Displaying items by tag: ANDRITZ

ANDRITZ to supply 10th high-efficiency PowerFluid circulating fluidized bed boiler to Japan

International technology group ANDRITZ has received an order from Toyo Engineering Corporation, Japan, to deliver a PowerFluid circulating fluidized bed boiler with a flue gas cleaning system. The boiler will be part of a new biomass power plant to be built in Niigata East Port in Niigata Prefecture, Honshu Island, some 300 km north of Tokyo, Japan. Commercial operations are scheduled to begin in September 2024.

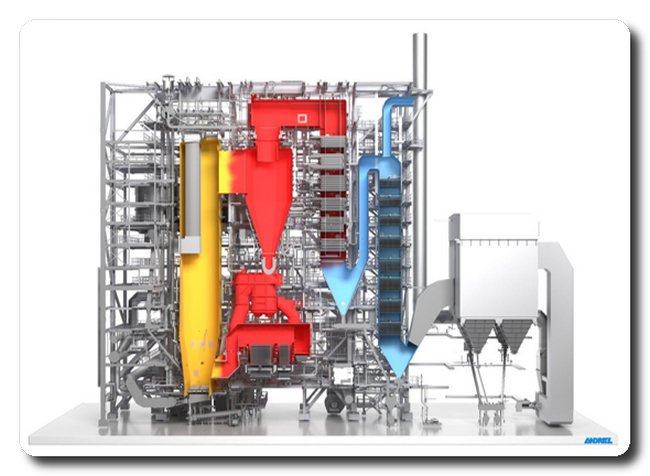

The ANDRITZ PowerFluid (CFB) boiler with reheating system to be supplied features low emissions, high efficiency and availability, as well as high fuel flexibility. It forms an essential part of a high-efficiency biomass power plant for supply of green energy to the national grid. The biomass power plant fired with wood pellets and palm kernel shells will generate around 50 MWel of power.

ANDRITZ PowerFluid circulating fluidized bed boiler “Photo: ANDRITZ”.

ANDRITZ PowerFluid circulating fluidized bed boiler “Photo: ANDRITZ”.

ANDRITZ is proud to be part of this remarkable project with Toyo Engineering Corporation and to make an important contribution towards the Japanese power industry in the transition from fossil fuel to renewable energy resources.

This ANDRITZ power boiler to be supplied to Japan confirms ANDRITZ’s strong market position as one of the leading global suppliers of power boiler technologies and systems for generating steam and electricity from renewable and fossil fuels, with a large number of very successful references worldwide.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply new spherical valves for Dinorwig power station in North Wales, United Kingdom, one of the largest pumped storage plants in Europe

International technology group ANDRITZ has received an order from First Hydro Company, UK, covering a contract for the supply of six new spherical valves for the Dinorwig pumped storage plant in Llanberis, North Wales, United Kingdom. First Hydro Company is owned 75% by ENGIE and 25% by Brookfield.

The first two valves will be installed in mid-2023, and the other four in mid-2025.

ANDRITZ's scope encompasses the design, manufacture, supply, installation, and commissioning of six spherical valves with a diameter of 2,500 millimeters and a pressure of 60 bar, including governors and the fire protection system.

With a total installed capacity of about 1,728 MW, Dinorwig is one of the largest pumped storage plants in Europe and provides balancing services including reserve and response. At peak, water flows through the turbines at 360m3 per second - the equivalent volume of a typical 25-meter length swimming pool.

Dinorwig pumped storage plant in Llanberis, North Wales, United Kingdom © ENGIE/ First Hydro Company

Dinorwig pumped storage plant in Llanberis, North Wales, United Kingdom © ENGIE/ First Hydro Company

The new ANDRITZ spherical valves will contribute to maintaining the overall availability of the entire plant, which has been in operation for nearly 40 years. Dinorwig plays a vital role in the safeguarding of Great Britain’s national grid.

First Hydro placed great confidence in ANDRITZ as a recognized worldwide specialist for spherical valves. ANDRITZ is proud to be part of the refurbishment project for Dinorwig power station.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. The global product and service portfolio is rounded off with plants for power generation, recycling, the production of nonwovens and panelboard, as well as automation and digital solutions offered under the brand name of Metris. The publicly listed group today has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ HYDRO

ANDRITZ Hydro is one of the globally leading suppliers of electromechanical equipment and services for hydropower plants. With over 180 years of experience and an installed fleet of more than 470 GW output, the business area provides complete solutions for hydropower plants of all sizes as well as services for plant diagnosis, refurbishment, modernization and upgrade of existing hydropower assets. Pumps for irrigation, water supply and flood control are also part of this business area’s portfolio.

ANDRITZ receives order for a new batt forming line for stitchbonding from Pratrivero, Italy

ANDRITZ has received an order from Pratrivero s.p.a. to supply a new eXcelle batt forming line for their production facilities in Valdilana, Italy.

The line will be dedicated to the production of Maliwatt products, used in furnishing, automotive, naval, medical, geotextiles, advertising, clothing, and packaging applications. Installation and start-up are scheduled for the third quarter of 2021.

The ANDRITZ batt forming line includes an eXcelle card and eXcelle crosslapper, a ProDyn™ web profiling correction system as well as a scanning gauge with a closed loop. The ProDyn system combines actions from the card doffers with dynamic speed variation at the crosslapper. This will result in substantial fiber savings and reduction in CV%, providing improved weight evenness in the final product. The ProDyn closed loop will ensure the best possible self-regulation for the equipment and thus enable Pratrivero to produce one of the best product qualities on the market. Pratrivero will be the world’s first company to use the ProDyn technology in the Maliwatt stitchbonding process.

ANDRITZ eXcelle card © ANDRITZ

ANDRITZ eXcelle card © ANDRITZ

Stitchbond is a nonwoven process made by mechanically interlocking fiber webs with continuous filaments, thus imitating textiles. Stitchbonded products are used in many applications due to their lower production costs compared to woven textiles. Among all the different nonwoven processes in which it operates, ANDRITZ is also a market-leading supplier of batt forming equipment for the stitchbonding processes producing Maliwatt, Malivlies and quilting.

Pratrivero has trusted in ANDRITZ once again because of its reputation regarding process expertise and high level of carding and crosslapping technology involved. The company already operates several ANDRITZ eXcelle batt forming units.

Pratrivero is an important player in the production of nonwoven fabrics using stitchbonding technology. The company has several plants in Italy and the USA, producing different types of stitchbonded products. The centuries-old tradition of the Italian company, founded in 1663, combined with modern technology has enabled Pratrivero to bring stitchbonding to a high-end quality level with unique characteristics.

ANDRITZ GROUP International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ to supply electro-mechanical equipment and maintenance service for one of the world’s first co-located solar pumped storage plants in Australia

International technology group ANDRITZ has received an order from the EPC contractors McConnell Dowell and John Holland to supply the electro-mechanical equipment for the 250-MW Kidston pumped storage plant in North Queensland, Australia.

Kidston will not only be Australia’s first pumped storage plant for more than 40 years, but also one of the world’s first to be co-located with a solar plant. The owner and developer of Kidston is Genex Power. Commissioning of the plant is expected in 2024.

Open pits from an abandoned gold mine © Genex Power Ltd

Open pits from an abandoned gold mine © Genex Power Ltd

The ANDRITZ scope of supply comprises design, manufacturing, supply, transportation, erection, and commissioning of two 125-MW reversible pump turbine units as well as full operation and maintenance services for more than 10 years.

The pumped storage plant was developed in a unique location by utilizing two open pits from an abandoned gold mine. Once filled up with water, it will operate as a closed-loop system and generate, store and dispatch renewable energy on demand during peak periods, capable of supplying enough sustainable and clean electrical energy for more than 280,000 Australian households. Additionally, the plant can be operated in a synchronous condenser mode to provide grid services such as reactive power management and synchronous inertia.

This order not only confirms once again ANDRITZ’s strong position in the Australian hydropower market, but also for pumped storage technology, which plays an important role in providing grid stability to cope with volatile solar and wind power supplies. The combination of hydro equipment supplies with state-of-the-art asset management services is also strong proof of ANDRITZ’s well diversified product and service portfolio for all applications and demands in the hydropower business.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. The global product and service portfolio is rounded off with plants for power generation, recycling, the production of nonwovens and panelboard, as well as automation and digital solutions offered under the brand name of Metris. The publicly listed group today has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ HYDRO

ANDRITZ Hydro is one of the globally leading suppliers of electromechanical equipment and services for hydropower plants. With over 180 years of experience and an installed fleet of more than 470 GW output, the business area provides complete solutions for hydropower plants of all sizes as well as services for plant diagnosis, refurbishment, modernization and upgrade of existing hydropower assets. Pumps for irrigation, water supply and flood control are also part of this business area’s portfolio.

