Super User

Boosting investments allocation among oil and gas operators could strengthen production in DJ Basin, says GlobalData

The Denver Julesburg (DJ) Basin located in Colorado and Wyoming has experienced a constant decline since production peaked in November 2019. Reversing this trend will depend on the capital allocation from major oil and gas operators in this region, says GlobalData, a leading data and analytics company.

According to GlobalData’s latest report, ‘DJ Basin in the US, 2021 – Oil and Gas Shale Market Analysis and Outlook to 2025’, the DJ Basin accounted for 7.02% of oil and 6.65% of natural gas production in the United States Lower 48 for 2020.

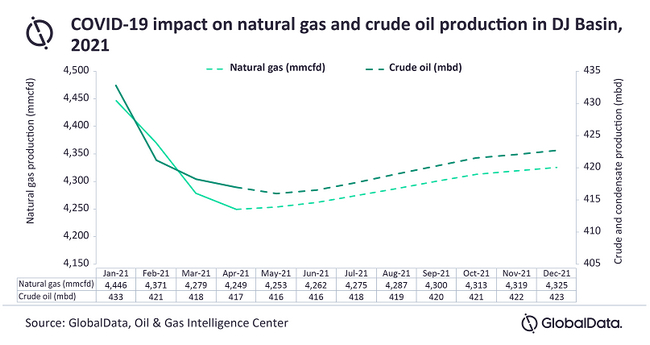

Oil and gas production in the DJ Basin was adversely affected by the COVID-19 outbreak and subsequent restrictions on economic activity. However, H1 2021 imparted optimism in the market, paving the way for recovery. As restrictions and travel bans were gradually eased, demand prospects improved and encouraged production. However, even with this improvement, production of both oil and gas is not expected to recover to pre-pandemic level.

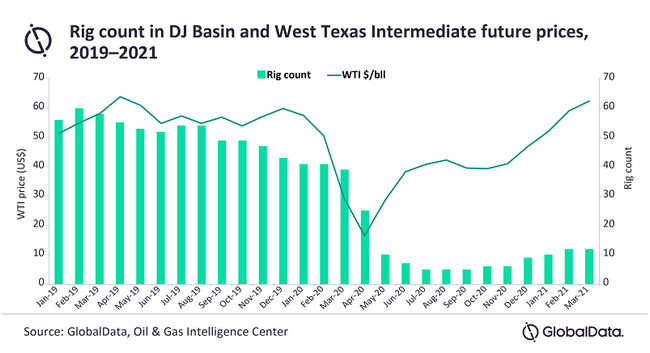

Svetlana Doh, Oil & Gas Analyst at GlobalData, comments: “The DJ Basin averaged 26 drilling rigs in 2019 and then decreased by 65% to an average of nine rigs in 2020. While other basins throughout the US have increased their rig count with commodity prices rising to pre-pandemic levels, the DJ Basin has lagged with its rig count and remained at seven rigs since the beginning of the year.

“A rise in production will depend on the capital allocation for the major operators in this region. Major operators, such as Occidental Petroleum and Chevron, are earning better returns from their investments in other basins, such as Permian. Thus, companies are going to deploy their capital to the acreage with the best economics in DJ Basin, but could grow production from drilled but uncompleted wells (DUCs).”

With West Texas Intermediate (WTI) future prices averaging US$62.85 per bbl for the remainder of 2021, GlobalData expects a slight uptick in the rig count, but it will not reach the level that was present in 2019. Additionally, while production is expected to increase over the next two to five years, it will still not recover to 2019 levels.

Doh adds: “Another effect on overall production growth from the DJ Basin will depend on small independent companies. While commodity prices have increased and companies are able to generate free cash flow, pure play DJ Basin operators are able to increase their rig count.”

- Quotes provided by Svetlana Doh, Oil & Gas Analyst at GlobalData

- Data taken from GlobalData’s report: DJ Basin in the US, 2021 – Oil and Gas Shale Market Analysis and Outlook to 2025

- The report provides a comprehensive review of the DJ Basin shale play, comprising the effects of the COVID-19 outbreak on operations in the Basin. The report also forecasts the future trend of oil and gas production supported by investment plans by major operators in the Basin.

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

Lighthouse Security bolsters data destruction services with UNTHA collaboration

A global specialist in protective security, surveillance, intelligence, cyber security, due diligence, training and dog handling, has further strengthened its portfolio of services in collaboration with UNTHA UK.

The business has bolstered the capabilities of its secure destruction division with the investment in a confidential waste shredder, certified to DIN-66399 standards.

The four shaft RS30 shredder with in-feed and discharge conveyor will handle a range of materials including hard drives, sensitive documentation, uniforms, and seized products which cannot get onto the black market.

