Super User

Konecranes launches new generation of energy-efficient mobile harbor cranes as global trade accelerates

Konecranes today launched its sixth generation of mobile harbor cranes, refreshing and reinforcing its industry-leading portfolio as global trade accelerates and the industry seeks more sustainable lifting solutions to reduce its climate impact.

- New Generation 6 high-performance model portfolio targets growing global bulk and general cargo handling market demand as COVID-19 pandemic eases

- Engineered for electric power, new cranes can also run on battery power, cutting fuel and maintenance costs and helping Konecranes’ customers meet their low-carbon targets

- New interactive MHC Product Advisor lets customers configure the right crane for their requirements, easing the impact of COVID-19 restrictions on face-to-face meetings

- Sales of the new products have now started

Generation 6 marks the first comprehensive revamp of Konecranes Gottwald’s mobile harbor crane portfolio in 15 years, and comes as growth in the global bulk and general cargo handling market accelerates. Research from Drewry Maritime Advisors forecasts the global bulk and general cargo handling market, excluding RoRo and vehicle traffic, to grow 6.8% year-on-year in 2021 to 7.4 billion tonnes. Drewry expects growth to continue in coming years, reaching 8.5 billion tonnes by 2025, a compound annual growth rate of 3.5%.

Konecranes, which launched the world’s first mobile harbor crane in 1956 and is a pioneer in Ecolifting™, has worked closely with customers around the world while developing the new cranes. The result is a range of products that can eco-efficiently service essentially any type of vessel and any kind of cargo – containers, general cargo, project cargo and bulk – in any location, either on the quay or on a barge. Sales are now underway.

“Konecranes is a pioneer and leader in high-performance mobile harbor cranes, and today’s launch underscores that pedigree at a time when growth in the global bulk and cargo handling market gathers pace and customers are seeking more sustainable solutions,” said Konecranes President and CEO Rob Smith.

“These cranes represent the best of Konecranes in terms of technology and durability, and thus also strongly support our commitment to sustainability. The carbon footprint of our customers is just as important as our own, and we aim to reduce it through low-carbon, eco-efficient solutions and by extending product lifecycles in ports, factories and everywhere our products and services are used,” Smith said.

Freedom to move – with lower emissions

Reflecting Konecranes’ commitment to a decarbonized and circular world for customers and society at large, Generation 6 is designed for electrical power use; power can be sourced from an onshore grid, meaning no direct carbon emissions during operation. Operators can also choose a new battery solution that also reduces emissions and gives greater flexibility by permitting crane operation independent from the grid. For quays without a power supply, a common occurrence in developing markets, the cranes come with fuel-saving diesel generators and Konecranes’ latest hybrid drives.

“Stevedores globally, big and small, are increasingly focused on reducing the carbon footprint of their operations in the near term. Growing trade and the need to replace old equipment will likely mean increased demand from ports around the world for more efficient cargo handling equipment to support increases in productivity, reduction of costs and CO2 emissions,” said Dinesh Sharma, Director at Drewry Maritime Advisors.

In addition to lower emissions, the design of the crane advances circularity through a more durable design: its robust construction doubles the cranes’ service life in container operation compared to earlier generations, and more powerful lifting capacity curves and high working speeds ensure greater efficiency and faster cargo turnaround times. The long-lasting design not only saves the resources needed to build new cranes – it supports resale values when customers choose to renew their fleets.

A truly connected fleet, designed by the customer

The new products also reflect Konecranes’ technology leadership. The new cranes will be equipped with smart crane features for safe, ergonomic and efficient crane operation, and will come equipped with TRUCONNECT remote monitoring, which collects condition, usage and operating data from control systems and sensors to help with maintenance planning and predicting possible component or equipment failure. Customers will also get access to the yourKONECRANES customer portal for a comprehensive view of equipment maintenance needs and performance.

These capabilities reflect Konecranes’ investment in the growing opportunities of data. The company has a data science laboratory in Lyon, France, as part of its continuing drive to digitalize products, services, and operations, and has tapped the real-time insights from its tens of thousands of connected devices and pieces of equipment around the world to balance demand and supply in real time and navigate through the COVID-19 pandemic.

Konecranes today also launched its online self-service Product Advisor, which gives customers the chance to configure their own cranes, facilitating the purchasing process at a time when face-to-face meetings – the main way the industry has done business for decades – can be difficult due to the pandemic.

