Super User

SGS Opens Peru’s First Port-Based Laboratory in Matarani

In May 2021, SGS opened its brand new laboratory for mineral concentrates and diesel testing in Matarani, Arequipa in Peru. This is Peru's first port-based laboratory for diesel testing, and the first port-based laboratory for the testing of mineral concentrates in all of Latin America.

The Laboratory's Capabilities

Our Matarani laboratory offers analyses of mineral concentrates and diesel product samples. Our experts can analyze samples of mineral concentrates for copper, silver, arsenic, iron, zinc, and moisture. They can also conduct detailed bacteria tests and particle counts for diesel samples.

The laboratory is 190 m2 and employs five full time staff. Strategically located, it provides rapid turnaround times 24/7, in line with our customers’ expectations.

Delivering Value and Quality Assurance

When trading, ensuring the quality of your commodities is key to maintaining a successful operation. The new laboratory allows SGS to continue to help customers ensure the quality of their commodities while meeting local and international regulations and contractual obligations. Its location within the port itself allows samples to be drawn from bulk cargo and testing to be done then and there, helping to prevent transportation processes and time consuming delays. Detailed analyses are delivered quickly and efficiently, so our customers can make crucial business decisions prior to cargo loading, ensuring any quality issues are addressed before it is too late.

Ernesto Labarthe, Business Manager for SGS in Peru said, "The new laboratory allows us to conduct diesel and mineral concentrates testing right in the heart of Matarani's port. This cuts the time hugely, as we no longer need to transport samples to our site in Callao, enabling us to provide customers with prompt expert analysis that informs key business decisions. We're delighted the new laboratory is open!"

Thanks to our new Matarani laboratory, SGS in Peru will now be able to provide even greater value to all our global minerals and diesel customers who operate in the region.

About SGS

SGS is the world's leading inspection, verification, testing and certification company. SGS is recognized as the global benchmark for quality and integrity. With more than 89,000 employees, SGS operates a network of over 2,600 offices and laboratories around the world.

Press brake specialist opts for NSK high-load ball screws

Following success with previous-generation machines, a leading manufacturer of press brakes is once again specifying high-quality NSK ball screws for its latest electric model. The company is using the NSK HTF-SRC high-speed, high-load ball screw with A1 seal for its new machine, which with 80 tonnes of press force is the most powerful in the range.

As with previous electric press brake models, the force will be carried by two HTF-SRC ball screws in tandem configuration, with independent electronic control of each axis. Thanks to the design of HTF series ball screws and NSK’s technical knowledge, the solution can withstand large forces while retaining a compact shaft diameter - smaller than ball screws from other manufacturers - to help OEMs minimise machine size.

Such is the customer’s confidence regarding the performance of NSK ball screws that its first order was for a full production batch, rather than prototype quantities.

NSK’s HTF-SRC ball screws offer numerous benefits to OEMs and end users, including super-high dynamic load, high speed, low noise and extended operating life thanks to proper load distribution.

NSK’s HTF-SRC ball screws offer high dynamic load and extended operating life thanks to proper load distribution

NSK’s HTF-SRC ball screws offer high dynamic load and extended operating life thanks to proper load distribution

The press-brake manufacturer has been using NSK HTF series ball screws since 2017, when it produced its first electric machine. Originally, the decision to select NSK was based on the company’s globally recognised leadership in high-load ball screws. Since then, the press brake manufacturer has seen first-hand the product quality and performance of these ball screws, leading to retained supplier status for the new 80-tonne electric model.

Compared with hydraulic press brakes, electric machines offer low maintenance thanks to automatic lubrication, low power consumption, low noise and shorter cycle times. The press brake manufacturer’s sales force also refer to the use of NSK ball screws as another key selling point to customers.

