Super User

Huayou Cobalt awards tailings filtration equipment order to Metso Outotec

Metso Outotec has been awarded a repeat order to deliver sustainable tailings filtration technology for Zhejiang Huayou Cobalt Co. Ltd.’s new laterite nickel mine project in Indonesia. The order value, which is not disclosed, has been booked in Minerals fourth-quarter 2022 orders received.

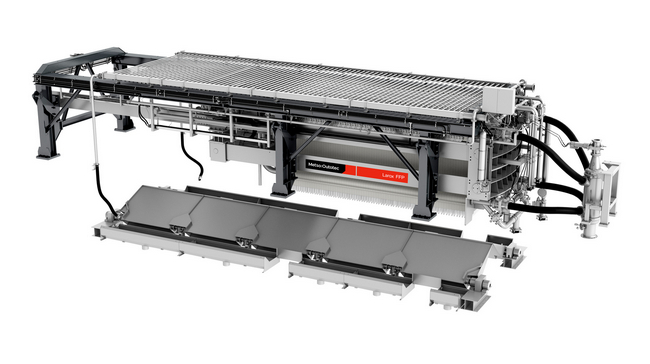

Metso Outotec’s scope of delivery consists of the engineering, manufacturing and supply of 15 Larox® FFP3512 filters, as well as installation and commissioning advisory services and spare parts. The fully automatic, fast-opening filter press (FFP) is part of Metso Outotec’s Planet Positive offering. The filter combines the benefits of membrane technology and sidebar design with high mechanical and process performance, providing safe and sustainable high-volume dewatering of tailings with low operating and life cycle costs.

“As a core supplier of Huayou Cobalt, we are honoured to be selected again to provide efficient and sustainable tailings filtration technology. The signing of this order represents not only the continuation and deepening of our long-term cooperation but also Huayou Cobalt’s trust in Metso Outotec technology and services. To date, we’ve received orders for 37 Larox® FFP3512 filters from Huayou,” says Xun Fang, General Manager, Minerals sales, Greater China at Metso Outotec.

Huayou Cobalt is a high-tech enterprise engaged in the research, development and manufacturing of new energy lithium-ion batteries and cobalt materials in China. Its nickel cobalt hydrometallurgy project in Indonesia is one of the largest and most advanced hydrometallurgy projects in the world. Metso Outotec has signed several cooperation agreements with Huayou Cobalt to provide comprehensive mineral processing solutions for its projects in Indonesia, including SAG mills, ball mills, as well as Larox® FFP3512 filters and thickening equipment of various specifications.

Read more about Larox® FFP filters on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2021 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

GreenGo Energy partners with Commerz Real and Hydro Rein - targeting 1GW solar portfolio in Denmark

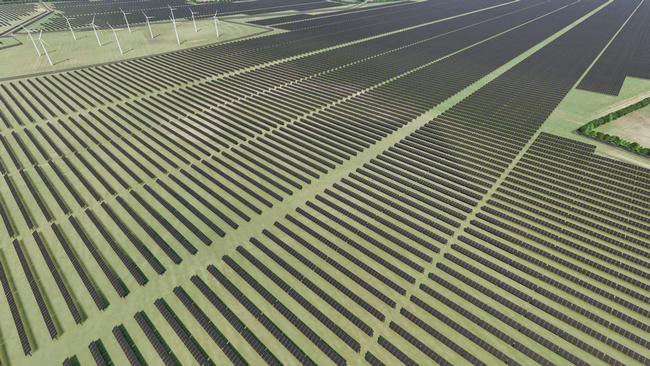

GreenGo Energy, one of Europe’s leading solar developers, has entered into a new GW-scale partnership agreement with a joint venture between Commerz Real and Hydro Rein, two significant institutions in the renewable energy industry. The parties target to execute a total portfolio of 1GWp+ from GreenGo Energy’s significant utility scale solar PV portfolio in Denmark, corresponding to an investment from the joint venture of more than 600 million EUR over the next 3-5 years.

