Super User

Low effort, low cost: 3D inspections for the used machinery market

It is not only during a pandemic that it is costly and time-consuming to inspect a used machine on site. Surplex.com offers its customers the ideal solution with virtual 3D inspections.

The coronavirus pandemic has had a far-reaching impact on companies in a wide range of industries and has fundamentally changed the way they can contact customers. The second-hand machinery market is no exception: the inspection and evaluation of machinery by an expert took place under difficult conditions. And for the interested parties themselves, travel and contact restrictions made it difficult to impossible to visit the factories' warehouses and get an idea of the machines on display.

But even independently of a pandemic, the inspection of second-hand machines involves a lot of personnel effort and costs. For such an inspection to be worthwhile, customers must be sure that the machine meets their expectations. Pictures and videos created by surveyors are a good approach to get at least a first impression, but it rarely comes close to a live inspection.

For this reason, the online auction house Surplex offers virtual 3D tours of its used machinery. In auctions with a large number of items, such as that of the insolvent automotive supplier TQM Europe in Heilbronn (Germany), the factory halls are filmed and photographed and finally merged into a 3D model. This gives interested parties the opportunity to take a detailed look at the machines - without having to be there in person.

This meant that inspections were possible even during the pandemic and public traffic in the factory hall could be reduced to a minimum. Various machines such as portal milling machines or hydraulic presses can be viewed in high resolution and in great detail. The long-term advantages, even after the pandemic, quickly become apparent.

Potentially interested parties are spared travel expenses and personnel costs. The first impression of the machines can be gained excellently thanks to the virtual 3D tour and a visit to the hall can still be arranged if there is interest. In addition, tours can be organised in a more sustainable and climate-friendly way. A trip to the inspection is only necessary if the machine really meets one's own expectations.

A trained appraiser ensures that only high-quality machines are included at the Surplex online auction house; interested parties can also be sure that the quality will be right when using the 3D inspections. Surplex offers all important services from a single source: from on-site quality checks to dismantling and transport, Surplex creates confidence when buying and selling used machinery. With 200 employees, offices throughout Europe and over 500 online auctions a year, Surplex is one of Europe's leading industrial auction houses.

Installation, validation, and operation of the world’s first subsea DAS installation offshore Gulf of Mexico

The world's first subsea DAS installation

Silixa is pleased to announce the successful installation, validation, and borehole seismic acquisition from a permanently installed fiber optic Distributed Acoustic Sensing (DAS) system, Carina® Subsea 4D, on bp’s Atlantis Phase 3 subsea field development.

The Atlantis Phase 3 development involves a new subsea production system with eight new wells tied into the current Atlantis platform, 150 miles south of New Orleans. The engineered fibre optic system enables high-definition seismic data acquisition along the entire subsea wellbore. This allows seismic acquisitions at a lower cost, enabling better reservoir management. The Carina Subsea system has been installed in two wells, and installation is continuing over the rest of the field. A zero offset DAS VSP was acquired to validate coupling and signal to noise characteristics and showed excellent data quality. Subsequent production noise recordings showed little impact even though there was significant production occurring.

The system is the world’s first permanent in well seismic acquisition system for subsea wells. It can operate independently or provide complementary data to ocean bottom node surveys. It is especially effective for reservoirs that are traditionally difficult to image using surface seismic such as pre-salt reservoirs or those beneath gas clouds.

The system is the world’s first permanent in well seismic acquisition system for subsea wells. It can operate independently or provide complementary data to ocean bottom node surveys. It is especially effective for reservoirs that are traditionally difficult to image using surface seismic such as pre-salt reservoirs or those beneath gas clouds.

The Silixa system delivers 100x improvement in signal-to-noise ratio compared to DAS systems utilising standard fibres. It features Constellation fibre engineered with brighter backscatter centres along its length to capture and reflect 100x more light back to the interrogator without introducing significant loss to the forward propagating laser pulses. This makes this new technology ideal for subsea tie-back applications where high optical losses from subsea connectors have previously prevented DAS deployment. A further advantage is that it does not require complex electronics to be placed on the seafloor.

“Until now, subsea fields had to rely on sparse data acquisition due to the risk and cost of acquisition,” Garth Naldrett, Silixa’s Chief Product officer, said. “Bringing our engineered distributed fibre optic sensing technology to subsea wells and allowing the same data acquisition we have already enabled on land and platform wells will have a tremendous impact on the industry.”