Further information about NSK’s HTF series ball screws is available at: www.nskeurope.com/en/products/nsk-innovative-products/ball-screws-htf-series.html

About NSK Europe

NSK Europe Ltd. is the European organisation of the Tokyo-based bearing manufacturer NSK, which was founded in Japan in 1916 and today employs nearly 30,400 people in its worldwide operations. The products and solutions provided by the industrial and automotive supplier can be found wherever things move. In addition to nearly all types of rolling bearings, the company’s portfolio includes housed bearings, linear technology, wheel bearing units, transmission and engine bearings and steering systems. The company is oriented to perfection in all of its business activities. Its aim is quality leadership in its industry, which it strives for through a continuous process of improvement, excellent product development, optimised production processes and customer-oriented service processes. In fiscal year 2020, the more than 4,350 employees of NSK Europe Ltd. generated sales of over € 792 million.

www.nskeurope.com

LKAB extends ABB service agreement for hoists at Swedish mine by three years, and adds hoisting motors

ABB’s service agreement with LKAB covers twelve hoists at Kiruna mine and has been extended until at least the end of 2023

Global technology company ABB has signed a long-term agreement with LKAB to provide service to twelve mine hoists and now of hoisting motors at the Kiruna mine. Kiruna in Northern Sweden is the largest underground iron ore mine in the world, producing more than 85,000 tonnes per day.

ABB has provided LKAB Kiruna with maintenance and hoist cycle optimization to maximize efficiency and increase capacity at the mine since 2010. The new contract extends these services to the end of 2023 with an agreement that LKAB may sign up for a further three years on a rolling basis.

Most of the ore mined at Kiruna is at depths of more than one kilometer, with large solid slabs of iron ore deposits extending several hundreds of meters down into the ground. Local ABB engineers, supported by ABB globally, have worked on site at Kiruna to increase hoist capacity through a reduced hoist cycle time to optimize production. They have improved equipment use, balancing capacity and wear and tear of the hoist equipment.

“LKAB places great emphasis on refining every element of the underground mining process, in order to make it as efficient as possible,” said Peter Ylivainio, Senior Maintenance Engineer at LKAB. “Mining ore at great depths is a logistical challenge that places demands for a well-functioning infrastructure and safe and resource-efficient production, with well-developed production methods and processes vital. We have a long successful relationship with ABB and their local presence, global expertise and remote operations technology support our goals.”

“This new agreement means ABB will ensure optimal capacity, greater efficiency, lower energy consumption and extended equipment lifecycles across control systems, motors, drives as well as the hoists up to 2023 and beyond,” said Erik Kjellgren, Strategic Account Manager, ABB. “Our experienced team of engineers provides regular support to LKAB and we look forward to seeing increased benefits for our customer in terms of insights and actions to optimize equipment performance.”

The hoists are the main artery of the production flow at the Kiruna mine as they raise the ore hundreds of meters, from the sublevel to ground level. Their continuous operation is critical for safety and to prevent costly interruptions to production. LKAB’s extended service agreement with ABB is designed to ensure the maximum reliability and availability for the hoist control system, motors and drives located both above and below ground.

ABB has a history of working with the mining and minerals industry at every stage of the mining cycle, beginning when the company delivered its first electrical motor for a mine hoist in Sweden in 1891. ABB has committed to helping its customers realize the all-electric mine, helping mines move towards carbon neutral operations and drawing upon 130 years of experience in the mining industry. It deploys world-class electrification, automation and digital solutions to design mines where electrification and digital are fully integrated, from hoists, grinding, conveyors to vehicles, optimizing processes and equipment and integrating stable, efficient systems to maximize energy efficiency.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries.

Process Automation: ABB’s Process Automation business is a leader in automation, electrification and digitalization for the process and hybrid industries. We serve our customers with a broad portfolio of products, systems, and end-to-end solutions, including our #1 distributed control system, software, and lifecycle services, industry-specific products as well as measurement and analytics, marine and turbocharging offerings. As the global #2 in the market, we build on our deep domain expertise, diverse team and global footprint, and are dedicated to helping our customers increase competitiveness, improve their return on investment and run safe, smart, and sustainable operations.

Is green energy an answer to Bitcoin's carbon emissions problem?

Cryptocurrencies have set the internet ablaze and quickly garnered the attention of some big shots over the last year. Elon Musk, the CEO of one such company, has also admired Bitcoin but from afar. Citing Bitcoin’s high carbon footprint, the tech icon delayed his plans to accept Bitcoin as a form of payment, highlighting a major issue surrounding cryptocurrency.

The need for greener cryptocurrency has never been more pronounced than now. The heavy carbon footprint of cryptocurrencies has borne concerns regarding the effect of their intensive usage on the environment.

The culprit here is not the cryptocurrency itself but the technology underpinning its transactions, known as the blockchain. Blockchain technology is an integral part of the crypto world. Its central function is to maintain a ledger of all transactions and ensure that a transfer between parties is secure.

