Super User

Gold production from top eight companies expected to increase by up to 3.1% in 2021, says GlobalData

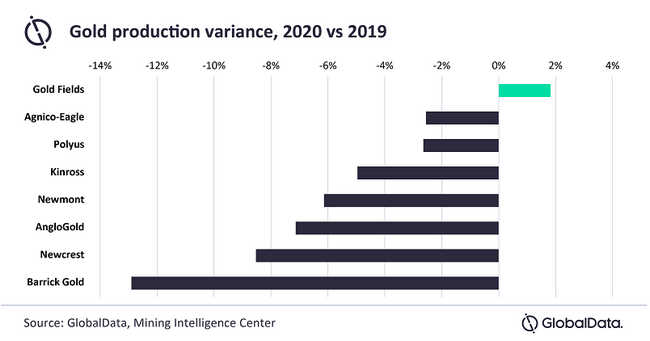

Production from the world’s eight largest gold producers (Newmont, Barrick, AngloGold, Polyus, Kinross, Gold Fields, Newcrest and Agnico-Eagle) decreased by 6.5% to 25 million ounces (moz) in 2020 due to lower ore grades, sale of assets, lower mill throughput and lower recoveries. Production from the top eight companies is expected to recover and will be between 25-25.75 moz in 2021, which is an increase of up to 3.1% compared with the collective output in 2020 (24.98moz), according to GlobalData, a leading data and analytics company.

The most significant falls in production were observed among the top three companies: Newmont (6.1%), Barrick (12.9%) and AngloGold (7.1%). The collective output from these companies declined to 13.7moz in 2020 from 15moz in 2019.

Vinneth Bajaj, Associate Project Manager at GlobalData, comments: “After a strong first quarter in 2020, Newmont’s production was impacted by lower ore grades at the Ahafo, Yanacocha and Merian mines and the temporary suspension of the Cerro Negro, Yanacocha, Eleonore, Penasquito and Musselwhite mines between March and mid-May. In addition, the sale of Red Lake and Kalgoorlie projects further reduced output.”

For Barrick, several gold mines were forced to cease operations temporarily due to the COVID-19 pandemic, including the Veladero, Pueblo Viejo and Porgera mines. Meanwhile, divestment of African assets by AngloGold was a major factor behind the fall in the company’s output in 2020.

Bajaj continues: “Lower ore grades, sale of assets, lower mill throughput and lower recoveries were key factors affecting production across the remaining major gold producers. For example, lower ore grades at Paracatu, Round Mountain and Chirano mines were behind the drop in production from Kinross, although it was partially offset by higher output from the company’s Bald Mountain and Kupol operations.”

Newcrest’s production was severely affected by the sale of Gosowong mine, which was acquired by Indotan Halmahera in Q2 2020. Lower throughput rates and lower grades at Cadia, Lihir, Red Chris, and Telfer mines, amid a series of planned shutdowns, also impacted the company’s production subsequently.

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

Petrobras must play its part to invest in other less capital-intensive sustainability efforts to reduce emission, says GlobalData

Despite a global effort in energy transition, Petrobras has expressed no interest to pivot into renewable energy due to lack of expertise. As a leader in Brazil, it must play its part to invest in other less capital-intensive sustainability efforts to reduce emission, says GlobalData, a leading data and analytics company.

The company laid out a comprehensive goal in reducing total operational emission by 25% by 2030. Its sustainability efforts include launching ten commitments to minimise GHG emission, increasing carbon capture and water reutilization, continuing to invest in reducing scope 3 emissions and finding new energy alternatives.

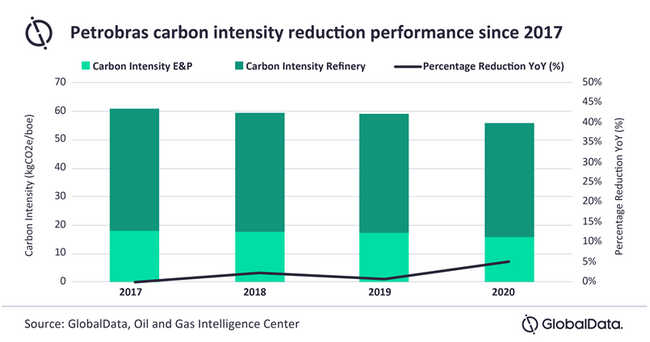

Petrobras has proved a successful track record in reducing carbon intensity since 2017. The majority of the carbon emission originates from the company’s downstream refinery. Some of its main efforts that drives the reduction of emissions in exploration and production and refinery is through reduction of flaring, improving energy transfer efficiency and introduction of carbon reinjection technology.

