Super User

New Alfa Laval ThinkTop pulse seat clean for drain valves saves up to 95% in CIP liquid

Drain valves comprise up to 20% of all valves in a typical processing plant. But cleaning them is costly, difficult and time-consuming due to long cleaning cycles and the risk of pressure shocks. The new Alfa Laval ThinkTop pulse seat clean addresses all these issues, quickly and effectively making drain valves spotless while delivering savings of up to 95% in Cleaning-in-Place (CIP) liquid.

ThinkTop is raising the bar on water savings yet again. The new pulse seat clean feature does for drain valves what the burst seat clean did in 2019 for mixproof valves. While burst seat clean reduces CIP liquid for mixproof valves by up to 90%, the pulse seat clean cuts drain valve CIP liquid consumption by up to 95%.

More savings, more uptime

Imagine the savings made possible by using this standard automated valve-position feature, triggered by a rising programmable logic controller (PLC) signal and controlled by the Alfa Laval ThinkTop V50 and V70 sensing and control units.

“The ThinkTop pulse seat clean brings unheard-of savings in CIP liquid to process plant owners and operators compared to conventional PLC timer-controlled seat cleaning,” says René Stietz, Product Portfolio Manager, Valves and Automation, Alfa Laval. “Alfa Laval is the first and only valve automation solutions provider to deliver significant savings in CIP liquid for drain valves.”

Faster, more effective pulse cleaning

Short bursts, or pulses, drive the valve cleaning process, activating the valve when shear forces peak. Each position-based pulse takes less than a second, preventing pressure shocks in the system. The pulse creates high turbulent flow as the liquid passes through the narrow gap between the valve house and valve seat, effectively removing all residuals for spotless drain valves.

100% cleaning validation of drain valves

The pulse seat clean makes control and validation of valve cleaning cycles easy. The valve position is not controlled by the PLC timer but by the Alfa Laval ThinkTop. Besides reducing the volume of CIP liquid used, programming the sensor to open and close the seat quickly ensures faster, more rigorous cleaning and hygiene than timer-controlled cleaning. The ThinkTop also verifies that valve cleaning has been completed.

Intended for use with single-seat valves or butterfly valves used as drain valves, pulse seat clean is a standard feature of ThinkTop V50 and V70 sensing and control units with one solenoid valve. Regardless of actuator mode, the drain valve may be configured as a normally open or normally closed shutoff or changeover valve. The pulse seat clean simplifies valve commissioning, prevents pressure shocks, and reduces CIP liquid and time.

To learn more, visit www.alfalaval.com/ThinkTop

This is Alfa Laval

Alfa Laval is active in the areas of Energy, Marine, and Food & Water, offering its expertise, products, and service to a wide range of industries in some 100 countries. The company is committed to optimizing processes, creating responsible growth, and driving progress – always going the extra mile to support customers in achieving their business goals and sustainability targets.

Alfa Laval’s innovative technologies are dedicated to purifying, refining, and reusing materials, promoting more responsible use of natural resources. They contribute to improved energy efficiency and heat recovery, better water treatment, and reduced emissions. Thereby, Alfa Laval is not only accelerating success for its customers, but also for people and the planet. Making the world better, every day. It’s all about Advancing betterTM.

Alfa Laval has 16,700 employees. Annual sales in 2020 were SEK 41.5 billion (approx. EUR 4 billion). The company is listed on Nasdaq OMX.

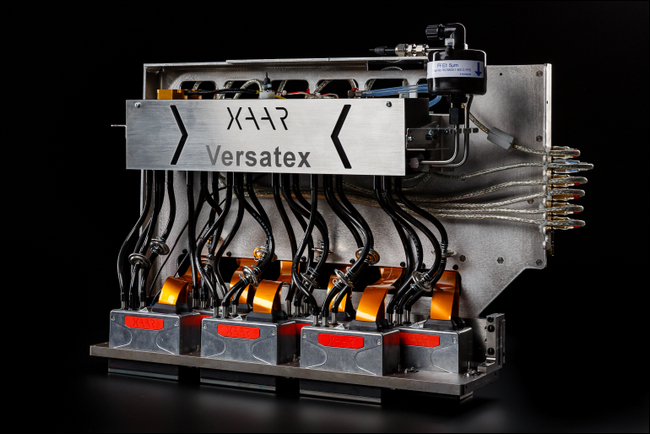

XAAR VERSATEX PRINT ENGINE AND NITROX ELITE GS3 PRINTHEAD TO DEBUT AT INPRINT

Xaar is launching its new Versatex ‘out-of-the-box’ print engine and the latest Nitrox Elite GS3 printhead at this year’s InPrint exhibition in Munich on 15-17th March.