While the significance of blockchain technology in the cryptocurrency market and other industries is quite evident, carbon footprint concerns associated with Bitcoin mining cannot be overlooked. To put things into perspective, estimates from a well-known platform Digiconomist suggest that one Bitcoin transaction generates carbon dioxide equivalent to about 1.79 million VISA transactions. In the given scenario, cryptocurrency enthusiasts have been compelled to seek low-energy solutions to the problem.

GOOD READ: Bitcoin vs Gold: Is “Digital Gold” better than the real thing?

A step in the right direction

Most crypto mining companies have resorted to greener energy methods to counteract the high carbon footprint caused by cryptocurrency mining. Interestingly, data released by the Bitcoin Mining Council (BMC) revealed that more than two-thirds of the membership have switched to low-emissions energy sources.

Additionally, many businesses have embraced the concept of carbon offsets to battle climate change. Under this practice, companies hire third parties to reduce the carbon emissions released by them as a counteractive measure against environmental concerns. Distributing the load of offsetting emissions on third parties is a unique yet viable solution to the problem.

However, these measures might not weigh equally against the rising emission levels in the long run. Thus, companies must constantly evolve to provide environment-friendly technology without compromising on the consumers’ experience. Those behind the Ethereum technology have taken one such push in the right direction.

As per Digital Currencies Governance Group, the second-largest cryptocurrency Ethereum left a carbon footprint less than half that of Bitcoin in mid-2021. In a bid to go greener, the cryptocurrency may soon move to a quasi-lottery-based reward structure that rewards Ether holders with more tokens. Effectively, this reward-based system would remove the need for a block-building method that uses relatively higher levels of energy with more complex calculations.

In the new lottery-based structure, known as the Proof of Stake (PoS), only those Ether holders who are known to have a concentrated amount of tokens would be awarded the major chunk of the rewards. Thus, holders with a bigger share are more likely to win greater prizes.

Global recognition: A necessity

At this point, when the crypto market is buzzing with a heavy influx of new entrants, appropriate policy measures might be a robust solution to the pressing issue of climate change. However, those against any kind of authority takeover in the crypto market would consistently look for solutions within the closed framework.

While the Proof of Stake system could provide some respite to the ongoing pressure, not all cryptocurrencies may be open to such a drastic functional shift. For instance, the PoS system may not see daylight in the realm of Bitcoin, where renewable energy sources are already in place. The world’s number one crypto token has denied involvement in any plans to switch to the PoS system. However, experts argue that Bitcoin might be pressured into adopting the new framework as more and more currencies warm up to it.

Interestingly, the fight to go green does not end at just individual private legislators of cryptocurrencies. Lawmakers in the EU have proposed green amendments in crypto bills, introducing a plan called Regulation on Markets in Crypto-Assets.

GOOD READ: How to diversify cryptocurrency portfolio?

What lies ahead for crypto players?

While it is certain that crypto players would require some time to shift to newer forms of energy, one can expect the coming months to be shaped by changing trends in the crypto playfield. Given the increased push by global organisations to embrace greener production methods, crypto giants may soon have to devise a new strategy that aligns with the global efforts.

Even if adopting a new functional method is not viable, miners may now be compelled to choose from either implementing renewable energy sources or carbon offsetting to stay in business. Additionally, many new cryptocurrencies might enter the market in the coming months, making greener standards for companies to abide by.

In a nutshell, the crypto industry’s success has primarily stemmed from its deregulated structure which may change once climate preservation laws come into play. However, given the heavy popularity of cryptocurrencies, it is difficult to estimate the extent to which crypto miners would budge with authoritative laws that can change the customer experience forever.

Global initiative formed to push responsible and circular electronics

More than 20 organizations have come together in a global initiative to tackle the social and environmental problems of electronics. The Circular Electronics Initiative aims to encourage organizations and consumers to take a more responsible approach to the electronic goods they use. One core activity of the initiative is the annual event #CircularElectronicsDay.

“#CircularElectronicsDay has now been running for a few years and has attracted a lot of attention, and we feel that more can be done. This is not an issue just one day of the year but something we should continue to talk about. That is why we have now formed this initiative”, explains Andreas Nobell, Development Manager at TCO Development, one of the founding organizations.

