Displaying items by tag: Metso Outotec

Metso Outotec completes the acquisition of Tesab Engineering Ltd

Metso Outotec has completed the acquisition of Tesab, a Northern Ireland based company specializing mostly on mobile crushing equipment for aggregates applications, including quarrying, recycling, asphalt and concrete.

Tesab’s offering will complement Metso Outotec’s offering in the mobile crushing and screening markets. Tesab continues as an independent product brand within Metso Outotec, with its more than 60 employees integrating to the Metso Outotec group.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2021 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Metso Outotec to deliver copper electrowinning technology to Africa

Metso Outotec has been awarded a contract for the delivery of advanced electrowinning equipment to a copper cathode production plant in Africa. The order value amounting to approximately EUR 11 million is booked in Minerals' Q2/2022 orders received.

Metso Outotec's scope of delivery includes the supply of basic engineering and equipment for the copper electrowinning plant expansion.

Metso Outotec’s offering for copper electrowinning tankhouses comprises pre-engineered solutions, key equipment, and services to ensure superior process performance, increased safety, and minimized environmental impact.

Discover more about our electrowinning technology on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2021 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com, twitter.com/metsooutotec

Metso Outotec awarded major order for key processing technology at a copper and gold plant in South-East Asia

Metso Outotec has been awarded a major order for the supply of key minerals processing technologies to a copper and gold mine project in South-East Asia. The contract value of approximately EUR 40 million has been booked to Minerals Q1/2022 orders received.

Metso Outotec has a strong presence in South-East Asia including a Service Center, which is able to support local mining customers.

More information about Metso Outotec minerals processing technologies is available on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2021 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Metso Outotec launches compact AC filter for advanced organics removal in battery metals processes

Metso Outotec is launching the Activated Carbon (AC) filter for efficient recovery and recycling of valuable battery chemicals. The energy- and water-efficient AC filter responds to the market’s increasing demand for advanced and sustainable battery metals processing technologies and is part of Metso Outotec’s Planet Positive portfolio.

“This launch will strengthen our capability to serve a large variety of industries and processes. Together with the Dual Media (DM) filter, Metso Outotec now has a complete filtration portfolio for solvent extraction (SX), electrowinning (EW) and crystallization processes. We have strong know-how from the hydrometallurgical industry with more than 50 successful filtration solutions references from SX and crystallization processes globally,” says Mika Vuorikari, Director of Industrial Filtration at Metso Outotec.

The modular AC filtration technology is designed for smaller side streams of copper and other metal-loaded aqueous streams. It is specifically suited for efficient organics removal before the electrowinning and crystallization processes. The AC filter utilizes the already proven design and operation philosophy of the Metso Outotec DM filter product family and is suitable for both greenfield and brownfield installations.

Metso Outotec AC Filter

Metso Outotec AC Filter

Benefits of the AC filter:

- Increased end-product yield and quality

- Increased recovery and recycling of valuable process chemicals

- Cost-effective and modular design

- Low energy consumption, due to low pumping pressure

- Minimized water consumption with optimized back washing

- Safe to use and operate, due to sealed pressure vessel and piping

Find out more about the Metso Outotec AC filter on our website.

Further information, please contact:

Timo Jauhiainen, Product Manager, Industrial Filtration, Metso Outotec Corporation, tel. +358 50 308 9900, email: timo.jauhiainen(at)mogroup.com

Helena Marjaranta, Vice President, Communications and Brand, Metso Outotec, tel. +358 20 484 3212, email: helena.marjaranta(at)mogroup.com

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales in 2021 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Metso Outotec launches a new mobile impact crusher to the Nordtrack range

Metso Outotec adds a new impact crusher to its Nordtrack mobile crushing and screening range, targeting especially smaller-sized applications and jobsites in the construction and demolition waste recycling segment. The Nordtrack™ I1011 mobile impactor has compact dimensions and a powerful, high-performance crusher, ideally suited for contractors and rental work. Equipped with a large hanging screen, it combines high crushing capacity with calibrated end product accuracy.

The versatile Nordtrack I1011 crusher is suitable for working in different jobsites from rock crushing to concrete and demolition waste recycling. It is transported on a standard trailer, making it cost-effective and quick to move between sites. Thanks to its agility, moving the equipment in tight places inside the jobsites is easy. With Metso Outotec’s service support and global inventory of parts like different blow bar options, Nordtrack I1011 is a dependable choice for contractors and as a rental machine.

