Displaying items by tag: Metso Outotec

Metso Outotec awarded EUR 100 million contract for the delivery of a nickel-copper concentrator in Russia

Metso Outotec has signed a landmark contract to deliver all key technology for a new concentrator plant in Norilsk, Russia. The concentrator is operated by Chernogorskaya mining company, which is part of the Russian Platinum group. The delivery is based on Metso Outotec’s proprietary technology and includes key equipment for grinding, flotation and separation. Metso Outotec will also deliver electrification, instrumentation and automation for the concentrator. The contract exceeding EUR 100 million has been booked into Minerals’ Q3/2021 orders received.

The new concentrator plant is expected to start production in 2023. It will process nickel-copper ore with high palladium and platinum content from the Chernogorsky deposit with an annual capacity of 7 million tons. Metso Outotec has done the basic engineering for the concentrator plant in the earlier stages of the project.

”Russian Platinum is aiming a highly efficient and environmentally friendly production process in the industrial region of Norilsk. The construction of the Chernogorsk GOK is the first stage of this large-scale project, the implementation of which will make our company one of the leaders in the production of palladium and platinum. Use of advanced technical solutions and reliable equipment is an absolute priority. The partnership with Metso Outotec and continuous support from its local operations in Russia are important components to ensuring the success of the project,” says Evgeny Vorobeichik, Managing Director at Russian Platinum.

"Metso Outotec has ample experience with the arctic environment in the Norilsk region as well as with its uniquely rich and demanding ore types. We are delighted to be able to support Chernogorskaya in this greenfield project, where we will be delivering the whole concentrator with the latest technology,” says Markku Teräsvasara, President of the Minerals business area at Metso Outotec.

Read more about Metso Outotec’s minerals processing technologies and Planet Positive solutions on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Smart and digital – Metso Outotec launches Index online tool for metal recycling machines

Collecting data, sifting through data and evaluating data – online tool for digital monitoring and analysis of metal recycling machines.

The new Index operating and production data collection system from Metso Outotec’s Metal Recycling business transfers relevant data from the recycling machine directly to the customer’s equipment. Metso Outotec Metal Recycling has taken the next step in terms of digitization and, with Index, introduced an intelligent way to increase machine productivity, optimize the cost-benefit ratio and identify limiting parameters at an early stage.

"Accessible via mobile app or from the dashboard any time, one click is all it takes to find out immediately how high the current capacity utilization is, which material is currently being processed, how many operating hours the equipment has already been running for, or what the general condition of the metal recycling machine is," explains Peter Thomas, Director of Products and Technology for Metal Recycling in Metso Outotec.

All the equipment data can be visualized, displayed and analyzed in the Index web portal and if necessary, transferred to programs and systems designed for controlling purposes. "We are talking about modern workflow and performance monitoring, which serves as the perfect basis for evaluating the various key performance indicators (KPIs)," he continues.

The server used to back up data is currently one of the most secure servers on the market.

The server is located in Europe and is therefore subject to European data protection regulations.

Index will be available immediately as standard equipment in these Lindemann shears: EtaCut II, EtaCut, PowerCut/LUC as well as PowerCut Wings/LIS and LU. In addition, customers have the option of retrofitting their current stock shears of the previously mentioned machine types with Index. "Additionally, Index will soon be available for presses and shredder systems for Metso Outotec’s metal recycling customers," says Peter Thomas.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Metso Outotec to deliver a large number of high-capacity slurry pumps for tailings treatment in Ukraine

Engineering Dobersek in Germany and Severniy Mining and Processing (SevGOK) in Ukraine have selected Metso Outotec’s mill discharge pumps for Severniy’s greenfield process waste thickening plant.

Metso Outotec’s reliable high-capacity pumps will be used to pump the iron ore concentrate plant`s waste sludge into the settling ponds from the thickeners. The 22 pumps to be delivered by Metso Outotec include ten large high-capacity MDM700 pumps. Together, the pumps are capable of handling a total volume of 117,500 m3 of waste sludge per hour.