Steven Ho, Upstream Oil & Gas Analyst at GlobalData, comments: “Petrobras very much remains bullish in global demand for oil and gas, along with many of its US counterparts. During rosy times, the company invested heavily in many oil and gas fields, resulting in a substantial load of debt. Therefore, the company’s current priority is to leverage on its expertise and increase production from its core assets such as Buzios pre-salt field, while reducing its operational cost to be able to sustain through a lower Brent price given the current volatility.”

Petrobras also plans to ramp up its natural gas production and in further term become a net exporter. The company recently entered a partnership with Golar Power for the development of an LNG distribution business, which displays its intention to expand into the LNG fuel domestic market. Besides that, the company also plans to diversify into LNG liquefaction plant in 2025, which may be the company’s first LNG export-related plan in the future. Petrobras’ effort to incorporate more natural gas and LNG into its production mix will indirectly support its sustainability effort due to the nature of the cleaner fuel which has lower carbon emission.

Steven continues: “Renewable energy projects are capital-intensive and may have longer pay out and are, therefore, deemed unsuited in Petrobras’ vision given its effort to conserve cash to repay debt in the shortest time possible. In fact, the company has recently divested of a wind farm, Eolica Mangue Seco 2. Therefore, the company has to rely heavily on its current initiative to reduce flaring and carbon capture projects to ultimately achieve its sustainability commitments.”

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

Innovative 3D vision system opens up new possibilities for automated inspection

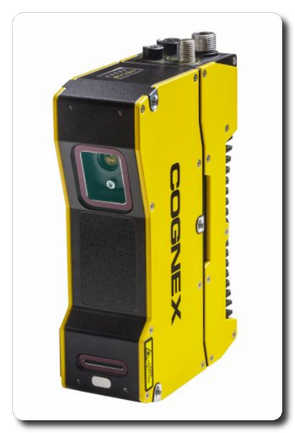

All in one: The In-Sight 3D-L4000 simplifies 3D inspections by having image processing already integrated in the system.An exciting new 3D vision system now makes inspecting parts in 3D as easy as using a 2D smart camera. While optical inspection in 3D previously required a great deal of programming but offered few benefits, Cognex's new technology brings better image quality, simplified application development, and a wide range of true 3D inspection tools - significantly expanding the range of applications in industrial automation.

All in one: The In-Sight 3D-L4000 simplifies 3D inspections by having image processing already integrated in the system.An exciting new 3D vision system now makes inspecting parts in 3D as easy as using a 2D smart camera. While optical inspection in 3D previously required a great deal of programming but offered few benefits, Cognex's new technology brings better image quality, simplified application development, and a wide range of true 3D inspection tools - significantly expanding the range of applications in industrial automation.

When it comes to inspecting parts, users can choose from several established technologies. If the decision is made in favor of machine vision, the question arises: Do you need an inspection in 2D or 3D and how much effort is required to implement the respective solution? Depending on the application, a proven 2D system is then often the first choice, even if the (theoretical) advantages of 3D image processing may be obvious.

There are two reasons for this. The first: Until now, there was no 3D vision system that met the requirements of most inspection applications in terms of ease of use and cost. Three-dimensional vision inspection was simply too expensive and complicated for most companies, and there were also few vision tools that worked with true 3D images. So, an additional PC had to be installed to actually solve the application, resulting in significantly more space and programming requirements. The second reason: 2D inspection with a smart camera works very robustly and with great ease of use. Therefore, in many cases, there is or was no real need to make the costly and difficult transition to a 3D inspection system.

New possibilities for automatic 3D inspection

This situation is now changing with the introduction of the In-Sight® 3D-L4000 vision system from machine vision specialist Cognex. This unique smart camera enables engineers to solve a range of inline inspection, guidance and measurement applications on automated production lines quickly, accurately and cost-effectively. It offers a comprehensive suite of true 3D vision tools that are as easy to use as Cognex's industry-proven 2D vision tools, thanks to the familiar and robust In-Sight spreadsheet environment. In addition, the patented speckle-free blue laser optics are an industry first, enabling the capture of high-quality 3D images.

Blue laser optics make the difference

Users of 3D image processing are probably familiar with this: Typically, 3D imaging systems struggle with speckle - light effects that occur when laser light is scattered from the surface of the part back to the imaging system. Speckle is a problem in existing 3D vision systems because it changes the appearance of the part and reduces image accuracy. The system can only estimate where the laser is located. To date, no 3D system has been able to eliminate speckle and thus produce good enough images to perform reliable inspection applications in 3D.

However, the type of laser used in the In-Sight 3D-L4000 is a significant technical advance in laser-based imaging - and a reason for the excellent results delivered. The 3D-L4000 eliminates speckle by using a special laser in the blue light range. As a result, the imager sees a clear laser line, resulting in higher accuracy 3D images. In addition, the laser provides its own illumination for both 3D and 2D images - the system does not require any external light.