To read more about these Electric, Smart and Powerful (ESP) mobile harbor cranes and their new genetic code for the future, please click here for a release with technical details

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2020, Group sales totaled EUR 3.2 billion. The Group has around 16,600 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

Sulzer Chemtech and Axens alliance delivers an advanced FCC naphtha processing solution

Axens, an international provider of process technologies, catalysts, adsorbents and services and Sulzer Chemtech (GTC Technology), a global licensor of refinery and petrochemical process technologies, have formed an alliance to license an advanced process for FCC (fluid catalytic cracking) naphtha processing. The combined offering is based on Axens’ Prime-G+® hydrodesulfurization technology and Sulzer Chemtech’s GT-BTX PluS® extraction technology.

Axens Prime-G+® technology is by far the leading technology for FCC gasoline selective desulfurization with more than 300 references worldwide and Sulzer Chemtech is incontestably positioned as the leader for aromatics recovery for downstream FCC applications through its extractive distillation technology GT-BTX PluS®. The combined solution of both technologies brings outstanding advantages for the gasoline and the petrochemical segments.

Sulzer Chemtech and Axens’s combined offer provides a unique and advanced solution for a refinery to achieve maximum performance in both ULS gasoline production and gasoline-to-petrochemical production.

Sulzer Chemtech and Axens’s combined offer provides a unique and advanced solution for a refinery to achieve maximum performance in both ULS gasoline production and gasoline-to-petrochemical production.

The combination of Prime-G+® and GT-BTX PluS® offers a unique solution to reduce octane loss to a very low level for the gasoline pool. The technology is especially important in countries that are upgrading fuel specifications to meet environmental requirements, and it can be applied in new, or retrofits of existing units in operation to maximize profit.

It also provides refiners with the option of converting FCC gasoline into petrochemical products – BTX and additional propylene – and get additional margin in regions where gasoline demand is not sufficient. For those, the combined offer can convert their excess gasoline into petrochemical products to adapt to the market change with minimum investment.

Axens’ Process Licensing Global Business Unit Executive Vice-President Patrick Sarrazin comments: “We look forward to collaborating with Sulzer Chemtech, to provide a comprehensive, high-quality processing solution to different players in the oil refining sector. The combination of Prime-G+® and GT-BTX PluS® and will help them address current and future market demands as well as increase their competitiveness.”

The combined technologies have the flexibility to switch between gasoline mode and petrochemical mode at any time to quickly adapt to market change.

The combined technologies have the flexibility to switch between gasoline mode and petrochemical mode at any time to quickly adapt to market change.

“We are excited about the partnership with Axens. We are committed to delivering state-of-the-art technologies and are confident that this combined solution will bring many benefits to our customers. It will allow them to prepare for the changing gasoline and petrochemicals demand in both the near and longer term,” says Sander van Donk, Head of Global Technology Business at Sulzer Chemtech.

About Axens’ Prime-G+® Technology

Axens’ Prime-G+® technology is the world leader technology for FCC gasoline selective hydro-desulfurization with more than 300 commercial references. As the FCC gasoline is a major contributor to the gasoline production, Prime-G+® is a key unit to ensure the production of Ultra Low Sulfur gasoline (ULSG) complying with the most stringent environmental regulations. The Prime-G+® technology specificity is to allow a deep hydro-desulfurization while keeping high octane number and has industrially demonstrated its capability to achieve less than 10 ppmwt sulfur content. Over the years the Prime-G+® has emerged as the key process unit for the refiners to meet the challenging gasoline specifications.

About GT-BTX PluS®

GT-BTX PluS® technology, derived from Sulzer Chemtech GTC’s world-leading GT-BTX® extraction process, is specifically designed for FCC naphtha processing. It utilizes high-efficiency solvent and state-of-the-art process design to extract and separate aromatics, sulfurs, olefins and other non-aromatics from FCC naphtha. By segregating different components to different destinations, GT-BTX PluS® provides flexibilities to reduce octane loss even lower than that of a standalone hydrodesulfurization unit at gasoline mode, and to convert gasoline into petrochemical products at petrochemical mode. It is a technology for the next generation of refineries.