Both exciting new developments will be on show in Hall A4, stand 2710, further establishing Xaar as industry leaders in unlocking the versatility and capability of digital inkjet in today’s manufacturing processes.

The Xaar Versatex provides users who have limited inkjet experience with the ability to fast track the digital inkjet development and integration process, allowing a speedy, cost effective and agile way for manufacturers to explore new potential applications.

Comprising a fully integrated datapath, ink supply system and supporting a large array of printheads from the ImagineX platform, the Xaar Versatex is a versatile, user-friendly and ready-to-go solution. It is available as both an evaluation kit, and a larger print engine and can be configured with multiple printheads up to 420mm in width.

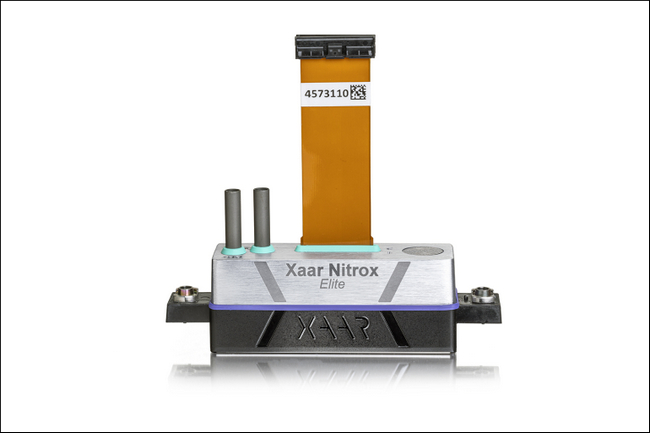

Alongside the Xaar Versatex, the Nitrox Elite GS3 printhead will be shown for the first time. The small drop variant printhead is the newest member of the Xaar Nitrox family and delivers improved print uniformity and drop placement, creating high-definition image resolutions for smoother skin tones, gradients and colours. This makes the Nitrox Elite GS3 ideal for label and graphic applications as well as enabling fine details and features for functional fluid applications, such as PCB printing.

Graham Tweedale, Chief Operating Officer at Xaar said, “We are delighted to be demonstrating our latest developments at InPrint, the leading show for emerging printing and industrial manufacturing.

“By providing our customers with the latest inkjet printheads, technologies and infrastructure – available all under one roof – Xaar is helping customers address their latest application requirements and seize their inkjet opportunity.”

About Xaar

Xaar is an inkjet innovator, providing printheads and technologies for OEM and UDI customers worldwide.

By helping customers lay down precise volumes of inks and fluids with absolute pin-point accuracy, time after time, Xaar’s inkjet printheads and technologies meet the needs of numerous markets. Covering graphics, labelling, direct-to-shape, packaging, product decoration, ceramic tile and glass decoration, décor, and outer case coding applications – as well as printing with specialist functional fluids for advanced manufacturing techniques.

Collaboration is at the very core of its business. Xaar works as a trusted partner from sites in Europe, China and North America, providing expert insights and technical support every step of the way.

With over 30 years’ experience, 280 patents registered or pending, and major ongoing R&D investment, Xaar’s digital printhead and precision jetting technologies create infinite opportunities for today’s sustainable manufacturing innovation.

New Revolutionary EcoSonic® VpCI®-125 ESD Shrink Film (HP-UV)

Multi-Metal Corrosion Protection with Strong Static Dissipative Properties!

