Super User

Siemens donates facemasks to charities with Brammer Buck & Hickman’s support

Siemens, working in conjunction with Brammer Buck & Hickman, the UK’s leading supplier of industrial maintenance, repair and overhaul (MRO) products and services, has donated protective facemasks to two overseas charities.

The facemasks were ordered by Siemens through Brammer Buck & Hickman – Siemens’ preferred supplier – at the start of the COVID-19 outbreak, as one of a number of measures to keep their staff safe. The masks were welcomed and used by Siemens’ factory staff and those deemed critical workers – including hospital maintenance and those working within power stations. However, with government rules and advice in 2020 regularly changing to reflect the shifting nature of the pandemic, the demand for disposal facemasks was considerably reduced. Rather than retain these facemasks, Siemens has donated them to two excellent charities for use overseas: Collective Aid and Medaid UK.

The facemasks were ordered by Siemens through Brammer Buck & Hickman – Siemens’ preferred supplier – at the start of the COVID-19 outbreak, as one of a number of measures to keep their staff safe. The masks were welcomed and used by Siemens’ factory staff and those deemed critical workers – including hospital maintenance and those working within power stations. However, with government rules and advice in 2020 regularly changing to reflect the shifting nature of the pandemic, the demand for disposal facemasks was considerably reduced. Rather than retain these facemasks, Siemens has donated them to two excellent charities for use overseas: Collective Aid and Medaid UK.

Collective Aid is committed to bringing dignity and care to refugees and other displaced people across Europe. Its mission is to fill the gaps left by other aid actors. The facemasks donated by Siemens will be sent to Calais for use by Collective Aid’s team to protect the vulnerable populations it distributes to, who do not have sufficient access to basic healthcare. To donate to Collective Aid’s Emergency Winter Appeal, click here.

Medaid provides sustainable medical solutions, advice and training for those working in low to middle income countries, to make healthcare safe and accessible to all. It specialises in optimising donated equipment to achieve the best possible results. A current project in Northern Uganda will be benefitting from the Siemens donated facemasks.

Paul Duncombe, Siemens Purchasing Commodity Manager, comments on this donation: “Our top priority at the start of this pandemic was to maintain the safety of our staff. We understood that facemasks had a role to play in this, but PPE was becoming difficult to obtain. We partnered with Brammer Buck & Hickman during the pandemic for our PPE needs as they are a tried and trusted partner for us. Brammer Buck & Hickman successfully sourced the facemasks we wanted and a large number have been put to good use within Siemens. With the remaining facemasks, we decided that rather than holding on to them, we could put them to use where they are needed most. Brammer Buck & Hickman kindly investigated suitable options and we are pleased to see the facemasks will now go to people who are in most need of them, via two admirable charities. This has been a joint effort between our two companies to achieve something positive in very trying times.”

Brammer Buck & Hickman is part of the Rubix group, Europe’s largest supplier of industrial MRO products and services. For more information, please go to https://uk.rubix.com.

About Brammer Buck & Hickman

Brammer Buck & Hickman is the UK’s leading technical specialist distributor of maintenance, repair and overhaul (MRO) products, as well as supplying multiple value-added services. Branches across the breadth of the UK provide customers with quick and easy access to more than 5 million products, from bearings, power transmission and fluid power through to tools and health & safety products. This extensive product portfolio is underpinned by specialist engineering services as well as condition monitoring. At the heart of Brammer Buck & Hickman’s service is a commitment to providing customers with cost savings through:

- reducing total acquisition costs

- improving production efficiency

- reducing working capital.

Brammer Buck & Hickman is part of the Rubix group, Europe’s largest supplier of industrial MRO products and services.

Delta’s New Compact, High-Performance ASDA-B3 Series

Delta, a world-class provider of industrial automation solutions, today announced the launch of its new compact and high-efficiency servo system ASDA-B3 Series, which offers a user-friendly operation environment with precise motion control functions, a newly- added safe torque off (STO) function, high responsiveness up to 3.1kHz and high positioning precision with over 16.7 million pulses per revolution to optimize production efficiency and output value in a wide range of applications, such as machine tools, electronics, semiconductors, industrial robots, printing, packaging, textiles, warehousing, and medical. Concurrently we have also launched the new generation motor of ECM-B3 Series, offering improved power density, stability, and stiffness while reducing 40% space requirements. Nevertheless, torque has increased 350% and the maximum speed is now 6000 rpm. With the new ASDASoft GUI, the time of commissioning and troubleshooting is shorter.