Capable of processing up to 1.5 tonnes of these materials per hour, the robust machine can produce a range of outputs from 10mm–100mm so that classified materials are completely destroyed. The cutting chamber also pre-shreds and re-shreds in a single pass, with a ‘mixing’ action for added peace of mind.

However, the low speed nature of Lighthouse Security’s new solution, means the materials can be shredded without damaging their fibres, which protects output quality and increases reuse or recycling potential. The zero-waste-to-landfill process therefore upholds high environmental standards, as well as compliance.

Plastic arisings are sent for recycling into plant pots and other products, for example, and textiles are shredded for reuse in the equestrian, surfacing and energy recovery markets.

Commenting on the investment, Lighthouse Security’s founding director Tim Jensen said: “Core to our security services, is a promise to safeguard our clients’ duty of care and accountability, in an increasingly high-risk world.

“Because we are an end-to-end security specialist, we can collect clients’ ‘items’, unload them into our secure CCTV manned and monitored facility, and apply a dedicated tracking number. Our secure storage facility also has an AI-driven security layer which proactively detects anything entering the area. Everything about this rigorously audited service is robust, so we set high standards for the shredder.”

The shredding process is recorded, with the option for the customer to remotely watch the destruction, in real-time.

“We take our business reputation very seriously, so in choosing a shredding partner, we looked for an organisation with equally high standards,” concluded Tim. “The UNTHA RS30 is a high performance, industry proven machine, and the changeable screen makes it highly configurable as our company continues to evolve.”

MICRODYN-NADIR becomes MANN+HUMMEL Water & Fluid Solutions

MICRODYN-NADIR, a MANN+HUMMEL company, announced a new name for their business segment: MANN+HUMMEL Water & Fluid Solutions. Since 2015, the globally active membrane manufacturer is part of MANN+HUMMEL's Life Sciences & Environment (LS&E) business unit and produces products and solutions for water, wastewater, and process membranes.

“At MANN+HUMMEL, we talk about One Team, One Goal, One Voice. Renaming MICRODYN-NADIR puts those words into action while simplifying and strengthening our global brand. It ties into the overall MANN+HUMMEL vision of leadership in filtration,” said Fua Nipah, President and General Manager LS&E at MANN+HUMMEL.

Along with a new name, the revamped Water & Fluid Solutions segment announced a new vision: To solve the world’s water and fluid treatment challenges so that together we can create a safe, sustainable, and healthy planet.

Along with a new name, the revamped Water & Fluid Solutions segment announced a new vision: To solve the world’s water and fluid treatment challenges so that together we can create a safe, sustainable, and healthy planet.

“Throughout name changes, rebranding, and acquisitions, the core of our company – our relationships with partners, clients, and customers – remains the same. We believe our new vision and closer ties to MANN+HUMMEL will allow us to enhance that focus. I am excited to move forward as the revitalized MANN+HUMMEL Water & Fluid Solutions,” said Jeff Sanchez, Vice President Water & Fluid Solutions.

The new name includes new MANN+HUMMEL email addresses for all employees. Furthermore, all documents and communication materials will be updated with the new logo. Existing certificates, contracts, manuals/guides, data sheets, compliance documents, and other papers remain valid. Additionally, product names including MICRODYN, TRISEP, and OLTREMARE will not change.

Visit www.microdyn-nadir.com to learn more.

About MANN+HUMMEL

MANN+HUMMEL is a leading global expert in filtration. The Ludwigsburg-based group develops filtration solutions for vehicles, industrial applications, clean air in indoor and outdoor spaces as well as for the sustainable use of water. In 2019, over 22,000 employees at more than 80 locations worldwide generated a turnover of EUR 4.2 billion. Products include, amongst others, air filter systems, intake systems, liquid filters, technical plastic parts, filter media, cabin filters, industrial filters and membranes for water filtration, sewage treatment and process applications.

You can find further information on MANN+HUMMEL at https://www.mann-hummel.com/

About MANN+HUMMEL Water & Fluid Solutions

MANN+HUMMEL Water & Fluid Solutions, part of the MANN+HUMMEL Group, is a global membrane manufacturer that delivers the membrane products to meet customers’ water and process needs. They offer the widest range of membrane products, including microfiltration, ultrafiltration, nanofiltration, and reverse osmosis in flat sheet, spiral-wound, and hollow-fiber configurations, as well as MBR technology for treatment of water and wastewater. The company is headquartered in Wiesbaden, Germany, with locations in the Americas, Europe, and Asia.