New EcoSonic® VpCI®-125 ESD Shrink Film (HP-UV) combines the latest film technology with the most effective corrosion protection for all of your metal products. This revolutionary ESD shrink film is mixture of high (UV) and Vapor phase Corrosion Inhibitor Technology. This film is unique in its ability to prevent corrosion and ESD damage. It combines multi-metal corrosion protection with strong static dissipative properties. EcoSonic® VpCI®-125 ESD Shrink Film (HP-UV) has many practical characteristics. Users of the film can shrink wrap their small or large components as normal to conform to the shape of the object.

EcoSonic® VpCI®-125 ESD Shrink Film (HP-UV) replaces conventional rust preventatives such as oils and desiccants, allowing your product to be used immediately without cleaning or degreasing. Sealing your product in this VpCI® ESD Shrink Film will protect a wide variety of metals from rust, tarnish, stains and oxidation. It enables cost savings because EcoSonic® VpCI®-125 ESD Shrink Film (HP-UV) will eliminate all the degreasing or coating removal required in the past. The products can be used immediately. Additionally, it does not contain free amines, phosphates, or halogen-based materials and is non-toxic and recyclable.

EcoSonic® VpCI®-125 ESD Shrink Film (HP-UV) effectively protects components from electrostatic discharge. It conforms to the surface resistivity and static decay requirements of MILPRF-81705 D (Static Dissipative Packaging Materials). The film is safe to use and does not contain any harmful Prop 65 ingredients. EcoSonic® VpCI®-125 ESD Shrink Film (HP-UV) has been tested effective for up to 2 years of corrosion protection and 1 year of ESD protection. The corrosion inhibitors vaporize and condense on all metal surfaces within the enclosed space and diffuse to every area of your part; protecting its exterior, as well as void spaces and recessed areas. Equipment is completely protected from corrosion during storage, lay-up, and staging as well as during domestic and overseas shipments.

ADVANTAGES

- Contains Vapor phase Corrosion Inhibitors (VpCI®) to protect void

spaces and recessed areas

- Will shrink using a wide variety of shrink tools including electric and

propane heat guns

- Provides UV protection for outdoor storage

- Provides multi-metal VpCI® protection to ferrous and non-ferrous metals

Designed with the “Circular Economy” in Mind

This recyclable and non-toxic film prevents ESD damage while not affecting optical properties. It will not affect plastics used in electronic industry. The film meets NACE TM0208-2008 “Vapor Corrosion Inhibiting Ability” and NACE RP0487-2000 “Selection of Rust Preventives Standards”. Today, “greener” ways to approach packaging have become imperative. This includes looking at the entire range of the product’s life cycle—from raw material sourcing to disposal. With this in mind, Cortec® Corporation has been working tirelessly to introduce viable packaging options that can make the “circular economy” a reality. For more than two decades, Cortec® has been a leader in environmentally safe films and bags.

Cortec® Corporation is the global leader in innovative, environmentally responsible VpCI® and MCI® corrosion control technologies for Packaging, Metalworking, Construction, Electronics, Water Treatment, Oil & Gas, and other industries. Our relentless dedication to sustainability, quality, service, and support is unmatched in the industry. Headquartered in St. Paul, Minnesota, Cortec® manufactures over 400 products distributed worldwide.

Metso Outotec launches compact AC filter for advanced organics removal in battery metals processes

Metso Outotec is launching the Activated Carbon (AC) filter for efficient recovery and recycling of valuable battery chemicals. The energy- and water-efficient AC filter responds to the market’s increasing demand for advanced and sustainable battery metals processing technologies and is part of Metso Outotec’s Planet Positive portfolio.

“This launch will strengthen our capability to serve a large variety of industries and processes. Together with the Dual Media (DM) filter, Metso Outotec now has a complete filtration portfolio for solvent extraction (SX), electrowinning (EW) and crystallization processes. We have strong know-how from the hydrometallurgical industry with more than 50 successful filtration solutions references from SX and crystallization processes globally,” says Mika Vuorikari, Director of Industrial Filtration at Metso Outotec.

The modular AC filtration technology is designed for smaller side streams of copper and other metal-loaded aqueous streams. It is specifically suited for efficient organics removal before the electrowinning and crystallization processes. The AC filter utilizes the already proven design and operation philosophy of the Metso Outotec DM filter product family and is suitable for both greenfield and brownfield installations.