On board: Intelligent processing on real 3D point cloud images

In most "traditional" laser-based 3D vision systems, the laser head captures an image that is sent to a PC for processing. At the same time, they offer a limited selection of tools, most of which can only be used for simple height measurement. The dependence on PC programming makes 3D inspections cost-effective only for very complex applications. The In-Sight 3D-L4000, on the other hand, has its processing power built right in. This allows the vision tools to perform true 3D point cloud inspections without the need for an external controller or third-party PC-based software. A nice side benefit is that with onboard processing, image analysis can be completed in a very short time.

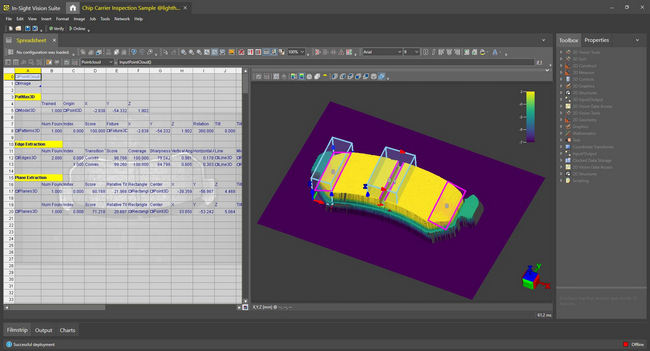

In the past, 3D visual inspection was difficult to understand and use. Most existing systems transform 3D data into 2D images. In doing so, the height of a point is represented as a gray value. So to understand the height information, one uses a false color representation of the rasterized 3D image in the 2D image. In this representation it is very difficult to see and successfully process the nuances of the 3D part. A common method is to convert a section of the rasterized 2D image into a 1D height profile. However, with the new technology used in the 3D-L4000, the image is a pure point cloud; what you see and evaluate is a true 3D image, not a reduction to a 1D height profile. And since 3D inspection is new to most users, the 3D tools are designed so that everyone can fully understand and use the new three-dimensional tools. In other words, you are essentially doing the same thing, but unlike before, you are working on an image that looks exactly like the part itself.

Intuitive setup with advanced 3D inspection tools – without programming skills

Another new feature of the In-Sight 3D-L4000 is the use of the intuitive In-Sight Spreadsheet development interface to quickly and easily set up and run 3D applications without the need for programming or external processing. It simplifies application development and streamlines factory integration with a complete I/O and communications feature set. It also allows 2D and 3D vision tools to be combined in the same application, resulting in faster deployments.

The In-Sight 3D-L4000 includes all the traditional 3D measurement tools expected of a 3D vision system, such as for plane and height determination. In addition, it has a comprehensive set of 3D vision tools such as PatMax3D, Blob3D, 3D Geometry and many more, designed from the ground up for inspections in a real 3D space. This makes it easy to measure or identify parts or irregularities on the surface, as well as gaps, edges and angles - even for parts with complex geometry such as pistons or hinges.

Is Now The Time For A War On Plastic?

The international consumer advocacy group Consumer Choice Center released a policy paper detailing the war on plastic, federal and state efforts at mitigating plastic waste, and potential legislative steps to better protect our environment.

In Deconstructing The War On Plastic the authors evaluate the issue of plastic waste in the United States including that of single-use plastics and alternatives and examine if legislative efforts to curb plastic waste will ultimately better serve the environment.

"In our report we highlight how local or state bans on plastic products often come with high negative environmental externalities," said co-author Yaël Ossowski. "These bans ultimately push consumers to high-impact alternatives, and don't necessarily reduce the total amount of plastic used by consumers. Rather than trying to ban their way out of this problem, we propose that state and local governments better collaborate to expand advanced recycling," said Ossowski, also deputy director at the Consumer Choice Center.

"In our report we highlight how local or state bans on plastic products often come with high negative environmental externalities," said co-author Yaël Ossowski. "These bans ultimately push consumers to high-impact alternatives, and don't necessarily reduce the total amount of plastic used by consumers. Rather than trying to ban their way out of this problem, we propose that state and local governments better collaborate to expand advanced recycling," said Ossowski, also deputy director at the Consumer Choice Center.

"At the federal level, the combination of the Break Free From Plastic Pollution Act and the CLEAN Future Act will make tackling plastic waste significantly more difficult. Both acts seek to put a moratorium on permits for advanced recycling facilities. This incredibly problematic because it hamstrings recycling efforts, which limits the nation's ability to properly recycle plastic waste," said co-author David Clement, North American Affairs Manager at CCC.

"Not only that, but the acts also seek to create a recycled content mandate for plastic products. Creating demand for recycled plastic, while at the same time limiting the capacity of plastic recycling facilities, is a recipe for disaster; specifically, one where demand for recycled plastic rapidly outpaces supply, which will drastically increase prices," added Clement.

The authors propose a 4-step solution for the issue of plastic waste:

1) A ban on the export of plastic waste to countries that fail to meet environmental stewardship standards.