More information on MICRODYN-NADIR can be found here https://www.microdyn-nadir.com/

Online training module for continuous casting now available at NSK academy

The popular NSK academy online platform now features a new training module: continuous casting. Added to the steels & metals section of the portal, the latest module will appeal to anyone involved in specifying bearings to withstand the harsh working environments found in continuous casting applications. As with all training modules available at NSK academy, registered users completing the course will require an 80% pass mark to receive a certificate.

The new training module provides essential understanding of the fundamental principles behind bearing selection for continuous casting applications

The new training module provides essential understanding of the fundamental principles behind bearing selection for continuous casting applications

The extreme operating conditions of continuous casting machines mean that it is easy to compromise the reliability and service life of bearings without undue care and attention in the selection process. Challenges include heat, heavy loads, ultra-low speeds and roll deflection, not to mention the application’s most common bearing failure mode: differential sliding/sliding friction.

At the start of the new training module, participants learn more about the continuous casting process and the machinery involved, with a particular focus on twin-strand technology. An in-depth look at the bearings follows, especially spherical roller bearings and their ability to accommodate heavy loads, misalignment and thermal expansion of the shaft - and how these bearing types deal with the fundamental issue of sliding.

NSK’s new training module also covers cylindrical roller bearings. The cylindrical roller contact pattern provides the advantage of pure rolling, again preventing any wear induced by sliding friction to ensure reliability and long service life.

Ultimately, the latest training module provides essential understanding of the fundamental principles behind bearing selection for continuous casting applications. Anyone working in the continuous casting arena, from sales, technical support and R&D, through to maintenance and engineering, is set to benefit.

At a time when online/remote learning is more relevant than ever due to the ongoing pandemic, the NSK academy can help platform users expand on the knowledge they apply on a daily basis, and utilise the latest NSK bearing solutions to maximise machine life.

The module can be found at www.nskacademy.com (a quick and easy registration process is required for new users).

BAC Meets Challenging Cooling Tower Need for Smithsonian National Air and Space Museum’s Steven F. Udvar-Hazy Center project with ENDURADRIVE Fan System

Cooling tower installation ensures peace of mind through trouble-free performance

Faced with challenging specifications for increasing cooling tower capacity and the need for reduced maintenance cost and inspection accessibility, Baltimore Aircoil Company (BAC) developed an innovative solution for the Smithsonian National Air and Space Museum’s Steven F. Udvar-Hazy Center.

Smithsonian National Air and Space Museum Udvar-Hazy Center

The Smithsonian National Air and Space Museum’s Steven F. Udvar-Hazy Center is home to several aircraft hangars with an exhibited collection of thousands of aviation and space artifacts, as well as a theater, observation tower, and restoration facilities. With extensive facilities and an HVAC system that could not keep pace with demands, it became clear to the museum and to the consulting engineers at AECOM, who managed the project, that a new HVAC system was desperately needed.

The museum, located in Chantilly VA, was supported by cooling towers that were old and lacked adequate capacity to serve the building’s increasing cooling load. Site conditions did not allow for a larger cooling tower footprint to meet the increased load. To deliver enough chilled water at peak efficiency and to fix the original hydronic design for the towers, the facility managers were faced with elevating the towers by six feet. While solving the HVAC system performance challenge, this created a service dilemma: how to safely and efficiently perform routine inspection and maintenance on cooling towers that were 25 feet above ground.

The museum, located in Chantilly VA, was supported by cooling towers that were old and lacked adequate capacity to serve the building’s increasing cooling load. Site conditions did not allow for a larger cooling tower footprint to meet the increased load. To deliver enough chilled water at peak efficiency and to fix the original hydronic design for the towers, the facility managers were faced with elevating the towers by six feet. While solving the HVAC system performance challenge, this created a service dilemma: how to safely and efficiently perform routine inspection and maintenance on cooling towers that were 25 feet above ground.

Working with the Smithsonian Institution and AECOM, the engineers at Baltimore Aircoil Company and The Morin Company, the local BAC representative, presented an innovative solution to dramatically improve the reliability of the cooling tower while reducing the need for regular service and maintenance of the fan-drive system.

“Other Smithsonian buildings have incorporated BAC’s towers, and we at AECOM have also worked with BAC in the past,” said Dilip Parikh, P.E., Senior Project Manager at AECOM. “We had seen positive results in these prior projects and the customer support from BAC is superb, so we elected to work with them again.”

The result was a recommendation to replace the existing cooling towers with new cooling tower technology from BAC, which would improve heat rejection capacity and chiller functions. The solution enhanced the capacity of the cooling tower within the existing tower footprint, and most importantly, reduce maintenance requirements.