“Customers across a broad range of manufacturing and industrial automation applications are going to be really excited about our new generation of servo drives,” said Davide Bagnacani, product manager, Industrial Automation Business Group at Delta Electronics EMEA region. “The ASDA-B3 Series is a big step up in performance and we think this will make it attractive for applications, such as machine tools, electronics, semiconductors, industrial robots, printing, packaging, textiles, and warehousing. Moreover, applications that might not have used a servo drive before will see a noticeable increase in throughput. This drive is going to make the decision to use a servo motor much easier.”

A new level of performance

Among the many performance highlights of the new 230VAC ECM-B3 motor from Delta is an auto tuning feature that ensures optimized operation without the need for manual adjustments.

Responsiveness has been bumped up to 3.1 kHz from the 1 kHz of the preceding model. Delta has programmed new motor control algorithms and increased the computing power of the drive to achieve this superior result.

A 40% reduction in settling time also contributes to improved production line productivity. Load tolerances have increased, allowing for better control resolution and system stability as well as higher response bandwidth for the same load conditions.

Further contributing to efficiency are the low cogging torque, increased speed, and lower acceleration and deceleration times. As with the previous line of Delta servo drives, customers can choose from motors with varying inertia ranges to achieve the most efficient inertia ratio.

The new drive enables a number of motion functions, for instance in PR mode. Operators can use up to 99 PR paths for flexible motion command planning. The Capture feature makes it possible to capture coordinates instantly from a single set of digital inputs.

State-of-the-art safety, communications, and control

Safety features include built-in STO with no additional module required (B3A family), reaching a safety integrity level of 2 (SIL-2) and performance level D (PL-D). The ASDA-B3 Series can also operate using several different control modes from traditional pulse train and analog input to the more current fieldbus systems including CANopen and EtherCAT. These different control modes were achieved with three different hardware designs to ensure good segmentation and achieve cost efficiency for the respective application. The EtherCAT command frequency has been raised to 125 µs / 8kHz for greater accuracy.

Positioning is now several orders of magnitude more precise thanks to the 24-bit encoder, which results in 16,777,216 pulses per turn and 46,603 pulses for a single degree. This absolute encoder also retains the motor’s position when the power is off.

Flexibility, compatibility, and enhanced usability

The new configuration application ASDA-Soft employs wizards to guide users through a fast and easy setup procedure. Onboard diagnostics features and usability have been improved with a new and intuitive layout.

The new servo drives of ASDA-B3 Series are compatible with the existing motors of ASDA-A2 Series and ASDA-A3 Series. Configurations are available with IP20 connectors and IP65 connectors are in planning.

About Delta

Delta, founded in 1971, is a global leader in switching power supplies and thermal management products with a thriving portfolio of smart energy-saving systems and solutions in the fields of industrial automation, building automation, telecom power, data center infrastructure, EV charging, renewable energy, energy storage and display, to nurture the development of smart manufacturing and sustainable cities. As a world-class corporate citizen guided by its mission statement, “To provide innovative, clean and energy-efficient solutions for a better tomorrow,” Delta leverages its core competence in high-efficiency power electronics and its ESG-embedded business model to address key environmental issues, such as climate change. Delta serves customers through its sales offices, R&D centers and manufacturing facilities spread over close to 200 locations across 5 continents.

Throughout its history, Delta has received various global awards and recognition for its business achievements, innovative technologies and dedication to ESG. Since 2011, Delta has been listed on the DJSI World Index of Dow Jones Sustainability™ Indices for 11 consecutive years. In 2021, Delta was also recognized by CDP with leadership level ratings for its substantial contribution to climate change and water security issues and named Supplier Engagement Leader for its continuous development of a sustainable value chain.

For detailed information about Delta, please visit: www.deltaww.com

Pfannenberg Announces PQF Premium Quick Filter

A Simple and Effective New Way to Protect Critical Equipment from Particulates and Oily Mist

Pfannenberg, Inc., a leading global manufacturer of thermal management technologies, announces PQF Premium Quick Filter, a new, easier way to filter out particulates and oily mist from an air inlet on critical equipment enclosures.

This simple and innovative solution increases the life of equipment and reduces downtime by solving one of the most common problems causing equipment failure–overheating caused by a clogged airflow path.