2) The expansion of advanced recycling and chemical depolymerization permits.

3) Embrace innovation and market solutions. There are a variety of new biodegradable plastics being brought to market, and those market solutions should be permitted to continue to develop.

4) Evaluate market mechanisms to price waste accordingly, so that externalities of mismanaged waste are not offloaded onto communities. We propose a full review of how the US can effectively price waste, in consultation with both consumers and producers.

The full report can be downloaded HERE

***The CCC's David Clement and Yael Ossowski are available to speak with accredited media on consumer regulations and consumer choice issues. Please send media inquiries to This email address is being protected from spambots. You need JavaScript enabled to view it..***

The CCC represents consumers in over 100 countries across the globe. We closely monitor regulatory trends in Ottawa, Washington, Brussels, Geneva and other hotspots of regulation and inform and activate consumers to fight for #ConsumerChoice. Learn more at consumerchoicecenter.org.

Biobased Diesel Fuel Highlighted as a Low-Carbon, Proven and Available Climate Change Solution

Industry leaders Neste, Renewable Energy Group and the National Biodiesel Board affirmed the significant opportunity for biofuels in a carbon constrained future compared to electrification and other approaches

Low-cost, low-carbon but high greenhouse gas reducing impact describes the opportunity for using biobased diesel fuel as helping achieve climate change. Biofuels are a ready solution for reducing greenhouse gas emissions and tackling climate change. The virtual session April 13, 2021 hosted by the Diesel Technology Forum is now available in a recorded version for online viewing.

“Diesel is the power of work and it moves 97 percent of large Class 8 trucks and bigger applications like locomotives, marine vessels and construction equipment. Unlike passenger cars, where there are zero-emissions options available today and consumers are warming to them, the promise of zero-emissions solutions in heavy-duty sectors is in the future. Today, more efficient diesel engines coupled with very low carbon biobased diesel fuels like renewable diesel and biodiesel, can do quite a lot to reduce emissions immediately,” said Ezra Finkin, session organizer and moderator, and also Policy Director for the suburban Washington, DC-based Diesel Technology Forum, an educational association representing diesel engine and equipment makers, suppliers and fuels interests.

For those that believe that electrification is the only strategy to reduce greenhouse gas emissions, this session provided important new perspectives on how to think about greenhouse gas reduction timelines and the broad suitability of biobased diesel fuels to be used immediately across wide sectors of the economy. And, through discussion of case studies of public and private fleets in California, demonstrated the proven success of biobased diesel fuels in real-world applications.

For those that believe that electrification is the only strategy to reduce greenhouse gas emissions, this session provided important new perspectives on how to think about greenhouse gas reduction timelines and the broad suitability of biobased diesel fuels to be used immediately across wide sectors of the economy. And, through discussion of case studies of public and private fleets in California, demonstrated the proven success of biobased diesel fuels in real-world applications.

“The way we have been thinking of greenhouse gas emissions is not quite accurate. What we emit today stays in the atmosphere long after it has been emitted. Waiting for the promise of zero-emissions solutions actually makes the problem worse as it does nothing to address cumulative emissions. When it comes to solutions to reduce emissions from the heavy-duty sector, we should rely on biobased diesel fuel to do the most to reduce these emissions today as zero-emissions solutions in some applications are planned for the future,” noted David Slade, Executive Director, Biofuel Technology and Services - Renewable Energy Group, Inc.

As policymakers move to tackle the climate change challenge on a local, regional and national level, a mix of near-term and longer-term strategies for the transportation sector are emerging. While all-electric and zero emissions strategies may dominate headlines, it is increasingly clear that they may not be available or suitable for all sectors in the immediate future.

“Biodiesel and renewable diesel are low carbon and low-cost fuels that are helping to reduce emissions today from trucks, buses and large equipment. Both are derived from waste feedstocks like vegetable oils and animal fats and their use does not require expensive investments in refueling or recharging infrastructure or the purchase of new trucks or engines. Diesel engines old and new can use these fuels to deliver big benefits. The market for these fuels has grown as the U.S. consumed about 3 billion gallons of biobased diesel fuel in 2020 and the market is set to double by 2030,” highlighted Jennifer Weaver, OEM Market Development Manager - National Biodiesel Board.

“Fleets are already adopting these very low carbon and very low-cost fuels to realize big benefits. Relative to zero-emissions solutions, these are low-cost options available today that do not require fleets to replace trucks and engines with expensive new powertrains or rely on recharging networks. The City of Oakland, CA since 2015 has been using renewable diesel in all of its fleet of heavy-duty trucks, equipment and generators to realize 3,400 tons of greenhouse gas emissions reduced each year. Other trucking fleets that rely on heavy-duty diesel engines, including Titan Freight and Argent Materials, are achieving low carbon and low-cost benefits of renewable diesel fuel without sacrificing power and performance needed to get the job done. Policies that encourage the use of low carbon fuels are technology neutral solutions that incentivize the right fuel for the right application,” noted Carrie Song, Vice President, Renewable Road Transport, North America - Neste.

