Super User

AHLSTAR peak pumping performance

Responding to our customers’ needs, we have developed additional features for the AHSTAR A pump series, and new options are also now available for demanding industries.

In the new ASTM A395 60-40-18 construction, the volute case and case cover of the pump are made of ductile iron. AHLSTAR A pumps in ductile iron have a maximum working pressure of 16 bars, with a temperature limit of 180°C.

Furthermore, a heating jacket option is available. The concept consists of a heating jacket and a jacketed case cover. The heating jacket is easy to install and maintain, providing evenly distributed heating across the entire pump. The solution is cost-effective because a standard AHLSTAR A pump can be used, and the same spare parts as for other AHLSTAR A pumps in the mill will fit. Proper temperature of the pumped liquid prevents undesired sedimentation, crystal growth, or solidification of the fluid handled.

Moreover, a case cover with internal recirculation has been developed for AHLSTAR pumps. In this design, an internal recirculation flushing fluid channel is integrated inside the case cover, enabling seal flushing without external piping.

Along with the new features, our AHLSTAR pumps have been assigned the Food Contact Materials Certificate (EC) 1935/2004. Food contact materials (FCMs) are widely used in food transfer equipment, packaging, etc. AHLSTAR pumps compliant with this regulation are the ideal solution for various food and beverage applications, from raw material production to processing and packaging.

Read more about the AHLSTAR A peak performance process pumps and their new features in our brochure. Learn more about the smart, cost-competitive and safe heating jacket in our flyer.

About Sulzer

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and purification technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class production facilities and service centres across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2021, our 13’800 employees delivered revenues of CHF 3.2 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN). The Flow Equipment division specializes in pumping solutions specifically engineered for the processes of our customers. We provide pumps, agitators, compressors, grinders and screens developed through intensive research and development in fluid dynamics and advanced materials. We are a market leader in pumping solutions for water, oil and gas, power, chemicals and most industrial segments.

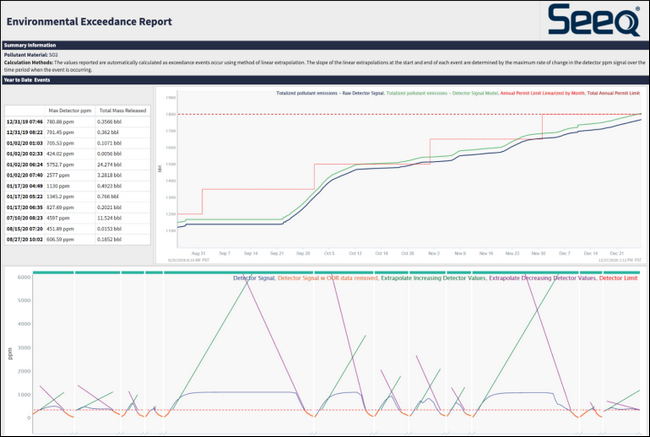

Seeq and Customers to Showcase Benefits of AWS Partnership at Hannover Messe

Presentations and demos to showcase how Seeq on AWS drives sustainability goals for Syngenta and provides access to process data via a new connection to GE Digital’s Proficy Historian for Cloud.

Seeq Corporation, a leader in manufacturing and industrial internet of things advanced analytics software, announced its gold-level sponsorship in the Amazon Web Services, Inc. (AWS) booth at Hannover Messe, the world’s foremost trade fair for industrial technology, in Hannover, Germany from May 30-June 2, 2022.

On Monday, May 30 at 1:30 p.m. CET and Wednesday, June 1 at 10:00 a.m CET, Syngenta, a leading agricultural science and technology company, will virtually share how it leveraged Seeq on AWS for carbon intensity tracking and nitrogen blanket balancing, enabling it to drive sustainability goals and business value through production, quality, yield, and environmental improvements.

At the conference, Seeq will announce that customers can now expand their use of Seeq by connecting it to GE Digital’s Proficy Historian for Cloud, which is available in the AWS Marketplace. The new connector empowers Seeq users to access their time-series process data from Proficy Historian for Cloud without moving or copying it. Seeq will demonstrate how the connector enables users to perform production optimization use cases within the AWS exhibit at booth A54 in Hall 5.

Within the AWS exhibit, the Seeq team will also demonstrate how organizations can leverage Seeq on AWS to enable emissions monitoring and reporting use cases and Seeq’s integration with Amazon Lookout for Equipment for predictive maintenance use cases.