The total energy production of the targeted project portfolio corresponds to approximately 4% of Denmark’s total yearly electricity demand today, equivalent to the demand of +300,000 Danish households. Under the partnership agreement, the joint venture will acquire projects from GreenGo Energy and provide financing through development and construction to commissioning (COD).

First two solar projects to be commissioned in 2026

The first two solar projects have already been acquired by the Joint Venture, a 170MWp project located in on Denmark’s west coast and one 192Wp project in the south Denmark,. Construction is scheduled to commence in 2024, completion is expected for 2026.

Strong partnership will accelerate the energy transition in Denmark

According to statements by the Danish government, all the electricity needed by the country is to originate from renewable sources by 2027. And the government targets a PV capacity of 20 GW by 2030 to reach the firmly set 2030 goals.

Barkha Mehmedagic, Global head of Institutional Sales and Group Treasury at Commerz Real comments:” The Danish investment market for photovoltaics is still relatively young and is seeing a correspondingly dynamic development. This offers the potential for growth and diversification for our institutional investors in particular “, and continues “With Hydro Rein and GreenGo Energy we also have experienced partners firmly rooted in the Scandinavian market by our side.”

Olivier Giradot, CEO of Hydro Rein comments:” We are proud to announce our very first investment in Denmark together with Commerz Real. This is also REIN’s first solar investment in the Nordics. The investment will diversify our Nordic portfolio in terms of technology and production, and we see great potential in combining wind and solar to help decarbonize major industrial players. Backed by strong governmental ambitions, we look forward to explore more opportunities in Denmark”.

Karsten Nielsen, CEO of GreenGo Energy comments. “Together with Commerz Real and Hydro Rein we can fully leverage the complementary capabilities of all the parties involved, leaning on the extensive experience in renewable investments and a strong industrial presence in the Nordic power market. This first GW-scale partnership agreement for our Mermaid portfolio in Denmark is a big milestone, helping Denmark to accelerate the energy transition with significant impact well before 2030”.

About GreenGo Energy

GreenGo Energy was founded in 2011 with the vision to accelerate conversion to renewable energy generation, by an innovative and scalable business model. GreenGo Energy’s 360 full services platform includes origination, development, offtake, engineering, procurement, construction management, O&M and asset management services, fully tailored and bespoke to our client’s needs and investment profile.

GreenGo Energy now has more than 7.5GWp of solar and storage projects in various stages of development and construction in selected U.S. states and Northern Europe, of which more than 3GWp has been contracted through partnership agreements with tier 1 investors in the renewable space.

About Commerz Real

Commerz Real is the asset manager for real asset investments of German Commerzbank Group and has over 50 years of international market experience. More than 800 employees manage assets of around 34 billion euros at the Wiesbaden headquarters and 17 other locations and branches in Germany and abroad. The company combines comprehensive know-how in asset management and a broad-based structuring expertise to deliver its signature range of services of fund products focused on tangibles and bespoke financing solutions. The fund spectrum includes the open-ended real estate fund Hausinvest, Germany’s first retail impact fund for real assets Klimavest, institutional investment products as well as entrepreneurial participations.

Commerz Real has been investing in solar energy since 2005 and in wind power plants and other energy infrastructure segments since 2016. The company currently manages more than 50 solar power plants and over 40 onshore and offshore wind farms in Germany and Europe with a total nominal output of more than 1.5GW.

About Hydro REIN

Hydro Rein is a leading provider of renewable energy solutions to industrials, fully owned by the global renewable energy and aluminium company Hydro. Hydro Rein has a diversified portfolio of 16 projects under development in core markets in the Nordics and Brazil. The company has an ambition of 3GW in construction or operation (gross) by 2026, leveraging on a unique customer offering and Hydro’s century-long track record in building industries that matter.

Hydro Rein is a wholly-owned subsidiary of the aluminium and renewable energy company Norsk Hydro, in which the Norwegian government also holds a stake of about one third. The company has already been active in the field of hydroelectric power for more than one hundred years.

