Super User

Raven SR, Chevron and Hyzon Motors Collaborate to Produce Hydrogen from Green Waste in Northern California

Raven SR Inc. (Raven SR), a renewable fuels company, Chevron New Energies, a division of Chevron U.S.A. Inc., and Hyzon Motors Inc. (NASDAQ: HYZN) have just announced they are collaborating to commercialize operations of a green waste-to-hydrogen production facility in Richmond intended to supply hydrogen fuel to transportation markets in Northern California.

- Hydrogen to be produced from green waste and food waste with non-combustion reforming process

- Richmond, Calif., production facility to serve local hydrogen transportation fuel market, replacing conventional fuels

- Commercial operations targeted for Q1 2024

The facility will be owned by a newly formed company, Raven SR S1 LLC (Raven SR S1). Raven SR will be the operator of the facility, which is targeted to come online in the first quarter of 2024. Chevron holds a 50% equity stake in Raven SR 1. Raven SR holds a 30% stake and Hyzon owns the remaining 20%.

To produce the hydrogen, the project is expected to divert up to 99 wet tons of green and food waste per day from Republic Services’ West Contra Costa Sanitary Landfill into its non-combustion Steam/CO2 Reforming process, producing up to 2,400 metric-tons per year of renewable hydrogen. Diversion of this organic waste will help fulfill SB 1383 mandates, and will potentially avoid up to 7,200 metric-tons per year of CO2 emissions from the landfill. In addition, Raven’s technology uses no fresh water, an important element given drought risks in California, and uses less electricity to power its units than competing processes. The project is expected to produce at least 60% of its own electricity by upgrading the currently permitted and zoned landfill gas electric generators at the landfill, further reducing both the current air emissions and the need for grid power for its non-combustion process.

Chevron plans to market its share of the hydrogen in Bay Area and Northern California fueling stations, enabling the energy transition to zero emission vehicles. Hyzon, a global supplier of fuel cell electric commercial vehicles, plans to provide refueling for hydrogen fuel cell trucks at a hydrogen hub in Richmond.

Chevron plans to market its share of the hydrogen in Bay Area and Northern California fueling stations, enabling the energy transition to zero emission vehicles. Hyzon, a global supplier of fuel cell electric commercial vehicles, plans to provide refueling for hydrogen fuel cell trucks at a hydrogen hub in Richmond.

"Our strategic partners’ commitment to the first non-combustion Steam/CO2 facility in the world will help drive our commercial operations in Richmond and accelerate similar facilities globally," said Matt Murdock, CEO of Raven. “This facility will be the first hydrogen production plant in the world to reduce greenhouse gases, including critically important short-lived climate pollutants, through its process and its product. By removing waste from the landfill, it will help reduce methane emissions. Not only will the greater Richmond community benefit from reduced emissions, investments, and jobs, it will also see economic benefits as local gas stations have a consistent supply of clean, zero-carbon hydrogen fuel for fuel cell vehicles. We are grateful to work with partners who share our mission to make cleaner fuel options available as soon as possible.”

Ahead of teaming with Raven SR on the Raven SR S1 facility, Chevron and Hyzon were among Raven SR’s initial strategic investors, along with ITOCHU, Ascent Hydrogen Fund and Samsung Ventures.

“We are excited about this collaboration and our expanded commitment to Raven and its waste-to-hydrogen technology,” said Austin Knight, vice president of Hydrogen for Chevron New Energies. “Not only are we positioned to commercialize a first-of-its-kind lower carbon hydrogen project, we are working to reduce emissions in a community in which we have a long and proud history. With a relatively short lead time, we will be able to further develop the hydrogen ecosystem in the region.”

The Raven SR technology is a non-combustion thermal, chemical reductive process that converts organic waste and landfill gas to hydrogen and Fischer-Tropsch synthetic fuels. Unlike other hydrogen production technologies, its Steam/CO2 Reformation does not require fresh water as a feedstock and uses less than half the energy of electrolysis. The process is more efficient than conventional hydrogen production and can deliver fuel with low to negative carbon intensity. Additionally, Raven SR’s goal is to generate as much of its own power onsite as possible to reduce reliance on, and/or be independent of the grid. Its modular design provides a scalable means to locally produce renewable hydrogen and synthetic liquid fuels from local waste.

“The Richmond hub enables a local, renewable hydrogen ecosystem by aligning hydrogen production, refueling infrastructure and vehicle availability geographically and technologically. This alignment is expected to reduce total costs to fleet operators, accelerating the transition to zero-emissions vehicles and global decarbonization,” said Parker Meeks, Hyzon president and interim CEO.