“The first subsea DAS VSP field recording has confirmed and shown excellent data quality with high fidelity measurements and signal-to-noise-ratio in the expected downhole array aperture for borehole seismic imaging in actively producing wellbores”, Sebastien Soulas, Senior Borehole Seismic Advisor at LYTT, said.

About Silixa:

Silixa is the global leading provider of fibre-powered data solutions that address the most critical measurement challenges in the Alternative Energy, Mining, Environmental & Earth Sciences, Infrastructure and Oil & Gas sectors.

The company offers dense array data sets of the highest fidelity that enable operators to gain actionable insight into their assets and systems to increase efficiency, enhance safety, prevent loss and extend lifespans.

With a heritage of cutting-edge innovation and technological leadership, Silixa helps its customers to chart their course towards a more sustainable future.

Made4CNC launches world’s first completely automatic CNC door opening solution for robots

A new Danish company has solved a well-known and previously unsolvable challenge in the metal industry. Made4CNC has developed the world’s first completely automatic door opening solution, which can be fitted to any CNC machine make in under an hour. The door opener removes the last barrier to the automation of component feeding at machine works. Made4CNC is now launching its first official product - the Safedoor SD100. But several end users and dealers have already caught the scent of a killer app and have taken the technology into use. The team behind Made4CNC are three professionals who are well-known for robot disruption: Thomas Visti, Lasse Kieffer and Peter Nadolny.

Currently only a small percentage of the industry’s CNC machines are automatically fed components. Most makes of CNC machine in the word rely on the operator having to open and close the machines’ heavy doors every few minutes.

For machine works, automation and competitiveness are two sides of the same coin. But investing in a new fully automatic CNC machine or upgrading an older model can be a tall order, both in practical and financial terms.

Automation must speed up

Today when CNC machines have to be automated, integrators often build “homemade” door opening solutions. But that risks errors, stoppages, and hazardous situations because the solutions typically require compressed air and are neither standardized nor tested. These challenges are overcome with Made4CNC’s Safedoor SD100.

“Around the world the need for faster and greater automation is a major trend, and for it to succeed, less time must be spent on each installation. With the SD100, we have integrated safety and robustness in a user-friendly solution, which we believe is the key to optimal productivity. Integration of cobots together with existing CNC machines makes a lot of sense, since the automation of existing machines generate low risk and a short payback period for the customer,” said Peter Nadolny Madsen, CEO at Made4CNC.

Made4CNC’s new product Safedoor SD100 is the world’s first completely automatic door opening solution.

Made4CNC’s new product Safedoor SD100 is the world’s first completely automatic door opening solution.

Global expansion in 12 months

Together with investors Thomas Visti and Lasse Kieffer, Peter Nadolny Madsen established Made4CNC in January 2021. The trio have played a central role in successful Danish robot companies like Universal Robots, OnRobot, Purple Robotics and Mobile Industrial Robots.

Investor Lasse Kieffer has contributed with his deep technological expertise, while investor Thomas Visti has provided market insight:

“Made4CNC has understood what is required to make the process easier. It’s win-win-win for the end customer, employees, distributors and the manufacturer. I therefore expect that Made4CNC will have established itself via robot dealers and integrators around most of the world in the next 12 months.”

Stable, safe door openers

Integrator Nordelektro has fitted two Made4CNC Safedoor SD100 door opening solutions at Randers Tandhjulsfabrik.

“It took less than an hour for each CNC machine and they are good and stable door openers,” reported Lars Bo Nielsen, factory manager at Randers Tandhjulsfabrik.

For Nordelektro, it makes a huge difference that they can provide customers with a standardized solution, which is designed as a solution-in-a-box:

“Safedoor SD100 is a complete solution, which makes it simpler to work with automation. It is a huge advantage for us as an integrator. We don’t need to invent something complicated and expensive, we have minimum project risk,” said Jesper Storm Simonsen, sales manager at Nordelektro.

Better flow and better work environment

Made4CNC has just entered into agreement with their first American distributor, Thinkbot Solutions: “Safedoor SD100 makes having a job as a machine feeder much more pleasant and easy-going, and the same time the employer will be able to optimize and get a better flow. Other people have tried unsuccessfully to develop a user-friendly door opener. Made4CNC has completely succeeded. I have chosen to distribute SD100 because attention has been given to all of the details in terms of the mechanics, software and safety. It’s because SD100 is UR+ certified and has a URCap, just like robot grippers from OnRobot and Robotiq, ensuring completely seamless integration with cobots from Universal Robots. Al operation can be done on the robot’s teach pendant,” said President Philip Courtois.