Secure magnetic mounting on the exterior of the air inlet makes for quick and easy installation and replacement. Installation takes less than 5 seconds and requires no training or shutdown procedure. No drilling, tapping or gluing is required, and the magnetic installation allows the filter to be installed vertically, horizontally or in any other position to fit around the air inlet.

The design saves time by eliminating multiple trips to the warehouse to cut filter mat to size when changing out a clogged filter and eliminates messy washing of filters using harmful chemicals. Studies have shown up to 30% savings on time and labor for filter maintenance.

Each PQF roll has 60 tearable, disposable sheets providing enough filter replacement for up to one year. The PQF is available in three different lengths: 200mm (8inch), 300mm (12inch) and 400mm (16inch) and is suitable for a variety of applications and air inlet sizes.

Visit https://www.pfannenbergusa.com/accessories/ to learn more about the PQF Premium Quick Filter and Pfannenberg’s innovative thermal management solutions.

About Pfannenberg

Pfannenberg, Inc. is recognized as a leading global manufacturer of Thermal Management, Liquid Cooling Solutions and Signaling Technologies. In 1958 we invented the Filterfan®, which continues to be recognized worldwide as a leading product to help manage the temperature in electrical enclosures. Our business philosophy: Protecting People, Machine, and the Environment.

Bally Ribbon Mills to Highlight Performance Webbing Options at SHOT Show 2022

Visit booth 52132 for specialty binding tapes, Berry-compliant polyester webbing, and new pistol belt/sling webbing

Bally Ribbon Mills (BRM), an industry leader in the design, development, and manufacture of highly specialized engineered woven fabrics, announces that it will showcase its high-quality, high-performance products at the SHOT Week Supplier Showcase to be held January 18-21, 2022 as part of SHOT Show.

Visit BRM at booth 52132 in the Palazzo Ballroom at the Venetian Congress Center in Las Vegas, Nevada. Subject matter experts will be on hand to highlight samples of our industry-leading specialty binding tapes, Berry-compliant polyester webbing, and new pistol belt/sling webbing to industry manufacturers attending SHOT Show. Visitors to the booth can also see samples of material BRM supplied for tie-downs and structural elements of both the deceleration and landing systems used in NASA’s mission to Mars. These materials are engineered to maintain the highest strength to weight ratio possible while also being resistant to extreme environmental conditions of space and Mars’s atmospheric conditions during entry. These same material have also been utilized for specialty applications here on Earth.

Visit BRM at booth 52132 in the Palazzo Ballroom at the Venetian Congress Center in Las Vegas, Nevada. Subject matter experts will be on hand to highlight samples of our industry-leading specialty binding tapes, Berry-compliant polyester webbing, and new pistol belt/sling webbing to industry manufacturers attending SHOT Show. Visitors to the booth can also see samples of material BRM supplied for tie-downs and structural elements of both the deceleration and landing systems used in NASA’s mission to Mars. These materials are engineered to maintain the highest strength to weight ratio possible while also being resistant to extreme environmental conditions of space and Mars’s atmospheric conditions during entry. These same material have also been utilized for specialty applications here on Earth.

Visit the booth to see representative samples of BRM’s highly abrasion resistant specialty binding tapes, ideal for edge binding on load bearing equipment and soft-sided backpacks and luggage. Our materials offer consistent quality and width, optimizing the sewing fabrication process. They also enable significantly better throughput, making them a better overall value than lower quality tapes.

Also on display are samples of our superior Berry Amendment-compliant polyester webbing, ideal for use by DOD contractors manufacturing aircraft seat belts, retractors, restraining harnesses, and tie-downs. BRM’s Berry-compliant webbing is a good choice for civilian agencies involved in U.S. military procurement activities. Webbing is available in a wide range of widths, from 1-inch to 6-inch and is offered in low minimum runs and custom colors.

The new pistol belt/sling webbing that will be showcased at the booth is available in small runs with customization of color, widths, and weave designs and patterns. Our experts offer complete design and textile engineering services.

Visitors to the booth can consult with our subject matter experts, who bring a wide breadth of design application and engineering knowledge and can leverage their experience to solve engineering challenges in woven tapes and webbing.

For more information, speak with BRM experts in booth 52132 at the SHOT Week Supplier Showcase, or visit https://www.ballyribbon.com/.