ENDURADRIVE™ Fan System technology solves maintenance concerns

BAC Series 3000 Cooling Tower with ENDURADRIVE™ Fan Systemn order to ensure safety of maintenance professionals during the life of the cooling tower and a reduction in overall maintenance costs, Parikh and the BAC team decided to replace the traditional fan power transmission with an innovative, simplified direct-drive fan system.

BAC Series 3000 Cooling Tower with ENDURADRIVE™ Fan Systemn order to ensure safety of maintenance professionals during the life of the cooling tower and a reduction in overall maintenance costs, Parikh and the BAC team decided to replace the traditional fan power transmission with an innovative, simplified direct-drive fan system.

“I knew that direct-drive would likely be the right path for us to take, since we wanted to avoid unnecessary gears or belts that would need to be maintained and replaced,” Parikh said. “BAC then brought their ENDURADRIVE Fan System to my attention, and I immediately recognized that it was a perfect fit.”

Direct-drive fan systems are becoming accepted as the gold standard for high reliability and low maintenance throughout the markets BAC serves. BAC has led the evaporative cooling industry for over a decade in applying innovative technologies to factory assembled evaporative heat transfer products. “With over 500 direct-drive motors installed in the U.S., including in some of the most demanding climates and applications, and with over 3.5 million operating hours, we knew that the ENDURADRIVE Fan System would provide AECOM and the Smithsonian Institution the peace of mind they needed. Also, by eliminating moving parts, gearbox oil changes, and other routine inspections, fan-drive maintenance costs are cut by 90%” said Stephen Kline, Applications Manager at BAC.

“Our experience is when applying the ENDURADRIVE Fan System to traditional cooling towers, our customers enjoy high reliability. They also reduce their costs for operating the cooling tower fan motor up to 10% by eliminating the usual transmission losses of gearboxes and belts. We expect their investment will pay for itself in less than 36 months” said Kevin Morin, President of The Morin Company.

Thanks to the customer choosing BAC’s ENDURADRIVE Fan System, the cooling towers at the National Air and Space Museum’s Udvar-Hazy Center are now capable of meeting the site’s cooling needs with extremely limited maintenance requirements.

“For other companies considering putting a new cooling tower on their own or a client’s building, I say, ‘Go for the ENDURADRIVE Fan System!” Parikh said. “Maintenance is the most important concern – who wants to go up on top of a 25-foot tower or up inside of it to look at gears or the belt drive when something breaks? With the ENDURADRIVEÔ Fan System that concern is just about eliminated, the efficiency is greater, and even the installation is easier.”

Conclusion

The BAC Series 3000 cooling tower with ENDURADRIVEÔ Fan System was installed at the National Air and Space Museum’s Udvar-Hazy Center at the end of 2018 and has been in continuous operation since then. As expected, BAC’s cooling tower solution has reduced maintenance and increased efficiency for the Smithsonian Institution, and it continues to meet the performance needs of the center.

The BAC Series 3000 cooling tower with ENDURADRIVEÔ Fan System was installed at the National Air and Space Museum’s Udvar-Hazy Center at the end of 2018 and has been in continuous operation since then. As expected, BAC’s cooling tower solution has reduced maintenance and increased efficiency for the Smithsonian Institution, and it continues to meet the performance needs of the center.

“BAC sized the new cooling tower with increased capacity while staying within the pre-existing footprint. Since its installation, it has helped enable the HVAC system to maintain precise temperature and humidity, a critical concern in the museum building and research facility,” Parikh said. “Most importantly, the need to climb the tower is rare, so the facilities personnel can remain safe even as the performance of the tower has improved.”

BAC’s innovative solution for the National Air and Space Museum, Steven F. Udvar-Hazy Center met the project’s challenging specifications for increasing cooling tower capacity and has led to dramatically reduced maintenance costs and greater inspection accessibility. Visitors and staff alike will enjoy the benefits of this enhanced cooling tower system for years to come.

Metsä Group plans to expand the production of mechanical wood products at the Äänekoski mill site

Metsä Group has started a planning process with the City of Äänekoski with the aim of expanding the production of mechanical wood products at the Äänekoski mill site in the future.

A detailed plan is being applied for as an industrial area for the Henttalanmäki area south of the existing mill site. The area currently has a general plan in force and it is mainly owned by Metsä Fibre, a part of Metsä Group.

A detailed plan is being applied for as an industrial area for the Henttalanmäki area south of the existing mill site. The area currently has a general plan in force and it is mainly owned by Metsä Fibre, a part of Metsä Group.

“One of Metsä Group's strategic targets is to increase the production of products that store carbon for a long time such as sawn timber, LVL and plywood. With the plan change that is now being launched, we are preparing to expand the production of our mechanical wood products at the Äänekoski mill site. The synergy benefits of operating in a large mill integrate are significant related e.g. to the utilization of raw materials, logistics and energy, ”says Ilkka Hämälä, President and CEO of Metsä Group.

