Displaying items by tag: Metso Outotec

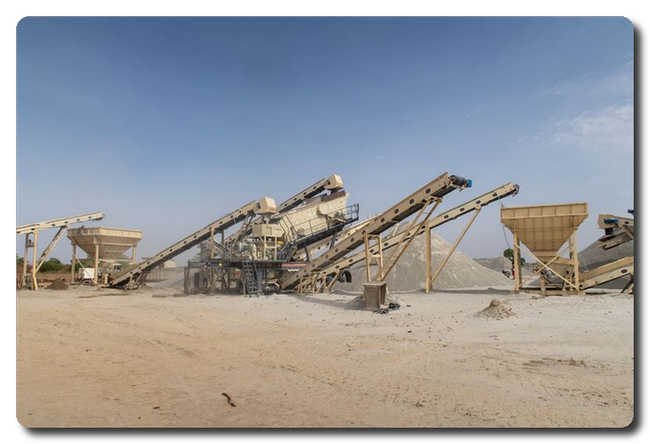

Metso Outotec and Hispano Japonesa de Maquinaria to expand partnership in Spain

Metso Outotec and Hispano Japonesa de Maquinaria S.L. (HJM) have agreed on an expansion of their distribution contract in Spain. In addition to mobile equipment, with the new scope the cooperation also covers Metso Outotec’s stationary crushing and vibrating equipment, crusher wear parts and spare parts, as well as service contracts, commissioning, and technical support. The contract comes into effect in July 2021.

“We have been very pleased with the cooperation with HJM so far,” comments Olli-Pekka Oksanen, who is heading the Distribution Management Office in Metso Outotec. “HJM is well-known and recognized in the Spanish construction business. Thanks to their solid expertise and local presence, we are able to strengthen the service levels for all our crushing and screening customers both in equipment and aftermarket support.”

To ensure continuity for the customers, part of the Metso Outotec personnel will transfer to HJM with the transaction. Olli-Pekka Oksanen continues: “Our foremost objective is to ensure a smooth transition to the existing customers.”

To ensure continuity for the customers, part of the Metso Outotec personnel will transfer to HJM with the transaction. Olli-Pekka Oksanen continues: “Our foremost objective is to ensure a smooth transition to the existing customers.”

“The past two years which we have represented Metso Outotec’s mobile equipment has proven that our visions are very well aligned,” says Juan Rodríguez, Managing Director at HJM. “Customers know what Metso Outotec solutions are and what they can do. They also know what kind of committed support is needed to keep the highest performance as standard, and that we at HJM put all in for the highest excellence. Together we want to be the preferred choice for all crushing and screening customers in Spain.

”HJM currently has 13 locations and over 100 employees. It has 40 years of experience in the wholesale of machinery for mining, construction and civil engineering and is located in the provinces of León, La Coruña, Guadalajara, Asturias and Málaga and has workshops in Basque Country, Almeria, Valencia, Mallorca, Zaragoza, Barcelona and Extremadura.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

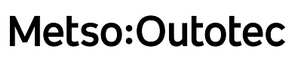

Metso Outotec to supply multiple Planet Positive Vertimill® grinding mills to iron ore mine in Ukraine

Metso Outotec will deliver multiple energy-efficient Vertimill® VTM-3000 stirred mills to Ferrexpo in Ukraine. These vertical grinding mills will be the largest of their kind to be installed in Ukraine. Once the mills have been installed, Ferrexpo’s iron ore beneficiation complex will be the largest VTM installation on the continent. Typical value for this type of an order is in the range of EUR 30 to 40 million, depending on the scope of delivery. The order has been booked in Minerals’ Q2/2021 orders received.

Vertimill® technology is part of Metso Outotec’s Planet Positive offering. It provides the lowest total cost of ownership compared to other grinding mills in many applications thanks to its high energy efficiency, reduced media consumption, low installation cost as well as minimal liner wear and maintenance. It is capable of handling feed sizes of up to 6mm and grinding to product sizes of 30 microns or less. Vertimill® is available in standard mill sizes ranging from 15HP (11kW) to 4500HP (3352kW).

Vertimill® technology is part of Metso Outotec’s Planet Positive offering. It provides the lowest total cost of ownership compared to other grinding mills in many applications thanks to its high energy efficiency, reduced media consumption, low installation cost as well as minimal liner wear and maintenance. It is capable of handling feed sizes of up to 6mm and grinding to product sizes of 30 microns or less. Vertimill® is available in standard mill sizes ranging from 15HP (11kW) to 4500HP (3352kW).