About Axens

Axens (www.axens.net) is a group providing a complete range of solutions for the conversion of oil and biomass to cleaner fuels, the production and purification of major petrochemical intermediates as well as all of natural gas' treatment and conversion options. The offer includes technologies, equipment, furnaces, modular units, catalysts, adsorbents and related services. Axens is ideally positioned to cover the entire value chain, from feasibility study to unit start-up and follow-up throughout the entire unit cycle life. This unique position ensures the highest level of performance with a reduced environmental footprint. Axens global offer is based on highly trained human resources, modern production facilities and an extended global network for industrial, technical supports & commercial services. Axens is an IFP Group company.

About Sulzer

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and application technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class manufacturing facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2020, our 15’000 employees delivered revenues of CHF 3.3 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN).

The Chemtech division is the global market leader in innovative mass transfer, static mixing and polymer solutions for petrochemicals, refining and LNG. Chemtech is also leading the way in ecological solutions such as biopolymers as well as textile and plastic recycling, contributing to a circular economy. Our product offering ranges from technology licensing to process components all the way to complete separation process plants. Customer support ranges from engineering and field services to tray and packing installation, tower maintenance, welding and plant turnaround projects – ensuring minimal downtime.

Tuk In Foods launches a new range of meal pots with the Co-op

Tuk In Foods continues to be a driver of innovation in the Food to Go category following growing demand for its curry in a naan and very successful launch of its online offer a year ago. They have just launched a range of delicious and nutritious curry, lentil and quinoa based meal pots with the Co-op. Tuk In Foods is launching initially with two variants; Chicken Tikka and Chicken Jalfrezi.

Sales Director Paul Grigg said; “This new innovation has been driven by demand from our online customers with an initial concept receiving rave reviews by customers. This launch builds on an already strong relationship with the Co-op, who already stock our award-winning range of Curry-in-a-Naan. “

The meal pots provide a really wholesome option for food to go customers being high in protein, low in saturated fat and low in sugar. The Chicken Tikka Lentil and Quinoa Meal pot delivers 65% of RDA protein in a portion size of 350g and 430kcal. The Chicken Jalfrezi Lentil and Quinoa Meal pot delivers 61% of RDA protein in a portion size of 350g and 368kcal. All of this before you get into the health benefits of the freshly ground spices and quinoa in the pots.

The launch comes at an exciting time for Tuk In Foods. The brand secured additional investment at the end of 2020 which is now driving significant business growth. Tuk In Foods is focused on growing its online delivery offering, expanding its Curry in Naan customer base and is making additional investment in its production site.

To find out more, visit: www.tukinfoods.com

About Tuk In Foods

Tuk In Foods is passionate about making delicious Indian restaurant quality food more accessible. We believe in wholesome freshly made recipes made using kitchen ingredients. The business was founded in 2015 and set up its own production in Leicester three years ago. The business is targeting growing to £4m of turnover during 2021.

China to lead global LNG regasification capacity additions by 2025, says GlobalData

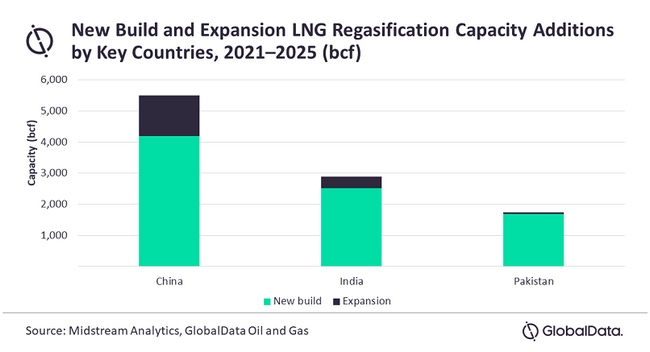

China is expected to lead the global LNG regasification capacity additions, contributing 27% of the total LNG regasification capacity additions between 2021 and 2025, says GlobalData, a leading data and analytics company.

The company’s report, ‘Global Capacity and Capital Expenditure Outlook for LNG Regasification Terminals, 2021–2025 - Asia Dominates Global Regasification Capacity Additions and Capex Spending’ reveals that China is expected to add a new- build LNG regasification capacity addition of 4,191 bcf (billion cubic feet) by 2025, while expansion projects account for the rest with 1,308 bcf.

Bhargavi Gandham, Oil and Gas Analyst at GlobalData, comments: “In China, 26 new- build and expansion projects are likely to start operations by 2025. Tangshan II is the largest upcoming project in the country with a capacity of 584.4 bcf by 2025. Yantai I and Zhoushan III are the other major projects with capacities of 487 bcf and 340.9 bcf, respectively.