“SevGOK’s complex is the second of its kind in Ukraine, and Engineering Dobersek in Germany has designed it. With this investment, SevGOK aims to decrease environmental impacts and costs by lowering energy consumption and water usage. They chose Metso Outotec pumps because of their reliability and efficiency, and the good support Metso Outotec has provided in their previous projects,” says Axel Stappen, Managing Director, Engineering Dobersek GmbH.

“SevGOK’s complex is the second of its kind in Ukraine, and Engineering Dobersek in Germany has designed it. With this investment, SevGOK aims to decrease environmental impacts and costs by lowering energy consumption and water usage. They chose Metso Outotec pumps because of their reliability and efficiency, and the good support Metso Outotec has provided in their previous projects,” says Axel Stappen, Managing Director, Engineering Dobersek GmbH.

“We are delighted to have been selected to supply our MD series pumps to SevGOK’s project. To give an idea of the size of an MDM700 pump, it can weigh as much as 31 tons and be 2.8 meters in diameter, and have an impressive pumping volume of up to 9,650 m3/h. The MDM pumps operate in very demanding conditions, and we’ve designed them to operate reliably and to withstand exceptional wear,” says Michael Nienhaus, Head of Sales, Slurry Pumps, Germany, Metso Outotec.

Metso Outotec mill discharge pumps have been designed for mill circuit applications, such as SAG/ball mill discharge pumps and hydrocyclone feed. Special emphasis has been placed on components that have to withstand exceptional wear from coarse heavy solids and flow turbulence. The extensive range of Metso Outotec pumps covers flows of up to 12,000 m3/h, with the inlet sizes ranging from 250 mm to 800 mm with either a metal or rubber lining.

Find out more about Metso Outotec’s pumps portfolio on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Metso Outotec launches new digital solutions for boosting iron ore pelletizing plant performance

Metso Outotec is launching leading-edge digital solutions to ensure the optimal operation and maintenance of iron ore pelletizing plants over the entire plant life cycle. Leveraging the company’s extensive experience as the original inventor of the pelletizing process, Metso Outotec has developed a suite of solutions that will improve process performance, production capacity, and product quality while at the same time reducing energy consumption, environmental impact, and operation and maintenance costs.

The new digital solutions include the Metso Outotec Optimizing Control System OCS-4D™ and the Planet Positive Optimus™ advanced process control system for ensuring a stable and efficient process, the VisioPellet™ pellet size-control system for optimizing the pelletizing process, and the Pallet Car Condition Monitoring System for improving preventive maintenance planning and execution. In addition, Metso Outotec is launching a unique operator training with advanced simulation technology in a risk-free virtual plant environment. The training can be tailored to simulate different operating conditions, standard procedures, emergency situations, and any other operational scenarios that are deemed to be beneficial.

Metso Outotec Advanced process control for pelletizing

Metso Outotec Advanced process control for pelletizing

“We are really excited about these new digital products. Based on pilot tests/refence cases, we know that they can make a true difference for our customers’ processes. These solutions can be implemented in all iron ore pelletizing plants delivered by Metso Outotec. Our experts are happy to give more information on how each of these would benefit and work in individual plants,” says Olavo Nolasco, Director, Product Competitiveness, Ferrous & Heat Transfer at Metso Outotec.

Metso Outotec digital solutions for iron ore pelletizing plants provide the following benefits:

- Improved process performance, production capacity, and product quality of iron ore pelletizing processes

- Reduced energy consumption, environmental impact, and operation and maintenance costs

- Safer and more efficient plant operation, thanks to comprehensive, risk-free operator training with advanced simulation technology

- Valuable process insights with real-time information on pellet size distribution

- Improved preventive maintenance planning and execution with real-time equipment condition monitoring

Find out more about the digital solutions for iron ore pelletizing plants on our website.