ANDRITZ to supply biomass boiler plant to Fjernvarme Fyn Produktion A/S in Odense, Denmark

International technology Group ANDRITZ has received an order from the Danish energy company Fjernvarme Fyn Produktion A/S to deliver a new biomass boiler plant complete with auxiliary equipment for their “Bio Blok 2” project. The plant will be located on Fjernvarme Fyn’s existing combined heat and power plant site in Odense, on the island of Funen in Denmark, some 170 km west of the capital Copenhagen. This new plant will supply district heat to the Odense area and is also prepared for electricity production at a later stage. Start-up of the boiler is scheduled for 2023.

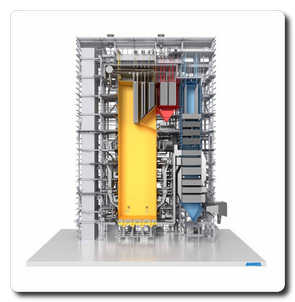

3D model of the ANDRITZ EcoFluid bubbling fluidized bed boiler “Photo: ANDRITZ”.The “Bio Blok 2” project is an important part of Fjernvarme Fyn’s goal of abandoning the use of coal at their combined heat and power plants by 2022 and contributing to the national objective of a 70 percent reduction in CO2 emissions by 2030. Fjernvarme Fyn delivers about 97 percent of the district heat requirement in Odense, providing heat for more than 100,000 households and large greenhouses.

3D model of the ANDRITZ EcoFluid bubbling fluidized bed boiler “Photo: ANDRITZ”.The “Bio Blok 2” project is an important part of Fjernvarme Fyn’s goal of abandoning the use of coal at their combined heat and power plants by 2022 and contributing to the national objective of a 70 percent reduction in CO2 emissions by 2030. Fjernvarme Fyn delivers about 97 percent of the district heat requirement in Odense, providing heat for more than 100,000 households and large greenhouses.

The ANDRITZ scope of supply includes a biomass-fired boiler with flue gas cleaning and a flue gas condenser with absorption heat pump technology. Based on the ANDRITZ EcoFluid bubbling fluidized bed design, the boiler combines high efficiency with excellent environmental performance. The flue gas condenser with heat pump technology after the boiler significantly increases the district heat output and, therefore, improves the plant efficiency.

This new plant will be fuelled by wood chips as the main fuel and wood, olive and/or sunflower shell pellets as secondary fuel. The plant is capable of supplying close to 180 MW of heat to the district heating network and reaching record efficiency of almost 120 percent.

This order from Fjernvarme Fyn once again demonstrates ANDRITZ’s strong global position in the supply of state-of-the-art and environmentally friendly biomass boilers.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 27,200 employees and more than 280 locations in over 40 countries.

Shredders installed at one of Finland’s largest waste-to-energy plants

UNTHA has installed a robust shredding system at a new facility in Leppävirta, Finland, as one of the country’s biggest waste-to-energy power plant edges another step closer to completion.

Two XR3000 Ripper pre shredders and two XR3000 Cutter post shredders have been supplied to ANDRITZ, the turnkey solution provider responsible for delivering the state-of-the-art 123.300.000 EUR project for local utility company Riikinvomia Oy.

Capable of processing 145,000 tonnes of waste a year – collected from a region inhabited by 640,000 citizens – the new CFB (Circulated Fluidized Bed) plant will produce 16MW of electricity as well as 38MW for district heating, per annum.

The electric-drive pre shredders will achieve throughputs of 41 tonnes per hour, before the post shredders produce 16.5 tonnes of homogenous <80mm output fuel per hour.

Commenting on the project, UNTHA’s sales manager Andreas Neureiter said: “We began talking to ANDRITZ almost three years ago, which shows the level of care and meticulous planning that has gone in to ensure this project is executed perfectly.

“Our shredders were chosen due to their proven robustness, low noise and ease of maintenance. UNTHA’s ultra-efficient Eco Drive concept was also key, given the finished plant will have outstanding environmental credentials.”

With the pre and post shredders part of the same UNTHA series, all machines will utilise the same spare parts – another value-adding benefit. The technology is also single-drive as opposed to the more power consuming, dual-drive concepts proposed by competitors for this facility.

Andy concludes: “The Riikinvomia Oy plant is a highly talked about, ‘next generation’ plant, which makes this a very prestigious contract for our team. We look forward to the full start up in the final quarter of 2016.”

Plant manufacturer ANDRITZ has also been contracted to supply the CFRB boiler, wider waste treatment technology, flue gas cleaning systems, a steam turbine, electrification, automation and auxiliary systems.