The planning process is estimated to last until early 2022.

Metsä Group

www.metsagroup.com

Metsä Group is leading the way in advancing the bioeconomy. We invest in growth, bioproduct development and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, as well as tissue and greaseproof papers.

Metsä Group’s annual sales amount to approximately EUR 5.5 billion, and we have around 9,200 employees in 30 countries. Our international Group has its roots in the Finnish forests: our parent company is Metsäliitto Cooperative which is owned by 100,000 forest owners.

Emerson to Host ACHEMA Sessions Aimed at Improving Operational Performance and Environmental Sustainability

Thought-leadership keynotes, customer case studies and technology presentations will outline ways to digitally transform operations

BAAR, Switzerland (June 1, 2021) – Emerson will host a series of presentations at ACHEMA Pulse that outline how advanced automation technologies can help chemical and life sciences companies make step change improvements in operational performance and environmental sustainability. As an exclusive partner of the virtual event, which takes place on June 15-16, 2021, Emerson will offer thought-leadership keynotes, customer case studies and technology presentations that inform participants how to successfully digitally transform operations to meet the challenges of decarbonisation, increasing efficiency, improving quality and reducing time-to-market.

Emerson is an exclusive partner of the ACHEMA Pulse virtual event and will host presentations that help chemical and life sciences companies make improvements in operational performance and environmental sustainability. Underpinning these sessions will be a range of customer experiences, with Covestro guiding participants through a distributed control system migration project at a batch production plant, BASF explaining the benefits of control system health monitoring, and Dow discussing the importance of applying functional margin, when proof-testing valves, to increase reliability and safety. A presentation by Evonik will provide insight into digital transformation in process plants, Dynea will discuss implementing wireless monitoring solutions, and Applikon will explain how to reduce drug research and development costs and reduce time-to-market.

Emerson is an exclusive partner of the ACHEMA Pulse virtual event and will host presentations that help chemical and life sciences companies make improvements in operational performance and environmental sustainability. Underpinning these sessions will be a range of customer experiences, with Covestro guiding participants through a distributed control system migration project at a batch production plant, BASF explaining the benefits of control system health monitoring, and Dow discussing the importance of applying functional margin, when proof-testing valves, to increase reliability and safety. A presentation by Evonik will provide insight into digital transformation in process plants, Dynea will discuss implementing wireless monitoring solutions, and Applikon will explain how to reduce drug research and development costs and reduce time-to-market.

In the first of two keynote presentations, Roel Van Doren, group president global sales at Emerson, will explain how advanced automation technologies can help industrial companies address their environmental sustainability challenges, such as improving energy efficiency by optimising equipment performance and meeting the demand for clean fuels, such as hydrogen. In a second keynote, Peter Zornio, Emerson’s chief technology officer, will look at how emerging technologies are creating new industrial computing architectures that help to transform operations and drive efficiency improvements.

“Equipment reliability and process availability impact the ability of chemical companies to achieve performance targets,” explained Van Doren. “The presentations we are hosting address this challenge, outlining ways to mitigate process upsets and maximise uptime, digitally transform operations for greater reliability, and safely migrate to modern solutions while maintaining production. For life sciences companies, there is a need to reduce costs and increase the speed from clinical to production with high regulatory compliance. To support this, we will demonstrate how Emerson can help to streamline operations and debottleneck processes, and create effective solutions for data management, real-time product quality, reliability and operating costs.”

A key focus of the Emerson-led sessions will be ways of achieving environmental sustainability goals. This includes implementing solutions that enable the use of alternative fuels and low-carbon power sources, the reduction of energy and material use in production systems, and the management and removal of production emissions. Emerson experts will address the subjects of emissions monitoring, control and optimisation, driving energy and reliability performance through improved control, and accelerating the transition to a hydrogen future.

“Industrial companies must make a strategic shift in environmental sustainability,” said Van Doren. “We are therefore dedicating multiple sessions to addressing this challenge, including presentations that highlight decarbonisation opportunities, examine how optimising control loop performance helps improve energy efficiency, and outline the role of automation in meeting greater demand for hydrogen.”

To get more information about Emerson’s ACHEMA Pulse sessions, go to:

www.Emerson.com/de-de/news/automation/achema-pulse.

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and engineering company providing innovative solutions for customers in industrial, commercial, and residential markets. Our Emerson Automation Solutions business helps process, hybrid, and discrete manufacturers maximise production, protect personnel and the environment while optimising their energy and operating costs. Our Emerson Commercial & Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency, and create sustainable infrastructure. For more information visit Emerson.com.