Metso Outotec AC Filter

Metso Outotec AC Filter

Benefits of the AC filter:

- Increased end-product yield and quality

- Increased recovery and recycling of valuable process chemicals

- Cost-effective and modular design

- Low energy consumption, due to low pumping pressure

- Minimized water consumption with optimized back washing

- Safe to use and operate, due to sealed pressure vessel and piping

Find out more about the Metso Outotec AC filter on our website.

Further information, please contact:

Timo Jauhiainen, Product Manager, Industrial Filtration, Metso Outotec Corporation, tel. +358 50 308 9900, email: timo.jauhiainen(at)mogroup.com

Helena Marjaranta, Vice President, Communications and Brand, Metso Outotec, tel. +358 20 484 3212, email: helena.marjaranta(at)mogroup.com

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales in 2021 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Automation supports large-scale production of green hydrogen

Semcon is supporting Norwegian Hystar to develop their new electrolyser technology for the production of green hydrogen. The aim is to produce up to 150% more hydrogen without using more energy than in conventional processes today.The project is now being expanded and Semcon is providing more expertise in order to automate the production of electrolyser stacks, which convert electricity to hydrogen and oxygen.

Hydrogen production technology using PEM electrolysers is currently well developed, but advanced development of automatic and flexible stack production processes is required in order to achieve large-scale hydrogen production. At the end of 2021, Hystar was granted additional funding from the Research Council of Norway for a project with the aim of optimising and automating the production of high-efficiency PEM electrolysers.

Electrolysers can be produced by similar mass manufacturing methods as fuel cells, a field of technology in which Semcon has extensive knowledge. These groundbreaking mass manufacturing methods are a prerequisite for Hystar to achieve its goal of revolutionising the production of electrolysers.

Semcon Hystar automation production green hydrogen

Semcon Hystar automation production green hydrogen

“We are happy and proud to contribute with our expertise in this Nordic collaboration, which ensures that both knowledge and production can be retained and developed in Sweden and our neighbour Norway,” says Robert Eliasson, Area Manager Production Development at Semcon.

The project, which is planned to run over two years, started in February 2022 on a smaller scale with the hope of expanding over time. Semcon has previously supported Hystar with expertise on stack design, in terms of mechanics and geometry, FEM (Finite Element Method) and CFD (Computational fluid dynamics).

“We are very excited to continue our collaboration with Semcon, and make sure our electrolysers stacks can be produced cost-effectively, automated, and at high volumes, “ says Alejandro Barnett, CTO at Hystar.

Read more about Semcon and Hystar’s collaboration for green hydrogen production.

Read more about Semcon’s offering in production development.

Semcon is an international technology company. We turn technology into excellent user experiences by combining digital edge and engineering expertise. With diverse multi-disciplinary teams we add new perspectives creating sustainable and competitive businesses. Regardless if you aim to recharge a current product or service, reinvent new technology or reimagine future needs, our focus is always on human needs and behaviour in order to develop solutions with the clearest benefits to people and our planet. By combining our 40 years of advanced engineering, strategic innovation, digital services and product information solutions, we drive transformation in a wide range of industries with more than 2,000 dedicated employees based in seven different countries. Read more on www.semcon.com

Steerprop Care online monitoring to enhance the reliability of three platform supply vessels

Steerprop has signed a five-year contract with Siem Offshore regarding the propulsion monitoring service Steerprop Care Premium for three of the Norway-based offshore vessel company’s platform supply ships.

Steerprop Care is designed to enhance the availability of a vessel by continuously monitoring the health of the main propulsion system, revealing any changes in the behavior that could indicate upcoming maintenance needs.

“Machine learning guides our experts in predictive maintenance to focus on the right measurements at the right time, revealing consequential changes in the behavior of the propulsion system,” says Jarkko Sirrola, PDM Manager at Steerprop. “With these insights, our team can work more efficiently, and we are able to provide information on equipment condition so well in advance that our customer can plan the upcoming maintenance as efficiently as possible.”

Mr. Sirrola points out that the new contract with Siem Offshore is an example of the marine industry’s increasing interest in streamlining the maintenance processes through online monitoring services.

Siem Offshore has signed a five-year-long monitoring contract regarding the online propulsion condition monitoring service Steerprop Care Premium on all three of its platform service vessels that are equipped with Steerprop’s propulsion system.