GlobalData identifies India to be the second-highest contributor to the global LNG regasification capacity additions with new build LNG regasification capacity additions of 2,882 bcf by 2025. Expansion projects account for the rest of the capacity additions with 365 bcf by 2025. ‘Karwar Floating’ and ‘Jaigarh Port Floating’ projects lead LNG regasification capacity additions in the country with capacities of 365 bcf and 274 bcf, respectively.

Pakistan is expected to be the third largest contributor to the LNG regasification capacity additions globally with 1,752 bcf. Of these, new build capacity additions account for 1,697 bcf and expansion capacity additions account for 55 bcf by 2025. Among the new build projects in the country, Port Qasim is the largest upcoming project with a capacity of 438 bcf. It is expected to start operations in 2023.

- Comments provided by Bhargavi Gandham, Oil & Gas Analyst at GlobalData

- Information based on GlobalData’s report: ‘Global Capacity and Capital Expenditure Outlook for LNG Regasification Terminals, 2021–2025 - Asia Dominates Global Regasification Capacity Additions and Capex Spending’

- Announced/Planned: Denotes only new-build assets that are in different stages of development and have not started commercial operations

- A new-build project that has not received relevant/ required approvals to develop/build the project is considered as Announced

- A new build project that has received relevant/ required approvals from the national government/ energy ministry/ regulatory authority/ local environmental authority/ port authority/local government, etc to develop/build the project is considered as Planned

- Expansion – Denotes capacity expansion of existing/operational terminal

- This report was built using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts.

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis, and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, technology, energy, financial and professional services sectors.

AkzoNobel powering ahead with solar projects in China to accelerate sustainability ambitions

Two major projects to install around 8,000 solar panels are being finalized by AkzoNobel in China, helping the company to accelerate its ambition of cutting carbon emissions in half by 2030.

Being installed at two Decorative Paints plants – more than 5,000 at the Shanghai site and almost 3,000 in Guangzhou – it represents further progress for the company’s greener manufacturing plans.

“Increasing the amount of renewable energy we use is a key part of our People. Planet. Paint. approach to doing business more sustainably,” explains Wijnand Bruinsma, AkzoNobel’s Program Manager for Sustainability. “The new installations will make an important contribution to our ongoing sustainability achievements in China and will help drive us towards our overall goal of moving to 100% renewable electricity by 2030.”

The Guangzhou site has now almost 3,000 solar panels installed

The Guangzhou site has now almost 3,000 solar panels installed

The new solar systems will become the primary source of power at each location. Now almost fully completed, they’ll generate around 1.66 million KWh in Shanghai and 1 million KWh in Guangzhou.

“We’re excited to see these two projects successfully come to life,” continues Mark Kwok, Director of AkzoNobel’s Decorative Paints business in China/North Asia. “Sustainability is at the core of everything we do, whether that means improving the eco-footprint of our sites or addressing the environmental needs of our local customers and communities at large.”

Kwok adds that plans are also in place to install more solar panels at the company’s manufacturing sites in Changzhou, Langfang and Chengdu. “By installing additional panels at our sites in China, we’ll be able to reduce our energy consumption throughout the entire manufacturing process,” he says.

At the end of 2020, AkzoNobel’s total share of renewable electricity use was 40%, with 34 locations and 12 countries already using 100% renewable electricity.

About AkzoNobel

We’ve been pioneering a world of possibilities to bring surfaces to life for well over 200 years. As experts in making coatings, there’s a good chance you’re only ever a few meters away from one of our products. Our world class portfolio of brands – including Dulux, International, Sikkens and Interpon – is trusted by customers around the globe. We’re active in more than 150 countries and have set our sights on becoming the global industry leader. It’s what you’d expect from the most sustainable paints company, which has been inventing the future for more than two centuries.

Metso Outotec introduces stirred mills portfolio for superior comminution performance and energy efficiency

Metso Outotec has been a frontrunner in driving stirred milling innovations for decades and is now excited to introduce its comprehensive portfolio featuring three frontrunning stirred milling solutions – Vertimill®, Stirred Media Detritor, and HIGmill™. Ideal for grinding finer products, stirred mills are known for their energy efficiency and compact design, reducing floor space requirements. These mills are based on gravity-induced and fluidized technologies, allowing for the optimum equipment solution for all comminution circuits covering secondary, tertiary, fine, ultrafine, regrind, and lime slaking applications.