Metso Outotec is the only manufacturer worldwide than can offer several stirred mill technologies (Vertimill®, HIGTM mill and SMD), enabling it to support customers with the most suitable and efficient mill for their application.

Discover more about Vertimill® at mogroup.com.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Metso Outotec introduces stirred mills portfolio for superior comminution performance and energy efficiency

Metso Outotec has been a frontrunner in driving stirred milling innovations for decades and is now excited to introduce its comprehensive portfolio featuring three frontrunning stirred milling solutions – Vertimill®, Stirred Media Detritor, and HIGmill™. Ideal for grinding finer products, stirred mills are known for their energy efficiency and compact design, reducing floor space requirements. These mills are based on gravity-induced and fluidized technologies, allowing for the optimum equipment solution for all comminution circuits covering secondary, tertiary, fine, ultrafine, regrind, and lime slaking applications.

“Stirred milling is an important growth area and integral to our customer’s efforts for sustainable and cost-efficient comminution. With our combined portfolio and our unrivaled experience in this field, Metso Outotec is in the unique position to offer the most suitable solution for any specific application. We are doing this with a holistic view towards efficiency, sustainability, availability, and total cost of ownership,” explains Christoph Hoetzel, Head of Grinding business line at Metso Outotec.

A solution for every need

The Metso Outotec stirred mills are suitable for a large range of product sizes. The standardized range includes chamber units of up to 50,000 liters and the world’s largest industry units with up to 6,500 kW of installed power. Floor space use is optimized, which reduces investment costs, and installation is easy. All our stirred mills are part of the Planet Positive product portfolio, thanks to the sustainability benefits they deliver.

Vertimill® is globally recognized as market-leading energy-efficient grinding mill. Through a low total cost of ownership due to its simple and robust design, it brings substantial improvement to the profitability of concentrators. Over the years, Vertimill® technology has proven to be efficient – especially in secondary and tertiary grinding, regrinding, fine grinding, and lime slaking applications.

HIGmill™ is an advanced, energy-efficient fine and ultra-fine grinding solution that relies on proven technology. With the tall, narrow, vertical body arrangement, grinding media is evenly distributed and mineral particles remain in constant contact, significantly increasing grinding efficiency. It takes advantage of gravitational forces and GrindForce™ rotor technology to produce a finer grind for mineral liberation.

Stirred Media Detritor (SMD) is a fluidized, vertical stirred mill designed for optimum grinding efficiency for fine and ultrafine grinding products. SMDs have the capacity to operate continuously at full load power draw with no steel contamination of the product. They are suitable for both open- and closed-circuit operation.

Key benefits of Metso Outotec stirred mills:

- Improved operational efficiency

- Improved energy efficiency

- Increased media savings

- Reduced carbon emissions

- Flexible and safe to operate

Discover more about stirred mills technologies and their differences at mogroup.com/stirred-mills.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

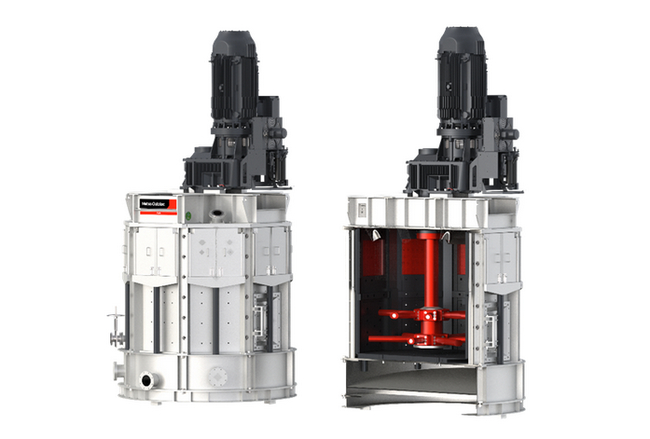

Metso Outotec to deliver state-of-the-art Premier™ and Vertimill® mills to gold mines in Liberia and Burkina Faso

The Turkish conglomerate Mapa Group has awarded Metso Outotec a contract for the delivery of key grinding technology to their gold mine expansions in Liberia and Burkina Faso. The value of the order is approximately EUR 19 million, and it has been booked in Minerals Q2/2021 orders received.

“Mapa is a major conglomerate working in various industrial and construction sectors. For us, good support, reliable project execution, and sustainable equipment and process performance are essential. Alongside the existing good relationship between the companies, they’re the reasons why we selected Metso Outotec for these projects,” explains Mustafa Bülent Karaarslan, COO, Mapa Group.

Metso Outotec will deliver identical grinding lines to both sites, consisting of state-of-the-art Premier™ ball mills and energy-efficient Vertimill® VTM-3000 stirred mills, each line featuring a capacity of 400tph. The deliveries are expected to take place in January 2022.

