Displaying items by tag: metso

Metso to deliver key crushing and grinding technology to the Hemi Gold Project in Australia

Australian mining company De Grey Mining Limited has awarded Metso orders for a Superior™ MKIII 50-65 primary gyratory crusher and two 14MW Premier™ ball mills. The equipment will be installed at De Grey Mining’s Hemi Gold Project located in the Pilbara region of Western Australia. The combined order value of over EUR 20 million is booked in the Minerals segment’s first-quarter 2024 orders received.

“Our aim with the Hemi Gold Project is to deliver a Tier 1 gold project and make a future top 5 Australian Gold Mine from a production perspective. The 10+ Mtpa process circuit will be equipped with state-of-the-art equipment and proven technologies contributing to responsible ore processing. We’ve just partnered with Metso in delivering the first key items for the process circuit, namely the primary gyratory and ball mills, and we’re looking to make the rest of the process equipment decisions soon. De Grey will make a series of payments according to milestones achieved over the manufacturing period and final commissioning, typical for contracts of this nature, commencing in March 2024,” says Glenn Jardine, Managing Director of De Grey Mining.

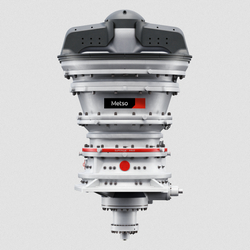

“Metso’s third generation Superior™ MKIII primary gyratory crusher, renowned for its safe and efficient operation, will be the driving force for Hemi Gold’s entire processing circuit, and the two Premier™ ball mills will provide optimized grinding performance and the highest availability for the concentrator. Both mills are equipped with failsafe Metso Polymer Hydrostatic Shoe Bearing (HSB) systems, significantly increasing reliability and reducing maintenance costs,” says Kai Rönnberg, Vice President, Minerals, Asia Pacific at Metso.

“We look forward to working on this project and future ones with De Grey Mining. In terms of servicing our customers when plants are operational, Metso also has an extensive footprint in Australia. Our state-of-the-art Karratha Service Centre in the Pilbara, which will be Metso’s largest Service Centre globally, opens this March. The Karratha Service Centre will be able to support our customers, as well as the Hemi plant, with the latest technologies and sustainable aftermarket solutions,” concludes Rönnberg.

About the products

The Metso Superior™ MKIII primary gyratory crushers provide high throughput and less downtime, enabling maximum efficiency for the operation. The product family has been developed especially to meet the needs of customers with changing ore grades and conditions in mining operations. Metso also provides a comprehensive scope of spare and wear parts and services to optimize the crushing circuit operation throughout the lifecycle. Since the product family’s launch in 2018, Metso has sold more than 50 Superior™ MKIII primary gyratory crushers around the world.

For horizontal grinding mills, Metso offers the industry’s widest selection, including the Planet Positive Metso Premier™ and Select™ mills. The energy-efficient mills can be easily integrated with Metso mill relining equipment and are supported by an extensive services network to ensure optimization during the mills’ lifetime. Metso also offers the market’s most comprehensive mill linings range and relining services, with materials and designs optimized for each application.

Learn more about Metso’s primary gyratory crushers and grinding mills on our website.

Metso is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. We improve our customers’ energy and water efficiency, increase their productivity, and reduce environmental risks with our product and process expertise. We are the partner for positive change.

Headquartered in Espoo, Finland, Metso employs over 17,000 people in close to 50 countries and sales for 2023 were about EUR 5.4 billion. The company is listed on the Nasdaq Helsinki. metso.com

Metso to deliver key crushing equipment for the Simandou iron ore project in Guinea

Metso has received an order from Winning Consortium Simandou (WCS) for the supply of key crushing equipment for their concentrator plant at Simandou Iron Ore Blocks 1 and 2 in the Republic of Guinea. The value of the order exceeds EUR 10 million, and it is booked in Minerals’ 2023 fourth-quarter order intake.

Metso’s scope of delivery consists of 16 Nordberg® HP900™ secondary and tertiary cone crushers. Metso’s Nordberg® HP Series has over 10,000 installations worldwide in the aggregate and mining industries.

“We are pleased to be chosen as the supplier of the state-of-the-art crushing equipment for the Simandou iron project by WCS. We will leverage our global knowledge and resources to support the success of this project,” says Xun Fang, Head of Metso’s Minerals Sales in Greater China.