“Stirred milling is an important growth area and integral to our customer’s efforts for sustainable and cost-efficient comminution. With our combined portfolio and our unrivaled experience in this field, Metso Outotec is in the unique position to offer the most suitable solution for any specific application. We are doing this with a holistic view towards efficiency, sustainability, availability, and total cost of ownership,” explains Christoph Hoetzel, Head of Grinding business line at Metso Outotec.

A solution for every need

The Metso Outotec stirred mills are suitable for a large range of product sizes. The standardized range includes chamber units of up to 50,000 liters and the world’s largest industry units with up to 6,500 kW of installed power. Floor space use is optimized, which reduces investment costs, and installation is easy. All our stirred mills are part of the Planet Positive product portfolio, thanks to the sustainability benefits they deliver.

Vertimill® is globally recognized as market-leading energy-efficient grinding mill. Through a low total cost of ownership due to its simple and robust design, it brings substantial improvement to the profitability of concentrators. Over the years, Vertimill® technology has proven to be efficient – especially in secondary and tertiary grinding, regrinding, fine grinding, and lime slaking applications.

HIGmill™ is an advanced, energy-efficient fine and ultra-fine grinding solution that relies on proven technology. With the tall, narrow, vertical body arrangement, grinding media is evenly distributed and mineral particles remain in constant contact, significantly increasing grinding efficiency. It takes advantage of gravitational forces and GrindForce™ rotor technology to produce a finer grind for mineral liberation.

Stirred Media Detritor (SMD) is a fluidized, vertical stirred mill designed for optimum grinding efficiency for fine and ultrafine grinding products. SMDs have the capacity to operate continuously at full load power draw with no steel contamination of the product. They are suitable for both open- and closed-circuit operation.

Key benefits of Metso Outotec stirred mills:

- Improved operational efficiency

- Improved energy efficiency

- Increased media savings

- Reduced carbon emissions

- Flexible and safe to operate

Discover more about stirred mills technologies and their differences at mogroup.com/stirred-mills.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Alfa Laval sets new standards for the hygienic fluid handling industries

Alfa Laval continues to bring innovative products to the market, and the Alfa Laval DuraCirc® pump is raising standards for the food, dairy, beverage, home and personal care industries. Alfa Laval has used its extensive experience from previously developed products to create a new design with unmatched customer value, delivering high performance, hygiene safety – and easy maintenance. This launch is another example of the company’s commitment to being a technology leader.

The unique design of this new Alfa Laval pump is focused on hygiene and safety, ensuring efficient performance that meets the latest global hygiene standards (EHEDG and 3A), whilst enabling easy maintenance. In the past, customers had to choose between pumps that were efficient or pumps that were easy to clean and service. The DuraCirc pump combines for the first time the best of both worlds, setting a new industry standard.

The unique design of this new Alfa Laval pump is focused on hygiene and safety, ensuring efficient performance that meets the latest global hygiene standards (EHEDG and 3A), whilst enabling easy maintenance. In the past, customers had to choose between pumps that were efficient or pumps that were easy to clean and service. The DuraCirc pump combines for the first time the best of both worlds, setting a new industry standard.

“Simplicity, efficiency and safety are the key qualities of our latest pump,” says Nish Patel, President of the Food & Water Division. “This is a landmark product for us. It highlights our dedication to innovating technologies that will positively impact business for our customers. It offers more efficient and sustainable processing, for better results and greater peace of mind.”

Did you know that… Alfa Laval launches approximately 100 products annually, which is the equivalent of around two products per week?

This is Alfa Laval

Alfa Laval, world leader in heat transfer, centrifugal separation and fluid handling, is active in the areas of Energy, Marine, and Food & Water, offering its expertise, products, and service to a wide range of industries in some 100 countries. The company is committed to optimizing processes, creating responsible growth, and driving progress to support customers in achieving their business goals and sustainability targets.

Alfa Laval’s innovative technologies are dedicated to purifying, refining, and reusing materials, promoting more responsible use of natural resources. They contribute to improved energy efficiency and heat recovery, better water treatment, and reduced emissions. Thereby, Alfa Laval is not only accelerating success for its customers, but also for people and the planet. Making the world better, every day.

Alfa Laval has 16,700 employees. Annual sales in 2020 were SEK 41.5 billion (approx. EUR 4 billion). The company is listed on Nasdaq Stockholm.