PulPac raises €31 million from cross-industrial alliance to roll-out breakthrough sustainable packaging technology

PulPac announces the closing of a €31 million private placement led by Aliaxis and followed by Stora Enso, Amcor Ventures and Teseo Capital. Combining key global partnerships and investments enables PulPac to accelerate the roll-out out of its patented Dry Molded Fiber technology globally. Investing in global commercialization, with additional production capacity, R&D and supply-chain availability. All supporting the target of establishing Dry Molded Fiber as the next global standard for sustainable packaging, replacing single-use plastics with circular fiber solutions.

Besides offering high-speed manufacturing, which makes it a competitive alternative to plastics, Dry Molded Fiber preserves enormous amounts of water and energy compared to traditional wet fiber molding.

Fredrik Östbye, Head of Aliaxis Next and Linus Larsson Green, CEO of PulPac, standing in front of the PulPac Modula at the PulPac Tech Center in Gothenburg, Sweden.

Fredrik Östbye, Head of Aliaxis Next and Linus Larsson Green, CEO of PulPac, standing in front of the PulPac Modula at the PulPac Tech Center in Gothenburg, Sweden.

Linus Larsson Green, co-founder and CEO of PulPac, commented:

“PulPac today is seen as leading the technological race for sustainable packaging and replacing single-use plastics. With backing and support of such world-class partners, we have laid a strong foundation across the value chain. I am really excited to execute our plans and roll-out our technology globally”

In this private placement, leading strategic partners (Aliaxis, Stora Enso, Amcor Ventures and Teseo Capital) join the existing shareholders of PulPac and its network to form a cross-industrial alliance. PulPac’s commercialization is catalyzed across the scaling value-chain with the aliiance, validating the global interest for the technology and its positive impact as a coming world standard in sustainable packaging. Each partner contributes complementary market-leading know-how that strongly contributes to the acceleration of Dry Molded Fiber.

Roderick Sundell, CFO at PulPac, also commented:

“Today marks a critical step forward on our mission of replacing single-use plastics at scale. We are extremely proud to welcome these leading partners into our cross-Industrial alliance. Together, we will drive the transition forward at great speed to provide scalable solutions that are both cost competitive and sustainable.”

Dry Molded Fibre

Dry Molded Fibre

Existing investors WPP, PP Intressenter AB, Marcus Palm also participate in the equity raise together with the founders through DryFiber Holding AB. Jointly, the private placement will enable PulPac to make further investments in three key areas:

- Increased global presence and representation of PulPac and Dry Molded Fiber to cater to enormous demand, building out application and demonstration centers in key markets close to industrial partners.

- Increasing product standardization and roll-out of applications ready to use, including commercial and third-party validation.

- Supply chain acceleration in key partnerships on production platforms and tooling, ensuring availability of material, chemistries, machines and tooling throughout the regional supply chains.

Collectively, these initiatives will facilitate PulPac’s target of replacing 1 million tons of single-use plastics by 2025, saving up to 5 million tons of CO2 emissions and up to 1 billion liters of water – compared to if the products had been made with conventional wet molded fiber.

Pareto Securities AS acted as financial advisors and Vinge acted as legal advisors to PulPac for the equity raise.

About Aliaxis

At Aliaxis, we design sustainable, easy to install, and innovative solutions to address the world’s water challenges and accelerate the transition to clean energy. Thanks to our 14,000+ employees, our pipes and fitting systems meet our customers’ most demanding needs for the building, infrastructure, industrial and agriculture sectors. Operating in over 40 countries, the Company is active through leading local brands and generated €3.7 billion revenue in 2021. More information available on www.aliaxis.com

About Stora Enso

Part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials, wooden construction and paper, and one of the largest private forest owners in the world. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has approximately 22,000 employees and our sales in 2021 were EUR 10.2 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). More information available on www.storaenso.com