“This marks a significant step in demonstrating the commercial viability of a localized, low-to-negative carbon intensity hydrogen economy,” he added. “Through Hyzon’s partnership with Raven, hydrogen supply can be synchronized with the demand for hydrogen fuel cell electric vehicles. Raven’s deployment of scalable hydrogen production facilities allows supply and demand to grow together as clean hydrogen for transport continues to gain market and regulatory support.”

About Raven SR

Raven SR, headquartered in Wyoming, transforms biomass, mixed municipal solid waste, bio-solids, sewage, medical waste, and natural or biogas into renewable fuels. Using its proprietary, non-combustion, non-catalytic “Steam/CO2 Reformation” technology, Raven SR dependably produces a hydrogen-rich syngas regardless of feedstock utilized. Raven SR, led by co-founders Matt Murdock and Matt Scanlon, is committed to adding value to local resources and communities while responsibly reducing greenhouse gases and achieving a low carbon economy. By using modular systems and producing low air emissions, their systems can be located closer to customers and feedstock, creating local fuel from local waste for local mobility. Visit https://ravensr.com/.

About Chevron

Chevron Corporation (NYSE: CVX) is one of the world’s leading integrated energy companies. We believe affordable, reliable and ever-cleaner energy is essential to achieving a more prosperous and sustainable world. Chevron produces crude oil and natural gas; manufactures transportation fuels, lubricants, petrochemicals and additives; and develops technologies that enhance our business and the industry. We are focused on lowering the carbon intensity in our operations and growing lower carbon businesses along with our traditional business lines. More information about Chevron is available at www.chevron.com.

About Hyzon

Hyzon is a global supplier in fuel cell electric mobility, with US operations in the Rochester, Chicago and Detroit areas, and international operations in the Netherlands, Australia, Germany, and China. Hyzon is an energy transition accelerator and technology innovator, providing end-to-end solutions in the transport sector with a focus on commercial vehicles and hydrogen supply infrastructure. Utilizing its proven and proprietary hydrogen fuel cell technology, Hyzon aims to supply zero-emission heavy duty trucks and buses to customers in North America, Europe and around the world to mitigate emissions from diesel transportation, which is one of the single largest sources of carbon emissions globally. The Company is contributing to the escalating adoption of fuel cell electric vehicles through its demonstrated technology advantage, leading fuel cell performance and history of rapid innovation. Visit www.hyzonmotors.com.

New Si124 range improved bandwidth yields big savings for energy-intensive industries

The Si124 range of acoustic cameras now detects air leaks from 2 - 65 kHz - and the small change means big operational improvements for industrial applications across sectors.

The Teledyne FLIR range of acoustic imaging cameras, the Si124, Si124-PD and Si124-LD, now offers an improved bandwidth range for detecting compressed air leaks in industrial settings. The change means that the industry-leading range can now detect leaks from anywhere between 2 to 65 kHz and adds crucial functionality to the previous peak bandwidth of 35 kHz.

While it may seem like a minor change, the operational impact of the improvements cannot be overstated: it means marked savings for industrial applications globally, reducing costs and improving reliability.

The improved Si124 range promises easier, more impactful inspections

The range of three cutting-edge Si124 models are now equipped to measure virtually all compressed air leaks in manufacturing settings - regardless of how small and seemingly insignificant. This unique range covering 63 kHz is scientifically the optimal sound spectrum range for detecting leaks, which occur on this measurable threshold. Detecting ranges outside of this spectrum actually detracts from long-term functionality as detecting background noise beyond 65 kHz can interfere with baseline readings and negatively impact leak detection.

Failure to detect air leaks can cost companies thousands of pounds in replacement costs for units that are not operating optimally, and can have a knock-on effect on production when parts are replaced and production lines forced into downtime.

Federico De Lucia, Team Lead of Condition Monitoring Specialists (EMEA Solutions) at Teledyne FLIR explains why this seemingly small change cements the Si124 range as operating across the optimum bandwidth for detecting compressed air leaks in industrial applications.

“Let’s look at, for example, a compressed air leak from a small hole of just 1.5 millimetres and on a network of compressed air at seven bars of pressure. Two years ago, with a price of €0.07 per kilowatt hour, that would have cost a company roughly €1500 (£1300) per year, if we assume an average operating time of 6000 hours.

“Now that the energy situation is more challenging, it means that costs may be three, four, even five times higher in some cases, which could be a cost of up to £7500 a year - which is a shocking amount simply for failing to identify a single small hole in a vital production component. This is staggering when you consider the scale of industrial manufacturing and the scope for leaks to crop up unnoticed.”