Lenzing welcomes clear positioning of the EU Commission in the fight against plastic waste

The Lenzing Group, the globally leading supplier of sustainably produced specialty fibers, welcomes the issuance of the guidelines for the implementation of the Single-Use Plastics Directive (EU) 2019/904, which took effect on June 05, 2019. In these guidelines, the EU Commission specifies which products fall within the scope of the directive, thus providing clarity in the joint fight of the EU member states against environmental pollution from plastic waste. Lenzing’s wood-based, biodegradable cellulosic fibers such as those of the VEOCEL™ brand comprise a sustainable and innovative solution to this man-made problem.

- Guidelines of the EU Commission to implement the Single-Use Plastics Directive have been published

- Uniform labelling obligation for wipes and feminine hygiene products containing plastics as of July 03, 2021

- Lenzing’s wood-based, biodegradable VEOCEL™ branded fibers as a sustainable alternative to plastic

“Pollution of the environment – especially marine pollution – is one of the biggest problems of our time. For this reason, we welcome the measures taken by the EU to reduce certain single-use plastic products and the transition to closed-loop models”, says Robert van de Kerkhof, Member of the Managing Board of the Lenzing Group. “Lenzing has been investing in the development of sustainable and innovative solutions for the textile and nonwovens industry for many years and will also continue in the future to intensively work on achieving systemic change towards a circular economy”, van de Kerkhof adds.

“Pollution of the environment – especially marine pollution – is one of the biggest problems of our time. For this reason, we welcome the measures taken by the EU to reduce certain single-use plastic products and the transition to closed-loop models”, says Robert van de Kerkhof, Member of the Managing Board of the Lenzing Group. “Lenzing has been investing in the development of sustainable and innovative solutions for the textile and nonwovens industry for many years and will also continue in the future to intensively work on achieving systemic change towards a circular economy”, van de Kerkhof adds.

Lenzing’s ambitious sustainability targets make it a trailblazer in manufacturing industry, especially the fiber segment. Lenzing’s considerable investments in developing sustainable innovations and implementing climate objectives focusing on carbon neutrality not only strengthen the company’s market position and increase shareholder value but also continuously create new jobs.

Uniform labelling rules for some single-use plastic products

The Commission implementing regulation (EU) 2020/2151 applying to the Single-Use Plastics Directive stipulate uniform labelling requirements for some of the single-use plastic products on the packaging or the product itself starting on July 03, 2021. They encompass feminine hygiene products and wet wipes for personal and household care containing plastic.

“The issue of hygiene is becoming increasingly important and is especially the order of the day in the light of the prevailing epidemic conditions”, states Jürgen Eizinger, Vice President Global Nonwovens Business at Lenzing. “The Single-Use Plastics Directive enables consumers to make a more informed purchase decision. That is why we welcome these implementation guidelines which now provide enhanced clarity. Lenzing‘s VEOCEL™ fibers already offer a natural solution today for the problem of global plastic waste, and the company is continually expanding its capacities for wood-based specialty fibers as a means of promoting the development of sustainable wipes and hygiene products“, Jürgen Eizinger adds.

Consumers want sustainable hygiene products

Even before the implementation of the Single-Use Plastics Directive, Lenzing already gives consumers clear guidance in their purchasing decisions. Products bearing the VEOCEL™ brand logo on their packaging are produced in line with stringent certification criteria. As a consequence, consumers can be assured that the products contain biodegradable, cellulosic materials.

A Marketagent survey carried out in German-speaking Europe in October 20192 concluded that nine out of ten consumers would immediately change their purchasing behavior for wipes if they found out that their current product contains plastic. This would seem to imply that new market dynamics will emerge once the labelling rules for single-use plastic products takes effect. According to a Smithers Report3, about 500,000 tons of petroleumbased fibers are used each year for the production of wipes.

#ItsInOurHands – the initiative for enhanced awareness and transparency

On the basis of its environmental initiative #ItsInOurHands, Lenzing has been supporting a movement since the end of 2019 in collaboration with its partners to create enhanced awareness and transparency for materials used in wet wipes. An online platform as well as a dedicated community strive to increase awareness on the part of producers and consumers and thus push ahead with the development of sustainable alternatives (more information at https://itsinourhands.com.

About the Lenzing Group

The Lenzing Group stands for ecologically responsible production of specialty fibers made from the renewable raw material wood. As an innovation leader, Lenzing is a partner of global textile and nonwoven manufacturers and drives many new technological developments.