“We have listened to the feedback from our customers and are happy to offer this newest addition to our Nordtrack range. The launch of Nordtrack I908S was very successful, and consequently we have been asked for a bigger mobile impactor unit,” says Vesa Tuloisela, who heads the Nordtrack product offering at Metso Outotec. “The I1011 has a more powerful crusher and engine, resulting in a capacity as high as 300 tph. As a mobile crusher it also is well suited for the recycling of demolition and concrete waste, or reclaimed asphalt,” he continues.

Nordtrack I1011 will be launched in Metso Outotec’s Nordtrack Liveroom, which is a 360° digital event experience platform. Liveroom features 3D demonstrations of the Nordtrack range as well as a wealth of information on the aftermarket offering.

Read more about Nordtrack™ at www.mogroup.com/nordtrack

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2021 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Update on Russia Ukraine conflict on Metso Outotec’s business

As a result of Russia’s military actions against Ukraine, the European Union, the United States and other countries have announced severe sanctions against Russia. While the mining industry is currently not directly targeted by the sanctions, sanctions against the banking sector and individuals as well as other restrictions may have an impact on Metso Outotec and our customers’ Russia related businesses. Due to the current unclear and changing sanction situation, Metso Outotec has temporarily ceased its deliveries to Russia.

As a result of Russia’s military actions against Ukraine, the European Union, the United States and other countries have announced severe sanctions against Russia. While the mining industry is currently not directly targeted by the sanctions, sanctions against the banking sector and individuals as well as other restrictions may have an impact on Metso Outotec and our customers’ Russia related businesses. Due to the current unclear and changing sanction situation, Metso Outotec has temporarily ceased its deliveries to Russia.

Metso Outotec’s customers in Russia operate in several mining and metals processing sites across Russia. Capital projects are typically long with deliveries taking place over the course of several years. Sales from Russia represented approximately 10% of Metso Outotec’s annual sales in 2021. Metso Outotec does not have own production in Russia, or any material procurement in the country.

Further information

Juha Rouhiainen, Vice President, Investor Relations, Metso Outotec Corporation, tel. +358 20 484 3253

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2021 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Metso Outotec wins major order for siderite calcination plant in Turkey

Metso Outotec has signed an agreement for the delivery of a siderite calcination plant to Hekimhan Madencilik, a subsidiary of Koloğlu Holding, located in Malatya, Turkey. The value of the order is approximately EUR 23 million, and it has been booked in Metals’ Q1/2022 orders received.

Metso Outotec’s scope of delivery consists of system design, equipment engineering, manufacturing and supply, and advisory services for the installation of the plant with an annual capacity of 600,000 tons of calcined siderite. The key components of the system include a rotary kiln, cooler, and heat recovery and gas cleaning equipment. The plant startup is expected in the second half of 2023.

“Our solution will enable Hekimhan Madencilik to achieve their production goals,” says Attaul Ahmad, Vice President of the Ferrous & Heat Transfer business line at Metso Outotec. “It was through our strong customer relationship and familiarity with Hekimhan’s processes that we were able to introduce the Metso Outotec Rotary Calcining system and Heat Transfer experts to develop an optimal equipment & system solution for the client,” Ahmad adds. Metso Outotec has previously supported the client with improvements to the operation of their existing calcining line.

Hekimhan Madencilik Fabrika Resim plant before the siderite calcination plant istallation Courtesy of Hekimhan

Hekimhan Madencilik Fabrika Resim plant before the siderite calcination plant istallation Courtesy of Hekimhan

Metso Outotec is a leading supplier of calcining systems with an installed base of over 1500 rotary kilns. The Metso Outotec technology provides dependable process performance with an emphasis on optimizing fuel efficiency and minimal emissions.

Discover more about our calcining systems on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2021 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com, twitter.com/metsooutotec

Metso Outotec to start next phase in development of its Metals business

Metso Outotec will take the next structural development steps in its business portfolio, following the completed integration of its Minerals business and the successful turnaround of its Metals business. The company plans to change its business area structure and related reporting segments by transferring the Hydrometallurgy business from Metals to Minerals. The objective of the change is to accelerate Metso Outotec’s profitable growth in the minerals processing industry by more efficiently leveraging the opportunities and synergies in the minerals and hydrometallurgical processes.

Having Hydrometallurgy as part of the Minerals business will enable enhanced customer service with a competitive and fully integrated Planet Positive product offering, as well as closer integration with the customers’ processes through digitalization. Going forward, gold and battery chemicals businesses are among the interesting new synergistic growth areas.

A strategic review will be conducted in the remaining Metals business area, consisting of the Smelting, Metals & Chemical Processing and the Ferrous & Heat Transfer business lines, as well as related aftermarket services. The review will focus on evaluating the best environment for developing the Metals business and its strategic fit in Metso Outotec’s business portfolio. All potential options will be considered, including development by Metso Outotec, co-development with a partner, or divestment. The review has no impact on Metals’ daily business conduct, sales, or project execution, which will continue with full commitment.