About Amcor

Amcor is a global leader in developing and producing responsible packaging solutions for food, beverage, pharmaceutical, medical, home and personal-care, and other products. Amcor works with leading companies around the world to protect their products and the people who rely on them, differentiate brands, and improve supply chains through a range of flexible and rigid packaging, specialty cartons, closures, and services. The company is focused on making packaging that is increasingly lighter weight, recyclable and reusable, and made using an increasing amount of recycled content. In fiscal year 2022, 44,000 Amcor people generated $15 billion in annual sales from operations that span 220 locations in 43 countries. NYSE: AMCR; ASX: AMC. More information available on www.amcor.com

About Teseo Capital

A Family Office in Luxembourg, Teseo Capital, which deals in alternative assets and agribusiness.

About WPP

WPP is the creative transformation company. We use the power of creativity to build better futures for our people, planet, clients and communities. For more information, visit www.wpp.com

About PP Intressenter AB

PPI is a consortium of prominent local investors. PPI’s indirect main owners include Johan Möller, one of the founders of the nische bank Collector, Lennart Grebelius, founder and owner of Sätila Holding AB, Mats Franzén and Pål Junhamn founders of Zetup AB, as well as Björn Engström, co-founder Forsman & Bodenfors.

About DryFiber Holding AB

DryFiber Holding is the holding company for Founders Linus Larsson Green and Ove Larsson as well as early team members.

About Marcus Palm

The Director of Legal Affairs at Välinge Innovation AB (leading global licensing company in click-lock-flooring). Palm is a minority shareholder in PulPac as well as part of PulPac’s board. Palm is a leading Nordic expert on Licensing business models and infringement control, he was elected the Swedish General Counsel of the Year 2017.

About PulPac

PulPac provides the packaging industry with a groundbreaking manufacturing technology for low-cost, high-performance fiber-based packaging and single-use products. By pioneering the technology of cellulose molding PulPac enables their customers to replace single-use plastics with a sustainable and cost competitive alternative globally. For additional information about PulPac, please visit www.pulpac.com or follow us on social media.

Metso Outotec celebrates groundbreaking ceremony for state-of-the-art service center in Australia

Metso Outotec celebrated on November 8th the groundbreaking ceremony of the company’s biggest service center globally to be built in Karratha, WA. The investment was announced in November 2021. The new center will offer comprehensive maintenance and repair services for mining and aggregates customers in the Pilbara and Gascoyne regions. Located in one of the world’s largest mining regions, the center offers increased productivity and shorter lead times as well as substantial environmental advantages due to shorter transportation journeys.

The new service center’s lot size is over 35,000 m2 and it will have a workshop of 5,000 m2 and a total of 18,000 m2 of storage space. The total investment value is approx. EUR 32 million, including the purchase of the land, assets, and construction of the service center. The center is expected to be operational during the fourth quarter of 2023.

“This is a great day for Metso Outotec and our customers. Reaching this milestone means that the construction work on the site is proceeding after a thorough planning phase. The service center is an expansion to our footprint and an important strategic investment in supporting our customers. The strong operational support and leading process knowledge we provide, will help our customers to meet their targets,” says Martin Karlsson, Senior Vice President, Professional Services, Metso Outotec.

“This is a great day for Metso Outotec and our customers. Reaching this milestone means that the construction work on the site is proceeding after a thorough planning phase. The service center is an expansion to our footprint and an important strategic investment in supporting our customers. The strong operational support and leading process knowledge we provide, will help our customers to meet their targets,” says Martin Karlsson, Senior Vice President, Professional Services, Metso Outotec.

The center will be equipped to repair and refurbish for example large mining crushers, grinding mills, screens, and car dumpers. Further, it will act as a base for field services, hold inventory for customer critical wear and spare parts, as well as providing a customer training facility.

“By investing in this state-of-the-art service center, we are demonstrating our long-term commitment to the Pilbara Region and the communities there. We can offer shorter lead times, and environmentally efficient service and delivery capabilities. The functionalities of the building have been carefully designed, and we are able to support our customers with a comprehensive service and repairs capability for all their needs,” says Stuart Sneyd, President, Asia Pacific market area, Metso Outotec.