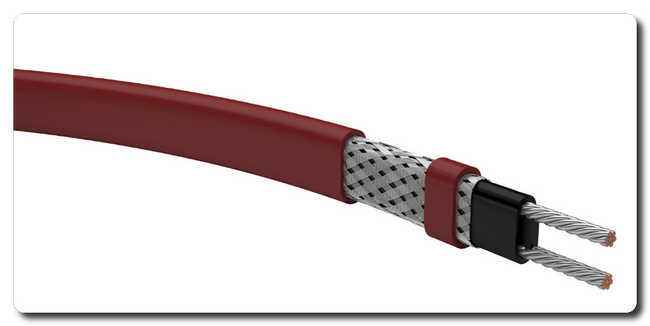

nVent Launches High Power Retention Technology with New nVent raychem htv Heating Cable

New Semi-Conductive Polymer Nanocomposite Provides Higher Power Retention at Increased Temperatures

nVent Electric plc (NYSE:NVT) (“nVent”), a global leader in electrical connection and protection solutions, today launched its newest nVent RAYCHEM self-regulating heating cable, the nVent RAYCHEM HTV. The new heating cable will be used in critical industrial applications with high exposure or maintenance temperatures. Offering superior levels of high power retention (HPR) during a design life of more than three decades, the brand new self-regulating heating cable, nVent RAYCHEM HTV, meets stringent demands for maximum process integrity while protecting people, processes and infrastructure.

Increased performance, extended design life

nVent RAYCHEM HTV surpasses previous self-regulating heating cables in performance and design life. Specifically designed for high temperature environments, the cable can operate under high continuous operating temperatures of 205°C/400°F and withstand temperatures up to 260°C/500°F. Its power retention levels are unparalleled: after 10 years of performance at 205°C/400°F, the HTV cable retains 95 percent of its power output. This not only reduces downtime risk and maintenance costs for decades, it also increases plant safety and productivity.

“We understand how important day-to-day operational integrity is,” said Marty Lee, nVent vice president of product management. “While long-term design life is important, the power retention profile over time is equally important. With 95 percent power retention for 10 years and a more than 30-year design life, our customers can be confident of improved process integrity and lower contingencies for decades to come. In an increasingly electrified world, the HTV heating cable will save our customers money and increase their overall operational efficiencies.”

New materials and ground-breaking research and development

To create such a high-performance heating cable, nVent turned to new materials, as well as new developments in nanotechnology and thermal structuring of the materials.

“The nVent RAYCHEM name has long been synonymous with innovative science; true R&D. nVent still operates that way today,” said Linda Kiss, nVent vice president of engineering. “We have almost 75 years of expertise in polymer materials science and have gained new knowledge about how best to construct the highest temperature composites. We created a ground-breaking, new semi-conductive polymer nanocomposite material with increased thermal stability, which provides superior power retention at high temperatures.”

nVent RAYCHEM heat tracing cables are already well known for their exceptional freeze protection capabilities and the maintenance of critical process temperatures, in many industrial facilities around the world. From critical chemicals to power plants, from oil & gas to pharmaceutical and renewable industries, nVent RAYCHEM products and solutions are associated with reliability, high-caliber performance and long operational life. The new nVent RAYCHEM HTV self-regulating heating cable will build upon this reputation by offering industrial plant owners the opportunity to advance their process integrity and operational efficiency for decades to come.

The nVent RAYCHEM HTV heating cable is internationally certified for use in hazardous areas, comes with a 10-year product warranty and is now globally available.

About nVent

nVent is a leading global provider of electrical connection and protection solutions. We believe our inventive electrical solutions enable safer systems and ensure a more secure world. We design, manufacture, market, install and service high performance products and solutions that connect and protect some of the world's most sensitive equipment, buildings and critical processes. We offer a comprehensive range of enclosures, electrical connections and fastening and thermal management solutions across industry-leading brands that are recognized globally for quality, reliability and innovation. Our principal office is in London and our management office in the United States is in Minneapolis. Our robust portfolio of leading electrical product brands dates back more than 100 years and includes nVent CADDY, ERICO, HOFFMAN, RAYCHEM, SCHROFF and TRACER.

nVent, CADDY, ERICO, HOFFMAN, RAYCHEM, SCHROFF and TRACER are trademarks owned or licensed by nVent Services GmbH or its affiliates

Xodus to support SMEs in growth of Scottish offshore wind supply chain

Scottish Enterprise has appointed global energy consultancy Xodus Group to the role of Offshore Wind Cluster Builder to develop and grow the offshore wind supply chain across Scotland.

The Offshore Wind Cluster Builder will support Scotland’s existing offshore wind clusters, DeepWind and Forth & Tay Offshore, in their remit to foster collaboration, drive competitiveness and improve productivity in Scottish Offshore Wind.