The use of renewable biofuels in diesel vehicles and equipment is an effective greenhouse gas mitigation strategy that every public and private fleet should have access to right alongside other solutions. The nature of tackling the climate challenge, its urgency and complexity, dictate that there is not a one-size-fits-all solution.

Investments in renewable diesel and biodiesel production are expanding rapidly both from conventional biofuel producers as well as the existing petroleum refining sector, signaling a strategy of greater access to low carbon fuels nationwide that will enable more governments and private fleets viable options to meet the near-term climate challenge head-on.

About the Diesel Technology Forum

The Diesel Technology Forum is a not-for-profit organization dedicated to raising awareness about the importance of diesel engines, fuel, and technology. Members of the Diesel Technology Forum are the leaders in advanced technology engines, vehicles, fuels, and equipment, both diesel and a range of alternative fuels, including electrification, hydrogen, natural gas, and others. For more information visit https://www.dieselforum.org/.

FutureOn strengthens leadership team with senior appointments

FutureOn, the global software company specialising in the energy sector and creator of the award-winning SaaS field design applications, FieldAP, and its APIcentric collaboration platform, FieldTwin, has made two key senior appointments as part of the company’s strategic growth plans.

Katherine Taylor-Jones brings significant experience and knowledge in strategic financial management and leadership to the newly created position of Chief Financial Officer. Having worked predominantly for fast growth global SaaS businesses in recent years, she joins FutureOn after successfully scaling several tech businesses. She has been responsible for the finance strategy for independent businesses throughout her career.

Drawing on her experience of scaling both start-up businesses and those with a SaaS offering, Katherine will be responsible for leading FutureOn’s corporate finance strategy in-line with the company’s growth plans, as well as creating a robust financial department to support global operations.

Commenting on her appointment, Katherine said: “FutureOn has delivered impressive growth since it started and I am very pleased to join this fast moving, ambitious company. Having secured investment from the Bentley Acceleration Fund at the end of 2020, FutureOn is ideally positioned to further develop new digital solutions for asset operators that unlock value through increased efficiency, improved safety, reduced costs, risk mitigation, lower carbon footprint and increased uptime.

“FutureOn has continued to experience demand from businesses across the world who are embracing pioneering digital twin solutions to meet their challenges. There are plenty of opportunities to grow FutureOn’s local capabilities and enhance the on-the-ground service on offer, as well as further grow our partnerships in the UK, and worldwide. I’m looking forward to supporting the company embark on this next phase of growth.”

Joining Katherine is David Bartley, who has been appointed to the role of Head of People. He brings a wealth of experience to the role having held a number of HR leadership positions, which has included establishing people focused operations to support the growth of several tech start-ups. David joins FutureOn from the global software firm, Callsign, where he held the role of Head of People.

In the newly created role, David will be responsible for implementing new HR processes and policies fit for a growing global business with the aim of attracting, developing and nurturing new and existing talent, as well as driving employee engagement internationally.

Commenting on his appointment, David said: “FutureOn’s people play a critical role in shaping its future, and so part of my focus will be on attracting and retaining the right skills and capabilities to move at pace to drive the business forward. During challenging times, fostering a supportive and inclusive culture is more important than ever, and it’s highly encouraging that FutureOn’s leadership team truly recognise that. It’s an exciting time to join this growing company.”

CEO of FutureOn, Paal Roppen, commented: “I am very pleased to welcome Katherine and David to our senior team, who together bring a wealth of leadership experience to their respective roles. It is highly encouraging that these high calibre professionals have chosen to join the already talented team at FutureOn. Their business acumen, experience in accelerating the growth of start-up businesses and technical expertise, will prove invaluable. I am confident that their expertise, passion and energy will see them play an important role in shaping our future growth.”

The appointments mark a key phase in the Norwegian firm’s international expansion as it grows its operations in the UK, across Europe, the USA, Middle East and Asia Pacific to meet demand for its suite of digital twin technologies.

Forming a key part of FutureOn’s growth strategy, the firm has made a number of strategic technology partnerships in recent months. This will allow the company to collaborate on joint- research and development projects, and further broaden the integration of its API digital twin solutions.

About FutureOn

Experts in data visualization, FutureOn emerged from Xvision in 2016 to become a standalone provider of state-of-the-art visual engineering for the global energy sector. The company transforms the performance of complex capital projects with our cutting-edge visualization technology.

FutureOn is proud to offer its global customer base industry-leading software solutions to create digital twins that deliver a complete asset visualization and integrated data model that unlocks value through increased efficiency, improved safety, reduced costs, risk mitigation, lower emissions and increased uptime.

