW. TotalEnergies will continue to expand this business to reach 35 GW of gross production capacity from renewable sources and storage by 2025, and then 100 GW by 2030 with the objective of being among the world's top 5 producers of electricity from wind and solar energy.

About TotalEnergies

TotalEnergies is a global multi-energy company that produces and markets energies: oil and biofuels, natural gas and green gases, renewables and electricity. Our more than 100,000 employees are committed to energy that is ever more affordable, cleaner, more reliable and accessible to as many people as possible. Active in more than 130 countries, TotalEnergies puts sustainable development in all its dimensions at the heart of its projects and operations to contribute to the well-being of people.