Safedoor SD100 opens doors that are up to 1 meter wide and weigh 400 kg, at a speed of 500 mm/s. The door opener is connected to a robot and CNC machine via galvanic insulated digital inputs and outputs.

BKK Nett one step closer to enabling the green transition of energy systems with Kognitwin Grid

Through the research project KogniGrid, Kongsberg Digital has investigated how digital twins can be used to ensure optimal operation of power grids. As a result, Kongsberg Digital recently launched a digital twin for power grids, called Kognitwin Grid. BKK Nett, have now signed an agreement on a six-month R&D project to further develop and test Kognitwin Grid.

Based on the company's proprietary digital platform Kognifai, Kongsberg Digital has developed the SaaS product, Kognitwin Grid, in close collaboration with industry and research partners. This is a digital twin of the power grid, which provides insights and forecasts to identify grid bottlenecks, simulate grid scenarios and optimize grid investments.

The focus has been to give operators the ability to foresee challenges to the grid infrastructure, automate alerts and complex processes, to ensure complete control and pave the way for the digitalized energy system of the future.

“While an increasing part of the world's energy systems and the means of transport are becoming electric, the pressure is increasing on the power grid infrastructure, which is not built to handle the new complexity. One of the solutions is to keep building out grids for maximum capacity, resulting in more costly infrastructure and thus more expensive electricity for consumers. Digital twins enable precise and data-driven real-time insight so that operators can forecast specific needs, introduce measures to balance the network and prevent black-outs without building it out”, says Hege Skryseth, President of Kongsberg Digital and EVP KONGSBERG.

Collaboration enables the green shift

Kognitwin Grid is a direct result of the KogniGrid project, launched in 2018, as a collaboration with BKK Nett, Tensio (NTE Nett), Statnett, Microsoft and SINTEF. BKK Nett has now signed a new six-month research project for further development and testing of Kognitwin Grid.

“The grid operators hold the key to solving the challenges on the power grid and thus contribute to the green shift. We are pleased that BKK Nett will continue the close collaboration with us through Kognitwin Grid so that we together can find solutions that enable increased electrification of the society”, says Skryseth.

Project manager R&D in BKK Nett, Eivind Flatlandsmo, says that they have learned a lot during the 3.5 years the project has been running. They are therefore looking forward to the further collaboration with Kongsberg Digital.

“One of our strategic goals is to become more data-driven in the decision-making processes for development, management and operation of the power grid. This requires large amounts of data and information from various sources, which in turn requires new tools and methods to generate the insight we need. Fundamental to everything is data quality and information security, without this we cannot rely on the results produced or the software itself", says Eivind Flatlandsmo, project manager R&D in BKK Nett.

"We have acquired valuable knowledge and experience from the close cooperation with the partners in the KogniGrid project over a period of 3.5 years. We now know more about what a digital twin is, the work required to create a twin of value, and the potential the twin enables. The project has also given us a picture of our digital maturity level, the capacity for development and implementation of new solutions. This requires the two most important resources we have and always want more of: people and time.

We are proud to continue our collaboration with Kongsberg Digital. We want to contribute to the green shift that challenges today's power grid. To solve this, we need help. We cannot solve all our challenges alone”, Flatlandsmo concludes.

Last week, Kongsberg Digital entered into a similar agreement with Tensio, which was also involved in the KogniGrid project. The agreement with Tensio includes a six-month trial of Kognitwin Grid.

KONGSBERG DIGITAL

Kongsberg Digital, a subsidiary of KONGSBERG, is a provider of next-generation software and digital solutions, to customers within maritime, oil and gas, and renewables and utilities. The company consists of more than 500 software experts with leading competence within the internet of things, smart data, artificial intelligence, maritime simulation, automation and autonomous operations. Kongsberg Digital is the group-wide center of digital expertise for the KONGSBERG group.

KONGSBERG

KONGSBERG (OSE-ticker: KOG) is an international, leading global technology corporation delivering mission-critical systems and solutions with extreme performance for customers that operate under extremely challenging conditions. We work with nations, businesses and research environments to push the boundaries of technology development in industries such as space, offshore and energy, merchant marine, defence and aerospace, and more. KONGSBERG has about 11,000 employees located in more than 40 countries, creating a total revenue of NOK 25.6bn in 2020.