Tightness testing is an outdated model

“The EV industry is a particularly timely example of how acoustic imaging can be used to replace outdated inspection models, given the rising cost of energy on all fronts.

“This is because the batteries for electric vehicles must be hermetically sealed to ensure they hit operational guidelines and safety standards. They must be both airtight and watertight to keep dirt, dust and other external contaminants from penetrating the core components, which could cause the device to short-circuit and become a fire risk.

“Traditionally, these units were probed by mass spectrometers to identify foreign compounds within the casing or through the more rudimentary method of immersing the units in water to identify leaks by looking for air bubbles - which we call tightness testing - but this was incredibly impractical, as well as wasteful.

“Teledyne FLIR’s improved range of acoustic imaging can detect leaks quicker than this outdated model as well as identify much smaller leaks that are not visible to the naked eye, able to be heard by the ear, or even detected on traditional thermography. The improved bandwidth range of the Si124 ensures that operators are only focusing on the exact and specific frequencies that compressed air leaks can be detected on - and not wasting valuable battery power or AI functionality struggling to filter out avoidable background noise on higher frequencies.”

Lighter and more ergonomic than any other acoustic imaging camera for industrial inspections

As well as benefiting from the optimum range of bandwidth for compressed air leak detection, the Si124 range also offers clear advantages for inspectors in industrial applications.

The Si124 range is incredibly lightweight. In fact, it is almost 60% lighter than rival models on the market at just 1.25kg including the battery. This makes sure that they can be used with a single hand, freeing up the operator to carry out harder-to-reach inspections in challenging environments. The lightweight range can be used for up to two hours and can even be operated in a range of challenging industrial settings from between –10°C to 50°C (14°F to 122°F), making it one of the most robust models available.

The acoustic imaging camera range is able to detect problems up to 10 times faster than traditional methods, including detecting air leaks, minimising excess utility costs and making avoidable equipment failures in pneumatic machinery a thing of the past.

The range also has an agile AI which uses projective algorithms to estimate how much a detected compressed air leak will cost by evaluating the air lost in real-time, calculating the spend per kWh and displaying an expected saving per year. Critically, this ensures that inspectors have valuable evidence needed to justify any incurred repair costs across the production line.

The Si124 range also benefits from Thermal Studio: a FLIR-exclusive plug-in which is able to build reports with more than 100 images quickly with fully customizable templates, overlays, and formulas. It streamlines thermal imaging analysis and ensures that inspectors are able to analyse, edit, segment and edit thermal video.

The improved FLIR Si124-PD, Si124-LD, and the original Si124 Industrial Acoustic Imaging Camera models are available for purchase globally from Teledyne FLIR and its authorised dealers. To learn more or to purchase, visit https://www.flir.com/products/si124.

About Teledyne FLIR

Teledyne FLIR, a Teledyne Technologies company, is a world leader in intelligent sensing solutions for defense and industrial applications with approximately 4,000 employees worldwide. Founded in 1978, the company creates advanced technologies to help professionals make better, faster decisions that save lives and livelihoods. For more information, please visit www.teledyneflir.com

Västra Götaland Region elevates ServiceNow to national security-rated cloud with Tietoevry

Västra Götalandsregionen (VGR) has selected Tietoevry for the task of developing and operating a modern, stable, accessible and secure IT environment and self-service portal through ServiceNow. With Tietoevry's Sovereign Cloud solution, which is based on a security-rated cloud solution on Swedish soil, the region will have a solution that meets the strict regulatory requirements for data storage.

After the public procurement process, Tietoevry has been trusted to become VGR's new cloud provider for ServiceNow. Tietoevry was considered to have provided the most advantageous bid for the four year contract. With the agreement, the region will have complete control over ensuring that data is securely stored in Sweden through Tietoevry's Sovereign Cloud solution, which ensures full compliance with current regulations.

After the public procurement process, Tietoevry has been trusted to become VGR's new cloud provider for ServiceNow. Tietoevry was considered to have provided the most advantageous bid for the four year contract. With the agreement, the region will have complete control over ensuring that data is securely stored in Sweden through Tietoevry's Sovereign Cloud solution, which ensures full compliance with current regulations.

– VGR, as a major public actor, has high demands on secure data management. We feel confident in starting a collaboration with Tietoevry and that their cloud solution ensures that all our employees' data is handled in Sweden and that we live up to the high regulatory demands for data storage, says Richard Karlsson at Region Västra Götaland.