Winning Consortium Simandou has been set up by the founders of SMB Winning Consortium, namely Winning International Group from Singapore, China Hongqiao, and UMS Guinea. WCS won the public tender to develop Simandou Iron Ore Blocks 1 and 2 in November 2019 and signed a Base Convention agreement with the Guinean Government in June 2020.

Read more about Metso’s offering for the mining industry on our website.

Metso is a frontrunner in providing sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By helping our customers increase their productivity, improve their energy and water efficiency and environmental performance with our process and product expertise, we are the partner for positive change.

Headquartered in Espoo, Finland, Metso employs over 16,000 people in close to 50 countries and sales for 2022 were about EUR 5.3 billion. The company is listed on the Nasdaq Helsinki. www.metso.com

Metso awarded contract to deliver MP800TM cone crushers for an Australian iron ore mine

BHP has awarded Metso an order for three high-capacity Nordberg® MP Series™ cone crushers to be installed at its Whaleback mine in Western Australia. This order is booked in the Minerals segment’s third-quarter 2023 orders received.

“The MP800™ cone crushers will replace the long-serving MP cone crushers. The robust and high-capacity MP Series crushers are a step change in the crushing process, enabling maximum operator safety and easy maintenance, as the key components can be accessed from the top of the crushers. They provide a more sustainable solution, delivering high crushing force with relatively low energy consumption,” explains Vinicius Vilela, Vice President, Mining Crushers at Metso.

Metso’s cone crusher offering includes four product families for different applications and operations. The Nordberg® MP Series™ cone crushers feature high capacity and high crushing force for size reduction with good energy efficiency. In addition, Metso has a wide offering of cone crusher spare and wear parts and services to enable stable production, safety, and reliability without unexpected downtime.

Metso’s cone crusher offering includes four product families for different applications and operations. The Nordberg® MP Series™ cone crushers feature high capacity and high crushing force for size reduction with good energy efficiency. In addition, Metso has a wide offering of cone crusher spare and wear parts and services to enable stable production, safety, and reliability without unexpected downtime.

Read more about MP Series™ cone crushers on our website.

Further information:

Kai Rönnberg, Vice President, Minerals Sales, Asia Pacific, Metso, tel. +61 407 020 306, email: kai.ronnberg(at)mogroup.com

Helena Marjaranta, Vice President, Communications and Brand, Metso, tel. +358 20 484 3212, email: helena.marjaranta(at)mogroup.com

Metso is a frontrunner in providing sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By helping our customers increase their productivity, improve their energy and water efficiency and environmental performance with our process and product expertise, we are the partner for positive change.

Metso to deliver 16 cone crushers for Rio Tinto’s iron ore mines in Australia

Rio Tinto has awarded Metso an order for ten HP Series cone crushers to be installed at the Tom Price iron ore mine in Western Australia. This order follows the initial award of six HP series cone crushers in late 2022. The crushers in the initial order are currently being delivered to the Paraburdoo iron ore mine and the Pilbara mine. The latest order is booked in the Minerals segment’s third-quarter 2023 orders received.

“The HP500™ cone crushers will replace the long-serving Symons cone crushers. The compact and versatile HP Series crushers are a step change in the crushing process, enabling maximum operator safety and easy maintenance as the key components can be accessed from the top of the crushers. They provide a more sustainable solution, delivering high output with decreased energy consumption despite their smaller size. Additionally, the new crushers feature an option for digitizing the operation,” explains Julius Mäkelä, Vice President, Mid-size and Mobile Crushers at Metso.

The compact size of the HP500™ cone crusher is well suited as a replacement for Symons crushers. The HP500™ is utilized in aggregates production, quarrying applications, and mining operations worldwide.

Read more about Metso HP500™ cone crushers on our website.

Metso is a frontrunner in providing sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By helping our customers increase their productivity, improve their energy and water efficiency and environmental performance with our process and product expertise, we are the partner for positive change.

Headquartered in Espoo, Finland, Metso employs over 16,000 people in close to 50 countries and sales for 2022 were about EUR 5.3 billion. The company is listed on the Nasdaq Helsinki. metso.com

Metso awarded orders for a gyratory crusher and a major apron feeder package in the Americas

Metso has been awarded orders for a gyratory crusher and apron feeders including related services and spare parts to support a mining customer project in the Americas. The value of the orders is approximately EUR 20 million, of which 80% were booked in Minerals segment’s first-quarter orders received and the balance in Minerals segment’s second quarter.