Follow us on: kongsberg.com, Facebook, Twitter and LinkedIn

BKK NETT

With about 260,000 customers and a power grid that covers approx. 22,000 kilometers, BKK Nett is one of Norway's largest electricity suppliers with an offensive growth strategy in Western Norway. The company puts customers at the center and digitizes the power grid for efficient and future-oriented operations in a modern society. To ensure a stable power supply, BKK Nett conducts continuous maintenance of power grids and plants. The company is building a future-oriented power grid in line with the social development in Western Norway.

BKK is structured as a group with BKK AS as the parent company. The group is organized into four business areas: Innovation and Development, Production, Network and Entrepreneur, and Market.

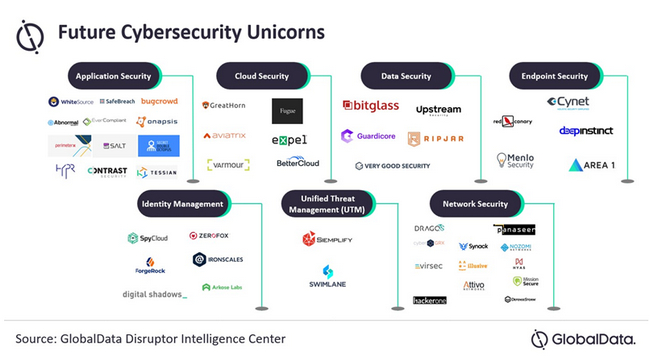

GlobalData predicts future cybersecurity unicorns

Right from the network and data security to identity management and unified threat management (UTM), startups are offering cybersecurity solutions to identify vulnerabilities, thwart attacks, and secure networks. Against this backdrop, the Unicorn Prediction Model of GlobalData, a leading data and analytics company, has released a list of 50 cybersecurity startups that have the potential to become unicorns (>US$1bn).

Apoorva Bajaj, Practice Head of Financial Markets at GlobalData, says: “As we are entering the Code War era, where every digital device, no matter how small, can be ‘weaponized’ and cyberattacks are proliferating globally, investors are investing heavily to back cybersecurity startups. At the same time, the COVID-19 pandemic has offered tailwinds to the industry, as firms embraced a remote work paradigm with more applications and data stored in the cloud, a flurry of new threats is likely to emerge, making cybersecurity investment a necessity.”

GlobalData’s latest report, ‘Future Cybersecurity Unicorns – 18 August 2021’, reveals that in Q2 2021, the industry reported an investment of over US$8.1bn, spanning 209 deals globally. The report also highlights a spike in venture capital (VC) investments in cybersecurity startups in Q2 2021, majorly driven by startups like Transmit Security, Trulioo, and Forter raising funding in the range of US$300m to US$550m. In Q2 2021, North America accounted for over 58% deal volume followed by Europe (17%).

Some of the cybersecurity startups in GlobalData's list of potential unicorns include BetterCloud, Guardicore, Deep Instinct, and Swimlane.

BetterCloud, a US-based SaaS Management Platform, enables IT professionals to discover, manage and secure the growing stack of SaaS applications in the digital workplace. The company recently launched BetterCloud Discover, a new centralized platform that gives enterprises insights into SaaS adoption, and visibility into full scope of sanctioned and unsanctioned applications within its multi-SaaS environment.

Guardicore, a startup offering cloud security solutions, is focused on delivering more effective ways to protect critical applications from compromise through visibility, micro-segmentation, and real-time threat detection and response.

Deep Instinct, a US-based cybersecurity solution provider, is leveraging deep learning and cybersecurity technologies. Recently, the company added new features and capabilities in its prevention-first solution, including increased resilience against adversarial machine learning attacks, credential theft protection, and malicious behavior reporting.

Swimlane, a cybersecurity automation solutions provider, assists organizations in handling all security operation (SecOps) requirements, including prioritizing alerts, orchestrating tools, and automating the remediation of threats. Recently, the company raised US$40m to accelerate partnerships and alliances, expand R&D, and enable further global expansion.

Mr. Bajaj concludes: “Increase in VC deals coupled with substantial growth in patents granted, along with positive news sentiments and growing mentions of cybersecurity in public company filings indicate that this technology is of considerable interest to both VCs and corporates. The COVID-19 pandemic is providing tailwinds to this industry, as companies are embracing remote work model. With cloud-based backup becoming the order of choice to save applications and data, a range of new online threats is likely to emerge, which will make investment in cybersecurity a necessity.”