A strategic review will be conducted in the remaining Metals business area, consisting of the Smelting, Metals & Chemical Processing and the Ferrous & Heat Transfer business lines, as well as related aftermarket services. The review will focus on evaluating the best environment for developing the Metals business and its strategic fit in Metso Outotec’s business portfolio. All potential options will be considered, including development by Metso Outotec, co-development with a partner, or divestment. The review has no impact on Metals’ daily business conduct, sales, or project execution, which will continue with full commitment.

Metso Outotec’s financial reporting will be adjusted to reflect the new segment structure as of January 1, 2022. The financial year 2021 will be reported in line with the segment structure used during 2021. The restated segment financials will be provided prior to the Q1/2022 reporting.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

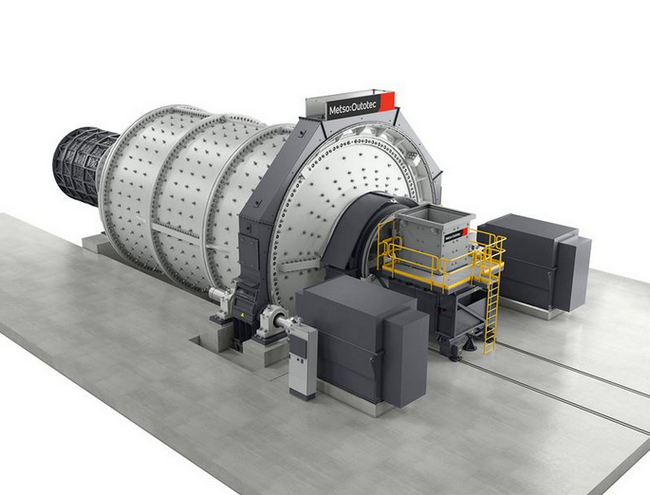

Metso Outotec to deliver grinding technology to ArcelorMittal’s Las Truchas iron ore project in Mexico

Metso Outotec has been awarded a contract to supply key grinding equipment for ArcelorMittal’s Las Truchas 2.3MTPA iron ore processing plant revamp project in Mexico. The value of the order is approximately EUR 17 million, and it has been booked in Minerals’ Q4/2021 orders received.

The order includes two Metso Outotec Premier™ grinding mills with a total installed power of 19MW. In addition, Metso Outotec will deliver an in-house designed Mill Reline Machine, enabling efficient and safe replacement of the steel and rubber lining systems, an operations-friendly Select™ Ball Feeder, and spare parts.

MetsoOutotec Premier Ball Mill Front

MetsoOutotec Premier Ball Mill Front

“We are pleased to have been chosen for this project. In Mexico, Metso Outotec is a leading grinding mill supplier and is supported by our strong local service and consumables presence. With our Planet Positive Premier™ grinding mills and associated life cycle service offerings, our customer will be able to expand their iron ore production in a safe, efficient, and environmentally responsible way in partnership with us,” says Andy Lingenfelter, Vice President, Minerals Sales, North and Central America at Metso Outotec.

For more information about our grinding mills, please visit the related product pages on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Metso Outotec to deliver grinding mill components to a copper and gold mine in Asia Pacific

Metso Outotec has signed a services contract for the delivery of four ball mill upgrade packages to a copper and gold mine in Asia Pacific. The value of the order is approximately EUR 19 million, and it has been booked in Minerals’ Q4/2021 orders received.

Refurbishment projects for older, existing assets are an efficient method to extend a mill’s operating life, increase energy efficiency, and minimize waste and plant downtime. Additionally, equipment refurbishments lead to improved machine availability and safety by delivering the latest available technology.

“We are pleased to have been chosen as the supplier for the grinding mill refurbishment project. The customer’s performance objectives were achieved by offering a technical solution which increased the operating volume of the mill and allows for future process optimization. Providing these thirty+ year old mills a new lease of life is exciting for Metso Outotec and builds on our sustainability promise of delivering circular offerings,” says Jonathan Allen, Senior Vice President, Grinding, Bulk and Pyro business line of Metso Outotec.

Metso Outotec has delivered and serviced over 8,000 grinding mills globally, including some of the largest and most powerful mills in the world. The company is a market leader in providing a wide variety of upgrades and service solutions to help customer’s older mills achieve performance like a modern-day machine.

Discover more about Metso Outotec Grinding Spare Parts and Grinding Upgrades on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com