Metso Outotec Premier Ball mill

Metso Outotec Premier Ball mill

“We are excited that Mapa has chosen us to deliver the key equipment for the expansion of these two projects in Liberia and Burkina Faso. Previously, we have delivered the key crushing, screening and grinding equipment to these two mines,” says Mert Katkay, Head of Minerals Sales for Metso Outotec in the Middle East and Turkey.

Discover more about Metso Outotec grinding technology and Planet Positive approach.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Enabling mines and quarries to haul more with less: Americas to get its first Metso Outotec Truck Body in operation

Metso Outotec’s unique Truck Body is designed to maximize the availability and performance of haul trucks while reducing the costs for service and maintenance. The groundbreaking innovation that combines the benefits of rubber and a high-strength steel structure was launched in 2019 and is well-received by customers. Recently, one of the world’s largest copper mines decided to invest in a Metso Outotec Truck Body. It is the first order globally for a truck with loading capacity of 360 tons and the first in Americas. The customer is looking to increase payload of its trucks while also reducing maintenance.

“We will supply a Truck Body with lower weight and major volume capacity compared to the OEM body. We can prove with objective calculation the benefits the customer is going to receive, such as fuel savings, less maintenance, more uptime, the possibility to increase payload on each hauling, as well as improving the truck body’s life. All these benefits are answering to growing demand for environmental efficiency,” says Alfredo Rios, Business Support Manager, Loading and Hauling, Americas, Metso Outotec.

Americas to get its first Metso Outotec Truck Body in operation

Americas to get its first Metso Outotec Truck Body in operation

The Truck Body is part of Metso Outotec’s Planet Positive offering.

Key benefits of Metso Outotec Truck Body:

- Up to 30% lighter than a conventional steel-lined truck body.

- Lower fuel consumption per hauled tonne, less CO2 emissions.

- The rubber lining lasts up to 300% longer than conventional steel lining, drastically reducing the need for maintenance.

- Modular design makes the lining easier to install and maintain.

- Noise cut in half; vibrations reduced by up to 97%, which significantly improves the working environment for truck drivers.

- Available for all common truck models.

Find out more about the Metso Outotec Truck Body on our website: www.mogroup.com/portfolio/truck-body/

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Unlocking the value of electronic scrap: Metso Outotec introduces leading-edge eScrap solutions

Metso Outotec is introducing a comprehensive eScrap solutions portfolio for the smelting and refining of e-scrap derived from Waste Electrical and Electronic Equipment (WEEE). The solutions portfolio consists of Metso Outotec’s proven smelting, refining, hydrometallurgy, and gas-cleaning technologies, all contributing to the safe and profitable recycling of e-scrap.

E-scrap, consisting of printed circuit boards and electronic devices containing copper, gold, and other valuable metals, is one of the fastest growing waste streams worldwide. Rapid technological development, especially in information technology, is one of the drivers for this change. Combined with the depletion of primary raw materials and the increasing complexity of e-scrap, the need for safe and environmentally friendly recycling and reuse of these valuable raw materials is of paramount importance.

It all starts from metallurgy

Metso Outotec’s sustainable eScrap solutions portfolio consists of complete process solutions and proprietary equipment to solve any e-scrap smelting challenge. The highly automated smelting solutions, complemented with highly efficient gas cleaning and wastewater treatment, comply with the strictest environmental regulations. Zero water discharge can also be provided as an option. The solutions are supported with in-house pilot testing and process modeling and are backed by process guarantees and advisory services.

“Process design for optimal efficiency, emissions control, and minimized energy use always starts from metallurgy – you need to understand the variability in the feed materials. At Metso Outotec, we have decades of technical expertise in dealing with diverse raw materials. Thanks to our state-of-the-art testing capabilities and proven references, we can provide an optimal process solution with high recovery and availability for a wide variety of secondary raw materials – all the way to the refined metal product,” says Lauri Närhi, Sales Director, Smelting at Metso Outotec.

“By helping to turn waste into valuable metals, our solutions help to take advantage of the exciting new opportunities being created now for the circular economy of today and the future. Metso Outotec is committed to the 1.5 °C journey in line with the Paris Agreement, and Planet Positive thinking is inherent in our eScrap offering.”