- Quotes are provided by Apoorva Bajaj, Practice Head of Financial Markets at GlobalData

- The information is based on GlobalData’s Disruptor Intelligence Center

- Based on GlobalData’s Startup Scorecard ranking of 10,000 top startups, 126 Cybersecurity startups globally are shortlisted, of which 50 Cybersecurity startups are predicted to become future unicorns based on GlobalData’s proprietary Machine Learning Model.

- GlobalData’s Startup Scorecard ranks startups relatively using quantifiable data on three pillars: Investments, Innovation and Market Presence to ensure that it is objective and can be comparatively measured across different sectors and themes

- This press release was written using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts

About GlobalData’s Disruptor IC

GlobalData’s Disruptor decodes emerging tech-enabled opportunities with must-have information on promising start-ups, technology led innovations, latest sector trends, strategic partnerships, consumer insights, and venture capital portfolio investments among others.

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

Super Duplex Tubing from Fine Tubes Now Available with Enhanced Strength and Improved Corrosion Resistance for Oil and Gas and Chemical Process Applications

Fine Tubes is pleased to announce that specialist metal tubing product, Super Duplex, is now available. Demonstrated capabilities include high strength and corrosion resistance for demanding applications. The tubing is NORSOK M-650 approved and made to order in specialist non-standard sizes for bespoke orders in the oil and gas and chemical process sectors. This enables it to meet very precise customer specifications, as well as offer high-quality, extremely reliable product performance.

The Super Duplex tubing can be produced with very short lead times and in small batch sizes for optimum versatility. It is available in straight lengths that can be seamless cold redrawn and annealed to suit customer specifications. Typical tubing sizes range from 3mm (0.040 inches) to 31mm (1.25 inches) outer diameter in seamless form.

Hostile working environments require optimum operating efficiency, excellent strength and corrosion resistant properties and complete product reliability. Super Duplex from Fine Tubes is ideal for use across multiple critical applications in the oil and gas and chemical process sectors. These applications include heat exchangers, flow meters, downhole pressure housings and smart wells, subsea Xmas trees and manifolds, injection and ballast water, and other critical subsea, downhole, and offshore oil and gas instrumentation.

Fine tubes super duplex

Fine tubes super duplex

Nick Head, Tube Product Manager at Fine Tubes says of the product: “We have a proven track record of supplying key tubing products like Super Duplex that meet the strict requirements of the oil and gas and chemical process sectors. Smaller batch capabilities ensure flexibility in the range of volumes we can produce. The ability to manufacture Super Duplex in non-standard sizes also enables us to meet the very precise requirements of our customers.”

Fine Tubes has a long and successful history of operating in the oil and gas and chemical process sectors. The company delivers a wide range of precision tubes that deliver extended product life, as well as reducing downtime and maintenance costs. Tubing products from Fine Tubes are made from high pressure stainless steel and nickel alloys. The high-quality materials used enable the tubes to perform without failure, time and time again, for maximum corrosion and pressure resistance up to 100,000psi.

The company is one of five business units that make up AMETEK Specialty Metal Products (SMP), alongside Hamilton Precision Metals, Superior Tube, AMETEK Eighty Four and AMETEK Wallingford.

Each of these business units manufacture metal products for the oil and gas and chemical process industries. These other products include hard-facing powder coatings used in thermal spray, spray and fuse applications, plus metal strip and engineered components for drill bits and shaped charges for well perforations. In addition, clad metal plate products are used for pressure vessels and transition plates.

Operating out of Plymouth in the UK, Fine Tubes manufactures precision metal tubing products in a range of specialty alloys at its highly integrated tubing mill. As well as the chemical process and oil and gas and industrial sectors, tubes produced by Fine Tubes are used in numerous critical applications across many global sectors, including energy, medical, aerospace and defence.

Located in Plymouth, Devon, UK, Fine Tubes manufactures high-performance precision tubes in specialty alloys. www.finetubes.com

Fine Tube’s precision engineered tubes are used in critical applications across a wide range of industries, from aerospace to nuclear power; oil and gas and medical.

Fine Tubes is part of the Specialty Metal Products division of AMETEK Inc., a leading global manufacturer of electronic instruments and electromechanical devices with annual sales in 2020 of more than $4.5 billion and more than 150 global operation locations in 30 countries.