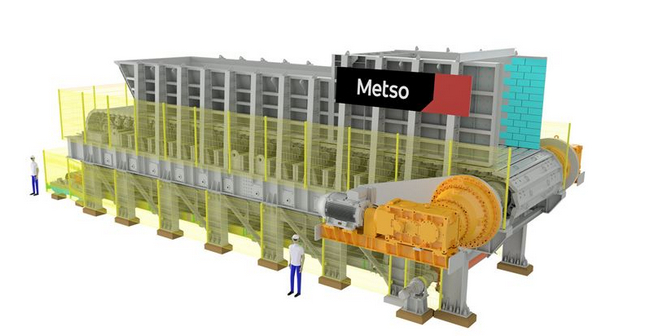

Metso Superior MKlll primary gyratory crusherMetso’s scope of delivery includes an impressive apron feeder package featuring Metso’s AF18 apron feeder, one of the largest feeders that Metso has ever produced. The apron feeder supplies material downstream to a Metso Superior™ MKIII primary gyratory crusher. The gyratory crusher accepts the largest top size feed in the market, allowing it to provide higher capacities, which makes this crusher the most cost-efficient primary gyratory crusher in the industry.

Metso Superior MKlll primary gyratory crusherMetso’s scope of delivery includes an impressive apron feeder package featuring Metso’s AF18 apron feeder, one of the largest feeders that Metso has ever produced. The apron feeder supplies material downstream to a Metso Superior™ MKIII primary gyratory crusher. The gyratory crusher accepts the largest top size feed in the market, allowing it to provide higher capacities, which makes this crusher the most cost-efficient primary gyratory crusher in the industry.

“We are excited to be able to support our customers to ensure their needs are met. It is especially rewarding when we are able to demonstrate our capabilities for flowsheet synergies such as crushers and apron feeders as this equipment works hand in hand for minerals processing,” says Guillaume Lambert, SVP, Crushing at Metso.

Metso has the capability to design and deliver even the largest apron feeder systems with high project quality. Combined with our advanced line of mining duty crushers, Metso offers complete solutions providing flexible and reliable material processing to meet high demands and ensuring the success of our customers.

Metso AF18 Apron Feeder

Metso AF18 Apron Feeder

Read more about Metso Outotec’s feeding and crushing solutions on our website.

Metso is a frontrunner in providing sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By helping our customers increase their productivity, improve their energy and water efficiency and environmental performance with our process and product expertise, we are the partner for positive change.

Headquartered in Helsinki, Finland, Metso employs over 16,000 people in close to 50 countries and sales for 2022 were about EUR 5.3 billion. The company is listed on the Nasdaq Helsinki. metso.com

Metso to supply service and spare parts to iron ore plant in Europe

Metso has received a repeat order to an iron ore processing plant in Europe, for a replacement chain for their iron ore pelletizing system.

Metso’s complete chain package delivery consists of more than 6000 high-quality grate plates, chain links, through rods, and side plates supported by comprehensive maintenance and full services to maximize production uptime.

The order valued EUR 9 million has been booked in the Minerals’ segment first-quarter orders received.

The order valued EUR 9 million has been booked in the Minerals’ segment first-quarter orders received.

"We are honored that the customer has chosen Metso to provide critical components for this important project," said Roar Vasboe, Vice President of Sales and Services Nordics for Metso. "Our team is dedicated to providing high-quality, reliable products that meet the needs of our customer. We are committed to sustainability and continuous improvement, and we are confident that our solution will help them to achieve their production goals safely and efficiently."

Metso is the only supplier in the world that has both the straight grate and the grate kiln process for pelletizing.

Metso has designed and supplied the most modern and largest grate kiln systems in the world. These plants have the highest outputs with the lowest fuel usage and lowest emissions.

Discover more about Metso iron ore pelletizing on our website.

Metso is a frontrunner in providing sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By helping our customers increase their productivity, improve their energy and water efficiency and environmental performance with our process and product expertise, we are the partner for positive change.

Headquartered in Helsinki, Finland, Metso employs over 16,000 people in close to 50 countries and sales for 2022 were about EUR 5.3 billion. The company is listed on the Nasdaq Helsinki. metso.com

VALVES - Metso’s industry-leading Neles globe valve technology selected for Abu Dhabi Oil Refinery’s (TAKREER) plant

Metso will supply industry-leading Neles® globe valve technology to Abu Dhabi Oil Refinery Company's (TAKREER) chemical refining complex in in the United Arab Emirates. The deliveries will include hundreds of Metso's Neles Globe control and on-off valves. Most of the control valves are equipped with Neles ND9000 intelligent valve controllers (FOUNDATION Fieldbus) for performance follow up and predictive maintenance, resulting improved process efficiency and uptime.