The Pilbara center is expected to provide long-term stable employment to skilled personnel from the local communities, including service engineers and experts.

Metso Outotec has today 140 service centers globally, over 3000 field services professionals, and additional support resources close to customer operations.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2021 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

For better recycling of textiles: Reliably identify textile materials on the spot with trinamiX mobile NIR spectroscopy

trinamiX, a leading provider of mobile spectroscopy and a wholly owned subsidiary of BASF SE, now enables flexible on-site identification of textiles. With trinamiX’s Mobile NIR Spectroscopy Solution, more than 15 textile types and compositions can now be identified and thus better sorted. Even pieces made of material blends can easily be determined without damaging the material. The solution includes easy-to-use hardware with intelligent data analysis, an intuitive app for fast results, and an extensive customer portal where in-depth analyses and reports can be created.

trinamiX thus opens up new ways for customers from the textile industry to exploit additional potential in the field of textile recycling. Textile collection companies and organizations are equipped with an efficient tool that enables them to pre-sort goods according to quality and next processor. Recycling companies can improve the quality of the recycling process by continuously checking incoming goods. Textile manufacturers also benefit from mobile textile recognition: they can use spot measurement at goods receipt to check if the delivered textiles are in conformity with the ordered quality.

"We are convinced that innovative solutions like ours make an important contribution towards a circular textile economy," explains Adrian Vogel, Business Development Manager at trinamiX GmbH. "Sorting is a key requirement for recycling and is largely done manually. Even experienced sorters cannot tell the difference between, for example, nylon 6 and nylon 6.6 just by looking at it or feeling it. This is where the handheld solution from trinamiX provides clarity."

With trinamiX’s Mobile NIR Spectroscopy Solution, more than 15 textile types and compositions can now be identified and thus better sorted.

With trinamiX’s Mobile NIR Spectroscopy Solution, more than 15 textile types and compositions can now be identified and thus better sorted.

The solution supports a wide range of common textile grades used in clothing, furniture and household goods, for example: acrylic, cotton, nylon 6/6.6, polytrimethylene terephthalate (PTT), polyester, polypropylene (PP), silk, sisal, viscose and wool. Textiles made from more than one material can also be identified. These include blends based on acrylic, cotton, nylon, polyester, silk or wool.

For the special requirements of recycling carpets, trinamiX has developed a dedicated application. It supports all common textile and plastic types used in carpets such as nylon 6 and nylon 6.6, polyacrylonitrile (PAN), polyethylene terephthalate (PET), polypropylene (PP), polytrimethylene terephthalate (PTT) and wool. The carpet application is the first one within trinamiX’s Mobile NIR Spectroscopy Solution to work offline. This means that the identification of carpet materials can be carried out when there is no connection to the internet. The data is evaluated and stored directly on the device and smartphone. A later upload to the customer portal is possible without any problems.

trinamiX will present the new applications on November 9 and 10 at two trade shows: Greener Manufacturing Show in Cologne, Germany (booth 5017 in hall 10.1) and Plastics Recycling World Expo in Cleveland, USA (booth 635).

About trinamiX's mobile near-infrared spectroscopy solution

trinamiX's NIR spectroscopy solution combines robust hardware with intelligent data analysis and a mobile app. NIR spectroscopy is a proven technology that trinamiX has converted into a portable format for on-site analysis. trinamiX relies on cloud-based data processing, which ensures continuous further development of the solution – there is no need to replace the hardware. More information: trinamiXsensing.com/textiles.

About trinamiX

trinamiX GmbH develops cutting-edge biometric and mobile NIR spectroscopy solutions, which are used in both consumer electronics and industrial designs. The company’s products enable humans and machines to better capture data with the goal of understanding the world around us. This results in improved decision making as well as stronger biometric security. trinamiX, based in Ludwigshafen (Germany), was founded in 2015 as a wholly owned subsidiary of BASF SE. The company employs over 200 people worldwide and holds more than 300 patents and patent applications.