Geek+ and WSR Solutions launch Smart Palletizing Solution

Geek+, a global AMR leader, is proud to announce the launch of a new solution for Smart Mixed Case palletizing, co-developed with WSR Solutions, a provider of intelligent warehouse management tools. The solution combines Geek+ autonomous mobile robots and WSR’s intelligent palletizing algorithm to help warehouse operators systematically handle the processing of multiple outbound orders in an efficient, safe, and flexible way.

- Save up to 30% truck space and reduce operational costs by up to 40% with Smart Mixed Case Palletizing

Lit Fung, Vice President of APAC, UK and the Americas at Geek+, says: “We are thrilled to work together with WSR Solutions to provide a tool that targets every aspect of the outbound logistics process, from how goods are stored and moved around the warehouse to how pallets are stacked, streamlining processes by eliminating the need for re-palletization, and optimizing overall space utilization.”

Based on real-time demand, Geek+ autonomous mobile robots optimize the movement of ordered goods between the storage area and picking station. At the picking station, WSR’s intelligent algorithm support warehouse operators to stack cases of varying weight, height, width, and so on in an optimal way. It is a one-stop solution that takes warehouse automation one step further, allowing operators to not only modernize logistics processes inside the warehouse but ensure agile supply chains through the efficient use of truck space.

Marcel van Schijndel, CEO of WSR Solutions, says: “Together with Geek+ we provide a full framework for the changing market requirements. Innovative mixed palletizing solutions that in effect serve one single goal: to optimize the customer's supply chain with efficient, flexible, and affordable automation solutions.”

The solution has four key components – storage area, buffer area, case picking area, and loading area.

Storage Area

The storage area is built on multiple layers using high-density racking and bulk lifts for more storage capacity. After inbound processing, pallets of incoming goods (donor pallets) are stored in high-density racking. Donor pallets are then moved horizontally by four-way shuttles and vertically by lifts. The system flexibly solves bottlenecks caused by rapid changes in required throughput. With no need for wires and long installation periods, the number of shuttles can be flexibly adjusted to handle changes in required throughput, and peak values can be changed using the system’s scheduling tool.

Buffer Area

Upon receiving the outbound order, items of high outbound volume go to a buffer area between the storage area and the workstation. Upon registering an incoming order, a picking robot picks up the donor pallet from the storage area and moves it to the buffer area for temporary storage. At the buffer area, picking robots streamline the movement of pallets, ensuring the smooth supply and optimal sequencing of source pallets to the workstation.

Case Picking Area

At the workstation, an operator picks cases from a donor pallet and stacks them on an order pallet based on a pre-calculated stacking pattern. The user-friendly interface provides the operator with information on outbound orders such as required type and quantity of goods, and the SAT laser pointer specifies case placement.

If one type of good is included in different orders, picking robots will move the donor pallet of that good to the next workstation, and new donor pallets containing other SKUs will automatically arrive at the previous workstation for continued order picking. The remaining items that do not require further picking will go to the storage area, creating a dynamic transit cycle.

Loading Area

At the loading area, optimally stacked pallets are loaded onto trucks by autonomous forklifts without the need for re-palletization. By optimizing how pallets are stacked it improves truck space utilization, lowering the overall transport costs. The algorithm enables efficient organization and order sequencing of large-scale, mixed case combinations. It can be tailored to fit customers' actual business needs for allocation and priority management, making a powerful tool applicable to a wide range of industry scenarios.

About Geek+

Geek+ is a global technology company leading the intelligent logistics revolution. We apply advanced robotics and AI technologies to realize flexible, reliable, and highly efficient solutions for warehouses and supply chain management. Geek+ counts 300 global customers and has sold more than 20,000 robots worldwide. Founded in 2015, Geek+ has over 1,000 employees and is headquartered in Beijing, with offices in Germany, the UK, the US, Japan, Hong Kong SAR, and Singapore.

For more information, please visit: https://www.geekplus.com/

About WSR Solutions

WSR Solutions is a technology innovator of optimized end of line mixed palletizing solutions for the global intralogistics market. Founded in 2014, WSR Solutions develops and supplies innovative depalletizing and mixed palletizing solutions that in effect serve a single goal: to make logistics efficient, flexible, and cost-effective. WSR Solutions is headquartered in Deventer (the Netherlands) and has partners/resellers in Sweden, Italy, Lebanon, Spain, and the USA.