The current, linear way of producing and consuming products is ruining fragile ecosystems, causing the loss of valuable natural resources and critical raw materials. In a circular economy, resources are handled more responsibly. The goal of the Circular Electronics Initiative is to create awareness around the need for a longer life for electronic products and greater recirculation of all materials while minimising waste.

“The resources on our planet are finite, and we need to take responsibility. The initiative is all about helping buyers and consumers to do this - to take a more responsible approach to the electronics they use.No one can do everything. But everyone can do something. The Circular Electronics Initiative has gathered some concrete things you can do to contribute to the transition to make IT more circular and sustainable ”, continues Andreas Nobell.

Check-list for more circular and sustainable management of IT:

- Re-evaluate. Do you really need to buy and replace your current gadget? If not make it a challenge to use it an additional year and re-evaluate again next year.

- Extend the life of your products. This is often the most critical thing you can do to reduce the environmental footprint of your use. Upgrade and repair your products so they last longer. Used products are in high demand, so make use of the second-hand market and buy and sell your products there.

- If you need to buy a new product, choose products that carry a sustainability certification that includes robust criteria and requires third-party verification.

- If you can buy a second-hand product, ensure you carry out necessary supplier due diligence to product quality and performance.

- Choose a durable product that can last longer. Avoid buying unrepairable electronics that you may risk having to throw away after a short usage time.

- Climate compensate the e-waste footprint of your new product, either by recycling a product with a similar footprint or by purchasing the offsetting as a service.

- Don’t throw it out! Electronics contain valuable resources that can be reused. If it’s not possible to reuse or sell your old products, take them to an electronics recycler or refurbisher where they will be handled responsibly.

“As almost 80 percent of carbon emissions of a laptop occur in the manufacturing phase, extending product life will clearly lead to lower average annual emissions. Adding two years to product life reduces emissions by as much as 30 percent. As you can see, circular approaches have a real impact on the environment”, Andreas Nobell highlights.

To help consumers and buyers, the organizations behind the initiative have developed the quiz “Quiz: what do you know about circularity and electronics?”

“The quiz is an easy way to get the conversation going about circular electronics. It creates awareness about the challenges we face concerning electronics production and consumption. Let’s all join the conversation!” concludes Andreas Nobell.

All electronics come with many social and environmental challenges.

Conflict minerals also referred to as 3TG, used in IT products are known to fuel wars and human rights abuses. Unsafe mining methods lead to severe health problems for workers and environmental degradation in the communities where they live.

Hazardous substances found in electronics and used in the production of electronics present a wide variety of human health and environmental risks. Throughout the life cycle, products release dioxins, halogens and other toxicants, which often persist in the natural environment and the human body.

Social responsible manufacturing is a continuing challenge throughout the IT supply chain. From raw materials extraction to final assembly, working hours, health and safety and forced labor are examples of industry-wide issues.

Fifty million metric tonnes of e-waste is generated every year, equalling the weight of nearly 4,500 Eiffel towers. Much of it is incinerated or placed in landfills, causing pollution, human health hazards and the loss of valuable finite resources.

About Circular Electronics Initiative

The Circular Electronics Initiative aims to encourage organizations and consumers to take a more responsible approach to the electronic goods they use. The initiative drives communication activities, including #CircularElectronicsDay. The organizations behind the initiative are 3stepIT, Advania, Aliter Networks, ATEA, Blocket, Chalmers Industriteknik, Circular Computing, Cistor, Closing the Loop, Dell, Dustin, ETIRA, European Remanufacturing Council, GIAB, Inrego, International Institute for Industrial Environmental Economics, IVL Swedish Environmental Institute, Lenovo, Recipo, Smithereens, TCO Development, and Tradera.

Södra’s green investment continues – with switch to recycled material in packaging

Södra’s investment in circularity continues. Through a new partnership with Swedish company Trioworld, Södra’s timber packaging will now contain 30 percent recycled plastic, which will reduce annual emissions from the packaging by around 23 percent.

“With the new packaging, we are ensuring high-quality deliveries for our customers, while also taking an additional step towards a more circular business model with lower emissions. This is a trend we will continue to pursue. On the challenges with sustainability, there is no finish line to pass and we are constantly working to be the market leader and develop our processes. This will help Södra and our customers contribute to a sustainable climate transition,” said Andreas Jonasson, Sales & Marketing Director at Södra Wood.