Siem Offshore has signed a five-year-long monitoring contract regarding the online propulsion condition monitoring service Steerprop Care Premium on all three of its platform service vessels that are equipped with Steerprop’s propulsion system.

“The new level of predictive maintenance will ultimately lead to an enhanced availability of the vessel, increased safety and optimized maintenance based on the real requirements of the propulsion system”, he says. “This also makes it possible to lengthen the overhaul intervals, to optimize the spare part consumption, and to avoid unplanned maintenance.”

Gives comfort

Siem Offshore’s contract covers the three 5.500 DWT platform supply vessels Siem Pride, Siem Symphony, and Siem Thiima, which are equipped with Steerprop’s propulsion units. The ships operate in Norwegian and Australian waters and the contract runs initially for five years.

Aaron Barbetti, Maritime Manager at Siem Offshore in Australia, says that Steerprop Care Premium appears to be the best and most efficient way to continuously monitor the state of the propulsion systems.

“We became interested in Steerprop Care Premium because it gives comfort in the operation of the vessels and streamlines the maintenance process onboard”, he says. “The experience so far matches our expectations, and we hope to see long-term dividends together with Steerprop.”

Three levels of monitoring

The basic version of Steerprop Care is named Standalone, and it gives the onboard crew basic information about the propulsion system condition. It is included in every propulsion unit delivery since 2019. The online versions Steerprop Care Plus and Premium offer more advanced measurement capabilities, and if any development occurs that might cause future disturbances on a ship, Steerprop’s predictive maintenance team will notify the crew, and provide remote assistance if necessary. Steerprop Care Plus and Premium are also available as a retrofit installation.

Siem Offshore

Siem Offshore’s fleet consists of 28 vessels, including platform supply vessels, tugs, and offshore subsea construction and well intervention vessels. The main office is in Kristiansand, Norway and the company has over 1.100 employees.

Steerprop

Steerprop is a leading designer and manufacturer of azimuth propulsion systems for the most demanding applications and toughest conditions. Since its founding in Finland in 2000, the company has delivered fit-for-purpose units for hundreds of vessels, including every third icebreaker in operation around the world. Steerprop’s unrivaled arctic experience and fit-for-purpose solutions are a testament to the company’s commitment to continuous development, steadfast dedication to meet the customers’ needs, and an unwavering resolve to perform.

Metso Outotec launches a new mobile impact crusher to the Nordtrack range

Metso Outotec adds a new impact crusher to its Nordtrack mobile crushing and screening range, targeting especially smaller-sized applications and jobsites in the construction and demolition waste recycling segment. The Nordtrack™ I1011 mobile impactor has compact dimensions and a powerful, high-performance crusher, ideally suited for contractors and rental work. Equipped with a large hanging screen, it combines high crushing capacity with calibrated end product accuracy.

The versatile Nordtrack I1011 crusher is suitable for working in different jobsites from rock crushing to concrete and demolition waste recycling. It is transported on a standard trailer, making it cost-effective and quick to move between sites. Thanks to its agility, moving the equipment in tight places inside the jobsites is easy. With Metso Outotec’s service support and global inventory of parts like different blow bar options, Nordtrack I1011 is a dependable choice for contractors and as a rental machine.

“We have listened to the feedback from our customers and are happy to offer this newest addition to our Nordtrack range. The launch of Nordtrack I908S was very successful, and consequently we have been asked for a bigger mobile impactor unit,” says Vesa Tuloisela, who heads the Nordtrack product offering at Metso Outotec. “The I1011 has a more powerful crusher and engine, resulting in a capacity as high as 300 tph. As a mobile crusher it also is well suited for the recycling of demolition and concrete waste, or reclaimed asphalt,” he continues.

Nordtrack I1011 will be launched in Metso Outotec’s Nordtrack Liveroom, which is a 360° digital event experience platform. Liveroom features 3D demonstrations of the Nordtrack range as well as a wealth of information on the aftermarket offering.