“Seeq's strategic partnership with AWS enables industrial organizations to easily access advanced analytics capabilities to improve production and business success,” says Megan Buntain, VP of Cloud Transformation at Seeq. “We’re thrilled to sponsor and participate in the AWS exhibit at Hannover Messe and demonstrate the benefits of this partnership to the greater cloud community.”

Seeq enables engineers and scientists in process manufacturing organizations to rapidly analyze, predict, collaborate, and share insights to improve production outcomes. Seeq customers include companies in the oil and gas, pharmaceutical, chemical, energy, power & utility, mining, food and beverage, pulp & paper and other process industries. Investors in Seeq include Insight Ventures, Saudi Aramco Energy Ventures, Altira Group, Chevron Technology Ventures, and Cisco Investments.

Seeq is available worldwide through a global partner network of system integrators, which provides training and resale support for Seeq in over 40 countries, in addition to its direct sales organization in North America and Europe.

To learn more about Seeq, visit Seeq.com.

About Seeq

Founded in 2013, Seeq publishes software applications for manufacturing organizations to rapidly find and share insights. Oil and gas, pharmaceutical, specialty chemical, utility, renewable energy, and numerous other vertical industries rely on Seeq to improve production outcomes, including yield, margins, quality, and safety. Headquartered in Seattle, Seeq is a privately held virtual company with employees across the United States and sales representation in Asia, Canada, Europe, and South America. To learn more about Seeq visit ww.seeq.com.

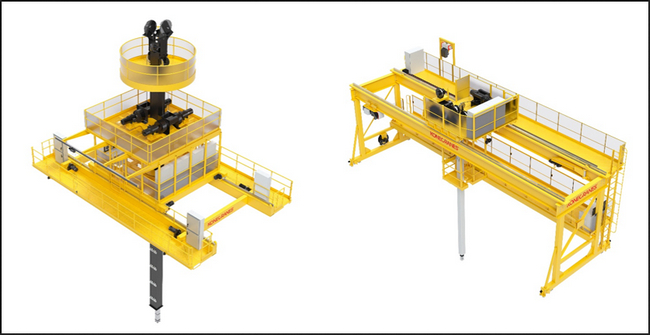

Konecranes to supply nuclear fuel handling machines to Sweden’s largest nuclear power plant

Konecranes will supply replacement fuel handling machines for three reactor units to the Forsmark nuclear power plant, the largest electricity producer in Sweden. The order is part of the plant modernization work. The new machines are equipped with the latest Konecranes technology and operator interfaces to improve the productivity and safety of the plant operations. The order was booked in April 2022.

Forsmark nuclear power plant in Sweden, mainly owned by Vattenfall, is currently modernizing its facilities to meet increased safety and environmental requirements, prolong the service life of the reactor and increase the output. They chose Konecranes to renew their fuel handling machines to support continued safe and productive operations.

The new Konecranes fuel handling machines comply with all major international nuclear standards and utilize single failure proof technology. This technology is designed to prevent load drop during the occurrence of any single failure of the lifting system. The Konecranes safety and diagnostic systems continuously monitor equipment operation which improves the safety of the fuel handling and the productivity of the nuclear power plant.

The equipment will be used to move the fuel assemblies between the reactor locations and fuel racks at each of the three units. The contract covers the replacement of all three fuel handling machines within five years to ensure they are ready for the scheduled refuelling outages.

“This contract showcases Konecrane's role in our customers’ work for securing critical societal functions, such as energy production. Forsmark nuclear power plant is a forerunner in their environmental work and imposes strict requirements on suppliers concerning quality and environmental issues, and we are proud to support them in their sustainability efforts,” says Steve Waisanen, Vice President and Head of BU Nuclear from Konecranes.

A strong focus on customers and commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.

Further information:

Steve Waisanen, Vice President and Head of BU Nuclear, Konecranes

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Konecranes is a world-leading group of Lifting Businesses, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity-enhancing lifting solutions as well as services for lifting equipment of all makes. In 2021, Group sales totalled EUR 3.2 billion. The Group has approximately 16,600 employees in around 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

A major breakthrough in the search to develop and produce “clean gas” energy source

A disruptive technology company has today confirmed it has made a breakthrough in its search to innovate a ground-breaking “clean gas” energy source that will not only provide an alternative supply to natural gas but also boasts zero CO2 emissions and is estimated will be cheaper than current domestic household and business energy supplies by as much as 80%.

Clean gas, which is carbon neutral with net-zero emissions, will give global economies access to a cheap, endless supply of clean energy. Importantly, it will allow countries to maintain the security of their gas and energy supplies whilst also meeting their carbon-neutral net-zero targets. This discovery could play a major role in reversing the global energy crisis, significantly reducing energy costs to the consumer and business sectors at a time when the cost-of-living crisis is worsening, and inflation has reached a 40-year high.