The Lenzing Group’s high-quality fibers form the basis for a variety of textile applications ranging from elegant ladies clothing to versatile denims and high-performance sports clothing. Due to their consistent high quality, their biodegradability and compostability Lenzing fibers are also highly suitable for hygiene products and agricultural applications.

The business model of the Lenzing Group goes far beyond that of a traditional fiber producer. Together with its customers and partners, Lenzing develops innovative products along the value chain, creating added value for consumers. The Lenzing Group strives for the efficient utilization and processing of all raw materials and offers solutions to help redirect the textile sector towards a closed-loop economy. In order to reduce the speed of global warming and to accomplish the targets of the Paris Climate Agreement and the “Green Deal” of the EU Commission, Lenzing has a clear vision: namely to make a zero-carbon future come true.

Voith Hydro and Swedish Mine Storage enter development partnership for the advancement of decarbonization

Voith Hydro, a leading global supplier of hydropower and pumped storage equipment, and Swedish company Mine Storage, a specialist in the field of underground pumped storage concepts, announce a development partnership to become the forerunners in a new market for underground pumped storage – offering so-called mine storages.

- Global phase-out of fossil fuels requires large-scale energy storage and grid stabilization.

- More than 90% of energy storage today is provided by pumped storage hydropower.

- Revolutionary concept for pumped hydropower in former mines will be elaborated in the collaboration between the two companies.

The Paris Climate Agreement has made clear that to prevent a global climate collapse, global warming needs to be limited to maximum 1.5°C. To achieve this, it is necessary to focus on the use of clean, renewable and resource-conserving technologies in energy generation. Hence, there is a need for transition from fossil fuels to low-carbon and sustainable alternatives, a move that Voith Hydro and Mine Storage aim to help facilitate.

For the global phase-out of fossil fuels, large-scale electricity storage is needed. More than 90% of energy storage today is provided by pumped storage hydropower, as it allows for quick response with incomparable flexibility to fluctuations in energy demand. This enables the integration of volatile renewable energy sources, such as wind or solar power, into the grid and stabilizes it. With the current stage of technology, it is the only possibility to store energy in an economically viable, large-scale way.

The concept

Mine Storage focuses on the rapidly emerging market for large-scale, fast-responding energy storage and plans to build sustainable pumped storage facilities in underground mines. These are called mine storages and can act as “batteries” that help balance the electric grid so that much more production from wind and solar energy can be added without creating a volatile electric grid that is prone to blackouts. There are more than one million abandoned mines in the world, and with mature, proven energy storage technology, mine storages can be a game changer for the environment.

Game changer for the environment

Replicating traditional pumped storage with upper and lower reservoirs in a new setting, like underground mines, can truly accelerate the transition from brown to green energy. The mining environment, however, puts new demands on the technology, thus the challenge lies in combining industry-specific knowledge from difference fields.

Voith Hydro has long been in the forefront of technology development and will take on these specific challenges. In collaboration with Mine Storage, the company is now engaged in the early project development at two specific sites Sweden in order to develop the necessary technical solutions.

”We are committed to sustainable technologies and concepts for a decarbonized future. As Mine Storage has shown an innovative approach, impressive speed and competence in this field, we are delighted to now bring in our long-standing expertise in pumped storage technology in order to develop first projects together,” says Uwe Wehnhardt, President & CEO Voith Hydro.

“Mine storages can have a huge impact on global CO2 emissions by enabling renewable energy production to scale. We do not have time to wait; we must act now,” says Thomas Johansson, CEO of Mine Storage. “Voith Hydro has shown a great flexibility and good understanding for the dynamics in early project development. Their approach and our shared vision of the global potential for mine storages make this partnership a valuable piece in our strategy to contribute to the phase-out of fossil fuels.”

Abandoned mines can serve as reservoirs for “green hydropower batteries”

About Mine Storage

Mine Storage is a Sweden-based company founded by experts with a strong track record in the energy sector. The idea for large-scale, fast-responding storage sprung out of the increasing amount of intermittent power generation, which causes imbalance in the transmission grids. The Mine Storage team will contribute to a sustainable future with fossil-free energy production by developing environmentally friendly energy storage plants in abandoned underground mines.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 20,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Hydro is part of the Voith Group and a leading full-line supplier as well as trusted partner for equipping hydropower plants. Voith develops customized, long-term solutions and services for large and small hydro plants all over the world. Its portfolio of products and services covers the entire life cycle and all major components for large and small hydro plants, from generators, turbines, pumps and automation systems, right through to spare parts, maintenance and training services, and digital solutions for intelligent hydropower.