– We are very happy to have VGR's trust in supporting and developing their IT environment and thus contributing to the critical societal functions they are providing for its citizens. We will focus on proactivity and innovation, and we proudly take on the mission to enable a security-grade cloud environment that safeguards the region's data sovereignty, says Lars-Erik Håkansson, head of Tietoevry Connect Sweden.

Tietoevry creates purposeful technology that reinvents the world for good. We are a leading technology company with a strong Nordic heritage and global capabilities. Based on our core values of openness, trust and diversity, we work with our customers to develop digital futures where businesses, societies, and humanity thrive.

Our 24 000 experts globally specialize in cloud, data, and software, serving thousands of enterprise and public-sector customers in more than 90 countries. Tietoevry’s annual turnover is approximately EUR 3 billion and the company’s shares are listed on the NASDAQ exchange in Helsinki and Stockholm, as well as on Oslo Børs. www.tietoevry.com

Parker to showcase H2 solutions for the entire value chain at Hyvolution 2023

Parker Hannifin, the global leader in motion and control technologies, will present a wide range of solutions for covering all aspects of hydrogen production and usage at Hyvolution 2023, Booth 6F58 on 1 and 2 February 2023 in Paris France.

Parker is at the forefront of hydrogen innovation and provides customers with solutions that address complex generation, transportation, storage, distribution, and utilization needs, enabling wider adoption and faster access to greener and renewable energy sources.

In addition to the processes of hydrogen production from petroleum products, storage, and transport, in which Parker has been present for a long time, we are also active in green hydrogen production by hydrolysis and applications in mobility.

Parker has been in the hydrogen business for over 50 years. “It was Parker engineers who contributed to the return of the Apollo 13 module to earth in 1970, by intervening from "Houston" to manage the "problem"!” said Marc Mendowski, Sales Manager OLAER Airborne & Special Products, Parker Sales Company France.

Visit Parker’s event page for more information by clicking HERE. For more information about Parker’s product offering in the hydrogen industry click HERE.

About Parker Hannifin

Parker Hannifin is a Fortune 250 global leader in motion and control technologies. For more than a century, the company has been enabling engineering breakthroughs that lead to a better tomorrow. Learn more at www.parker.com or @parkerhannifin.

Decommissioning engineers expand into South America

Decommissioning consultancy RVA Group has completed its first assignment in South America, following a two-week financial provisioning exercise for Portugal’s largest electricity giant, EDP.

EDP is no stranger to RVA’s services, having engaged the decommissioning engineers to write the specification for the demolition of the Barreiro power station in Portugal, in 2011.

This project, in the state of Ceará in Brazil, was part of a due diligence report for the Pecém 1 Energia thermal power plant. With a total capacity of 720 megawatts, the plant produces the equivalent of half the electricity generated for the state.

Keen to secure independent expertise regarding the potential future of this 210-acre site, EDP appointed RVA to produce a detailed decommissioning costings study.

This estimating exercise does not mean that clearance of all – or even part – of the plant is imminent. Instead, RVA’s evidenced data provides EDP with costed options – underpinned by financial integrity – if or when it decides to embark on any decommissioning works moving forward.

This means the fiscal obligation of any future project, is understood and anticipated, therefore minimising the commercial risks for stakeholders.

“As with any project like this, knowledge is power,” commented RVA Group’s managing director Richard Vann. “So, the earlier that decommissioning engineers can become involved in a potential assignment, the greater the quality of any ensuing outputs.”

EDP’s director of decommissioning Bruno Travassos added: “As an organisation, we’re now empowered with information that will support us in future decision-making processes and allow us to better plan the resources and milestones required for any future decommissioning works, large or small. Such projects are complex and have a large number of variables, so preparation is key.”

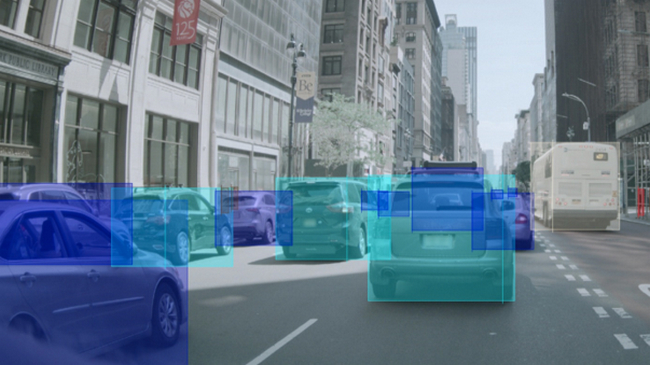

understand.ai Receives 2022 Frost & Sullivan Market Leadership Award in European Autonomous Driving Annotation Solutions Market