Brenntag chooses Amazon Web Services as its preferred cloud provider enabling Brenntag’s digital and data ambitions

Brenntag, the global market leader in chemicals and ingredients distribution, has just announced a multi-year project with Amazon Web Services (AWS), an Amazon.com company (NASDAQ: AMZN). AWS will enable Brenntag to accelerate the integration of digital processes and services and unlock the value from its data. In a fast-paced and complex world, customers and supply partners want simple yet personalized interactions to work efficiently and pivot quickly when needed. Brenntag’s global supply chain network provides proprietary data and insights that enable the company to deliver more value to its customers and supply partners. With AWS, Brenntag can provide systems and data processing across a variety of systems while also ramping up internal capabilities to facilitate an agile modular deployment of systems, automation solutions and services.

“We are excited to work with AWS,” said Ewout van Jarwaarde, Chief Transformation Officer at Brenntag. “At Brenntag we put our customers and supply partners at the heart of what we do every day to ensure we are the easiest to do business with. Ensuring seamless interconnection of data and data-as-a-service for our customers and supply partners across the globe, and across a variety of platforms and systems in a fast and secure way, will allow us to ultimately serve our partners more efficiently. AWS is supporting our transformation through trainings, services and provides a holistic integration of data streams.”

“We are excited to work with AWS,” said Ewout van Jarwaarde, Chief Transformation Officer at Brenntag. “At Brenntag we put our customers and supply partners at the heart of what we do every day to ensure we are the easiest to do business with. Ensuring seamless interconnection of data and data-as-a-service for our customers and supply partners across the globe, and across a variety of platforms and systems in a fast and secure way, will allow us to ultimately serve our partners more efficiently. AWS is supporting our transformation through trainings, services and provides a holistic integration of data streams.”

The support and training provided by AWS during specially dedicated cloud immersion days will provide consistency for scalability and the broad integration of interconnected platforms globally. This will make internal and external data connections faster, smoother, and more secure.

This training will take place across several Brenntag locations to Brenntag employees and will support the company’ digital transformation by providing best-in-class cloud infrastructure to enable a hub-and-spoke system of data connectivity.

Over the coming years, Brenntag will utilize AWS infrastructure and support to implement a variety of best practice solutions, such as a multi-modal track and trace program for customer and supply partner orders.

About Brenntag:

Brenntag is the global market leader in chemicals and ingredients distribution. The company holds a central role in connecting customers and suppliers of the chemical industry. Headquartered in Essen, Germany, Brenntag has more than 17,000 employees worldwide and operates a network of about 700 sites in 78 countries. In 2021, Brenntag generated sales of around 14.4 billion EUR. The two global divisions, Brenntag Essentials and Brenntag Specialties, provide a full-line portfolio of industrial and specialty chemicals and ingredients as well as tailor-made application, marketing and supply chain solutions, technical and formulation support, comprehensive regulatory know-how, and digital solutions for a wide range of industries. In the field of sustainability, Brenntag pursues specific goals and is committed to sustainable solutions in its own sector and the industries served. Brenntag shares have been listed at the Frankfurt Stock Exchange since 2010, initially in the MDAX and since September 2021 in the DAX. In addition, the Brenntag SE shares are listed in the DAX 50 ESG and DAX ESG Target. For more information, visit www.brenntag.com

Hedinn fishing for efficiencies as PP C&A helps it deliver €11m deal

One of the UK’s leading strategic manufacturing outsourcing specialists is celebrating a fifth birthday of supplying the fishing sector in style by supporting a new €11m project.

PP Control & Automation, which employs more than 230 people at its world class facility in Cheslyn Hay, will provide complete electrical build services on the dual Hedinn HPP-10000s that are destined for Sildarvinnslan, Iceland’s biggest fishmeal and fish oil producer.