About Bally Ribbon Mills

Bally Ribbon Mills (BRM) designs, develops, and manufactures highly specialized engineered woven webbing, tapes, specialty fabrics, woven preforms, and two-dimensional and three-dimensional structural fabrics. With more than 95 years of textile manufacturing experience, BRM has earned a reputation for meeting new advanced design challenges. Working in aerospace, defense, medical, safety, automotive, commercial, and industrial applications, BRM offers ingenuity, technical know-how, extensive weaving capabilities, and rigorous quality assurance systems. For more information, visit www.ballyribbon.com or call 610-845-2211.

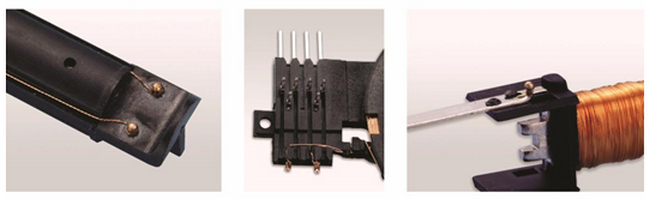

AMADA WELD TECH Announces Pulsed Arc Welding Solutions for Coil Termination

AMADA WELD TECH offers a full range of pulsed arc welding power supplies for precision joining applications, ensuring exact control and repeatability. These supplies range from lab models with customizable options, to production machines offering streamlined features to match the customer’s exact needs. Every item is designed and built in-house, from equipment for small-scale manual production to fully automated systems.

With a specialist product portfolio developed for precision joining of materials and spanning many industrial sectors, AMADA WELD TECH Europe can uniquely offer the correct technology to suit customers’ specific needs. Each system solution is available with easy-to-program PLC or industrial PC software. Also, each system benefits from SPC integration, automatic alignment, advanced user interfaces, remote diagnostics, CNC motion, robotics, and product transport systems, as required.

The systems are available in 1, 2, 3, and 4 output models to allow for a single power supply in high-speed production automation. Single output standard models include the PA-60P and PA-200P. Multiple output models are available from 20-60 amps.

Each unit produces a pulse of accurately controlled current. A specially developed arc start system incorporates a high voltage DC impulse, operating with a stabilizing power supply. This ensures consistent arc ignition with minimal radiated interference. All models offer gas flow control and voltage monitoring, to detect arc failure.

Closed loop techniques ensure stable outputs independent of temperature, cable lengths, and mains supply variations. AMADA WELD TECH Europe accomplishes this through transistorized output control and an analogue feedback and drive circuit. This control system responds rapidly to process changes and stabilizes output, ensuring consistency.

About AMADA WELD TECH

AMADA WELD TECH is a leading manufacturer of equipment and systems for Laser Welding, Laser Marking, Laser Cutting, Resistance Welding, Hermetic Sealing and Hot Bar Reflow Soldering & Bonding. We customize our products around specific micro-joining applications for all our customers around the globe. AMADA WELD TECH product markets include medical devices, battery, automotive, solar industry, electronic components and aerospace. We are an ISO9001 certified company. Contact AMADA WELD TECH at This email address is being protected from spambots. You need JavaScript enabled to view it.. Find out more about the company’s products and services at www.amadaweldtech.eu.

Matara supplies converting solutions provider with machine guarding

Matara UK Ltd, specialist in automation, pneumatics and linear motion products, has completed a substantial project for the manufacture and supply of machine guard frames for T S Converting Equipment Ltd. (Elite Cameron).

T S Converting provides solutions for slitting, coating and lamination of a wide range of substrates, tailored to suit customers’ requirements. To ensure people do not get too close to the machinery when in operation, and to comply with safety regulations, machines are supplied to customers with a protective guard frame. Until recently, this frame was produced in-house, which was very time-consuming, costly and did not allow for key accessories, such as screw-in feet or castors, be used.

With T S Converting’s latest project – a substantial order of mixed machines – the company turned to Matara, which has over two decade’s experience in this field.

Working from T S Converting’s CAD drawings, Matara cut the aluminium to the correct size and assembled the guarding panels to T S Converting’s exact specifications. Aluminium profile was selected for this order due to its adaptability and the speed in which it can be produced, and for its cost-effectiveness when compared to steel.