understand.ai, a dSPACE company, presents AI-based solutions at CES

understand.ai has just announced that the company has earned the 2022 Frost & Sullivan Best Practices Market Leadership Award in the European autonomous driving annotation solutions market. understand.ai is a leading software and SaaS service solutions provider specializing in automated ground truth data annotations using artificial intelligence. Following a rigorous evaluation, Frost & Sullivan recognizes the capabilities and the rapid growth of understand.ai and its ability to make AI accessible for automated annotated solutions in real-world applications for the advanced driver assistance systems/autonomous driving (ADAS/AD) market.

“understand.ai is addressing an unmet AD market need not easily replicated by competitors. Frost & Sullivan commends the company on its steadfast approach towards focusing on providing robust core annotation products backed by machine learning and AI expertise,” said Steven Lopez, Best Practices Research Analyst at Frost & Sullivan.

According to the Frost & Sullivan report, ”understand.ai is one of the world’s top providers that develop AI-driven data annotation solutions for the AD industry, working with world renowned automotive clients in Europe, North-America, and Asia-Pacific.“ Customers benefit from understand.ai’s automotive domain expertise, delivering complex ground truth ADAS/AD programs at scale with consistent quality. From 2-D bounding boxes to 3-D lidar point cloud annotations or 3-D sensor fusion projects - understand.ai covers the broad diversity of all regular ADAS/AD requirements, annotation types, and sensor data formats.

understand.ai‘s portfolio can be used for training and validation to produce ground truth data in the ADAS/AD development process. The company offers a labeling service for training data. Training data projects typically come with moderate data volumes and highly variable and demanding labeling. With its highly flexible labeling platform, understand.ai can tailor workflows to the exact customer needs. understand.ai excels in sensor fusion projects with complex multisensor setups which require sophisticated frame registration, lidar scan stitching, ego-motion compensation, motion distortion compensation, ground-plane estimates, highly precise 3-D to 2-D projections, multi-camera labeling, and more.

From 2-D bounding boxes to 3-D lidar point cloud annotations or 3-D sensor fusion projects - understand.ai covers the broad diversity of all regular ADAS/AD requirements, annotation types, and sensor data formats.

From 2-D bounding boxes to 3-D lidar point cloud annotations or 3-D sensor fusion projects - understand.ai covers the broad diversity of all regular ADAS/AD requirements, annotation types, and sensor data formats.

understand.ai is also an expert in the field of very large validation projects which can only be processed with an exceptionally high amount of automation. Its successes in automating complete labeling workflows mean that manual work can be reduced significantly and that consistently high quality can be achieved and delivered in a predictable timeframe. This way, the validation of advanced driving functionalities even enables the introduction of functionalities into markets which would otherwise be too small to justify the cost.

The UAI data anonymization, and data annotation portfolio integrates seamlessly with dSPACE solutions for data logging on one hand and data replay and simulation on the other.

“Receiving Frost & Sullivan's Best Practices Award proves our leadership position in the annotation market. By applying our AI-based technology and our domain competence, we provide value for our customers accelerating the development process, ensuring the right data quality, " commented Jürgen Daunis.

At CES in Las Vegas (Jan. 5-8, 2023), the company is showcasing its offerings and services in Las Vegas Convention Center West Hall, Booth 4417.

One-stop shop for compressor services

As of January 2023, Arkos Field Services, acquired by Burckhardt Compression in 2019, is integrated with Burckhardt Compression (US) Inc. Customers benefit from combined knowledge, expertise and unrivalled solutions for reciprocating compressors and other equipment from one provider. The integration of the two brands streamlines business processes to provide easy access and a solutions-driven customer experience.

With 10 service centers across the USA and a dedicated workforce Burckhardt Compression US is qualified and equipped to deliver a comprehensive range of services to customers. From emergency call-outs to parts manufacturing and planned maintenance, the company offers the best from both sides of the integration process from one platform. The fast response to get equipment back up and running as well as the knowledge and expertise to keep all makes and models of reciprocating compressors in perfect working condition.

At Burckhardt Compression, the mission is to establish working partnerships that promote trust, communication and a paramount commitment to safety, health, and excellent stewardship of the environment.

Burckhardt Compression US is qualified and equipped to deliver a comprehensive range of services to customers.

Burckhardt Compression US is qualified and equipped to deliver a comprehensive range of services to customers.