Metso Outotec will host two free webinars where the solutions will be discussed in more detail:

- October 21, 2021, at 11:00 a.m. and 6:00 p.m. CET: Pallet Car Condition Monitoring & Green Pellet Size-Control for improved performance of iron ore pelletizing processes

- October 28, 2021, at 09:00 a.m. and 6:00 p.m. CET: Maximize your ROI by optimizing production costs with Metso Outotec’s Advanced Process Control System & Metso Outotec Training Simulator

You can register for the webinars here.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Metso Outotec and Cyriac Tor Ltd to provide slurry pump solutions in the UK

Metso Outotec has appointed Cyriac Tor Ltd as a distributor of Metso Outotec’s pumps in the UK. The distribution agreement covers Metso Outotec’s slurry pumping solutions, including slurry pumps, spare parts, seals and hoses, commissioning, service contracts, and technical support to all industry sectors in England, Scotland, and Wales. The contract has come into effect in September 2021 and will run alongside all existing distribution agreements.

“We are very pleased to announce the partnership with Cyriac Tor,” says Saso Kitanoski, President, Europe in Metso Outotec. “This partnership allows us to extend our presence in multiple industry sectors within this key market. With Cyriac Tor’s local presence and extensive knowledge, we will be able to expand the level of support we give to customers as well as increase our presence in industrial processes.”

“We are very pleased to announce the partnership with Cyriac Tor,” says Saso Kitanoski, President, Europe in Metso Outotec. “This partnership allows us to extend our presence in multiple industry sectors within this key market. With Cyriac Tor’s local presence and extensive knowledge, we will be able to expand the level of support we give to customers as well as increase our presence in industrial processes.”

"Cyriac Tor Limited is very happy to work alongside Metso Outotec, with an enlarged territory, looking forward to increasing our customer base and supplying a top class service," says Cyriac Tor Ltd. Managing Director, Ben Oliver.

“Our target was to find a partner who could help us better serve process industry customers requiring market-leading slurry pumping solutions,” comments Greg Dixon, European Pump Sales Director at Metso Outotec. He continues, “By holding both equipment and local inventories with an increased service capability, we will be able to offer our customers a world-class, responsive service.”

Cyriac Tor Ltd. has many years of experience in the design and service of slury pump equipment, making them specialists in the field. Read more at their website: http://www.cyriac-tor.co.uk/

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Metso Outotec to deliver a raw water treatment plant to a gold mine in the Middle East

Metso Outotec has signed an engineering and technology contract to deliver a raw water treatment plant for a gold plant project in the Middle East. The order value exceeds EUR 10 million, and it has been booked in Minerals’ Q3/2021 orders received.

The raw water treatment plant, which represents one of Metso Outotec’s many Planet Positive technologies, will help ensure the gold plant’s process performance and efficiency. Cleaned municipal waste water is used as the raw water source for the new raw water treatment plant.

The raw water treatment plant, which represents one of Metso Outotec’s many Planet Positive technologies, will help ensure the gold plant’s process performance and efficiency. Cleaned municipal waste water is used as the raw water source for the new raw water treatment plant.

Metso Outotec has delivered over 30 water treatment plants for the minerals processing industry around the world.

More information on Metso Outotec Water Treatment Systems is available on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

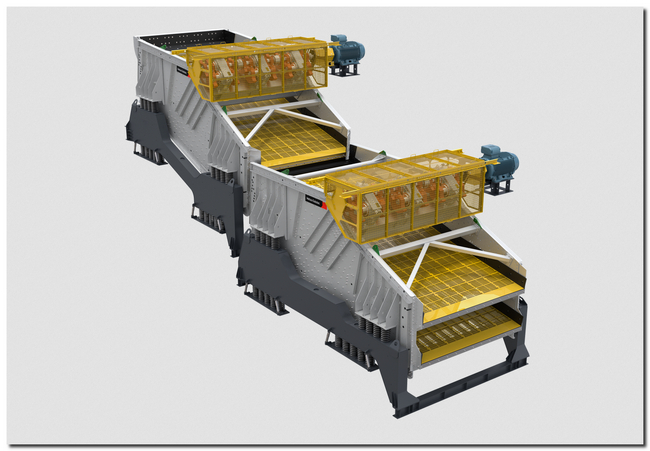

Metso Outotec’s sustainable screening technology to iron ore project – Unique solution eliminates water consumption in the screening process

Metso Outotec will supply unique sustainable screening technology for an iron ore project in the Southern Hemisphere. The order value, which is not disclosed, has been booked in Minerals segment’s Q3 2021 orders received. The start-up of the project is scheduled for the first half of 2024.

The order for the product screening and scalping application covers 12 Metso Outotec BSE Series™ (Banana Screen Elliptical) tandem screens and 4 MF Series™ screens, all equipped with 305PS screening media. In addition, the contract covers Metrics monitoring system for screens, expert support, and installation services.

The need to reduce water in iron ore production and other minerals processing is a critical global challenge. The innovative and patented BSE Series screens enable iron ore processing even with higher natural moisture content without adding water.

“We are pleased that the customer chose Metso Outotec for sustainable screening solutions for their process. The BSE screen is an outstanding option for their needs. The elimination of process water ultimately results in lower processing costs, increasing the customer’s competitiveness and profitability in the iron ore global markets,” says Jouni Mähönen, Vice President, Screening business line, Metso Outotec.

CNS BSE Screen

CNS BSE Screen

Results the customer can expect after implementation

- BSE Series™ screens enable elimination of process water in the screening process

- 93% reduction of the plant’s overall water consumption and eliminates the need for tailing dams

- Reduced energy consumption from the entire plant compared to the wet screening process: 18,000 MWh/year electricity saving

- 30% increase in screening capacity compared to traditional screening

- Increased safety during media change-outs using the unique Hammerless Attachment system

- Reduced CAPEX due to the adoption of high-performing BSE screens

Metso Outotec BSE™ screening technology is a Planet Positive solution. More information is available on https://www.mogroup.com/portfolio/bse-series/

Metso Outotec offers a wide range of screening solutions designed to meet the regional specifications and needs.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Metso Outotec to supply copper solvent extraction and electrowinning technology to US

Metso Outotec has signed an agreement with Florence Copper Inc., a subsidiary of Taseko Mines Limited, to supply copper solvent extraction and electrowinning technology for a plant to be built in Arizona. The order exceeding EUR 20 million has been booked in the Metals’ segment Q3/2021 orders received.

The Metso Outotec delivery includes the modular VSF®X solvent extraction plant and the main process equipment for the electrowinning plant.

Metso Outotec VSF X solvent extraction lines

Metso Outotec VSF X solvent extraction lines

“We are very excited to have purchased the key SX/EW process equipment from Metso Outotec, a world leader in mineral processing and hydrometallurgical technologies. The VSF®X technology is ideally suited for our Florence Copper Project, which is set to become one of the most energy-efficient and low-carbon copper producers in the world. The modular nature of the equipment will reduce construction time and allow Florence to commence copper production quicker than with other technologies available,” says Stuart McDonald, President and CEO of Taseko Mines.

“We are looking forward to working with Taseko Mines on the Florence Copper Project. The energy-efficient VSF®X solvent extraction plant, which is part of our Planet Positive product range, reduces emissions and is safe to operate. The Florence Copper Project will become an important new reference for Metso Outotec in the US copper market as a supplier of a complete production plant that uses solvent extraction and electrowinning technology for copper recovery,” says Jari Ålgars, President of the Metals business area at Metso Outotec.

Read more about solvent extraction and electrowinning technologies on our website.