Matara machine guarding for TS Converting

Matara machine guarding for TS Converting

This latest order has required over 200m of 40x40mm aluminium profile, which has been powder coated safety yellow (RAL1003). All sections of this guarding have been supplied with UK stocked 25x25 black powder coated wire mesh or clear polycarbonate panels. A wide range of accessories has been included into the guard frames, including feet for mounting the sections to the floor for stability, connecting plates complete with fixings, door handles and hinges.

With T-slots pre formed into the aluminium profile, adding further accessories couldn’t be easier as they simply slide into these slots without the need for welding or drilling holes. This has enabled T S Converting to make further on-site adaptations, including adding switch panels to certain areas of the profile as well as safety switches on the doors of the guard frame.

Commenting on their decision to out-source the machine guard frame production to Matara, James Self, Director at TS Converting Equipment said: “One of the main reasons we chose Matara is the time it has saved us in production. We now have the guarding cut, powder coated and fully assembled, saving our engineers valuable time in our busy production schedule. The guarding has been a huge success not just for saving money but also how smart it looks.”

T S Converting has also been impressed with the service Matara has delivered: “The service provided from Matara has always been helpful and professional. Every member of staff at Matara have always been welcoming and more than happy to help. Because of the success on the guarding, we are now discussing other areas of the business that we can work together on. The partnership between T S Converting and Matara has a very bright future.”

Matara is part of Rubix, Europe’s largest supplier of industrial maintenance, repair and overhaul products and services. For more information, please go to www.matara.com/

About Matara

Matara, established in 1995, is a specialist supplier of bespoke linear motion, automation, and pneumatic components. Based in Tewkesbury, Gloucestershire, Matara are a team of 27 employees, serving a wide range of industries, including printing & packaging, food & drink, pharmaceutical and metal processing. In the year ended 31 March 2020, Matara reported sales in excess of £5m.

About Rubix

Rubix is Europe’s largest supplier of industrial maintenance, repair and overhaul products and services. It was created from the merger of IPH with Brammer in 2017, following the acquisition of Brammer by Advent International.

From around 750 + locations across 22 countries, 8,000 employees help to identify, install and provide a leading range of industrial products and services to more than 200,000 customers. The business had combined sales of €2.4bn in 2020 and is a leading distributor in bearings, transmission and automation, fluid power, machining, assembly, tools and protective equipment.

Clearwater Paper Launches NuVo® with BioPBS™ Cup

Clearwater Paper Corporation (NYSE: CLW) has just introduced NuVo® withBioPBS™, a sustainable cup stock that provides foodservice operators with a compostable alternative to hot cups coated with low-density polyethylene.

NuVo® withBioPBS™ is the first cup stock to combine a compostable barrier, 35% post-consumer fiber, Forest Stewardship Council® (FSC®) chain-of-custody certification (FSC-C008402), and a high-definition print surface.

“When we launched the NuVo® brand in 2019, we made a promise to continually innovate to maximize product differentiation and sustainability. We are pleased to continue delivering on that commitment by introducing NuVo® withBioPBS™, a next-generation cup stock that we believe will allow our customers to be at the forefront of growing trends in sustainability,” said Steve Bowden, senior vice president and general manager of the pulp and paperboard division.

You can find additional information about NuVo® on the Clearwater Paper website at Clearwater Paper Corporation - Paperboard Products.

ABOUT BioPBS™

BioPBS™ is supplied to Clearwater Paper by Mitsubishi Chemical Corporation and PTTMCC Biochem Company Limited, a 50-50 joint venture between MCC and PTT Global Chemical Public Company Limited.

ABOUT CLEARWATER PAPER

Clearwater Paper is a premier supplier of private-branded tissue to major retailers, including grocery, drug, mass merchants and discount stores. In addition, the company produces bleached paperboard used by quality-conscious printers and packaging converters, and offers services that include custom sheeting, slitting, and cutting. Clearwater Paper's employees build shareholder value by developing strong relationships through quality and service.

FORWARD-LOOKING STATEMENTS

This press release contains certain forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995, as amended, including statements regarding product quality, attributes, and development; sustainability and customers. These forward-looking statements are based on current expectations that are subject to change, and actual results may differ materially from the forward-looking statements. Factors that could cause actual results to differ materially include those risks and uncertainties described from time to time in the company's public filings with the Securities and Exchange Commission. The company does not undertake to update any forward-looking statements based on new developments or changes to the company’s expectations.

For additional information on Clearwater Paper, please visit our website at www.clearwaterpaper.com.