Safety ethos

Working in gas gathering and processing means safety is of paramount importance and Burckhardt Compression sets the benchmark by ensuring that all staff and operators are properly trained and certified for working in such a challenging environment.

As an OEM with over 175 years’ experience in engineering excellence, the company offers unrivalled knowledge and expertise in compressor operation and maintenance. Central to the continued success of the company is a program of continuous training for both staff and customers. Only by improving the knowledge of people working with compressors can they be expected to deliver more reliable and efficient service.

Burckhardt Compression believes in delivering the optimal solutions for every individual situation. Listening and understanding the needs of customers is essential to establishing the best course of action. The exceptional knowledge base within the company ensures that the most effective and efficient solutions are offered, by taking account of all the stakeholders’ considerations.

The exceptional knowledge base within the company ensures that the most effective and efficient solutions are offered.

The exceptional knowledge base within the company ensures that the most effective and efficient solutions are offered.

Driving sustainability

Reciprocating compressors face many challenges operating in a difficult environment where reliability is crucial. Maintaining optimum performance requires expert support that offers operators long-term solutions as well as rapid responses to any emerging challenges.

In today’s market, customers expect suppliers to have very high standards and sustainability is of great importance. Burckhardt Compression enables customers to optimize their efficiency and extend the service life of their equipment. By minimizing energy consumption and reducing emissions, operators can benefit from reduced operating costs as well as reducing their impact on the environment.

The partnership between operator and maintenance provider is crucial to the long-term, reliable service of any gas compressor. As new markets, such as hydrogen fuel, emerge from their infancy, Burckhardt Compression will lead the field in driving sustainable solutions and outstanding customer support.

About Burckhardt Compression

Burckhardt Compression is the worldwide market leader for reciprocating compressor systems and the only manufacturer and service provider that covers a full range of reciprocating compressor technologies and services. Its customized compressor systems are used in the gas gathering and processing, gas transport and storage, refinery, chemical, petrochemical as well as in the industrial gas and hydrogen mobility and energy sectors. Burckhardt Compression’s leading technology, broad portfolio of compressor components and the full range of services help customers around the world to find the optimized solution for their reciprocating compressor systems. Since 1844, its highly skilled workforce has crafted superior solutions and set the benchmark in the gas compression industry.

SIX Swiss Exchange: BCHN

For further information please visit www.burckhardtcompression.com

Outokumpu has completed the divestment of majority of its Long Products business

On July 12, 2022 Outokumpu announced the divestment of the majority of its Long Products business, and the company has today completed the divestment to Marcegaglia. The prerequisites for the completion of the transaction were, among others, necessary approvals by the competition authorities, and Outokumpu announced these approvals on December 14, 2022. The transaction was carried out as a share sale, and with the transaction, melting, rod and bar operations in Sheffield, UK, bar operations in Richburg, US, and wire rod mill in Fagersta, Sweden were sold to Marcegaglia. The transaction excluded Outokumpu Long Products AB operating in Degerfors and Storfors in Sweden, which continue as a part of Outokumpu.

“I want to thank the personnel in Sheffield, Richburg and Fagersta for our joint journey as part of Outokumpu. It makes us pleased that the new owner, Marcegaglia, is a responsible and committed owner to develop Long Products business even further. As for Outokumpu, we can now fully focus on our core business of stainless steel flat products and ferrochrome according to our strategy,” says Outokumpu’s President and CEO Heikki Malinen.

“I want to thank the personnel in Sheffield, Richburg and Fagersta for our joint journey as part of Outokumpu. It makes us pleased that the new owner, Marcegaglia, is a responsible and committed owner to develop Long Products business even further. As for Outokumpu, we can now fully focus on our core business of stainless steel flat products and ferrochrome according to our strategy,” says Outokumpu’s President and CEO Heikki Malinen.

The total consideration of the transaction on a debt and cash free basis was approximately EUR 228 million, strengthening Outokumpu’s financial position. Cash proceeds for equity and net debt item are approximately EUR 224 million of which EUR 5 million paid to an escrow account. Transaction costs are estimated to be approximately EUR 7 million. The consideration is subject to closing accounts that are finalized during the first half of 2023.

Outokumpu recognized an impairment loss of EUR 35 million in the third quarter 2022 results and does not expect any material gain or loss on the transaction. The cumulative translation adjustment relating to foreign subsidiaries held for sale will be reclassified into profit and loss at the time of disposal and will impact the gain or loss. These impacts will be refined in financial statements release 2022, which will be published on February 9, 2023. Starting from interim report January–September 2022, Outokumpu has classified its Long Products businesses to be divested as assets held for sale and reports the businesses as discontinued operations.