FutureOn technology includes:

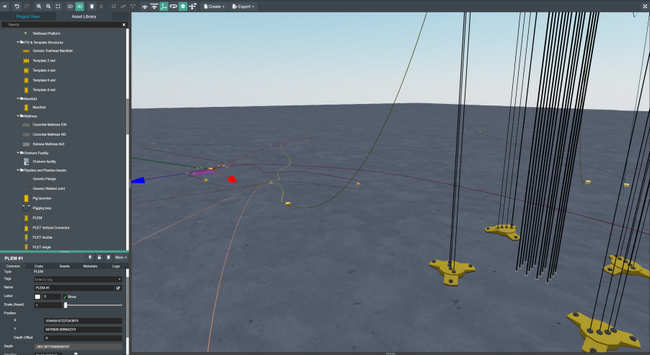

FieldAP, a cloud-based digital platform that provides rapid visual workflows for early-stage subsea engineering work. Multiple data streams from geography to bathymetry, topography, existing infrastructure and other physical constraints can be combined with proprietary information such as reservoirs, wells and drilling to create a information-rich 3D visualization of any potential project location.

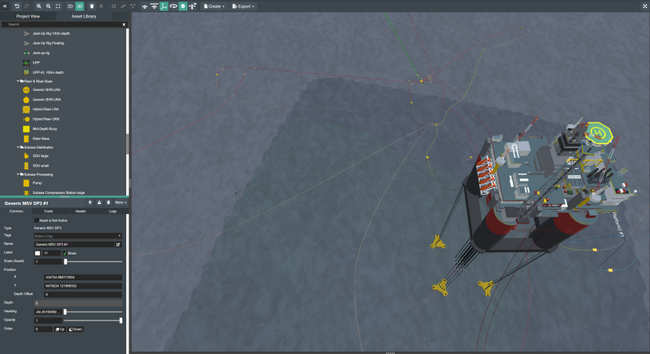

FieldTwin provides a visual representation of the entire life cycle of a field by creating and maintaining a digital twin — an exact digital copy of an oil and gas company’s physical asset — which enables producers to maximize asset performance and value.

Rohde & Schwarz updates R&S PWC200 to provide even more accuracy in 5G FR1 base station OTA testing

The latest software update to the R&S PWC200 plane wave converter (PWC) increases measurement accuracy and refines usability thanks to a new calibration method. With these updates, Rohde & Schwarz extends the possible use cases of its innovative 5G massive MIMO base station testing solution in R&D, quality assurance and production as well as conformance testing. While the software will be preinstalled in new units, existing R&S PWC200 units can be upgraded.

The level of integration of 5G base stations in the FR1 frequency range is increasing, as a new generation of base stations, designated the 1-O type, is becoming more and more common. The 1-O type base stations operate at FR1 frequency range and they have antenna arrays with integrated transceivers, without any access to internal RF ports. This requires all conformance and production testing to be performed over-theair (OTA). However, OTA testing can be technically challenging.

For accurate OTA measurements, signal waves sent from the antenna must be plane when reaching the device under test (DUT). The area encompassing the DUT where the waves are plane is called the quiet zone (QZ). This can be achieved through a large distance between the antenna and the DUT, resulting in large and expensive shielding chambers. Rohde & Schwarz has a strong portfolio of solutions for OTA testing, designed to answer these challenges. Some of them are based on compact antenna test range (CATR) technology, where a gold-plated reflector is used to create the plane waves, allowing the DUT to be relatively close to the antenna. However, with large DUTs such as base stations, the size of the highprecision mirror would be prohibitively large and increase the price of the system considerably. With a solution based on the PWC technology in its OTA test portfolio, Rohde & Schwarz is broadening the options available to the users, especially for large DUTs.

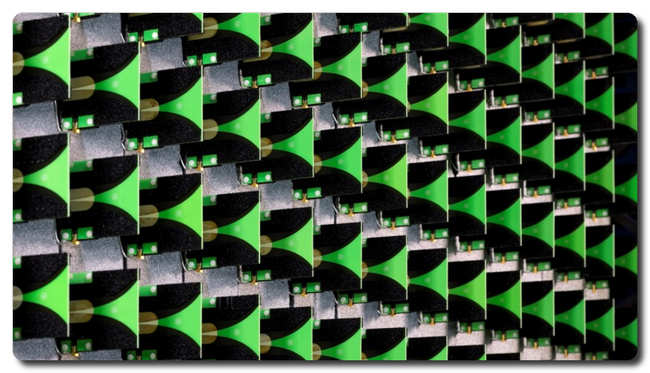

The R&S PWC200 needs four times less space than solutions based on other OTA technologies such as CATR. The R&S PWC200 is based on a phased antenna array consisting of 156 wideband Vivaldi antennas to form plane waves within an adjustable QZ, placed in the radiating near field of the DUT. It functions as a planar-wave synthesizer and near-field scanner and is designed for 5G massive MIMO base station testing for real-time radiated power and transceiver measurements (EVM, ACLR, SEM, etc.) in a controlled anechoic test chamber environment. The R&S PWC200 features an internal RF verification solution. This makes it possible to perform precise monitoring and correction of the R&S PWC200 antenna without using an external antenna.