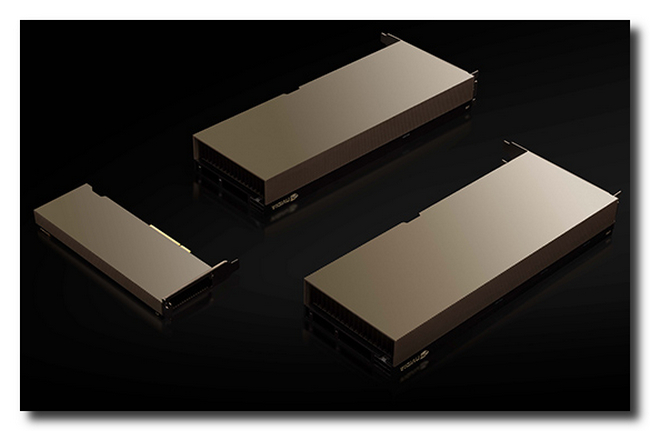

Advantech Releases HPC-6240+ASMB-622 Industrial Edge Inference Server Powered by NVIDIA A2 Tensor Core GPU

Advantech, a leading provider of industrial intelligent systems, is pleased to announce the HPC-6240+ASMB-622 industrial edge Inference server. This innovative solution is specially designed for the rapid deployment, management, and scaling of AI and inference workloads in the modern hybrid cloud. Advantech's HPC-6240+ASMB-622 also works perfectly with the newly announced NVIDIA A2 Tensor Core GPU, an entry-level, low-power, compact accelerator for inference and edge workloads.

The Everywhere AI Made with NVIDIA and Advantech

The opportunity for artificial intelligence (AI) to transform every industry is greater than ever. From thousands of sensors and Auto-Optical Inspection (AOI) equipment in smart factories to enhance the safety, accuracy, and efficiency, to over one billion smart city cameras working to ensure public safety, to the 500 million calls per day to contact centers, the demand for AI to serve these needs is enormous.

Inference is key to optimizing production procedures, making them more convenient, preventing revenue loss, and increasing operational efficiency as we ascend into an AI economy. However, developing inference solutions from concept to deployment is not easy. Advantech HPC-6240+ASMB-622, powered by the soon to be available NVIDIA A2, offers a complete end-to-end stack and suite of products and services to deliver the performance, efficiency, and responsiveness that is critical to powering the next generation of AI inference in embedded devices. With only 20.5" depth and multiple expansion slots, this system is especially suitable in Industrial Equipment Manufactures (IEM), robotics, retail, intelligent video analytics (IVA), and other applications of AI at the edge.

The NVIDIA A2 GPU's versatility, compact size, and low power requirements exceed the demands for edge deployments at scale. Combined with the Advantech HPC-6240+ASMB-622, it can deliver up to 20X higher inference performance versus CPUs and 1.3X more efficient IVA deployments than previous GPU generations — all at an entry-level price point.

Advantech HPC-6240+ASMB-622 Industrial Edge Inference Server

Advantech's HPC-6240+ASMB-622 is a 2U short-depth compact edge server with dual 3rd Gen Intel® Xeon® scalable processors. It provides 8 expansion slots and multiple PCIe for flexible GPU, NIC, Frame Grabber Card, and motion-control card integrations. Four PCIeX16 design supports up to four NVIDIA A2 GPUs for AI and HPC.

Low power requirement, compact size, and multiple expansion capability with four A2 GPUs, this solution empowers complex AI Auto-Optical Inspection and manufacturing equipment applications.

Accelerate AI Capabilities with Advantech

HPC-6240+ASMB-622 leverages Advantech's innovative thermal management system to increase airflow and pressure. This feature enables high computing workloads at the industrial edge by cooling GPU cards and reducing noise output.

HPC-6240+ASMB-622 is able to scale out from a single-GPU node to multi-GPU nodes when needed in industrial applications, especially in the areas of AOI, voice recognition, and translation.

HPC-6240+ASMB-622 enables enterprises to confidently deploy hardware solutions that securely and optimally run their modern accelerated workloads while using the NVIDIA AI platform for inference. The NVIDIA AI platform for inference includes software such as NVIDIA Triton Inference Server and NVIDIA TensorRT, which can be accessed directly from the NVIDIA NGC catalog.