The scientific breakthrough, which is 10 years ahead of its time, has been made by a team from Voltage Enterprises, a disruptive tech company based in Abu Dhabi. The company, which has been funded by Aquarius Global, an investment company and tech incubator also based in Abu Dhabi, is also working on further innovations and disruptive technology projects.

Code-named KINETIC 7™, the scientific breakthrough is a clean gas energy source that is a stable and efficient gas derived solely from water. Whilst creating gas from water such as hydrogen is not new, KINETIC 7™ has a unique molecular chemistry that is way more advanced than hydrogen gas. For example, hydrogen gas is obtained through electrolysis, where pure distilled water (H2O) is broken down into (H2) and (O2) gases. Not only does this use a huge amount of energy to create the molecular process; it requires high-pressure storage and has a low flash point, making it very unstable.

KINETIC 7™ patented technology reconstructs and converts water into molecular clusters, which are electrically charged to create constant oxidisation and friction. This makes the molecules more efficient, causing them to vibrate, which in turn creates a very reactive gas, providing a clean gas and flame.

Unlike hydrogen gas KINETIC 7™ is also inert, making it a safe and controllable gas for domestic and industrial supply. Most importantly, the cost savings by using KINETIC 7™ will be substantial against current gas and energy costs. The KINETIC 7™ generators which create the clean gas will be manufactured to high standards in Europe. The current process of making the gas is both EU-approved and CE-certified.

The KINETIC 7™ discovery, which has taken more than eight years of research and development, will not only enable countries and global economies to maintain their gas independence and sovereignty but will also ensure global energy security, with an unlimited supply of carbon-neutral gas to both domestic and industrial customers.

It comes at a time of global instability in the energy markets, fuelled by the Russian invasion of Ukraine, which has sent gas prices soaring. EU energy ministers have also held talks over recent weeks to tackle the energy crisis that has been negatively impacting 218 million households throughout the bloc. Households in the UK faced a record energy bill spike of 54% at the beginning of April and prices are set to rise again in October. Many engineering, industrial and manufacturing businesses have also been severely impacted by the energy crisis. Soaring gas costs have led to partial factory shutdowns, and reductions in production and output, all of which have impacted on the supply chain.

It follows unprecedented demand for energy and a perfect storm of war in Ukraine, a post-pandemic recovery in manufacturing and industrial production, coupled with an unusual downturn in wind power supply to national grids.

Rick Parish, Founder and Executive Chairman of investment incubator Aquarius Global, which has funded the research and development of Voltage Enterprises, said:

“KINETIC 7™ represents more than eight years of scientific research, development and tech innovation by a dedicated team of scientists and tech disruptors, all working to produce a clean energy source that is carbon-neutral, significantly cheaper, and stable and efficient – but disruptive in every sense to the status quo.

“KINETIC 7™ is a major gamechanger in the global energy market. Just as we saw with the oil boom, the technologies and science that we are innovating, developing and disrupting in the energy sector through Voltage Enterprises are truly ground-breaking – a world-first for the energy sector!”

Governments around the world are desperately considering other options for energy supply and security, including the highly controversial fracking for shale gas, which is not only hugely damaging to the environment and public health but has also been known to cause earthquakes. Other options include the importing of gas from Iran and the building of further nuclear reactors, both of which carry huge risks and have inherent downsides attached. These include the geopolitical sanctions on Iran, the US oil and gas ban and the huge cost of building nuclear reactors. Sizewell C in the United Kingdom is estimated to cost UK taxpayers £20 billion with costs set to increase. Construction time to build a nuclear reactor takes on average 10 years, coupled with the safety concerns and health issues that have long plagued nuclear energy.

Rick Parish added:

“In much the same way that solar power is currently being used in domestic housing, KINETIC 7™ will allow households to produce their clean gas energy source, using water and a small amount of electricity. The cost to create clean gas is minimal. The KINETIC 7™ generator unit will be retrofitted into homes. The plug-n-play product, which uses a small amount of AC or DC power and water, will allow the householder to enjoy the same natural gas/LPG benefits without the high costs, supply disruptions and dramatic price increases. An external wall unit can be fitted to a domestic household and used for stove cooktops and ovens, hot water systems, ambient heating and underfloor heating.”