Released originally two years ago, the R&S PWC200 was the first PWC-based solution on the market. It has been accepted as OTA base station measurement methodology by 3GPP in the conformance test specifications for NR (3GPP TS 38.141-2) and advanced antenna system (AAS) for LTE and WCDMA (3GPP TS 37.145-2). The latest updates improve several aspects of the solution. As the 5G frequency bands vary from country to country, the original frequency range of the R&S PWC200 from 2.3 GHz to 3.8 GHz was extended to now cover 1.7 GHz to 5 GHz. This increases applications for users worldwide. Additionally, thanks to a novel approach to the PWC calibration the accuracy of the plane wave synthesis has been increased even further. This results in three times better accuracy in magnitude and phase uniformity compared to the previous solution.

Dr. Adam Tankielun, Senior Development Expert of Antenna Test Systems at Rohde & Schwarz, says: “Our creative and enthusiastic development team completely redefined the calibration procedure of the R&S PWC200. Consequently, we are able to offer our customers the opportunity of testing their new generation base station products with the lowest possible measurement uncertainty and the maximum usability of a PWC test system. And they get a turnkey solution from a single vendor, complete with full support and service that can be tailored to their needs.” The R&S PWC200 plane wave converter is available from Rohde & Schwarz. For more information go to: https://www.rohde-schwarz.com/product/pwc200

Rohde & Schwarz Rohde & Schwarz is a leading supplier of solutions in the fields of test and measurement, broadcast and media, aerospace | defense | security and networks and cybersecurity. The technology group's innovative communications, information and security products help industry and government customers ensure a safer and connected world. On June 30, 2020, Rohde & Schwarz had about 12,300 employees worldwide. The independent group achieved a net revenue of EUR 2.58 billion in the 2019/2020 fiscal year (July to June). The company is headquartered in Munich, Germany, and has subsidiaries in more than 70 countries, with regional hubs in Asia and America. R&S® is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

AFRY signs framework agreement with the Danish Road Directorate

The Danish Road Directorate has entered into a new framework agreement with AFRY. The framework agreement covers planning, construction and operation of all intelligent transportation systems (ITS) and applications on the Danish state roads, and has an estimated value of 196 million SEK.

”We have worked with the Danish Road Directorate for more than 25 years and we are very happy to continue to help maintain Denmark’s infrastructure and help thousands of people in Denmark moving from A to B in an efficient, safe and environmentally safe manner,” says Kenneth Habo, Business Unit Manager for Transportation at AFRY.

The activities that are included in the framework agreement are going to ensure ongoing operation and development of traffic control systems and traffic signal installations, which will be carried out in close cooperation with the Road Directorate. This includes equipment on the roads, central surveillance and management systems, as well as maintenance performed to ensure the functioning of traffic facilities and the technical standards.According to the Danish Road Directorate the amount of traffic is going to increase on the roads in Denmark in the future. In order to avoid problems on the state roads, to ensure traffic flow and provide good service to the road users, traffic management is going to play a significant role. For this task there is a shared focus on the green transition and working with sustainability and the UN Sustainable Development Goals.

“Efficient operation and maintenance of traffic management and signal systems helps reduce CO2 emissions, because traffic becomes more free-flowing with fewer stops and interruptions. Red lights and traffic jams on the roads mean waiting time for the road users, extra fuel consumption and higher CO2 emissions”, says Susan Appel, Team Manager Traffic at AFRY.

For further information, please contact:

Kenneth Habo, Business Unit Manager, Transportation

+45 40 82 96 98

Susan Appel, Team Manager Traffic

+45 61 85 20 80

AFRY is a European leader in engineering, design, and advisory services, with a global reach. We accelerate the transition towards a sustainable society.

We are 16,000 devoted experts in infrastructure, industry, energy and digitalisation, creating sustainable solutions for generations to come.

Making Future

ABB’s new cobot GoFa™ wins prestigious Best of the Best Red Dot award

Leading product design experts recognize ABB’s GoFa™ collaborative robot for innovative design to make robots more approachable

ABB’s GoFa cobot was awarded the prestigious Red Dot Best of the Best design award in recognition of its unique design concept to make the new robot appealing and accessible to users.

The global Red Dot Design Awards recognize achievements in product design, with the jury assessing thousands of entries every year. Red Dot’s “Best of the Best” award is for groundbreaking design and is the highest award in the competition, reserved for the most aesthetically appealing, functional, smart or innovative design.