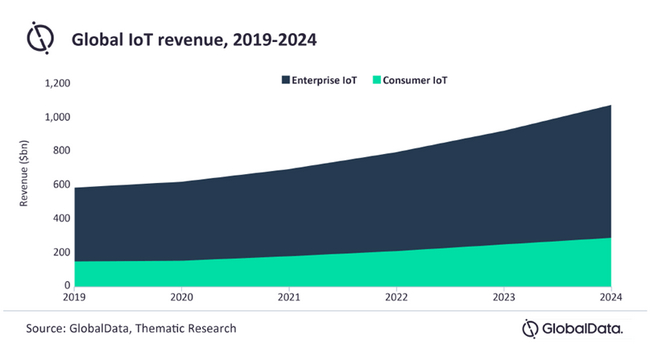

Global IoT market will surpass the $1 trillion mark by 2024, says GlobalData

The global internet of things (IoT) market by revenue will be worth $1.1 trillion by 2024, with much of the growth coming from wearables, says GlobalData, a leading data, and analytics company.

GlobalData’s latest report, ‘Thematic Research: Internet of Things,’ explains how a COVID-19 driven new digital transformation wave will fuel higher growth across all IoT markets. The global IoT market was worth $622bn in 2020, up from $586bn in 2019, and will grow to reach $1,077bn by 2024, with a compound annual growth rate (CAGR) of 13% over the period, according to GlobalData forecasts. The enterprise IoT dominates the overall IoT market, generating 76% of total revenue in 2020. This dominance of the enterprise IoT will continue for the foreseeable future. GlobalData expects this segment to still occupy 73% of the overall IoT market in 2024.

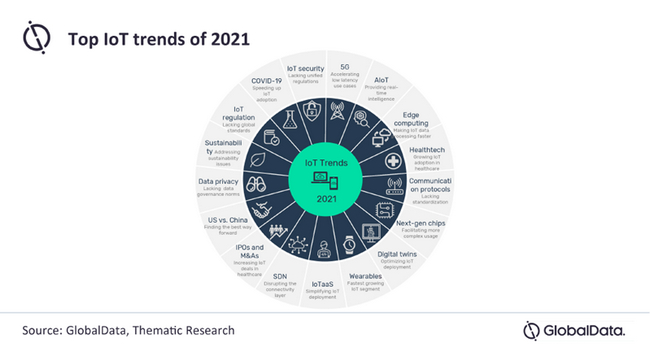

Jasaswini Biswal, Associate Project Manager for Thematic Research at GlobalData, comments: “The ongoing COVID-19 pandemic has highlighted the crucial role the IoT has come to play in our lives. Several IoT use cases saw growing adoption during the pandemic, including using connected thermal cameras to detect potential COVID-19 infections and sensors for monitoring office occupancy levels.

“The demand for technologies that can help the workforce get safely back to work is rising and will likely continue to grow. IoT applications such as contact tracing devices and health-monitoring wearables provide critical data to help fight the pandemic.”

These new use cases have created a positive attitude towards IoT as a critical enabler of the future. According to Globaldata’s ‘*Emerging Technology Trends Survey 2020’, approximately 48% of respondents showed a positive sentiment towards IoT, and 45% believed IoT would play a critical role in the new business generation over the next three years.

Biswal continues: “The next phase of IoT has the potential to transform how we live and work. As IoT penetration extends to the point of being pervasive, entirely new business models will emerge. IoT networks will even do business with one another - providing services resulting from autonomous or near-autonomous collaboration.

“However, today’s IoT systems lack three critical features: Firstly, unstructured and fragmented security regulations are major roadblocks to broader IoT adoption: be it in consumer or enterprise IoT.

“Secondly, there is no global IoT communication standard. The global IoT market can only take off once all connected devices speak the same language.. Thirdly, alongside this lack of standardization, current IoT ecosystems lack real-time intelligence, which relies largely on edge computing and the artificial intelligence of things (AIoT). In order for IoT to be pervasive, these three deficiencies need to be addressed.”

*GlobalData Emerging Technology Trends Survey 2020- polled more than 1,700 senior executives worldwide in the summer of 2020.

- Quotes provided by Jasaswini Biswal, Associate Project Manager for Thematic Research at GlobalData

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.