Reduce emissions by 23 percent

The new timber packaging is called Trioworld Loop and will be used for all Södra’s timber deliveries – both domestic and exported. The material contains at least 30 percent Post-Consumer Recycled (PCR) Plastics. As a result, Södra expects to cut its emissions by nearly 385 tonnes of CO₂ equivalents per year, corresponding to 23 percent of annual emissions from the packaging.

Södra is first to offer timber packaging with PCR plastic in larger scale. The development is in line with Södra’s targets for reducing its emissions and building a climate-positive business.

“Trioworld believes in long-term partnerships. When developing sustainable solutions for tomorrow, ambitious partners such as Södra are a key lever for minimising the environmental impact of packaging without compromising on transport safety or the protection of the timber. Our solution with 30 percent post-consumer recycled content will significantly reduce the environmental impact of the packaging – and that’s just the beginning of sustainable packaging for the forest industry from Trioworld,” said Adam Fransson, Senior Account Manager, Trioworld.

Södra’s timber products will be delivered with the new Trioworld Loop packaging from September.

Founded in 1938, Södra is Sweden’s largest forest-owner association, with 53,000 forest owners as its members. We conduct modern and responsible forestry, and operate state-of-the-art mills in which we process our raw material. In 2020, net sales amounted to SEK 20 billion and employees totalled 3,100. Through value-generating relationships and a long-term approach, Södra shows the way for the next generation of forestry.

Rayonier Releases 2020 Sustainability Report and Updated Carbon Report

Rayonier Inc. (NYSE:RYN) has just released its 2020 Sustainability Report, which highlights actions the Company is taking to enhance the long-term well-being of its investors, employees, communities, and other stakeholders. This report illustrates Rayonier’s commitment to transparency around Environmental, Social, and Governance (ESG) factors and how they are incorporated into its strategic and operational decision-making.

“We view our Sustainability Report as a written declaration of the values that are the foundation of our ESG practices, strategies, and goals,” said David Nunes, President and CEO. “While the publication of this report is a key milestone, there is still much work to be done as we introduce new ESG initiatives and continue our relentless focus on improving the transparency of our disclosures.”

Concurrent with the release of its 2020 Sustainability Report, the Company is also releasing its latest Carbon Report. This report is unique and comprehensive in quantifying the carbon impacts across the Company’s value chain. In 2020, Rayonier’s timberland assets sequestered an estimated 14.5 million metric tons of CO2 equivalents from the atmosphere versus corporate emissions of roughly 380,000 metric tons of CO2. At year-end 2020, the Company’s timberland assets stored an estimated 757 million metric tons of CO2 equivalents in total.

“Over the past few years, we have observed many large global corporations announce commitments to achieve carbon neutrality. Many of the goals that have been unveiled are both admirable and ambitious, and we believe our industry is well-positioned to be part of the solution. Rayonier’s forestry assets provide a natural climate change solution—our trees remove carbon from the atmosphere during their growth cycle, and after harvesting, a significant portion of this carbon remains stored for an extended period of time within downstream wood products. We are proud of the unique role that our timberlands play in protecting the planet and look forward to capitalizing on innovative strategies to drive positive climate impacts,” stated Nunes.

The 2020 Sustainability Report, as well as the updated Carbon Report, can be found on the Company’s Sustainability web page.

About Rayonier

Rayonier is a leading timberland real estate investment trust with assets located in some of the most productive softwood timber growing regions in the United States and New Zealand. As of June 30, 2021, Rayonier owned or leased under long-term agreements approximately 2.7 million acres of timberlands located in the U.S. South (1.74 million acres), U.S. Pacific Northwest (499,000 acres) and New Zealand (419,000 acres). The Company also acts as the managing member in a private equity timber fund business with one fund comprising approximately 31,000 acres. On a “look-through basis”, the Company’s ownership in the fund equates to approximately 6,000 acres. More information is available at www.rayonier.com.