Capable of turning 380 tonnes of fish waste and offal into high quality protein meal and oil for animal feed, the plants are the largest ever delivered and will involve PP C&A assembling sensors, prefabricated cables, junction boxes and I/O cabinets, labels for sensors and motor isolator switches.

The technology here utilises significantly less energy than existing traditional methods, is 30% more compact and has 30% fewer components. Importantly, it also offers the dual benefits of increased profitability and greener environmental performance, attributes very much in demand.

Tony Hague, CEO of PP Control & Automation, picked up the story: “Hedinn was our first involvement in the fishing industry and the relationship underlines how a lot of the values of strategic outsourcing transcend all sectors.

“By working with a specialist, we have given it access to skill, capability and capacity, which, in turn, has led to faster builds, improved product quality and the ability to cost-effectively scale.”

He added: “As the partnership has developed, we have also collaborated to look at standardising some of the manufacturing processes across all its different protein plants. This can only be done so far, but we have certainly reached a stage where increases in volumes can be easily met.”

Ragnar Sverrisson, Managing Director of Hedinn, added his support: “The Sildarvinnslan deal is a major project for our business and one we can deliver on time and to budget thanks to our team of experts and the support we receive from PP C&A.

“As a strategic partner, it has access to our whole electrical package, which means it holds a comprehensive understanding of the requirements for each build and any customisation that needs to be incorporated. The workmanship is second to none and wiring faults are virtually non-existent, which gives us great confidence and a significant commercial advantage.”

Since the first project, PP Control & Automation has helped produce the HPPm-2000, HPP-5000, HPPsh-300 and HPP-15000, a mixture of land and at sea solutions for using 100% of fish waste and offal to produce high quality protein meal and oil for animal feed.

The partnership has evolved so that Hedinn can importantly focus more of its time and resource on the design and development of its plants, as well as providing a quality service to its growing legion of global customers.

Today, the Icelandic business employs 120 people and has a group turnover of approximately €30m, with HPP Solutions launched in January as a standalone business to help drive its HPP division.

PP C&A’s Tony Hague concluded: “It’s great news that we can celebrate 5 years of working together by supporting Hedinn with such a landmark project. Everything is in place in the UK to scale volumes as interest in the technology will grow – a real UK/Icelandic success story!”

For further information, please visit www.ppcanda.com or follow @ppcanda on twitter. More details on Hedinn can be found at www.proteinplant.is

Outokumpu aims to improve its energy efficiency significantly in 2023 and 2024 amidst the European energy crisis

Outokumpu has decided to significantly increase its energy efficiency improvement target and prioritize related investments in 2023 and 2024.

So far, Outokumpu’s target has been to improve energy efficiency by 0.5% annually. Until the end of 2024, Outokumpu now aims to improve its energy efficiency by 8% across the group compared to the January–September 2022 level. These measures would correspond to energy saving of approximately 600,000 MWh which is equal to annual electricity usage of 15,000 households.*

“The European energy crisis has created a turbulent operating environment. To tackle the uncertainty, we have decided to take immediate action on our own energy efficiency. This means that we will prioritize investments to improve our energy efficiency and also increase related annual capital expenditure by EUR 20 million in 2023 and 2024”, says Outokumpu’s Chief Technology Officer Stefan Erdmann.

These additional investments do not impact Outokumpu’s capital expenditure frame of EUR 600 million for the second phase of the strategy by the end of 2025. For 2023 and 2024, the annual capital expenditure remains EUR 200 million.

Outokumpu’s target is to reduce its carbon dioxide emissions by 42% by 2030 compared to 2016 baseline. “The new efficiency measures will support Outokumpu to achieve our ambitious climate targets”, continues Erdmann.

*) MWh per ton of stainless steel. Energy savings calculated by average electricity use of 20,000 kilowatt hours by a family of four living in a detached, electrically heated house.