Metso will supply industry-leading Neles® globe valve technology to Abu Dhabi Oil Refinery Company's (TAKREER) chemical refining complex in in the United Arab Emirates. The deliveries will include hundreds of Metso's Neles Globe control and on-off valves. Most of the control valves are equipped with Neles ND9000 intelligent valve controllers (FOUNDATION Fieldbus) for performance follow up and predictive maintenance, resulting improved process efficiency and uptime.

The valves will be installed in a carbon black and delayed coker plant currently under construction. Once completed in December 2015, the plant will process 30,000 barrels of crude oil per day and have an annual production capacity of 40,000 tons of carbon black. The refining complex is located in Ruwais some 240 kilometers west of Abu Dhabi City in the United Arab Emirates.

South Korean Samsung Engineering, which will provide project management services for the engineering, procurement, construction and commissioning processes on a turnkey basis, has chosen Metso's valve technology for the demanding project. "It is the largest project ever executed by our company, and the total valve quantities are huge," says Mr. YunKi Sung, Vice President, Procurement Dept., Samsung Engineering. "We chose Metso as our valve partner because we can rely on fast expediting; their valve factory is conveniently located close us to us in South Korea.''

''Also, we have had good support from Metso in our past projects. To ensure smooth startups, Metso offers its wide product knowledge and application expertise, global manufacturing facilities and sourcing, full expediting and inspection support, a global service network and comprehensive startup support.''

Metso has valve technology centers and production facilities in Finland, the United States, Germany, China, South Korea, India and Brazil. Metso's deliveries will take place in August 2014.

Most comprehensive control valve range on the market

Today, Metso's control valve range is the most comprehensive one on the market. It includes globe valves, top entry rotary valves, triple eccentric disc valves, eccentric rotary plug valves, and segment valves. There is a suitable product for every application, ranging from general to severe service and from low temperature or pressure to high temperature or pressure.

Metso's control valve solutions are known for providing optimized performance and extreme reliability in demanding refining processes. "Cutting-edge valve solutions provide measurable operational efficiency and increased profitability. They increase yield, reduce energy consumption, lower maintenance costs and manage changes in the process, among others," points out Daisy Kim, Product Manager, Automation, Metso.

Reliable and safe process operation gained with Metso's technology is visible through fewer production interruptions and less downtime, longer uptime between maintenance shutdowns, as well as compliance with environmental regulations and safety legislation.

"During the engineering, procurement and construction stages of a project, cooperation with Metso means fewer engineering and planning hours, expert engineering and application support, as well as easier product sizing and selection with hi-tech tools and services," Ms Kim continues. "We also provide customers with our total project planning and management capabilities, along with application-specific valve technologies."

Experienced in valves with strong production foothold

Metso has a long track record of delivering engineered performance and reliability to the oil & gas industry through its leading product brands - Neles®, Jamesbury® and Mapag® - and has delivered millions of valves, control valves, and on-off valves globally more than 90 years, and has become one of the leading suppliers of intelligent valve controllers. Metso's valve technology and services offering helps maximize production efficiency and reduce safety risks throughout the life cycle of a plant, all the way from simplifying valve selection to improving process availability and maximizing production performance.

About the Abu Dhabi Oil Refining Company (TAKREER)

The Abu Dhabi Oil Refining Company (TAKREER) was established in 1999 as a public joint-stock company to take over the responsibility of refining operations previously undertaken by the Abu Dhabi National Oil Company (ADNOC). The company's areas of operation include the refining of crude oil and condensate, supply of petroleum products and production of granulated sulfur in compliance with domestic and international specifications.

Metso's automation solutions are designed to maximize the profitability of our customers' businesses by improving their production performance and their cost, material and energy efficiency. Our extensive range of flow control and process automation solutions and services is supported by a worldwide network of automation experts. The Automation business' biggest customer industries are oil & gas, and pulp and paper. We also have a strong growth focus in mining and construction and power generation.

www.metso.com, www.twitter.com/metsoautomation

Metso is a leading process performance provider, with customers in the mining, construction, and oil & gas industries. Our focus is on the continuous development of intelligent solutions that improve sustainability and profitability. Metso's shares are listed on the NASDAQ OMX Helsinki Ltd. Metso employs around 16,000 professionals in 50 countries. Expect results.

For further information, please contact: This email address is being protected from spambots. You need JavaScript enabled to view it.