The Metso Outotec eScrap solutions offering consists of the following plant products:

- Ausmelt TSL® process

- Kaldo TBRC process

- Gas Cleaning Plant

- Electric Slag Cleaning Furnace

- Peirce Smith Converting process

- Fire Refining process

- Anode Casting Shop

- Electrorefining

- Electrowinning

- Precious Metals Plant

- Process Water Recycling Plant

Discover more about our eScrap offering at mogroup.com.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

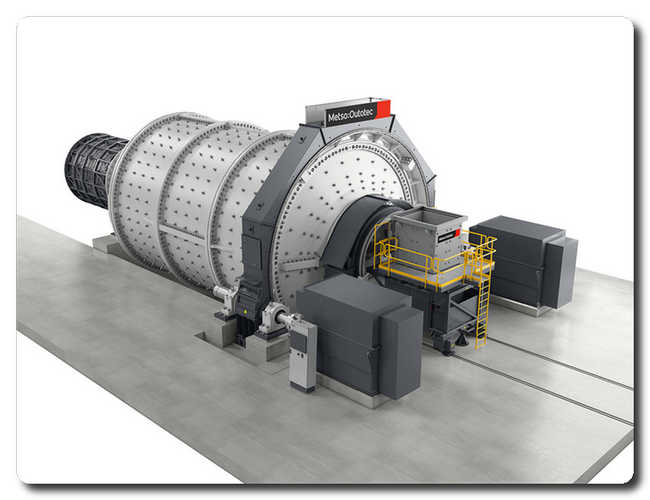

Metso Outotec wins yet another pelletizing plant order in China

Metso Outotec has signed a contract with Beijing Shougang International Engineering Technology Co, Ltd. (BSIET) on the delivery of environmentally sound pelletizing technology for Yunnan Yuxi Yukun Iron and Steel Group Co., Ltd. The iron ore pelletizing plant will be built in the Dahua industry park of Eshan, Yuxi, Yunnan, China. The order value is not disclosed. The contract has been booked into Metals’ Q2/2021 orders received.

Metso Outotec's scope of delivery covers the engineering and design of the indurating system, engineering of the process gas fan system, supply of proprietary equipment, instrumentation and control systems, as well as supervisory services and technical training. The Yukun plant targets annual production of 4 million tonnes of pellets. Production is expected to start in 2023.

Metso-Outotec-Indurating-machine

Metso-Outotec-Indurating-machine

“This is the third pellet plant order we’ve received within a short period of time from China. Today, China is the largest crude steel producer in the world, accounting for over half of the world’s production. Driven by rapid modernization of its economy, construction, infrastructure and manufacturing industries, China is continuously developing its production facilities and capabilities to meet the domestic and world demand, as well as the increasing sustainability requirements related to emissions control and carbon neutrality. Metso Outotec’s traveling grate technology used in the pelletizing plants ensures high performance and quality while decreasing energy consumption and emissions significantly,” says Attaul H. Ahmad, Vice President, Ferrous & Heat Transfer business line at Metso Outotec.

Find out more about the traveling grate pelletizing technology on our website.

Further information, please contact:

Matthias Gabriel, Director, Ferrous Product Group Metso Outotec, tel. +49617 1969 3280, email: matthias.gabriel(at)mogroup.com

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Metso Outotec and Advanced Engineering Group to sign distribution contract for screening media

Metso Outotec and Advanced Engineering Group Pty Ltd (AEG) have signed a contract concerning Metso Outotec’s screening media distribution. Since March 2021, AEG sells and supports all Metso Outotec synthetic screening media products to aggregates producers in Australia.

The distributor partnership combines Metso Outotec’s premium brand and its high reliability screening media products with AEG’s recognized knowledge and reputation on the market into a unique, compelling offering. Metso Outotec provides the technical support and backs up AEG through its focused global supply chain.

“The production of aggregates in Australia has increased with newer and larger operations which have higher focus on cost-efficiency and quality of materials. The move towards synthetic media has evolved from this demand,” says Shaun Fanning, Vice President, Asia Pacific Distribution at Metso Outotec. “Metso Outotec has developed a range of synthetic screening media to support the customer needs. Together with AEG, we can offer fast and easy access to screening media for the Australian customers.”

Metso Outotec Trellex screening system

Metso Outotec Trellex screening system

“It is exciting times for us and the customers,” says Dave Hastie, Managing Director of AEG. “We have built our business on quality products and service during the past 25 years. We look forward to growing the Metso Outotec brand as well as introducing our range of products to a wider clientele. The partnership is an important step in building our new superstore where the customers have access to a one-stop shop of synthetic media, screen mesh and accessories on a timely and simplified manner.”