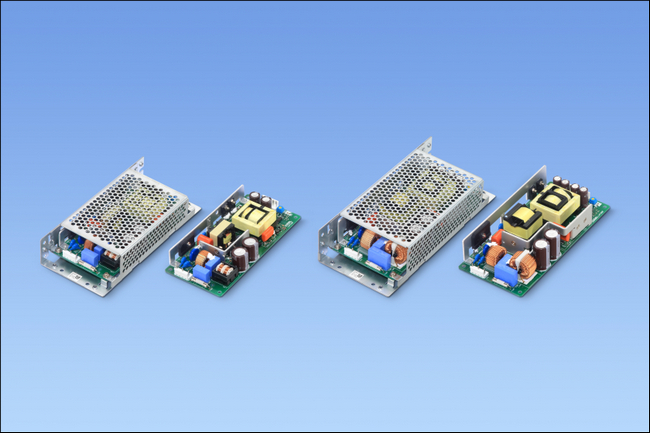

COSEL announces free-air convection cooled open-frame power supplies with 200% peak-power for industrial applications

COSEL Co, Ltd (6905: Tokyo) have just announced the addition of 150W and 300W free air convection cooled power supplies, the LHP150F and the LHP300F. Designed for industrial applications requiring high levels of safety, the LHP150F and the LHP300F are certified according to EN62477-1 (OVC III). The products work over a wide universal input voltage range of 85 to264VAC and have a high typical efficiency rating of 93%. The LHP150F and LHP300F are available in five different output voltages commonly used in industrial automation and processes, with 200% peak power capability for up to 10 seconds for dynamic loads. The standard product is an open frame PCB type, with a chassis and cover available as an option.

Industrial applications require efficient power supplies able to work in various environments with a high level of safety. The LHP150F and LHP300F are certified to the EN62477-1 Over Voltage Category Three (OVC III), meaning that a final equipment powered by the products can be connected directly to the main distribution panel without adding an extra level of isolation. This simplifies the system designer’s task, reducing cost and guaranteeing the highest level of efficiency.

Designed for world-wide applications, the LHP150F and LHP300F have an input voltage of 85 to 264VAC. Five output voltages are available: 24V, 30V, 36V, 42V and 48V with respective output current of 6.3A, 5.0A, 4.2A, 3.6A and 3.2A for the LHP150F and 12.5A, 10.0A, 8.4A, 7.2A and 6.3A for the LHP300F. The output voltage can be adjusted using a built-in potentiometer.

Industrial applications often require higher current during start-up or during peak operation.

The LHP150F and LHP300F are designed with a high dynamic control level and a power stage able to sustain long peak loads making it possible to deliver 200% for up to 10 seconds of the nominal power when a peak load situation occurs. For example, the LHP150F 24V output version delivers a permanent current of 6.3A with up to 12.6A peak. The same ratio applies to all versions of the LHP150F and LHP300F.

Designed for industrial applications requiring high levels of safety, the LHP150F and LHP300F are certified to meet EN62477-1 (OVC III).

Designed for industrial applications requiring high levels of safety, the LHP150F and LHP300F are certified to meet EN62477-1 (OVC III).

For low harmonic current distortion, the LHP150F and LHP300F use an active Power Factor Corrector (PFC), and the switching stage uses an LLC resonant topology combined with the latest generation of power semiconductors, conferring a typical efficiency of up to 94%.

Optimized for convection cooling, the power supplies can be operated within an ambient temperature range of -10 to +70 degree centigrade. Depending on the assembly method and ventilation across the final equipment, a derating may apply as specified in the technical documentation.

Open frame type, the LHP150F measures 75 x 27 x 160mm (2.95 x 1.07 x 6.30 inches and weighs 320g max, while the LHP300F measures 84 x 37 x 180mm (3.31 x 1.46 x 7.09 inches) and weighs 580g max.

The LHP150F and LHP300F have an input to output isolation of 3,000VAC, input to ground (FG) of 2,000VAC and output to ground (FG) of 500VAC. They include built-in inrush, overcurrent and overvoltage protection circuits.

Both power supplies comply with safety requirements UL (USA), C-UL (Canada), DEMKO (Denmark), and TUV (Germany). The products are UL62368-1, C-UL (equivalent to CAN/CSA-C22.2 No.62368-1), EN62368-1, EN62477-1 (OVC III) certified. The LHP150F and LHP300F are as well complying with DEN-AN.

Exhibiting versatility and attention to detail, to accommodate application specific requirements, a number of options are available including Coating (C), Low leakage current (G), EP connector type (J4), Remote ON/OFF (R), Chassis (S), Chassis & Cover (SN), Terminal block type (T), Connector to an external capacitor bank (U1), Output 8 pin connector (LHP300 only) (J5), Push-in terminal block (T4), and Built-in DC fuse (DC).