KINETIC 7™ represents a significant breakthrough in providing an alternative and viable energy source of clean gas that has zero carbon emissions. KINETIC 7™ can then be utilised in three ways:

The KINETIC 7™ flame can be used for domestic energy supply in ambient heating, cooking and hot water heating.

KINETIC 7™ gas also has a major role to play in providing clean energy for industrial production. Large-scale manufacturing, engineering and industry are all hugely reliant on vast amounts of energy in their production and manufacturing processes. Food production, restaurants and hotels are also gas- and energy-intensive, and KINETIC 7™ can now provide a cleaner more efficient energy source that is carbon-neutral and significantly cheaper than existing natural gas supplies.

KINETIC 7™ can also be used as a clean energy gas source for heating and cooking from portable stoves in remote locations and developing countries which do not have access to gas or energy.

Rick Parish said:

“With KINETIC 7™ we have the world’s first commercially viable clean gas energy source that can be used in domestic households. At the same time, KINETIC 7™ can power large-scale industrial production and manufacturing, providing clean energy that is carbon neutral from water. We anticipate KINETIC 7™ will be 80% cheaper than current energy supplies.

“This will not only help solve the global gas and energy crisis, but the innovation will allow countries and global economies to maintain stability in the energy sector, reduce costs and maintain the security of supply.”

KINETIC 7™ will also bring efficient cooking and heating across Africa to developing nations, war-torn countries and places where poor infrastructure has inhibited or restricted access to clean energy. The company will be manufacturing miniaturised KINETIC 7™ portable cooking and heating stoves that will change the lives of millions for the better, providing low-cost energy and heat using clean or untreated water.

Ultimately, in developed countries, the cost of KINETIC 7™ gas will be cheaper than current energy providers. KINETIC 7™ is low-maintenance, safe, efficient and significantly reduces household energy costs.

Aquarius CEO, Rick Parish, added:

“As an investment incubator in disruptive industries, Aquarius Global has been supporting companies like Voltage Enterprises to work on several disruptive technologies and innovations in energy and healthcare. Our corporate objective is to support companies using science and technology in a disruptive manner, to develop and deliver beneficial innovations for mankind and the environment. We are currently working on ground-breaking projects to capture carbon emissions and reduce CO2, whilst also creating anti-microbial and immune-boosting water that can be used in a whole range of applications.

“The whole ethos of Voltage Enterprises is to innovate and disrupt using technology and science to change the lives of millions of people for the better, to arrest the environmental damage that has been caused by oil and gas exploration and leave a positive legacy for future generations.”

The founders of Voltage Enterprises both have a philanthropic desire to help change the world for the better. They will be donating 20% of their global profits from KINETIC 7™ to provide African nations and those in need with free clean energy.

A series of “real-world” R&D trials are currently underway using KINETIC 7™ in residential properties for domestic cooking stoves, hot water systems and residential heating. Several factories and engineering plants are also part of an R&D program to integrate the technology and use the clean gas in several commercial and industrial applications.

It is envisaged that after further R&D trials have been completed, a programme of rolling the technology and clean gas out into domestic households and commercial premises could feasibly start within 6-12 months. Voltage Enterprises has confirmed that it is around three months away from manufacturing the miniaturised portable cooking and heating stoves that it will be supplied to developing countries.

Further announcements are expected from the company over the coming months as it also looks for global energy partners to work with and assist in the rapid rollout and deployment of clean gas technology.

VOLTAGE ENTERPRISES

Voltage Enterprises Limited was founded in 2021 under the Abu Dhabi Global Market, Abu Dhabi, United Arab Emirates.

The company was established as a technology and scientific disruptor in energy, healthcare and smart MedTech. It was established as an alliance with investment incubator Aquarius Global Limited, whose investments and interests span oil, gas, marine and offshore energy.

Voltage Enterprises is also partnered with one of the leading scientific research laboratories in disruptive technologies. The partnership has innovated several patented solutions related to clean energy, human immune systems, water treatment and restructuring via antioxidants, proprietary technologies, hygiene disinfection and ecological solutions.

Voltage Enterprises Limited is also creating innovative, unique products for the water, health and cosmetic industries. Within its first year of formation, Voltage Enterprise secured UAE patents for restructured drinking water and has several other disruptive tech patents approved.

AQUARIUS GLOBAL

Aquarius Global Limited is a proprietary investment incubator under Abu Dhabi Global Market, Abu Dhabi, the United Arab Emirates, established in 2018.

Aquarius Global Limited’s business investments include disruptive technology, scientific and technical activities, educational training and management, and business consulting services. Aquarius Global Limited provides consultancy in healthcare, oil and gas, aviation and other heavy industries.