Metso Outotec is a global frontrunner in sustainable technologies, and end-to-end solutions and services for aggregates processing, as well as minerals and metals refining. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5 degrees centigrade through climate targets certified by Science Based Targets. In 2021, we ranked eighth in the Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, the company has more than 15,000 employees in over 50 countries and had net sales of approximately EUR 3.9 billion in 2020. The company’s shares are listed on Nasdaq Helsinki. mogroup.com

Metso Outotec to supply Planet Positive grinding technology to a greenfield iron ore mine in China

Metso Outotec Stirred millMetso Outotec will deliver several energy-efficient stirred mills to a greenfield iron ore processing plant in Liaoning Province in northeastern China. The stirred mill installation, which corresponds to 11 MW of power, will be the largest of its kind in China. The value of the delivery is not disclosed. The order has been booked in the Minerals segment’s Q3/2021 orders received.“We are very pleased that we have been chosen as a supplier for this project. Previously, we agreed on the delivery of a PG4265™ primary gyratory crusher and three HP900™ cone crushers for the same project. Our stirred milling technology with its excellent performance and ability to increase both iron ore concentrate and recovery has proven itself multiple times in the Chinese market. The new installation will also benefit from class-leading energy efficiency and wear life,” says Christoph Hoetzel, Head of Grinding business line at Metso Outotec.

Metso Outotec Stirred millMetso Outotec will deliver several energy-efficient stirred mills to a greenfield iron ore processing plant in Liaoning Province in northeastern China. The stirred mill installation, which corresponds to 11 MW of power, will be the largest of its kind in China. The value of the delivery is not disclosed. The order has been booked in the Minerals segment’s Q3/2021 orders received.“We are very pleased that we have been chosen as a supplier for this project. Previously, we agreed on the delivery of a PG4265™ primary gyratory crusher and three HP900™ cone crushers for the same project. Our stirred milling technology with its excellent performance and ability to increase both iron ore concentrate and recovery has proven itself multiple times in the Chinese market. The new installation will also benefit from class-leading energy efficiency and wear life,” says Christoph Hoetzel, Head of Grinding business line at Metso Outotec.

Metso Outotec is the only manufacturer worldwide than offers several stirred mill technologies (Vertimill®, HIGTM mill, and SMD), enabling it to support customers with the most suitable and efficient mills for their applications.

Discover more about Metso Outotec’s grinding technology and Planet Positive approach.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Metso Outotec to divest Outotec Turula Oy in Finland

Metso Outotec has signed an agreement to sell Outotec Turula Oy, located in Outokumpu in eastern Finland, to UAB Arginta Engineering in Lithuania. Closing of the transaction is expected to occur on October 1, 2021. The parties have agreed not to disclose the value of the transaction. The transaction has no material impact on Metso Outotec’s financial results.

Outotec Turula Oy manufactures equipment and components used in the minerals processing and metals refining industries. All the existing approximately 120 employees will continue as employees of Outotec Turula Oy. Metso Outotec has signed a long-term manufacturing service agreement with the new owner.

”Our target was to find a new owner for the Turula workshop, a partner who would be fully focused on manufacturing and engineering with the ability to develop and grow the operations to better meet the future needs of all its customers. Arginta Engineering is such a company, and it can also provide development opportunities for the Turula employees,” says Jari Ålgars, President of the Metals business at Metso Outotec.

Metso Outotec Turula

Metso Outotec Turula

Arginta Engineering specializes in the engineering and manufacturing of machinery and equipment for several industry segments, and its customers are mainly located in the Nordic countries. Arginta Engineering operates two manufacturing locations in Lithuania and employs over 200 manufacturing and engineering specialists.

”Our strategy is based on professionalism and close cooperation with our customers. Turula’s professionals and their advanced machining and assembly expertise together with the unit’s demanding and robotized welding capability will be a great addition to our team. We see a lot of demand for this type of expertise also in the future,” says Tomas Jaskelevičius, Managing Director of Arginta Engineering.

More information about UAB Arginta Engineering is available on their website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com