Outokumpu is the global leader in stainless steel. The foundation of our business is our ability to tailor stainless steel into any form and for almost any purpose. Stainless steel is sustainable, durable and designed to last forever. Our customers use it to create civilization’s basic structures and its most famous landmarks as well as products for households and various industries. Outokumpu employs some 9,000 professionals in more than 30 countries, with headquarters in Helsinki, Finland and shares listed in Nasdaq Helsinki. www.outokumpu.com

Metso Outotec to deliver solvent extraction technology to South America

Metso Outotec has been awarded a contract for the delivery of VSF® solvent extraction technology to South America. The order value of, approximately EUR 10 million, has been booked in Minerals’ fourth-quarter orders received.

Metso Outotec’s scope of delivery includes engineering, proprietary and key equipment, spare parts, and advisory services for the mechanical installation as well as commissioning and start-up of the solvent extraction plant.

Metso Outotec VSF solvent extraction plant

Metso Outotec VSF solvent extraction plant

Read more about solvent extraction technologies on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2021 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Geek+ automates operations for Dr.Max e-commerce warehouse in Romania

Geek+, the global leader in autonomous mobile robots (AMRs), has brought smart automation to Dr.Max’s e-commerce warehouse in Bucharest, which handles more than 25 000 SKUs monthly. The goods-to-person robots have vastly increased Dr.Max’s efficiency and storage capacity, while delivering order fulfillment accuracy of over 99%.

Dr.Max’s e-commerce platform is among the top 10 websites in Romania, measured by number of unique visitors, and offers a wide variety of OTC products, cosmetics, medical devices, food supplements, dermato-cosmetics, mother & baby products, diet and nutritional products, and natural remedies. With the help of nearly one hundred Geek+ autonomous mobile robots that can process orders 24/7, Dr.Max increases the order processing capacity and thus efficiently responds to the needs of online patients, especially in peak e-commerce order seasons. The flexibility to add more robots to keep up with Dr.Max’s growing e-commerce business was a key factor in the decision to automate with Geek+’s solutions.

The Geek+ Picking System uses AMRs to bring the products ordered from storage locations to picking stations, where operators package the goods and send them to Dr.Max’s patients. The algorithms and software place as many orders in each batch moved from storage as possible, keeping special orders to a minimum, and also takes into account the expiration date of goods, a key step in reducing waste.

Brian Lee, Managing Director of Europe at Geek+, said: ”Dr.Max is a key player in the pharmaceutical industry across central and eastern Europe, and we are very pleased to support them. The past couple years have driven home how important access to medical supplies is, and we are very proud that Geek+ technology is able to make such a direct impact on people’s quality of life.”

Sorin David, Supply Chain Director at A&D Pharma - Dr.Max Group, said: “As part of our group’s development strategy, we continue to make long term investments in the logistics infrastructure in order to respond efficiently to the needs of our patients. The technology provided by our partner Geek+ allows us to have a more accurate overview of our work processes. We are glad to have Geek+ as our trustworthy partner.”

Dr.Max is expecting rapid growth to continue over the coming years, and Geek+ will continue to support their progress with further applications of advanced AMR technology. Geek+’s robots are just beginning to assist in the provision of critical medicines and supplies to people around the world.

About Geek+

Geek+ is a global technology company leading the intelligent logistics revolution. We apply advanced robotics and AI technologies to realize flexible, reliable, and highly efficient solutions for warehouses and supply chain management. Geek+ is trusted by over 500 global industry leaders and has been recognized as the world leader in autonomous mobile robots. Founded in 2015, Geek+ has over 1500 employees, with offices in Germany, the United Kingdom, the United States, Japan, South Korea, Mainland China, Hong Kong SAR, and Singapore.

For more information, please visit: https://www.geekplus.com/

About A&D Pharma Group, part of the Dr.Max family

With over 25 years of experience on the local market, A&D Pharma is one of the largest pharmaceutical groups in Romania, offering pharmaceutical retail and drug distribution services, with a turnover of over 1 billion euros in 2021 and over 5000 employees.

A&D Pharma has two business lines, both of strategic importance: The drug distribution line and the pharmaceutical retail line.

For more information about the Dr.Max brand, visit the website https://www.drmax.ro/