AEG has facilities in Melbourne and Brisbane, with 22 staff members.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

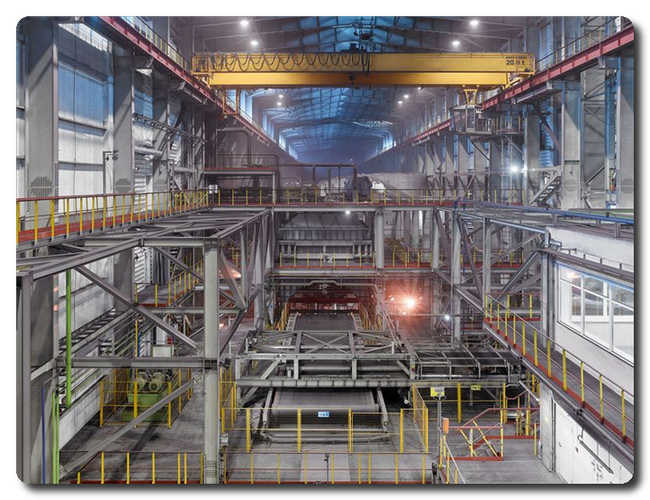

Metso Outotec to supply large-capacity Grate-Kiln iron ore pellet plant to India

Metso Outotec has signed a contract with an Indian customer for the supply of a large-capacity Grate-Kiln pellet plant in the State of Odisha, India. The contract is booked in Metals’ Q1/2021 orders received. Typically, the value for this type of an order is in the range of EUR 30-40 million, depending on the scope of delivery.

Metso Outotec’s scope of delivery includes basic engineering and process technology for the Grate-Kiln pellet plant, including the core proprietary equipment consisting of traveling grate, kiln, and cooler, as well as supervisory services for commissioning, and spare parts.

Metso Outotec’s scope of delivery includes basic engineering and process technology for the Grate-Kiln pellet plant, including the core proprietary equipment consisting of traveling grate, kiln, and cooler, as well as supervisory services for commissioning, and spare parts.

“The energy-efficient Metso Outotec Grate-Kiln process produces pellets of uniform quality with low emissions, high availability, and it has low investment and operating costs,” says Jari Ålgars, President, Metals business area at Metso Outotec. “With its annual pellet production capacity of 6 million tons, the new plant will be the first large-scale Grate-Kiln pellet plant in the country.”

Find out more about Metso Outotec Grate-Kiln technology on our website.

Further information, please contact:

Christopher Urban, Vice President, Heat Transfer, Metso Outotec, tel.+1 570 850 3251, email: christopher.urban(at)mogroup.com

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki.mogroup.com

Metso Outotec and BIA Group expand distribution partnership to Africa

Metso Outotec and its distribution partner BIA Group have signed a contract to expand their aggregates distribution coverage to Africa. Starting in March 2021, Metso Outotec’s stationary and mobile equipment, spare and wear parts coupled with BIA’s technical expertise and local presence will be available for aggregates customers in West and Central Africa.

The two companies have successfully partnered in the Benelux region since 1930. The decision to expand the long-lasting partnership to Africa was driven by shared ambition to reach and serve customers in the region better than ever before. Enhancing both companies’ offering, Metso Outotec and BIA put themselves in an unrivalled position now able to offer a complete product portfolio with the highest possible services levels.

With the dynamic nature of the African markets driven by both GDP and population growth and large construction projects impacting positively the aggregate demand, Metso Outotec and BIA have high expectations on the possibilities provided by the expansion.

“This expansion of our distribution partnership with BIA enables us to reach out to new territories, where we were not present earlier,” explains Olli-Pekka Oksanen, Senior Vice President, Global Distribution Management at Metso Outotec. “With the agreement, we provide equipment, parts and support for customers in new areas. Whether the customer is looking for a full stationary plant or a single mobile equipment, we can offer them all – with the desired support level. Our portfolio covers the needs of different types of customers and applications and meets the local requirements and standards.” He concludes: “We are happy to be able to utilize the opportunities in the region in collaboration with BIA.”

“This distribution agreement extension for West and Central Africa demonstrates the willingness of BIA and Metso Outotec to strengthen their historical partnership that started over 90 years ago with Nordberg for Belgium,” says Vincent Bia, the CEO of BIA Group. “Since then, both companies have continuously developed their products and services to gain an unrivalled expertise that serves both the aggregates and mining customers. We are confident that BIA’s market knowledge and local presence together with Metso Outotec’s solutions and technologies will form complementary assets to meet the ever-growing customer needs.“

Further information, please contact:

Karima Dargaud, Head of Aftermarket Sales EMEA, Distributor Management Office, Metso Outotec, tel. +33 631 522 413, karima.dargaud(at)mogroup.com

Carlos Padin, Head of Capital Equipment Sales EMEA Hub South, Distributor Management Office, Metso Outotec, tel. +33 607 272 002, carlos.padin(at)mogroup.com

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com