Read more about Nordtrack™ at www.mogroup.com/nordtrack

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2021 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Joint EMITE and Anritsu solution adds 6 GHz band to test latest Wi-Fi 6E devices

EMITE and Anritsu Corporation have added the 6 GHz band to their newly integrated testing system, allowing testing to the new IEEE 802.11ax WLAN standard. The new band adds to the already available 2.4 GHz and 5 GHz bands.

Anritsu’s Wireless Connectivity Test Set MT8862A has been integrated with the EMITE E600 Reverberation Chamber, allowing developers to test the OTA TRP/TIS performance of IEEE 802.11ax devices in a repeatable environment.

Offering integrated communications protocols and optimized performance for testing, the EMITE reverberation chamber and Anritsu MT8862A provide reliable characterization of the latest Wi-Fi 6E devices on the market.

The newly integrated system can measure the total radiated power (TRP) and total isotropic sensitivity (TIS) OTA performance indicators in IEEE 802.11ax devices. With the ability to test and implement the latest standards, developers and service providers can offer solutions to the market with total confidence in their performance.

“We are proud to commit ourselves to a continuous improvement process in order to deliver the newest solutions with the collaboration of Anritsu’s platform and our E600 Reverberation Chamber. Taking small steps is the key to success in such fast-changing markets and technologies. Once again, we have worked closely with leading companies in the telecommunication sector to help develop this solution for their OTA platforms,” said Miguel Mora, Head of Support department at EMITE.

Keita Masuhara, Product Manager, IoT Test Solutions Div., Anritsu Corporation, said, “Expanding to the new frequency range and wider bandwidth will benefit many vertical industries.

We are proud to release this addition supporting applications that link emerging technologies and our products. Anritsu continues to provide test solutions by working with its leading-edge partners.”

About EMITE

EMITE Ingeniería, S.L. is a high‐tech company, spin‐out from the Technical University of Cartagena (Spain). EMITE designs, develops, manufactures and commercializes OTA Test Systems for performance, compliance and pre‐compliance testing of any 2G to 5G standards and pre‐standards worldwide, including 5G, LTE‐A and Wi-Fi (up to 6E). Headquartered at the Fuente Álamo High Tech Park in the Region of Murcia (Spain) and with distributors in 25 countries, test house show rooms in America, Asia and Europe, and both national and international awards, EMITE OTA Test Systems are being used worldwide by carriers, OEMs, test labs, regulatory authorities and many others around the wireless ecosystem. With a customer‐driven roadmap and a vision of changing the way technology gets through our life, EMITE OTA Test Systems are more than just chambers, bringing OTA testing into a new era of capabilities and easiness. EMITE MIMO OTA Test Systems were selected by 3GPP and CTIA as candidate methodology for the study and work items through standardization of LTE MIMO OTA test methods.

About Anritsu

Anritsu Corporation (www.anritsu.com), a global provider of innovative communications test and measurement solutions for 125 years. Anritsu’s philosophy engages customers as true partners to help develop wireless, optical, microwave/RF, and digital solutions for R&D, manufacturing, installation, and maintenance applications, as well as multidimensional service assurance solutions for network monitoring and optimization. Anritsu also provides precision microwave/RF components, optical devices, and high-speed electrical devices for communication products and systems.

The company develops advanced solutions for 5G, M2M, IoT, as well as other emerging and legacy wireline and wireless communication markets. With offices throughout the world, Anritsu has approximately 4000 employees in over 90 countries.

Driving up renewable fuel technology

Sulzer Chemtech will provide a BioFlux® technology package to support the creation of the Sabah Maju Jaya Renewable Energy Industrial Complex (SMJREIC) in Malaysia. This new state-of-the-art facility will produce sustainable fuels with limited greenhouse gases emissions by using locally-sourced, renewable feedstock. By leveraging Sulzer Chemtech’s leading expertise in innovative licensed technologies, the new plant located at Sapangar Bay, Kota Kinabalu, will deliver an annual production capacity of 250’000 tonnes.

Sulzer Chemtech will provide key technology and engineering services to support the creation of the Sabah Maju Jaya Renewable Energy Industrial Complex (SMJREIC) in Malaysia.

Sulzer Chemtech will provide key technology and engineering services to support the creation of the Sabah Maju Jaya Renewable Energy Industrial Complex (SMJREIC) in Malaysia.