About Advantech

Advantech's corporate vision is to enable an intelligent planet. The company is a global leader in the fields of IoT intelligent systems and embedded platforms. To embrace the trends of IoT, big data, and artificial intelligence, Advantech promotes IoT hardware and software solutions with the Edge Intelligence WISE-PaaS core to assist business partners and clients in connecting their industrial chains. Advantech is also working with business partners to co-create business ecosystems that accelerate the goal of industrial intelligence. (www.advantech.eu)

Stora Enso appoints Johanna Hagelberg as Head of Biomaterials division

Stora Enso has appointed Johanna Hagelberg Executive Vice President, Biomaterials division. She will continue as a member of the Group Leadership Team (GLT).

Johanna HagelbergJohanna Hagelberg joined Stora Enso in 2013 and has been a member of the GLT since 2014 as Head of Sourcing and Logistics. Prior to joining Stora Enso, she held leadership positions at companies including General Motors, NCC and Vattenfall. Johanna holds two M.Sc. degrees in: Management of Manufacturing Systems and Industrial Engineering and Management. The search for a new Head of Sourcing and Logistics has been initiated. In the interim period, Tuomas Mustonen, currently SVP Performance, Controlling and Strategy for Sourcing and Logistics, will assume the acting role in this position.

Johanna HagelbergJohanna Hagelberg joined Stora Enso in 2013 and has been a member of the GLT since 2014 as Head of Sourcing and Logistics. Prior to joining Stora Enso, she held leadership positions at companies including General Motors, NCC and Vattenfall. Johanna holds two M.Sc. degrees in: Management of Manufacturing Systems and Industrial Engineering and Management. The search for a new Head of Sourcing and Logistics has been initiated. In the interim period, Tuomas Mustonen, currently SVP Performance, Controlling and Strategy for Sourcing and Logistics, will assume the acting role in this position.

“Biomaterials is a core strategic business for Stora Enso. As we now move into an innovation-driven era for biomaterials, I am delighted to appoint Johanna as head of the division. Her proven leadership skills and experience from various industries, including the automotive industry, will enable us to take this business to the next level. Johanna has the background and ability to accelerate commercialisation of new bio-based products, such as Lignode, lignin-based battery carbon for mobile electrification,” says Stora Enso’s President and CEO Annica Bresky.

“I am excited for the opportunity to together with the team lead the Biomaterials division. As we transform towards bio-based innovation, we continue development of current business, while enabling fast market readiness for new regenerative products,” says Johanna Hagelberg.

Markus Mannström, the previous EVP and Head of Biomaterials, will leave his position to pursue new career opportunities outside the company.

“I would like to thank Markus Mannström for his significant contributions to Stora Enso during his long career with us. As a leader in several large investment projects and in heading our Biomaterials division, he has helped us transform into the renewable materials company. We wish him the best of luck in the future,” says Annica Bresky.

Part of the bioeconomy, Stora Enso is a leading global provider of renewable solutions in packaging, biomaterials, wooden constructions and paper. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has some 23 000 employees and our sales in 2020 were EUR 8.6 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com/investors

Metso Outotec to deliver grinding mill components to a copper and gold mine in Asia Pacific

Metso Outotec has signed a services contract for the delivery of four ball mill upgrade packages to a copper and gold mine in Asia Pacific. The value of the order is approximately EUR 19 million, and it has been booked in Minerals’ Q4/2021 orders received.

Refurbishment projects for older, existing assets are an efficient method to extend a mill’s operating life, increase energy efficiency, and minimize waste and plant downtime. Additionally, equipment refurbishments lead to improved machine availability and safety by delivering the latest available technology.

“We are pleased to have been chosen as the supplier for the grinding mill refurbishment project. The customer’s performance objectives were achieved by offering a technical solution which increased the operating volume of the mill and allows for future process optimization. Providing these thirty+ year old mills a new lease of life is exciting for Metso Outotec and builds on our sustainability promise of delivering circular offerings,” says Jonathan Allen, Senior Vice President, Grinding, Bulk and Pyro business line of Metso Outotec.

Metso Outotec has delivered and serviced over 8,000 grinding mills globally, including some of the largest and most powerful mills in the world. The company is a market leader in providing a wide variety of upgrades and service solutions to help customer’s older mills achieve performance like a modern-day machine.

Discover more about Metso Outotec Grinding Spare Parts and Grinding Upgrades on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com