As a holding company, Aquarius has partnered with several industry experts to drive sales and distribute various products around the globe. In these challenging times, Aquarius Global Limited continues to play a role in sourcing and supplying vital medical products and PPE.

Geek+ automates German 3PL provider Bergler’s picking operations

Geek+, the global leader in AMR technology, is pleased to announce that German third-party logistics provider Bergler Industrieservices has put their faith in Geek+’s Picking and Put-away solution, now fully operational in Bergler’s new logistics center in Erlensee, not far from Germany’s transportation hub, Frankfurt.

- Geek+ AMRs have allowed Bergler to fully automate picking operations in their highly anticipated logistics center

Bergler’s success is derived from providing top-quality logistics services, including order fulfillment and returns management, for German and international e-commerce actors. To modernize their picking and put-away processes, Bergler opted for Geek+’s P-800 picking AMRs and sophisticated warehouse management system. With the picking process automated, Bergler can leverage their considerable advantages and know-how to offer top-of-the-line service to their clients.

This know-how is based, among other things, on experience from the production sector, allowing Bergler Industrieservices to offer its customers value-added services such as component assembly, quality control, packaging, and much more in addition to handling typical fulfilment tasks.

The automated order picking system is therefore a great help for the around 40 employees who have been assembling, packing, and shipping a large number of orders for customers of various e-commerce operators every day since moving to the 11 000m2 Erlensee site in 2019. Bergler’s warehouse employees are now front and central in both the inbound and outbound operations and enjoy much more comfortable conditions. The P-800s bring the racks to the operator at the workstation, then return the racks to an optimized position based. This saves countless hours that would otherwise be spent walking through the vast site.

Saverio Carella, Sales Director DACH at Geek+, said: “We have greatly enjoyed working with Bergler to make this project a reality. Together, we have achieved a modern logistics center that represents the best of what AMR technology and expertise have to offer. Bergler, their employees, and their customers all stand to benefit from this modernization.”

Thanks to the integration of advanced robotics technology, not only is picking faster, more comfortable, and more accurate, but storage density is also much higher, thanks to the AMRs’ low profile and modest space requirements. This allows Bergler more freedom to scale up their operations and expand their business horizons.

Bergler CEO Raimund Bergler said: “The Geek+ robotics solution is something we have been looking forward to for some time now, and we’re thrilled with the results. The picking robots allow us to embark on a new phase in our development and ensure that we continue to guarantee our customers an extremely high level of service.”

Geek+ is once again very proud to have enabled an independent third-party logistics provider to scale up their operations and deliver new levels of quality. The AMR leader stands ready to assist Bergler in making the most of their newly expanded capacities.

About Geek+

Geek+ is a global technology company leading the intelligent logistics revolution. We apply advanced robotics and AI technologies to realize flexible, reliable, and highly efficient solutions for warehouses and supply chain management. Geek+ is trusted by over 500 global industry leaders and has been recognized as the world leader in autonomous mobile robots. Founded in 2015, Geek+ has over 1500 employees, with offices in Germany, the United Kingdom, the United States, Japan, South Korea, Mainland China, Hong Kong SAR, and Singapore.

For more information, please visit: https://www.geekplus.com/

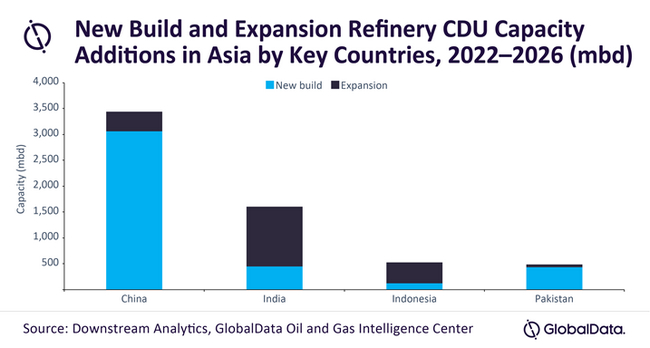

China to lead Asia’s refinery CDU capacity additions through 2026, says GlobalData

Asia is expected to witness the highest crude distillation unit (CDU) capacity additions globally contributing about 47% of the total CDU capacity additions by 2026, according to GlobalData, a leading data and analytics company.

GlobalData’s report, ‘Refining Industry Market Installed Capacity and Capital Expenditure (CapEx) Forecast by Region and Countries including details of All Active Plants, Planned and Announced Projects, 2022-2026’, reveals that Asia is likely to witness a total CDU capacity addition of 7.1 million barrels per day (mmbd) by 2026. Of this, new build capacity would be 4.3 mmbd while the rest is from expansion of existing refineries.

Teja Pappoppula, Oil and Gas Analyst at GlobalData, comments: “China and India primarily drive refinery CDU capacity additions in Asia by 2026. Yulong and Jieyang, both in China, are the largest upcoming new-build projects in Asia during 2022 to 2026 outlook period, each with a capacity of 400 thousand barrels per day (mbd). Among the expansion projects, Vadinar in India is expected to witness the highest capacity additions of 515 mbd by 2026 in the region.”

GlobalData identifies the Africa as the second highest contributor to the global CDU capacity additions accounting for about 22% of the total additions by 2026. New build projects contribute to almost entire capacity additions in the region with Lagos I refinery in Nigeria leading the way with a capacity of 650 mbd by 2026. The major expansion project in the region is the Assiut I refinery in Egypt. It is expected to start operations in 2024 with a capacity of 100 mbd.

Middle East ranks third globally contributing about 19% of world’s CDU capacity additions during the outlook period 2022–2026. Al-Zour in Kuwait drives the new build CDU capacity additions in the region with 615 mbd by 2026. Ruwais in United Arab Emirates and Isfahan in Iran drive the expansion capacity additions with 200 mbd and 120 mbd, respectively.

- Comments provided by Teja Pappoppula, Oil & Gas Analyst at GlobalData

- Information based on GlobalData’s report: ‘Refining Industry Market Installed Capacity and Capital Expenditure (CapEx) Forecast by Region and Countries including details of All Active Plants, Planned and Announced Projects, 2022-2026’

- New build: Denotes only assets/projects that are in different stages of development and have not started commercial operations

- Expansion – Denotes capacity expansion of a unit(s) in an existing refinery

- This report was built using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts.

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis, and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, technology, energy, financial and professional services sectors.

TES Wilhelmshaven Import Terminal Included as a “Priority Project” in the German Government Acceleration Law

Tree Energy Solutions’ (TES) import terminal has been included in the list of priority projects supported by the German Government’s LNG Acceleration law. The law was passed by parliament on May 19th, 2022 and was approved by the Federal Council on May 20th, 2022. The aim of this law is to accelerate the implementation of the critical infrastructure needed to secure the energy supply of the country and its short-term gas imports.

The new law is designed to reduce permitting and associated approval periods for the construction of onshore import facilities as part of the Wilhelmshaven Green Energy Hub development by TES, specifically on the Voslapper Groden location. Such acceleration will support the targeted commencement of operations of gas imports from 2025 onwards to secure German gas supplies. Subsequently, fossil-gas imports will be replaced by fossil-free hydrogen-based green gas imports to decarbonize and diversify the energy system from 2028 onwards. TES has been preparing to obtain required permits and to clarify nature protection measures since 2019.

The Wilhelmshaven terminal layout is planned to comprise 6 ship berths, 1,600,000 cubic meters of onshore storage capacity using 8 onsite tanks, (of which 4 will be available during the initial stage) the regassification equipment and the main connection to the OGE gas grid. This terminal will play a key role in reducing Germany’s energy dependence on Russia, as well as in the shift to obtain fossil-free energy imports, based on green hydrogen.

Paul van Poecke, co-founder and managing director of TES said: “We are delighted that the German government has included the TES onshore terminal in the new LNG law. It is a recognition of the importance the project will play in ensuring the security of gas supply while concurrently accelerating the energy transition and fossil-free gas imports. This will also bring clarity to the Open Season participants that are currently considering the booking of capacity through our terminal. The trust placed in us by the Government is greatly appreciated and a reward for leading the development of the onshore terminal at Wilhelmshaven.”

About TES

Tree Energy Solutions (TES) is a green and clean hydrogen company supplying long term non-intermittent carbon neutral energy on demand at industrial scale. TES aims to accelerate the energy transition by leveraging existing global energy infrastructure to reach customers with green hydrogen, green gas and green power, while accelerating the phase-out of fossil fuels from the energy system worldwide and adopting a circular carbon economy.

TES is currently developing energy supply and import terminal locations in Germany, Belgium, France, The Netherlands, and the United States to provide an integrated network of significant global scale. Initial production and export terminal locations are being developed in the Middle East and North America.

Metsä Group’s and Valmet’s 3D fibre product demo plant is now operating

The operations at Metsä Group’s and Valmet’s 3D fibre product demo plant in Äänekoski has begun. At the end of 2020, Metsä Group’s innovation company Metsä Spring and Valmet announced they would be investing a total of approximately 20 million euros in the demo plant.

The demo plant is part of Metsä Group’s integrated mill site in Äänekoski, and it produces finished 3D fibre packaging products directly from wet pulp without intermediate phases. The moulded fibre-based packaging can replace plastic for example in food packaging. The demo plant currently employs approximately ten people.

“Our fibre-based packaging products are a significant new initiative in the global packaging market. The novelty in our products include their layered structure, which, in turn, allows their production in a raw material and energy efficient manner applying a highly automated production process. The layered structure also allows the products to be easily modified for different purposes. The customers’ reception of the new product has been very positive. We know we’re on the right path,” says Metsä Group’s project lead, VP, Jarkko Tuominen.

3D fibre product

3D fibre product

“We are very satisfied with our cooperation with Metsä, and we think the mould casting technology is an excellent prospect as a future packaging solution. This is a good example of Valmet’s capacity for developing new technology, and I’m especially proud of how we’ve been able to make use of our broad process expertise in this project,” says Petri Rasinmäki, VP, Board and Paper Mills Business Unit at Valmet.

The demo plant has started a testing and development phase that will last a few years. The goal of this phase is to prove the competitiveness of the production and of the product in the packaging market. If this goal is achieved, it will be possible to consider building a larger production unit.

The 3D fibre product is renewable, recyclable and biodegradable, and its raw material comes from sustainably managed forests, which are primarily owned by Finnish families. Metsä Group is actively developing new business opportunities and researching new wood-based products that can increase the value of its owner-members’ forests. Moreover, the Äänekoski site is also the home of another demo plant, namely a facility developing a process for the production of the Kuura textile fibre.

Pictures of 3D fibre products and demo plant

Metsä Spring

www.metsaspring.com

Innovation company Metsä Spring invests expertise and financial resources into initiatives with the ambition to reshape the forest-based bioeconomy, aiming to increase the value for Metsä Group’s stakeholders in the long-term.

Metsä Group

www.metsagroup.com

Metsä Group is leading the way in advancing the bioeconomy. We invest in growth, bioproduct development and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, as well as tissue and greaseproof papers.

Metsä Group’s annual sales amount to approximately EUR 6 billion, and we have around 9,500 employees in 30 countries. Our international Group has its roots in the Finnish forests: our parent company is Metsäliitto Cooperative which is owned by nearly 100,000 forest owners.

Lhyfe and Trelleborgs Energi join forces for renewable green hydrogen production in Sweden

Lhyfe, a world pioneer and pure player in renewable green hydrogen Lhyfe (Euronext: LHYFE) and the Swedish local energy company Trelleborgs Energi have joined forces in a pre-study that aims to build a local renewable hydrogen production system in southernmost Sweden. As committed change makers, both companies are set to act now for the climate, focusing on green hydrogen as a solution. The results are due to be presented in the summer 2022.

The initial study focuses on 5 MW of green hydrogen production capacity, in Trelleborg. The study covers the questions of energy supply, production capacity, technology selection and location, as well as utilization of waste heat and oxygen. Trelleborg is a major transport hub that will require hydrogen to supply refuelling stations as well as to already ordered hydrogen vehicles. The number of heavy trucks passing through Trelleborg harbour is forecasted to increase from today’s 800,000 per year, to 1.8 million in 2026. Situated in the Öresund region, this project study in Trelleborg may contribute to securing hydrogen supply for both mobility and industry in efforts to reach zero carbon emissions. The utilization of waste heat and oxygen (a by-product of hydrogen production) is already being discussed with potential partners.

Lhyfe, which is counting among the world’s largest and most advanced players in the green hydrogen market with 93 projects in development in Europe (more than 4.8 GW of total installed capacity) and a first industrial plant inaugurated in September 2021, connects its production sites directly to local renewable energy sources to fuel local industry and mobility uses.

We are proud to work hand in hand with Trelleborgs Energi, a company in a city that is putting green hydrogen on the Swedish map and above all also into action, says Björn Arvidsson, Area Manager Nordics & UK at Lhyfe. We share a common DNA: we both want to act now for the climate, with focus on renewable hydrogen. It is inspiring to collaborate to further propel the energy transition in the region.

The joint pre-study will point towards an optimum initial set up for the production of hydrogen, using renewable electricity.

We want to create sustainable energy solutions locally and renewable green hydrogen is part of that plan, says Magnus Sahlin, CEO of Trelleborgs Energi. Hydrogen is a clever, multi-purpose energy carrier and can play a part in solving the climate challenge. We believe in making a real difference, in “walk the talk”, and our renewable hydrogen initiative is one way of doing that.

Trelleborgs Energi and Lhyfe are both committed to transitioning the energy sector and pushing the boundaries of possible solutions.

We want to win the climate fight, says Björn Arvidsson. That means investing in new technology, and building and operating green hydrogen production as soon as possible. This is targeted for 2024 here in the very south of Sweden. We strongly believe in the need and value of green hydrogen within industry and mobility. This project confirms Lhyfe's strategic presence on the Swedish market, from south to north!

We need to use all the means available to us, to combat climate change, adds Magnus Sahlin. We are serious about our commitment to changing the energy sector to better, sustainable solutions for the future. Hydrogen has been used for almost a century, but it has proven to be a smart, modern solution, that can make a difference for us here and now.

About Lhyfe

Created in Nantes in 2017, Lhyfe produces and supplies renewable green hydrogen for mobility and industry. Its production plant and its commercial pipeline will allow access to renewable green hydrogen in industrial quantities and form part of a virtuous energy model benefitting the environment. It is a member of France Hydrogène, Hydrogen Europe and Vätgas Sverige, SHDC. Lhyfe inaugurated its first green hydrogen industrial production site in September 2021. It currently has 93 projects in its pipeline across Europe, 20 of which will be in advanced development by 2026, contributing to the decarbonization of mobility and industry. A research programme started in 2019 should also lead to the start of a test phase in real conditions for the world’s first floating electrolyzer linked to a floating wind farm planned for autumn 2022. Lhyfe is listed at Euronext in Paris (LHYFE - FR0014009YQ1).

For more information go to Lhyfe.com

About Trelleborgs Energi

Trelleborgs Energi is a modern energy company with the future in mind. All our work evolves around sustainable and innovative solutions, connected to the local community. We aim to turn our customers into climate heroes, make our owners proud, and establish Trelleborg as the most climate smart city in Sweden. For more information go to www.trelleborgsenergi.se

Busch Celebrates Grand Opening of New Service Location in Pennsylvania

Servicing all equipment including industrial and medium high vacuum pumps

Busch Vacuum Solutions U.S., one of the largest manufacturers of vacuum pumps, blowers, compressors, and systems globally, held a ribbon cutting and grand opening for its new Service Center in Norristown, Pennsylvania on April 18, 2022.

The remodeled 19,000 sq. ft. service facility serves the Northeastern vacuum equipment market enabling Busch to provide rapid service, support, and customer training. The approximately 80 attendees included Busch customers and suppliers, top management, and local political and industry dignitaries. Kaya Busch from the Busch Executive Board, Turgay Ozan, President of Busch LLC and Joe Webster of the Commonwealth of Pennsylvania's 150th House offered remarks. After the opening presentations, attendees toured the facility and enjoyed refreshments and entertainment.

Larry Skinner, The Chamber of Commerce for Greater Philadelphia; Turgay Ozan, President Busch LLC; Joe Webster, The Commonwealth of Pennsylvania's 150th House District; Kaya Busch, Executive Board, Busch Vacuum Solutions; Jason White, PA Service Center Manager Busch LLC; at ribbon cutting during the Busch grand opening event

Larry Skinner, The Chamber of Commerce for Greater Philadelphia; Turgay Ozan, President Busch LLC; Joe Webster, The Commonwealth of Pennsylvania's 150th House District; Kaya Busch, Executive Board, Busch Vacuum Solutions; Jason White, PA Service Center Manager Busch LLC; at ribbon cutting during the Busch grand opening event

“We are thrilled to celebrate the opening of our newest service center here in Pennsylvania. This is an excellent area to recruit top-notch employees and we are excited to create local jobs and contribute to the local economy.” said Turgay Ozan, President, Busch LLC. “The facility is also located closer to many key accounts, and able to provide comprehensive vacuum technology service for both industrial and medium high vacuum customers.” added Ozan.

The new Service Center is located at 2450 Boulevard of the Generals, Norristown PA 19403. Customers can make an appointment for service by calling 484-690-7200. Further information about Busch can be found at www.buschusa.com.

Busch Vacuum Solutions

Busch Vacuum Solutions offers vacuum and pressure solutions for all industries from individual vacuum pumps, blowers, and compressors to tailor-made vacuum systems. Busch USA headquarters is in Virginia Beach, VA where a team of 500 dedicated employees takes care of all their customer's industrial vacuum needs. Busch USA is part of the global Busch family-owned company with over 3,500 employees in more than 40 countries. For more information about Busch visit: www.buschusa.com