Vandelay Ventures Sdn Bhd has preselected Sulzer Chemtech (GTC Technology) to be the preferred process technology provider for the main processes at the ambitious 10’000 m2 processing complex in Kota Kinabalu. This will utilize plant-based oils for the production of sustainable aviation fuel (SAF), renewable diesel (HVO) and renewable naphtha as a byproduct. More precisely, the SMJREIC’s infrastructure will rely on the proprietary BioFlux® technology offered by Sulzer Chemtech in cooperation with Duke Technologies for the conversion of various pretreated feedstocks to either HVO or SAF while generating much lower emissions than conventional processes.

The unit will complement the centralized edible oil bulking terminal, which will have an annual capacity of 30’000 tonnes, and supply high-quality feed the HVO/SAF plant, with capacity of 250’000 tonnes per year. In addition to this key technology, Sulzer Chemtech will provide engineering services as well as installation, commissioning and startup support.

The company was selected for its leading expertise in sustainable manufacturing technologies as well as the ability to provide the BioFlux® licensed solution. Bioflux®, developed by Duke Technologies LLC in the US and licensed by Sulzer Chemtech (GTC Technology) globally, is the only licensed technology with an innovative liquid phase full reactor design that maximizes hydrogen availability and eliminates the vapor recycle loop. This significantly reduces the capital expenditure (CAPEX) and operational expenses (OPEX) while improving yield and catalyst life.

Vandelay Ventures Sdn Bhd has preselected Sulzer Chemtech to be the preferred process technology provider for the production of sustainable fuels.

Vandelay Ventures Sdn Bhd has preselected Sulzer Chemtech to be the preferred process technology provider for the production of sustainable fuels.

Haji Mohamed Mohar, CEO at Vandelay Ventures Sdn Bhd, comments: “Our goal to build an energy complex to help drive forward Malaysia’s decarbonisation efforts and economic development needs to be backed by state-of-the-art technology. Sulzer Chemtech and BioFlux® were the obvious choices to help us make SMJREIC a reality. We look forward to starting operations and producing high-quality biodiesel.”

Chan KorWeai, Commercial Director Asia Pacific for Global Technology Business at Sulzer Chemtech, concludes: “We are excited to support such a visionary project that aims to drive up renewable fuel production and usage in Malaysia. In particular, as a native of this country and working for Sulzer Chemtech for many years, I am proud to be leveraging advanced technologies to sustainably fuel the local economy and generate future-oriented job opportunities. We look forward to supporting more ambitious green projects such as SMJREIC.”

About BioFlux®

BioFlux® is a registered trademark of Duke Technologies, LLC. Sulzer Chemtech (GTC Technology) licenses the BioFlux® technology and provides engineering services for the process under a technology and business cooperation agreement.

About Sulzer

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and application technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class manufacturing facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2021, our 13’800 employees delivered revenues of CHF 3.2 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN).

The Chemtech division is the global market leader in innovative mass transfer, static mixing and polymer solutions for chemicals, petrochemicals, refining and LNG. We are steering the way in ecological solutions such as bio-based chemicals, polymers and fuels, recycling technologies for textiles and plastic as well as carbon capture and utilization/storage, contributing to a circular and sustainable economy. Our product offering ranges from process components to complete process plants and technology licensing.

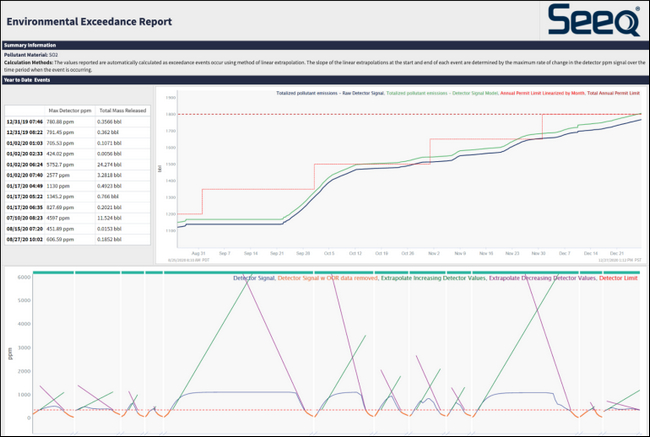

Seeq to Showcase Work with AWS at CERAWeek

Seeq helps customers reduce carbon intensity and increase productivity as a launch partner for the AWS Emissions Monitoring and Surveillance Solution and Flare Monitoring and Optimization Solution.