Outokumpu is the global leader in stainless steel. The foundation of our business is our ability to tailor stainless steel into any form and for almost any purpose. Stainless steel is sustainable, durable and designed to last forever. Our customers use it to create civilization’s basic structures and its most famous landmarks as well as products for households and various industries. Outokumpu employs some 9,000 professionals in more than 30 countries, with headquarters in Helsinki, Finland and shares listed in Nasdaq Helsinki. www.outokumpu.com

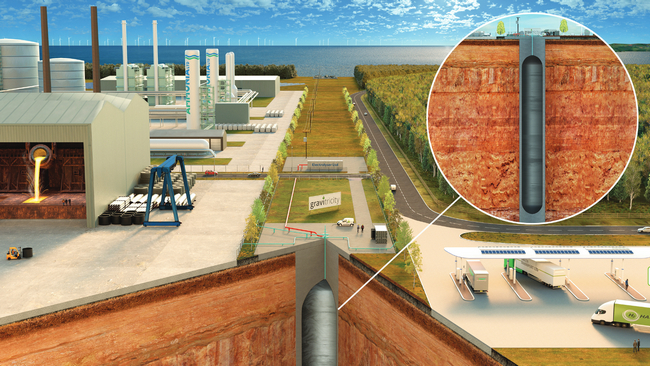

Underground green hydrogen stores offer ‘goldilocks’ solution to UK’s future hydrogen needs

The UK could see the construction of hundreds of new purpose-built underground hydrogen stores to help fuel the green economy of the future.

- Gravitricity signs MoU with infrastructure major VSL to build prototype green hydrogen FlexiStore

- Purpose built lined rock shafts can be located where required

- Each shaft can hold 100 tonnes – sufficient to refuel 1000 HGVs

- 1000 stores could meet a quarter of UK’s predicted hydrogen storage needs

- ‘Goldilocks’ solution is bigger than above ground storage and more flexible than salt caverns

- Fleets of FlexiStores could utilise vast and growing amounts of unused (‘constrained’) wind

Underground energy storage specialists Gravitricity have signed a memorandum of understanding (MoU) with infrastructure major VSL Systems UK to complete the design of the purpose-built underground lined rock shafts which could be rolled out nationwide. They plan to build a scale demonstrator in the next 24 months ahead of commercial rollout.

VSL is part of the French Bouygues Construction group and is a specialist contractor for the construction, preservation and repair of major engineered structures and infrastructure. Gravitricity is an Edinburgh based energy storage company which is developing below ground gravity energy storage systems in the UK and mainland Europe.

Gravitricity believes their storage technology – known as FlexiStore – is a ‘goldilocks’ solution to the future challenge of green hydrogen storage – offering a system that is larger and more secure than above ground hydrogen storage, and more flexible than subterranean salt caverns, the two most commonly-proposed alternatives.

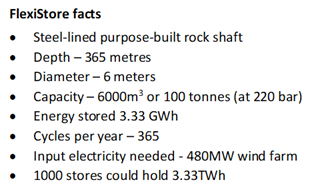

Each rock shaft would be six metres in diameter and 365 metres deep and lined with steel. A single store would hold up to 100 tonnes of green hydrogen – sufficient to refuel more than 1000 HGVS, or to power 500 buses for a week.

Gravitricity calculates that construction of just 1000 FlexiStores would meet a quarter of the UK Government’s predicted 2050 hydrogen storage needs[i].

Crucially, the stores can be constructed wherever required and are not dependent upon specific geological locations (a drawback of salt caverns). This means single or multiple FlexiStores can be built close to renewable-powered green hydrogen production facilities where they can fuel hydrogen-powered industrial hubs and commercial hydrogen filling stations.

A single FlexiStore would store the green hydrogen generated by a 460 MW offshore wind farm and could be emptied and refilled daily, whilst multiple stores could soak up vast amounts of otherwise wasted or ‘constrained’ wind – which amounted to 3.6TWh in 2020[ii].

The Edinburgh firm is now seeking funds along with VSL to build their first scale demonstrator project in the UK. Once complete Gravitricity then plans the rollout of hundreds of purpose-built green hydrogen FlexiStores nationwide. The company is also in advanced discussions with Cumbrian steel specialists Bendalls Engineering to fabricate the linings for the rock shafts.