GoFa is the fastest cobot in its class and is intended to work side-by-side with humans, without the need for fences, on a wide range of tasks. Advanced safety features, including intelligent sensors in each joint which bring the cobot to a stop in milliseconds if it senses any unexpected contact, allow GoFa to safely operate directly and continuously alongside workers.

The brief for the product designers was to create an intuitive, user-friendly, approachable design to encourage people, and particularly first-time users, to confidently use and interact with GoFa.

“Making robots more approachable, easier to use and more intuitive is key to our vision to make robots as familiar in the workplace as a laptop is today,” said Sami Atiya, President of ABB’s Robotics & Discrete Automation Business Area. “I am delighted that our new cobot GoFa has been recognized by the Red Dot jury for how user-friendly it is. GoFa is a game-changer, reinforcing the importance of good industrial design to make it easier for more people to work with robots. Creating an approachable design will ensure robots are adopted across a range of workplaces outside traditional factory environments, helping us to unlock automation for new users and new industries around the world.”

GoFa’s design is a departure from the look of traditional industrial robots, narrowing the boundaries between industrial and consumer products. It employs slim, straight arms that give the cobot a user-friendly yet strong appearance, while the advanced use of color, material and finish gives GoFa a modern, sleek look. Its simple arm-side interface design with two buttons and light ring echoes the easy-to-use interfaces of consumer products. This makes it accessible even for first-time robot users more accustomed to consumer technology and who may be unfamiliar with industrial machinery.

“Industrial design is not just about the aesthetic! Form follows function, and our emphasis on human-centric design, using the approach of a consumer product means GoFa communicates the proposition of usability, utility and ease of use,” said Andie Zhang, Global Product Manager, Collaborative Robotics for ABB Robotics. “Creating an attractive, approachable design allows people to get the best out of their cobots. We not only want people to feel comfortable working alongside it, we want users to enjoy working with the robot. GoFa is programmed by touching the robot’s arm and leading it, so it’s important that users are comfortable with holding and guiding the cobot as they teach it.”

ABB’s cobots are intuitively designed so customers need not rely on robot programming specialists. This will help industries that have low levels of automation, with customers able to operate their cobot within minutes of installation, straight out of the box, with no specialized training.

“With their ease-of-use digital tools, integrated safety features and higher payloads, our new cobots represent the future of human and robot collaboration. This next generation will enable even more businesses to automate repetitive, mundane and dangerous processes, to enhance productivity and flexibility while leaving employees free to do more value-add activities,” added Andie Zhang. “If you can use a tablet or smartphone, you can work with our cobots.”

The launch of ABB’s new GoFa cobot builds on the success of ABB’s YuMi® family, which has been helping businesses safely automate key tasks since YuMi launched in 2015. The design concept of YuMi, the world’s first truly collaborative robot, also won the Best of the Best Red Dot award in 2011.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 110,000 talented employees in over 100 countries. www.abb.com

ABB Robotics & Discrete Automation is a pioneer in robotics, machine automation and digital services, providing innovative solutions for a diverse range of industries, from automotive to electronics to logistics. As one of the world’s leading robotics and machine automation suppliers, we have shipped over 400,000 robot solutions. We help our customers of all sizes to increase productivity, flexibility and simplicity and to improve output quality. We support their transition towards the connected and collaborative factory of the future. ABB Robotics & Discrete Automation employs more than 10,000 people at over 100 locations in more than 53 countries. www.abb.com/robotics

Metso Outotec and Advanced Engineering Group to sign distribution contract for screening media

Metso Outotec and Advanced Engineering Group Pty Ltd (AEG) have signed a contract concerning Metso Outotec’s screening media distribution. Since March 2021, AEG sells and supports all Metso Outotec synthetic screening media products to aggregates producers in Australia.

The distributor partnership combines Metso Outotec’s premium brand and its high reliability screening media products with AEG’s recognized knowledge and reputation on the market into a unique, compelling offering. Metso Outotec provides the technical support and backs up AEG through its focused global supply chain.

“The production of aggregates in Australia has increased with newer and larger operations which have higher focus on cost-efficiency and quality of materials. The move towards synthetic media has evolved from this demand,” says Shaun Fanning, Vice President, Asia Pacific Distribution at Metso Outotec. “Metso Outotec has developed a range of synthetic screening media to support the customer needs. Together with AEG, we can offer fast and easy access to screening media for the Australian customers.”

Metso Outotec Trellex screening system

Metso Outotec Trellex screening system

“It is exciting times for us and the customers,” says Dave Hastie, Managing Director of AEG. “We have built our business on quality products and service during the past 25 years. We look forward to growing the Metso Outotec brand as well as introducing our range of products to a wider clientele. The partnership is an important step in building our new superstore where the customers have access to a one-stop shop of synthetic media, screen mesh and accessories on a timely and simplified manner.”

AEG has facilities in Melbourne and Brisbane, with 22 staff members.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com