Seeq Corporation, a leader in manufacturing and industrial internet of things advanced analytics software, announced that it is a launch partner for Amazon Web Services, Inc. (AWS) Emissions Monitoring and Surveillance Solution and Flare Monitoring and Optimization Solution at CERAWeek 2022, an energy conference held in Houston, Texas from March 7-11. Seeq is also speaking and exhibiting at the event.

The AWS Emissions Monitoring and Surveillance Solution automates integration of methane emissions data sources from disparate third-party sources into tools and workflows to prioritize repairs, analyze operations, and lower emissions. The AWS Flare Monitoring and Optimization Solution helps customers accelerate deployment of architecture to measure venting and flaring volumes, pilot status, and combustion efficiency, as well as enable flare optimization models and workflows.

Seeq will be demonstrating its emissions monitoring and reporting use cases in the AWS Agora House, located within the Innovation Agora, the conference’s open marketplace for conversations and presentations on energy innovation, emerging technologies, and solutions.

Additionally, Seeq’s Chief Executive Officer, Dr. Lisa Graham, will join fellow industry leaders at CERAWeek in the Innovation Agora to discuss how digitalization is driving sustainability in the energy sector.

- Accelerating Insights and Impact for Sustainability with Industrial Analytics: On March 8th at 9:00 a.m., Dr. Graham will discuss how digitalization—including industrial data analytics—empowers manufacturers to leverage existing assets to achieve measurable progress toward environmental key performance indicators in Agora Pod #5. Her presentation will highlight Seeq’s use cases for predictive energy modeling and greenhouse gas emissions reporting.

- New generation data analytics tools for emission reduction in oil and gas: On March 9th at 1:00 p.m., Dr. Graham will participate in a Carbon Management Hub panel discussion on the need for improved analytics capabilities to ensure the success of emissions reduction projects in oil and gas.

“The energy sector recognizes that it has a moral, social, and economic obligation to address sustainability issues as a top corporate objective, but many organizations still struggle with determining the best approach to address concerns,” said Dr. Lisa Graham, Chief Executive Officer at Seeq. “As part of a larger digitalization effort, organizations can use advanced analytics applications to enable greater insight into environmental performance and engage employees at all levels to directly and positively impact their environmental footprints.”

Seeq customers include companies in the oil and gas, pharmaceutical, chemical, energy, mining, food and beverage, and other process industries. Investors in Seeq, which have raised over $100M to date, include Insight Ventures, Saudi Aramco Energy Ventures, Altira Group, Chevron Technology Ventures, and Cisco Investments.

Seeq is available in AWS Marketplace, has achieved AWS Partner Network Energy and Industrial Software Competency status, and supports many AWS services including Amazon Redshift, Amazon Simple Storage Service (Amazon S3), AWS IoT SiteWise, IoT data from Amazon Monitron, plus machine learning in Amazon SageMaker, Amazon Lookout for Equipment, and others.

In addition to AWS data services, Seeq connects to an extensive set of data storage platforms from vendors including OSIsoft, Siemens, GE, Honeywell, Inductive Automation, AVEVA, AspenTech, Yokogawa, InfluxDB, Snowflake, and others. Seeq is available worldwide through a global partner network of system integrators, which provides training and resale support for Seeq in over 40 countries, in addition to its direct sales organization in North America and Europe.

To learn more about Seeq, visit Seeq.com.

About Seeq

Founded in 2013, Seeq publishes software applications for manufacturing organizations to rapidly find and share insights. Oil and gas, pharmaceutical, specialty chemical, utility, renewable energy, and numerous other vertical industries rely on Seeq to improve production outcomes, including yield, margins, quality, and safety. Headquartered in Seattle, Seeq is a privately held virtual company with employees across the United States and sales representation in Asia, Canada, Europe, and South America. To learn more about Seeq visit ww.seeq.com