The project will do this by delivering a range of services to SMEs including one-to-one support, events, workshops and market intelligence, as well as facilitating collaboration between SMEs and academia.

Xodus will also work to consolidate the offshore wind landscape for SMEs, connecting and simplifying elements of the sector to enable greater engagement by Scottish companies, helping them to capitalise on opportunities presented by offshore wind. An event will be held on Tuesday 15 June to formally launch the Cluster Builder and a new Offshore Wind Supply Chain Survey. Developed in conjunction with DeepWind, Forth and Tay Offshore, Scottish Offshore Wind Energy Council (SOWEC) and Scottish Renewables, the survey aims to build a more detailed picture of Scotland’s Supply Chain in order to showcase the breadth of capabilities across our companies.

With speakers from SOWEC, DeepWind and Forth & Tay Offshore as well as Xodus, the event will outline the Cluster Builder remit, launch the Offshore Wind Scotland Supply Chain Survey and discuss how this will benefit the wider Scottish Supply Chain.

Aberdeen Bay windfarm. Credit Richard Crighton

Aberdeen Bay windfarm. Credit Richard Crighton

Head of Low Carbon Transition for Scottish Enterprise, Andy McDonald, said: “The Offshore Wind Cluster Builder will be an important project to support the development and growth of the offshore wind supply chain across Scotland. SMEs will have access to services to collaborate, grow and secure business within the offshore wind industry locally, nationally and internationally leveraging Scottish capabilities to strengthen the offshore wind supply chain for a sustainable industry and net zero future economy.

“The new project will align with the work of DeepWind and Forth & Tay Offshore to ensure Scotland benefits from the many opportunities presented by offshore wind.”

David Webster of Forth & Tay Offshore said: “We are looking to build on the opportunity from the growing pipeline of Scottish, UK and global offshore wind projects and the need to grow local content in the sector. We are shaping the resource provided by Scottish Enterprise for the development of a competitive supply chain in Scotland. We aim to increase Scotland's success in winning orders for projects inside and outside Scotland's waters and to help support and scale up the Scottish supply chain.”

Paul O’Brien of DeepWind added: “The Cluster Builder initiative offers our SME members a further layer of support to help them navigate the complex offshore wind supply chain landscape. By working closely with the Xodus team we can help our members to develop a compelling business case, increase their competitiveness and deliver a sustainable business model. Cluster Builder will be an important tool to help build a strong and successful offshore wind supply chain in Scotland”

Scott Hamilton, Renewables Division Manager at Xodus said: “We are committed to this development and have established a suite of services to help companies active in relevant other industries to identify the opportunity in offshore wind and other renewable energy sectors and assist in building a strategic and coherent approach to this. The sector deal commitment of 60% local content by 2030 is an ambitious one, and it is important to prioritise those supply chain areas already available in the UK, while simultaneously targeting an expansion into areas identified as gaps.”

Xodus has worked with Scottish Enterprise on several projects to support and grow supply chain capability in Scotland. This work includes supply chain analysis for sensing and remote monitoring in marine renewable energy, Offshore Wind Expert Support for SMEs and the collation of Scottish supply chain databases in the offshore wind and green hydrogen sectors.

The ‘Cluster Builder’ project also strengthens Xodus’ offering to the global offshore wind supply chain across the Atlantic, where the company is conducting a similar research project. The Boston team is assessing the local and regional supply chain around Massachusetts and has also recently won work to carry out a related assessment and gap analysis for Hampton Roads and the southern Virginia region.

Jeff Tingley, Xodus’ US Head of Strategy and Market Development, added: “We’re in the rare position of providing genuine international partnership opportunities for local companies through our Scottish and US clusters and we’re seeing a steep rise in this type of work as more and more regions explore the opportunities available through offshore wind. Our renewables team provides a 360-degree view on how to develop successful energy projects and can draw upon the skills from the integrated discipline divisions across our international offices.”

For further info contact: This email address is being protected from spambots. You need JavaScript enabled to view it.

Experts with Energy

As a leading global energy consultancy, we help clients overcome challenges, add value to opportunities and maximise returns on investments, responsibly. Our values of trust, responsibility and excellence underpin our vision. They are at the heart of decision making and inform our future strategy.

In offering expert advice and solving complex problems, our multi-skilled specialists work across the energy spectrum to address industry problems. By combining technology with our knowledge, we create better business outcomes whether it is advisory, project development or in operational support.

Together, we will deliver a responsible energy future - www.xodusgroup.com

Headquartered in Aberdeen, Scotland with a global operations centre in London, Xodus has offices in Edinburgh, Glasgow, Orkney, Egypt, Perth, Australia and Boston and Houston in the US.