[i] National Grid’s ‘Future Energy Scenarios 2021’ suggest that between 12TWh and 51TWh of hydrogen storage will be required in 2050 across varying net zero compliant scenarios. UK Hydrogen Strategy, August 2021: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/1011283/UK-Hydrogen-Strategy_web.pdf

[ii] Storage could ‘slash curtailment of British wind’ - reNews - Renewable Energy News

“Green hydrogen will be a vital fuel of the future in industrial applications and in heavy transport, where electrification is just not feasible, or where industrial grey hydrogen is already used,” says Charlie Blair, Managing Director of Gravitricity.

“Green hydrogen will be a vital fuel of the future in industrial applications and in heavy transport, where electrification is just not feasible, or where industrial grey hydrogen is already used,” says Charlie Blair, Managing Director of Gravitricity.

“Purpose-built lined rock shafts will be the safest and most affordable way to store large volumes of hydrogen near to where it will be required. It is difficult to transport hydrogen. It therefore makes sense to locate hydrogen storage systems close to sources of renewable power – which can generate green hydrogen – and to potential users.

“At present, the main proposals for storage are underground salt caverns and above ground storage. Salt caverns offer scale, but very little flexibility – they only exist in certain locations; whilst above ground systems lack scale.

“We believe we have a ‘Goldilocks’ solution which can be delivered safely and affordably to meet the growing hydrogen economy’s needs,” Blair says.

Commenting on the MoU, Peter Hughes, Managing Director of VSL UK said:

“VSL is delighted to partner with Gravitricity to develop and deliver these pioneering ground engineering solutions for renewable energy generation and storage. This project is fully aligned with the VSL vision to focus our engineering capabilities and solutions on the global transition to a low carbon future.”

The UK Government has highlighted a number of electrolytic hydrogen projects across the UK which will require hydrogen storage alongside renewable powered electrolysers[iii].

Gravitricity has already identified a number of sites for the UK pilot project and is in discussion with site owners, including utilities, regarding the pilot project and future commercial schemes.

Gravitricity recently completed a £300,000 feasibility study, conducted with ARUP and funded by the UK Government’s BEIS HySupply programme, which showed it is technically and commercially feasible to store large amounts of compressed hydrogen in an underground lined rock shaft.

“If green hydrogen is to become a mass market fuel of the future then we need to find ways to store it safely and in large quantities close to where it is needed,” Blair says.

[iii] Page 11, UK Hydrogen Strategy, August 2021: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/1011283/UK-Hydrogen-Strategy_web.pdf

About Gravitricity

At Gravitricity we are developing long-life, below-ground technologies which store energy safely and deliver it on demand at a lower lifetime cost than current alternatives.

Our gravity and hydrogen storage technologies each offer unique attributes, ideally suited to the fast-evolving energy markets of tomorrow.

About VSL Ltd

As a specialist in post-tensioned and cable-stayed structures, foundations and ground engineering, VSL contributes to the design and construction of transport infrastructure (bridges, tunnels, roads), buildings, and industrial & energy-producing structures, and it maintains, repairs and upgrades all structural systems that guarantee performance, safety and durability.

VSL is part of Bouygues Construction group. It has 3,800 employees in 25 countries, mainly located in Asia, Oceania, the Middle East, Europe, Canada and Latin America.

Nouryon broadens innovative crop nutrition portfolio through ADOB acquisition

Nouryon, a global specialty chemicals leader, announced that it has completed the acquisition of ADOB, a leading supplier of chelated micronutrients, foliars and other specialty agricultural solutions headquartered in Poland.

“The acquisition of ADOB reflects Nouryon’s continued commitment to the Agriculture & Food end-market and allows Nouryon to expand its services and product offerings for customers in the industry,” said Ignacio Garin, Vice President of Agriculture and Food at Nouryon.

“The acquisition of ADOB reflects Nouryon’s continued commitment to the Agriculture & Food end-market and allows Nouryon to expand its services and product offerings for customers in the industry,” said Ignacio Garin, Vice President of Agriculture and Food at Nouryon.

All business operations will transfer to Nouryon as part of the transaction which includes two manufacturing sites located in Poznań and Wrocław in Poland.

Additional terms of the agreement were not disclosed.

About Nouryon

Nouryon is a global, specialty chemicals leader. Markets and consumers worldwide rely on our essential solutions to manufacture everyday products, such as personal care, cleaning goods, paints and coatings, agriculture and food, pharmaceuticals, and building products. Furthermore, the dedication of more than 7,650 employees with a shared commitment to our customers, business growth, safety, sustainability and innovation has resulted in a consistently strong financial performance. We operate in over 80 countries around the world with a portfolio of industry-leading brands. Visit our website