The LHP150F and LHP300F series have a five-year warranty and conform to the European RoHS, REACH and Low Voltage Directives.

About Cosel:

Established in Japan 1969, COSEL is one of the world’s leading designers and manufacturers of high performance AC-DC Power Supplies, DC-DC Converters and EMI Filters. With quality, reliability & flexibility as our main focus, we pride ourselves on developing some of the highest quality and most reliable products seen anywhere in the world today. The Cosel Group is a $250m global company employing some 700 staff with sales offices throughout Japan, Asia, Europe and North America. Our product range is aimed mostly at demanding applications within the Industrial, Factory Automation, Medical, Telecoms, Lighting, Audio/Broadcast & Renewable Energy sectors. A flexible approach with full in-house design means we deliver products using the very latest technology meeting the growing demands of our customers.

NSK Self-Lube® bearing units save steel plant €292,136

Certain sectors and applications place particularly challenging demands on bearings. Steelmaking is one such example, where the aggressive operating environment means potential bearing failures present a genuine threat to production. Extreme temperatures, particle contamination, shock/heavy loads, water, vibration, high speeds and rapid acceleration/deceleration are just some of the daily hazards that steel plant bearings have to endure. However, the NSK RHP Self-Lube® range of bearing housings and inserts can overcome these issues, as confirmed by a major steel plant.

The international steel plant in question was struggling with up to three bearing failures a year on a rotary coal valve used in its ore preparation process. In addition to the cost of replacement bearings, the failures had knock-on effects in terms of lost production, downtime and damage to associated components. The plant clearly needed a solution to this expensive problem.

The steel plant was struggling with up to three bearing failures a year on a rotary coal valve used in its ore preparation process

The steel plant was struggling with up to three bearing failures a year on a rotary coal valve used in its ore preparation process

NSK duly conducted a full application review, which included a temperature survey and a bearing condition report. The review revealed that the current bearing was inadequate for the high process temperatures, while the lubrication quantities and frequencies were incorrect. As a result, NSK recommended a customised RHP Self-Lube® HLT bearing insert within an RHP Self-Lube® cast iron FC housing, plus a bespoke adaptor plate and a special heat-isolating spacer.

RHP Self-Lube® units include two basic components, the insert and the housing. Each unit consists of a sealed single-row ball bearing with spherical outside diameter and extended inner ring mounted in a high-quality flanged housing made from a rigid one-piece design. Importantly, spherical seating accommodates any initial misalignment when mounting.

Self-Lube® inserts, which feature hardened, high-quality steel for inner and outer rings, also offer optimised internal geometry, a two-piece riveted high-strength steel cage, high-performance grease and durable silicone seals. Notably, the Self-

Lube® HLT inserts implemented at the steel plant provide opportunities to reduce maintenance, downtime and replacement costs when operating at temperatures up to 180°C.

NSK RHP Self-Lube® HLT inserts help to reduce maintenance, downtime and replacement costs when operating at temperatures up to 180°C

NSK RHP Self-Lube® HLT inserts help to reduce maintenance, downtime and replacement costs when operating at temperatures up to 180°C

The units are available with various locking methods for close-fit shaft mounting. This feature, combined with a complete range of sealing solutions for all environments, makes NSK RHP Self-Lube® a very versatile product. As the name suggests, re-lubrication capability is standard.

For the rotary valve bearings at the steel plant, the expert team of NSK engineers also recommended changes to the lubrication quantities and frequencies. To ensure correct application, NSK oversaw the fitting of the new bearings as part of a trial.

After more than 12 months the bearings still had not failed, delivering a total annual cost saving for the customer of €292,136. This calculation includes cost savings associated with: the elimination of downtime due to bearing failures; fewer bearing purchase orders; reduced bearing replacement time; and the removal of compressed air cooling to help control the overheating of previous bearings.

For further information about NSK RHP Self-Lube® bearing units: www.nskeurope.com/en/products/nsk-innovative-products/self-lube-units

About NSK Europe

NSK Europe Ltd. is the European organisation of the Tokyo-based bearing manufacturer NSK, which was founded in Japan in 1916 and today employs nearly 30,400 people in its worldwide operations. The products and solutions provided by the industrial and automotive supplier can be found wherever things move. In addition to nearly all types of rolling bearings, the company’s portfolio includes housed bearings, linear technology, wheel bearing units, transmission and engine bearings and steering systems. The company is oriented to perfection in all of its business activities. Its aim is quality leadership in its industry, which it strives for through a continuous process of improvement, excellent product development, optimised production processes and customer-oriented service processes. In fiscal year 2020, the more than 4,350 employees of NSK Europe Ltd. generated sales of over € 792 million.

www.nskeurope.com

Les vergers Boiron doubles up its efforts for Sirha 2021!

Hall 4 Booth 4D80 from September 23 to 27 at Lyon Eurexpo

Les vergers Boiron, global leader in frozen fruit purées, will attend Sirha 2021 alongside all major Food service and Hospitality actors. To celebrate the recovery of one of the sectors that has been most severely impacted by the pandemic, Les vergers Boiron will offer food professionals not one, but two fruit-themed immersive experiences. These are two opportunities to discover Les vergers Boiron latest products and gain valuable inspiration.

Innovation at the service of professionals

For over 75 years, Les vergers Boiron has been innovating to give food service professionals fruit at its best with products with preserved organoleptic properties but also make their day-to-day work easier and provide support in their creation process.

Helena Augusto, Strategic Marketing Manager, said: “Besides switching gradually the frozen fruit purée range towards a 100% range with no added sugars, the 3 new ranges of Les vergers Boiron fruit purées (ambient, PGI, Organic) are in line with gastronomy trends and consumption patterns. Our goal is to give professionals more freedom in creating their preparations and pave the way to new uses (savoury, sweet and beverage).”

At Sirha 2021, Les vergers Boiron will showcase their 4 latest innovations:

Launched in March 2021, the 100% ready-to-use fruit purées of the ambient range are praised for being easy and quick to use, saving valuable time for restaurant owners and bartenders without compromising quality; and for easy storage.

Launched in March 2021, the 100% ready-to-use fruit purées of the ambient range are praised for being easy and quick to use, saving valuable time for restaurant owners and bartenders without compromising quality; and for easy storage.

The 6 flavours of the ambient range – strawberry, raspberry, mango, blackberry, passion fruit and yellow peach – are guaranteed with no added sugar.

Packed into 1-liter cartons that can be easily stored, they are perfect for “à la minute” dish preparations: starters, main courses, desserts, cocktails.

In line with the long-term trend for more naturalness and healthier and less processed products, Les vergers Boiron are gradually switching to no added sugar products. The entire range will be available in a 100% fruit version with no added sugar by 2022, giving professionals more creative freedom.

Launched in early 2021, the premium frozen purée range made with PGI-certified fruit (Protected Geographical Indication) highlights excellent fruits from renowned regions, which give them unique organoleptic characteristics. With no added sugar, the PGI range currently includes 3 citrus fruit references: Corsican Clementine, Siracusa Lemon and Sicilian Blood orange.

The fruit purées of the Organic range, which are the result of four years of hard work in order to meet the standards Les vergers Boiron is known for, are made by processing and blending organic fruits. Organic certified by Ecocert, they comply with very strict specifications, guaranteeing respect for the environment, traceability and labelling that complies with regulations. The 6 first Organic references with no added sugar – Strawberry, Raspberry, Mango, Passion fruit, Lemon, Blackcurrant – are packed into 10-kg buckets and adapted for ice cream makers’ use.

About Les vergers Boiron For over 75 years, Les vergers Boiron has concentrated all its energy and experience into developing fruit solutions that unleash the creative talent of chefs, pastry chefs and mixologists from all over the world. In 1970, 50 years ago, Les vergers Boiron invented the first frozen fruit purée with a unique know-how: strict selection of the best varieties in the best terroirs, mastery of the art of blending ensuring a constant flavour season after season, preservation of the organoleptic properties with a specific process to each fruit. This experience guides the family-owned business, which is now managed by the 3rd generation under Alain Boiron. Les vergers Boiron offers a range of more than 54 flavours of purées and coulis, from fruits of the orchard to tropical fruits, including red fruits and citrus. Every year, Les vergers Boiron sells more than 15,000 tonnes of products in 80 countries, i.e. 15 million trays around the world. Now it has a turnover of € 80 million, 80 % of which come from exports, and 180 employees. More information: https://www.my-vb.com