The Offshore Wind Cluster Builder project is part-funded by the 2014–2020 European Structural and Investment Fund.

The Scottish Government is the Managing Authority for the European Structural Funds 2014-20 Programme. For further information visit our webpages or follow @scotgovESIF.

About Scottish Enterprise (SE)

Scottish Enterprise is Scotland's national economic development agency. We’re committed to growing the Scottish economy for the benefit of all, helping create more quality jobs and a brighter future for every region.

Supporting analytical innovation with advanced heaters

~ How ULTRAMIC heaters support innovative analytical equipment designs ~

Advanced ceramic heaters offer numerous benefits in the design of analytical equipment. Many of the heaters used in industry today are metal sheathed, a long-standing technology that has been available for over 30 years. While such heaters are excellent for a wide variety of complex thermal applications, today’s newer and more advanced analytical equipment requires higher performance and precision. Here, Andy Selvy Chief System Designer at industrial technology company Watlow, explores the benefits of advanced ceramic heaters.

Analytical equipment, such as gas-chromatograph mass spectrometers (GC-MS), is used to determine the presence of trace chemicals, alcohols and hormones and separate complex mixtures in a number of research, industrial and clinical applications. For example, GC-MS detect concentrations of drugs in blood, as well as contaminants in air, water and soil, and can help to develop new pharmaceutical products.

The MS component breaks each separated compound coming from the GC into ionized fragments, which requires a high energy beam of electrons to pass through the sample molecule to produce electrically charged particles or ions.

The equipment requires the ionization of the sample and inert gas, and so a heating element that can reach a precise temperature quickly is a vital component. However, many legacy heating technologies that have exerted their performance and reliability and now must be designed to reflect the smaller, higher throughput analytical equipment that is taking over the market. This means heaters must also be smaller to enable miniaturization and optimize performance.

Today’s heaters

Modern advanced ceramic heaters can achieve higher performance and precision criteria, while allowing for greater design flexibility and faster time to market.

To appreciate the recent innovation in heating technology, it helps to understand some of the limitations faced by more traditional metal heaters. These heaters must be inserted into another block of metal inside the equipment in order to perform their thermal job. As the heater sheath and the block are made of metal, they cannot meet the ion source and often require additional electrical isolation.

These design tradeoffs require a larger carbon footprint, as well as a more complex assembly procedure. Metal-sheathed heaters also typically require longer heat-up and cool-down times, given that there is more mass in the heater and holder. This results in slower system startup and changes between set points.

Advances in ceramic heater technology overcome many of these issues and offer greater design flexibility and performance. Advanced ceramic heaters allow equipment designers to create room for new components, reduce a machine’s overall footprint, improve accuracy and performance, all while simplifying the manufacturing and assembly process.

The benefits of advanced heaters

To allow for more innovative designs, Watlow has developed ULTRAMIC, an advanced, high-performance ceramic heater. ULTRAMIC advanced ceramic heaters are designed for optimal performance in thermal applications where rapid thermal cycling and more precise control is needed.

ULTRAMIC heaters are constructed from aluminum nitride (AIN) and incorporate a thermally matched, proprietary heating element. AlN is especially suitable for applications requiring a clean, non-contaminating heat source. Additionally, excellent geometric stability ensures consistent part-to-part thermal contact during heating cycles.

These components, used together in the right circumstances, give rise to a number of unique properties including high electrical isolation, with low-leakage current, superior chemical resistance, high thermal conductivity and temperature uniformity across the heater surface, plus high durability.

Today’s analytical equipment has surpassed the innovation of heaters designed 30 years ago. To ensure design innovation is not limited, equipment designers must consider more advanced heaters in their equipment.

Advanced ceramic heaters are smaller, respond faster and can be more resistant to environmental contamination compared to conventional heaters. In particular, Watlow’s ULTRAMIC advanced ceramic heaters can help analytical equipment manufacturers improve product performance and design, as well as accelerate their time to market.

For more information about Watlow’s products, go to www.watlow.com.

About Watlow:

Watlow is a global technology and manufacturing leader that provides world class engineering expertise and innovative thermal products and systems that enable customers to thrive.

Watlow brings its experience to numerous industries, including semiconductor processing, environmental chambers, energy processes, diesel emissions, medical and foodservice equipment.

Since 1922, Watlow has grown in product capability, market experience and global reach. The company holds more than 980 patents and employs 2,000 employees working in nine manufacturing facilities and three technology centers in the United States, Mexico, Europe and Asia. Watlow also has sales offices in 50 countries around the world. The company continues to grow, while the commitment remains the same – to provide its customers with superior products and services for their individual needs.