For more information, please visit: www.mixedpalletizing.com

Bluetest and Anritsu Supporting OTA Measurement on IEEE 802.11ax 6 GHz-Band (Wi-Fi 6E) Devices

Anritsu Corporation and Bluetest combine their recent product upgrades to create a strong and up-to-date OTA measurement solution for verifying the WLAN RF-performance in this new 6 GHz band, as well as of existing WLAN standards (802.11 a/b/g/n/ac/ax) in the 2.4 and 5 GHz bands. The collaboration provides customers with a complete WLAN Over-the-Air (OTA) test solution capable of transmit power (TRP) and receiver sensitivity (TIS) measurements on devices and access points. Measuring the OTA performance in life-like, but repeatable conditions, enable manufacturers of small and large WLAN equipped devices, including IoT and smart home appliances, to optimize the radio performance and end-user satisfaction.

6 GHz has for a long time been the upper frequency limit of most public communication systems. This is now changing with the WLAN standard IEEE 802.11ax expanding up to 7.125 GHz range (“Wi-Fi 6E”). The growth of WLAN connected devices and services are expected to benefit greatly from this increase in available frequency space and number of 160 MHz channels.

The Anritsu Wireless Connectivity Test Set MT8862A is dedicated to the WLAN standard, hence optimized for stable and reliable connections with wider dynamic range, even in a faded environment such as in the Bluetest reverberation chamber. It is now updated with a new radio module adding support for the 6 GHz band and 160 MHz channels, in addition to the already supported 2.4 and 5 GHz bands. The test setup is easily expanded to support 2x2 MIMO measurements using two MT8862A units.

Bluetest has meanwhile upgraded the complete range of reverberation test systems with an increased default frequency coverage. The compact and cost-effective RTS25 chamber is upgraded by adding the new 6-7.125 GHz band. This chamber is primarily targeting the buzzing WLAN and Bluetooth industry. The best seller RTS65, as well as the larger RTS85 and RTS95 now feature 4x4 MIMO support for frequencies all the way up to 12 GHz, in addition to previously released 5G FR2 packages with 2x2 MIMO support up to 43.5 GHz.

Bluetest Product Manager Klas Arvidsson says: “Increasing the default frequency range from 6 to 12 GHz with full support for multiple 4x4 MIMO carriers means we are fully prepared for continued evolution of the WLAN and 5G standards and shows the strength of our flexible product design.”

Keita Masuhara, Product Manager, IoT Test Solutions Div., Anritsu Corporation, adds: Expanding to 6 GHz band spectrum is expected to bring new services and it will require concrete performance evaluation to prevent issues regarding to new challenges. Anritsu has been working with Bluetest to provide valuable solutions for OTA RF performance evaluation. I am convinced that the new measurement system will contribute to efficient performance testing.

The Anritsu MT8862A as well as all Bluetest chambers with the extended operating frequency range are available for order, and upgrade packages are offered for already installed systems. The updated Bluetest chambers are accompanied by corresponding upgrades to the line of accessories, such as reference antennas, ISS11 Attenuator System and ISS11 Instrument Switch.

About Bluetest

Bluetest is the pioneer and market leader in reverberation chamber technology for OTA testing of wireless devices and small antennas. Bluetest’s innovative RTS system has been adopted by the largest mobile phone and antenna manufacturers, network operators, and other providers of wireless solutions. For more information visit https://bluetest.se/.

About Anritsu

Anritsu Corporation (www.anritsu.com), a global provider of innovative communications test and measurement solutions for 125 years. Anritsu’s philosophy engages customers as true partners to help develop wireless, optical, microwave/RF, and digital solutions for R&D, manufacturing, installation, and maintenance applications, as well as multidimensional service assurance solutions for network monitoring and optimization. Anritsu also provides precision microwave/RF components, optical devices, and high-speed electrical devices for communication products and systems. The company develops advanced solutions for 5G, M2M, IoT, as well as other emerging and legacy wireline and wireless communication markets. With offices throughout the world, Anritsu has approximately 3,800 employees in over 90 countries.

Welltec becomes a key partner in Project Greensand

Project Greensand is an ambitious and innovative initiative to develop new ways to capture and store CO2. Welltec has a long history of engineering and delivering solutions that target complex challenges in the energy sector and now looks to help address and meet the 70 percent reduction of CO2 targets by 2030 as set by Danish government.

On August 9th, the UN Climate Panel published its report that paints a bleak forecast for our climate and signals a ‘code red for humanity’. A summer of floods and fires across Europe, only proving that the climate crisis continues to move closer to our reality. There is an immediate need for measures to effectively reduce CO2 emissions and CO2 capture and storage (CCS) has a critical role to play.

Project Greensand is one such groundbreaking initiative. It consists of a consortium of 29 companies led by INEOS Energy and Wintershall Dea with the goal to develop a full CCS value chain in Denmark. The ambition is safe CO2 storage in Danish North Sea fields by 2025 and will address 25-40 percent of remnant emissions that must be managed in order to reach Denmark’s ambitious 70 percent reduction target by 2030.

”We are very proud to become a central partner for Project Greensand. Through 25 years of providing well intervention and completion solutions to the energy sector, including high concentration CO2 projects, Welltec has built an extensive knowhow within material selection, testing and solutions,” says Mette Fürstnow, Solutions Director, Green Initiatives, Welltec who will lead the well completions design team.

The testing of the well materials will take place at Welltec’s testing center in Esbjerg, which will boast a newly constructed full-scale CO2 test loop, one of Europe’s largest.

Welltec's CEO Peter Hansen sees great potential in the development of wells that can handle the complicated process of storing captured CO2.

”The world has significant demand for technologies contributing to solving the climate challenges we are currently facing – particularly within the energy sector which plays a vital role in delivering on CO2 emission reduction targets. It is important for Welltec to take an active role to deliver solutions to CCS projects globally. We have uniquely positioned technologies with a strong track record within oil and gas, providing advanced solutions designed to operate under challenging subsurface conditions. We are already engaged in various CO2 projects and high temperature geothermal applications, we absolutely have a key role to play in CCS too”, says Peter Hansen.

About Welltec

Welltec® is a global technology company that develops and provides efficient hi-tech solutions for the energy industry. The company’s cutting-edge products and services are designed to optimize well performance and well integrity in all environments. Through advanced engineering and lightweight design, Welltec’s solutions have been helping clients reduce environmental emissions and carbon footprints in a safe and sustainable way for more than 25 years. Welltec maintains 24/7 state-of-the-art, in-house manufacturing operations spread across two dedicated sites in Denmark, with additional global facilities including a newly constructed base in Al-Khobar, Saudi Arabia.

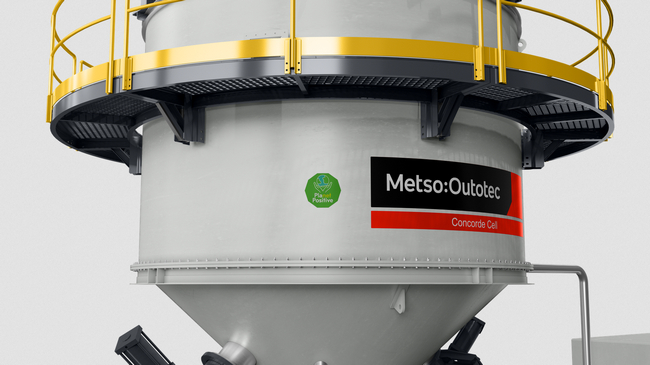

Metso Outotec provides cutting edge flotation technology for nickel concentrator in Australia

Metso Outotec will supply cutting edge flotation technology for a major nickel producer in Western Australia as part of their concentrator modernization. The site is one of the largest nickel producing sites in the world. Start-up of the new flotation cells is scheduled for 2022. The order value, which is not disclosed, has been booked in Minerals’ Q3/2021 orders received.

Metso Outotec’s delivery includes nickel rougher and cleaner flotation technology based on new and proprietary Concorde Cell™ flotation technology. The Concorde Cell™ uses a high-pressure aerated slurry jet through a choke to force the bubbles and particles to attach. This technology was originally invented by Laureate Professor Graeme Jameson to improve ultrafine particle flotation. Metso Outotec will be launching the Concorde Cell™ technology this fall.

Concorde Cell™

Concorde Cell™

“Metso Outotec is a leading provider of flotation technology. Thanks to intensive R&D efforts, we have successfully developed the new Concorde Cell™ flotation technology for superior performance in fine and ultrafine particle recovery. This is in response to the global industry trend towards efficient use of the Earth’s resources with more environmentally efficient technologies for more finely disseminated and complex orebodies,” says Paul Sohlberg, Vice President, Separation business line at Metso Outotec.

The Concorde Cell™ technology is a part of Metso Outotec’s Planet Positive portfolio.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki.