Uncategorised (4996)

Kemira announces long-term polymer supply agreement extension with Ithaca Energy

AdministratorKemira, a global leader in the manufacture and supply of high-quality polymers, has signed a multiyear extension to the current polymer supply agreement with Ithaca Energy. The new contract is an extension to a contract signed in 2018 to supply polymers in order to enhance oil extraction performance on one of Ithaca Energy’s operated assets in the UK North Sea.

In 2017, Kemira expanded the polymer manufacturing capacity for Chemical Enchanced Oil Recovery (CEOR) in its Botlek site in the Netherlands. The now announced multiyear supply agreement extension with Ithaca Energy will ensure good utilization of the investment at Botlek.

In 2017, Kemira expanded the polymer manufacturing capacity for Chemical Enchanced Oil Recovery (CEOR) in its Botlek site in the Netherlands. The now announced multiyear supply agreement extension with Ithaca Energy will ensure good utilization of the investment at Botlek.

Pedro Materan, SVP Global Oil & Gas at Kemira: ”We are very pleased to continue our partnership with Ithaca Energy long-term. Kemira’s fully tailored polymers for CEOR offer excellent opportunities to improve resource efficiency and sustainable operations as well as profitability.”

Kemira is a global chemicals company serving customers in water intensive industries. We provide best suited products and expertise to improve our customers’ product quality, process and resource efficiency. Our focus is on pulp & paper, oil & gas and water treatment. In 2019, Kemira had annual revenue of around EUR 2.7 billion and over 5,000 employees. Kemira shares are listed on the Nasdaq Helsinki Ltd. www.kemira.com

Ithaca Energy’s strategy is centered on building a highly profitable, leading North Sea oil and gas company. The Company is an experienced North Sea operator focused on the delivery of lower risk growth through the appraisal and development of UK undeveloped discoveries and the exploitation of its UK producing asset portfolio. The Company was founded in 2004 and has grown through the execution of both new field development activities and acquisitions. Ithaca is a wholly owned subsidiary of the Tel Aviv stock exchange listed Delek Group Limited (TASE: DLEKG, US ADR: DGRLY), Israel’s leading integrated energy company. For further information please consult the Company’s website www.ithacaenergy.com.

Konecranes wins order for two more mobile harbor cranes from ZHD Stevedores in the Netherlands

AdministratorIn July 2020, ZHD Stevedores (ZHD) ordered two eco-efficient Konecranes Gottwald Model 6 Mobile Harbor Cranes for their operations in the Netherlands – one for Dordrecht and one for Moerdijk. With delivery in February and commissioning by the end of March 2021, the cranes will handle dry bulk, steel coils, breakbulk and containers.

Established in 1968, ZHD Stevedores is a privately owned, independent stevedoring company with over 50 years of stevedoring experience. Active in the so-called Rotterdam-Rijnmond area, ZHD operates terminals (including open and covered storage) in the ports of Dordrecht and Moerdijk. ZHD also renders floating stevedoring services in the Port of Rotterdam.

Today, this fourth-generation family business handles cargo from ships of all sizes. In order to maintain its continuing success in one of the largest port regions in the world, ZHD regularly renews its equipment to improve their technology and competitiveness. ZHD is already operating several Konecranes Gottwald mobile harbor cranes. The present investment is made to both further improve services towards customers as well as to further comply with future environmental requirements.

Today, this fourth-generation family business handles cargo from ships of all sizes. In order to maintain its continuing success in one of the largest port regions in the world, ZHD regularly renews its equipment to improve their technology and competitiveness. ZHD is already operating several Konecranes Gottwald mobile harbor cranes. The present investment is made to both further improve services towards customers as well as to further comply with future environmental requirements.

“Exactly 20 years ago, we ordered our first legacy Gottwald mobile harbor crane – a HMK 300 EG,” says Alain Bornet, Managing Director of ZHD Stevedores. “This crane has served us well, but it’s time to get a replacement. We already have two Model 6 cranes, one of which is placed on a self-propelled pontoon and has been constructed and engineered as a one-of-a-kind 50-ton floating crane called “Ahoy 50”. We believe an investment in two more cranes is the right answer to our growing operations. The cranes have proven to be durable, high-performance machines and have really helped to build our business. So, it was logical for us to rely on Konecranes again to expand our capacity.”

The two new Konecranes Gottwald Model 6 mobile harbor cranes are the G HMK 6407 B variant in a four-rope grab configuration for dry bulk handling. With a maximum lifting capacity of 100 tons, they are suitable to handle steel coils, breakbulk and containers. Both cranes will be prepared for operations on a pontoon, a modification that provides the versatility needed for multiterminal and multimodal operations. Furthermore, they have different propping bases allowing the crane to be placed and operated in narrow spaces.

Both cranes feature advanced mobile harbor crane drive technology from Konecranes that meets EU Stage V emission standards. Additionally, the cranes are prepared for connection to an external power supply, providing ZHD maximum flexibility in terms of energy source and points of operation.

The cranes are also equipped with the latest Konecranes digital services such as web reporting and bidirectional remote access that allows ZHD to share crane data in order to improve performance and maintenance work.

“We have been collaborating very intensively to achieve as much operational flexibility as possible. The outcome is very impressive. This joint effort proves the strength of our customer relationship with ZHD,” says Alexandros Stogianidis, Director Sales Benelux for Konecranes Port Solutions. “They use our equipment to boost their productivity, improve their eco-efficiency and add flexibility to their stevedoring business. We look forward to their future success as we continue to work together.”

With this transaction, ZHD and Konecranes have further consolidated their cooperation into the future and are therefore confident that they will further optimize their mutual services.

Further information:

Alexandros Stogianidis, Director Sales Benelux, Konecranes Port Solutions

Email: This email address is being protected from spambots. You need JavaScript enabled to view it. or phone: +32 3 546 4508

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2019, Group sales totaled EUR 3.33 billion. Including MHE-Demag, the Group has around 17,300 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

Metso Outotec wins two orders for high-capacity copper anode casting shops

AdministratorMetso Outotec has won two orders for its Outotec® Anode Casting Shops, which are to be delivered to copper production plants in China and Bulgaria. Yangxin Hongsheng Copper Co., Ltd., which is constructing its greenfield copper smelter in Huangshi, Hubei, China, expects to start its operations in 2021. Aurubis Bulgaria AD’s copper production plant in Pirdop, Bulgaria, has been operating since the end of the 1950s and is a longtime customer of Metso Outotec.

Both anode casting shops are equipped with fully electric systems to improve maintainability, energy efficiency and safety. The shops are expected to be commissioned in 2021. Typically, the combined value for two shops of this type would be close to EUR 10 million. The orders have been booked in Metso Outotec’s Q3 2020 orders received.

Anode Casting Shop

Anode Casting Shop

“We are extremely pleased to have won these two important orders. Both shops will feature two casting wheels for high capacity and yield. They will also be equipped with advanced automation to ensure high availability and high casting accuracy to produce high quality anodes,” says Jari Ålgars, President, Metals business area at Metso Outotec.

World-leading copper processing technology

Metso Outotec is a global leader in anode casting technology, which is used to produce a significant proportion of the world’s copper anodes.

Metso Outotec has delivered more than 90 anode casting shops around the world, and its offering features all the technology and expertise required for the end-to-end copper production process and its lifetime servicing.

More information on Metso Outotec’s Anode Casting Shop

For further information, please contact:

Jyrki Makkonen, Vice President, Smelting, Metso Outotec, Tel. +358 20 529 4022, E-mail: jyrki.makkonen(at)mogroup.com

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing, metals refining and recycling industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its illustrative combined sales for 2019 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

APAC to lead global wind gearbox and direct-drive equipment markets over next four years, says GlobalData

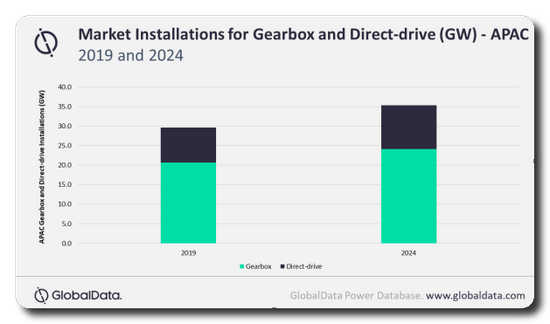

AdministratorAsia-Pacific (APAC) is expected to continue to lead the global wind gearbox and direct-drive equipment markets between 2020 and 2024 with a projected market share of 50.7% and 64%, respectively, says GlobalData, a leading data and analytics company.

GlobalData’s latest report, ‘Wind Gearbox and Direct-Drive, Update 2020 - Global Market Size, Competitive Landscape and Key Country Analysis to 2024’, reveals that the dynamic shift towards low carbon modes of power generation, improvements along the supply chain and technology maturity are creating viable business opportunities within the wind power sector.

Emerging economies are beginning to embrace wind, which is driving new installations while prominent markets such as China, the US and EU, with their legacy installations, are creating a significant market for gearbox refurbishments.

The global installations of wind gearbox and direct-drive equipment are estimated to aggregate 221.2GW and 78.1GW, respectively, over the forecast period.

In 2019, the global total installation of wind gearbox stood at 41.2GW as compared to 13GW for direct-drive. Although gearbox will continue leading the market over the forecast period in absolute terms, the direct-drive market is projected to witness higher growth, as they offer lower system weight, higher reliability due to fewer parts, and reduced maintenance, with higher power ratings. The direct-drive market is expected to witness an annual installation of 17.5GW, i.e., 27% of the total installation in 2024.

Nirushan Rajasekaram, Power Analyst at GlobalData, says: “Within APAC, major countries such as China, India and Australia are significantly driving the direct-drive market, with other countries such as Japan, South Korea and Taiwan playing a minor role in supporting the market. Similarly, for wind gearbox equipment, trends in the major markets of China and India will underpin the regional gearbox market, which is estimated to grow at a compound annual growth rate (CAGR) of 7%, over the forecast period.”

China accounted for approximately 38% of the global gearbox market value in 2019. The country is committed towards enhancing its renewable portfolio, to sustain its development agenda and the growing electricity demand, while reducing power sector emissions. However, the market is projected to decline over the forecast period, due to policy changes instituted by the government.

Rajasekaram adds: “India is estimated to be the fastest growing market for gearbox, growing at a CAGR of 19.5% over the forecast period. Similar to China, the government has proposed ambitious renewable energy targets, which are expected to drive the wind equipment market. With respect to the refurbishment market, the large-scale historical installations of wind turbines in China will drive the regional market value for gearbox refurbishment, which is projected to grow significantly over the forecast period.”

However, despite the positive outlook for wind gearbox and direct-drive markets, certain market uncertainties exist. The emergence of other technologies, changing regulatory landscape, and financial constraints threaten the market. Major countries such as China and the US are likely to experience a market slowdown. Nevertheless, opportunities for refurbishment are plenty, owing to legacy turbine installations in the aforementioned countries.

Rajasekaram concludes: “The growing role of smart technologies and other low carbon modes of power generation could result in wind power becoming uncompetitive and thereby limiting its growth prospects. Countries with significant wind capacities are exploring other clean power generation sources, while emerging markets will require the construction of sufficient grid infrastructure to support new generation capacity addition, which could slow the overall market deployment of wind power.”

Konecranes wins order for fleet of Konecranes Noell Sprinter Carriers

AdministratorThe HDC Hyundai Development Company of Korea has ordered a fleet of 28 Konecranes Noell Sprinter Carriers for Busan New Port 2-4 in Busan, Korea. The Sprinter Carriers will be delivered as part of the port’s expansion project 2-4. The order was booked in August 2020.

“The HDC Hyundai Development Company is a renowned developer of container terminals and we are proud to have received this repeat order as Busan New Port continues to expand,” said Peter Kania, Head of Sales for Straddle Carriers, Konecranes Port Cranes. “We delivered Sprinter Carriers as part of Busan New Port’s earlier growth phase. This further order is a vote of confidence and trust in the performance and reliability of these machines as horizontal transport vehicles from the quayside, working closely with the automated stacking cranes in the container yard,” continued Kania. When the Sprinter Carriers on order are delivered and working, Busan New Port will have a Konecranes Noell Sprinter Carrier fleet of 64 machines.

The Sprinter Carriers on order are man-driven, diesel-electric machines stacking containers 1-over-1 as part of swift container transfer between the quayside and container yard. The order will be delivered in three batches starting at the end of 2021 and ending by July 2022. All of the machines will be equipped with Stage IV diesel engines, and they will all have 8 wheels by special customer request to reduce ground pressure. The standard Konecranes Noell Sprinter Carrier has 6 wheels.

All of these Konecranes Noell Sprinter Carriers will have built-in readiness for automation. This puts Busan New Port on Konecranes’ path to port automation, where container terminals improve productivity and safety in manageable steps. The path to port automation applies to all container handling equipment brands. Full automation can be the final goal but it doesn’t have to be. Flexibility is the key.

Further information:

Peter Kania, Head of Sales for Straddle Carriers, Konecranes Port Cranes

Email: This email address is being protected from spambots. You need JavaScript enabled to view it. or phone: +499312053216

Further information for investors and analysts:

Kiira Fröberg, Director of Investor Relations, Konecranes

Email: This email address is being protected from spambots. You need JavaScript enabled to view it. or phone: +358 20 427 2050

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2019, Group sales totaled EUR 3.33 billion. Including MHE-Demag, the Group has around 17,300 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

BASF New Business and G-Philos sign MoU for cooperation in power-to-gas (P2G) business

AdministratorBASF New Business GmbH (BNB), a wholly owned subsidiary of the German chemical company BASF SE, and the leading Korean P2G system company G-Philos have signed a memorandum of understanding (MoU) to cooperate in P2G projects globally. Up to 2022, BNB will supply NAS® batteries that can provide a total of 19.2 MWh of energy to G-Philos for P2G projects. BNB will support G-Philos in further P2G projects and in the development of business with Power Conversion Systems (PCS) for NAS® batteries in South Korea as well as in the global market. Through the collaboration, the two companies expect synergy effects in the field of P2G systems for green hydrogen production.

- Up to 2022, BNB will supply NAS® batteries to G-Philos for P2G projects

Green hydrogen production from renewable energies, such as solar, wind and hydro, without CO2 emissions has been drawing ever-more global attention in recent years. In South Korea, the Green New Deal comprises plans to invest KRW 73.4 trillion ($61 billion) in projects, including renewable energy and hydrogen, as a part of South Korea’s policy to transform into a low-carbon society. P2G technologies will be one of the key elements of this plan. South Korea is expanding its renewable energy supply and clean hydrogen production in a similar manner to the E.U., which recently announced its own Hydrogen Strategy. With the recently signed MoU, BNB and G-Philos are now joining forces to support the expansion of green hydrogen production from renewable energy.

BNB distributes NAS® batteries produced by NGK Insulators Ltd. NAS® batteries are high-energy, long-duration sodium-sulfur batteries designed for stationary energy storage. With their capability to discharge for 4–8 hours, NAS® batteries are ideally suited for applications such as renewable power stabilization and integration into the grid. In order to use the electrical energy stored in the battery, a power conversion system (PCS) is needed.

BNB distributes NAS® batteries produced by NGK Insulators Ltd. NAS® batteries are high-energy, long-duration sodium-sulfur batteries designed for stationary energy storage.

BNB distributes NAS® batteries produced by NGK Insulators Ltd. NAS® batteries are high-energy, long-duration sodium-sulfur batteries designed for stationary energy storage.

G-Philos has developed a suitable PCS for a 200 kW NAS® battery system. The battery and the PCS have already been commissioned in a P2G project implemented by G-Philos in collaboration with Korea Midland Power (KOMIPO) at Sangmyung Wind Farm (21 MW), Jeju Island, South Korea. In this case, the NAS® battery serves as an energy buffer between wind turbines and electrolyzers to ensure stable hydrogen production from surplus wind power despite the fluctuating nature of wind. G-Philos can now supply PCS products for the NAS® battery systems ranging from 200 kW up to 800 kW.

Gawoo Park, CEO of G-Philos, said: “In order to stably produce green hydrogen while accommodating the variability of renewable energy, the NAS® battery is expected to play an important role in securing system operation safety and reliable long-term operation as an energy buffer. G-Philos will keep focusing on commercializing green hydrogen production through various P2G projects.”

BNB’s Director of E-Power Management, Frank Prechtl, said: “Green hydrogen production is an upcoming market and a promising application for NAS® batteries. With G-Philos, we now have a strong and competent partner to develop this opportunity into a sizeable business.”

About BASF New Business

BASF New Business GmbH (BNB) is a wholly owned subsidiary of BASF SE. The purpose of BNB is to support the growth targets of BASF by identifying and generating new businesses which are beyond the core business of BASF group but within target portfolio of BASF. BNB is primarily active in arising markets with higher-than-average growth rates. In addition to its head office in Ludwigshafen, Germany, BNB has offices in Hong Kong, Korea, Japan, Taiwan and the United States. Founded in 2001, BNB utilizes startup-like structures and methods as well as an extensive internal and external collaboration network. It works closely with future customers to build-up and expand new businesses.

BNB includes the unit Foresight & Scouting as well as Chemovator GmbH, a wholly owned BNB subsidiary based in Mannheim, Germany, which serves as BASF’s internal incubator, offering a protected space for all employees to accelerate speed-to-market for innovative business ideas. In addition, BNB currently has three Business Build-Up units: 3D printing (in the form of wholly owned BNB subsidiary BASF 3D Printing Solutions GmbH), E-Power Management and Functional Feed Additives.

The activities of BNB are complemented by BASF Venture Capital GmbH (BVC), a wholly owned subsidiary of BNB. BVC invests worldwide in young companies and funds with disruptive technologies and business models based on chemistry.

Further information at: www.basf-new-business.com.

About BASF

At BASF, we create chemistry for a sustainable future. We combine economic success with environmental protection and social responsibility. More than 117,000 employees in the BASF Group work on contributing to the success of our customers in nearly all sectors and almost every country in the world. Our portfolio is organized into six segments: Chemicals, Materials, Industrial Solutions, Surface Technologies, Nutrition & Care and Agricultural Solutions. BASF generated sales of €59 billion in 2019. BASF shares are traded on the stock exchange in Frankfurt (BAS) and as American Depositary Receipts (BASFY) in the U.S.

Further information at www.basf.com.

About G-Philos

G-Philos has been on the right path to realizing its vision of becoming a global leader in the development and manufacture of power conversion systems for renewable energy applications since 2009.

After investing considerable efforts into developing and manufacturing highly efficient power conversion systems for over 10 years, G-Philos has established itself as a market leader in power conversion systems (PCS) for fuel cells and power-to-gas (P2G) systems linked to renewable energies for green hydrogen production in Korea.

Further information at www.g-philos.co.kr

Russia to dominate global working gas capacity additions by 2024, says GlobalData

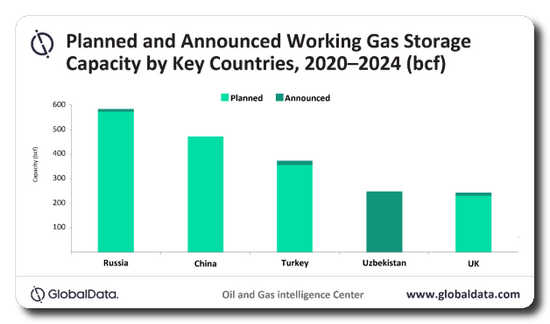

AdministratorRussia is expected to witness the highest global working gas storage capacity additions, contributing around 21% of the global capacity additions by 2024, says GlobalData, a leading data, and analytics company.

The company’s report, 'Global Capacity and Capital Expenditure Outlook for Underground Gas Storage, 2020−2024 – Russia Leads Global Working Gas Capacity Additions,' reveals that Russia is likely to witness a working gas storage capacity addition of 585 billion cubic feet (bcf) by 2024. Out of which, the capacity of planned projects that have received necessary approvals for development accounts for nearly 573 bcf.

Haseeb Ahmed, Oil and Gas Analyst at GlobalData, comments: “Russia is expected to witness the start of six new-build gas storage sites by 2024. Of these, five are planned and the remaining is an announced site. Stepnovskoe II is the largest upcoming gas storage site in the country, with a capacity of 199 bcf followed by Bednodemyanovskoye I with 177 bcf by 2024.”

GlobalData identifies China as the second-highest contributor to the global working gas storage capacity additions contributing around 17% or 473 bcf by 2024. The country is expected to witness the start of operations of four planned projects. Liaohelei 61 is the largest upcoming gas storage site in the country with a capacity of 406 bcf by 2024. Tongluoxia is the second largest upcoming gas storage site with a capacity of 53 bcf.

Ahmed continues: “Turkey ranks third across the globe contributing roughly more than 13% of the world’s working gas storage capacity additions during the outlook period 2020–2024. The country has six upcoming projects, of which five are planned and the remaining one is an announced project. Tuz Golu II and Mersin II are the largest upcoming gas storage sites in the country with respective capacities of 148 bcf and 106 bcf by 2024.”

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis, and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, technology, energy, financial and professional services sectors. PR10309.

State-of-the-art natural gas detection instruments now available

Q.E.D. Environmental Systems, Inc., a leading manufacturer of innovative environmental products and subsidiary of Graco Inc., announces Huberg instruments will now be available in the American markets through QED distribution.

Established in 1987, Huberg is known among industry professionals as a top manufacturer of safety instrumentation systems for gas and water mains supply. Through the years, Huberg has provided customers with well-engineered products, continuous innovation, professional information and consulting, as well as customized services, all to guarantee the highest quality and reliability. QED acquired Huberg in 2019, and will now distribute Huberg products to new American markets.

Used by leading natural gas mains distribution network operators (DNOs) and gas utility and service companies, the Huberg product range focuses on equipment for the survey of gas distribution networks and operator protection in hazardous environments. The Huberg product portfolio offers solutions for both vehicular-based technology for roadside surveys and hand-held devices for accurately identifying and pinpointing leaks. QED has fully integrated the Huberg sales and service operations into its Dexter, Michigan organization, while design and manufacturing is taking place in its new UK plant.

“Our new state-of-the-art production and calibration facility in the United Kingdom is now the design and manufacturing center for all Huberg products since our acquisition. We are excited to expand the reach of Huberg’s legacy of excellent service and engineered solutions into the Americas,” said Peter Bloem, Huberg Business Unit Manager for QED.

A highlight of the Huberg by QED product portfolio is the state-of-the-art LASER OneTM portable natural gas leak analyzer with LASER spectroscopy. This highly-sensitive detector offers all of the advantages of optical detection in a highly compact and portable device. The instrument provides precise and reliable findings when detecting methane leaks, with accurate detection of leaks of down to 0.5ppm in a response time of 2.5 seconds. It is not sensitive to cross-gas contamination and does not require a gas cylinder for operation, which makes it ideal for the detection of natural gas leaks in underground natural gas distribution networks. The LASER One instrument is ATEX and IECEX-certified for safe operation in Zone 1 areas. Proprietary software offers DNOs the ability to integrate into their data reporting systems.

For more information on the Huberg product line or how to become a distributor, contact QED Environmental Systems at (800) 624-2026 or visit www.qedenv.com.

About Q.E.D. Environmental Systems, Inc.

Q.E.D. Environmental Systems, a subsidiary of Graco Inc., is a leading manufacturer of innovative environmental pumping systems, landfill products, landfill gas products, and air strippers for use at landfills, mines, oil refineries and other industrial sites, as well as hazardous waste cleanup sites. Our products are used around the world for a wide range of environmental applications, including groundwater sampling, groundwater remediation pumping, landfill leachate and condensate pumping, landfill gas collection and control, landfill and biogas analysis, air stripping and VOC removal, and wireless data acquisition. Based in Dexter, MI, QED serves customers from support centers in Michigan, California and England. For more information, call 734-995-2547 or contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

Metso Outotec receives recognition in Mining Suppliers’ Ranking in Chile

AdministratorMetso Outotec has received recognition as the leading supplier in the Mining Suppliers’ Ranking conducted by Phibrand in Chile. In the winning categories, Metso Outotec was nominated under the name Metso, as the survey was initiated in May 2020, prior to the merger of Metso Minerals and Outotec on July 1, 2020. These categories include Crushers, Mills and Plant Maintenance as well as the highest recognition in the ranking, the Best Performing International Supplier.

“This recognition makes us happy and this is truly a moment of pride for us, as the winners are nominated by the customers themselves in a very competitive, high-end market. We want to continue improving and delivering the best service to our customers by knowing their needs and innovating solutions,” says Eduardo Nilo, President of Metso Outotec’s South America market area and notes that the circumstances have been unusual this year.

“We are experiencing a historic year for several reasons – we have taken a new step of growth by becoming Metso Outotec, and the pandemic has led us to develop new, safer ways to operate in factories and service centers as well as in the field. I want to take this opportunity to thank everyone for their exceptional work,” he concludes.

Pictured in the middle from left to right are Marcelo Iannello, VP of Finance in Metso Outotec's South American market area, Eduardo Nilo, President of Metso Outotec's South American market area and Cristian Mansilla, General Manager of Phibrand.

Pictured in the middle from left to right are Marcelo Iannello, VP of Finance in Metso Outotec's South American market area, Eduardo Nilo, President of Metso Outotec's South American market area and Cristian Mansilla, General Manager of Phibrand.

The Mining Suppliers’ Ranking is a globally unique survey in the mining industry. It gives an outlook on how suppliers are positioned in the Chilean market. Metso Outotec has a strong presence in the whole South American market with six service centers, four factories, four distribution centers, a foundry and a performance center established in 2019 to focus on remote monitoring.

For further information, please contact:

Macarena Vallejo, Director, Marketing, South America, Metso Outotec, tel. +56 32 2270800, E-mail: macarena.vallejo(a)mogroup.com

Helena Marjaranta, Vice President, Communications and Brand, Metso Outotec, Tel. +358 20 484 3212, E-mail: helena.marjaranta(a)mogroup.com

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing, metals refining and recycling industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its illustrative combined sales for 2019 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

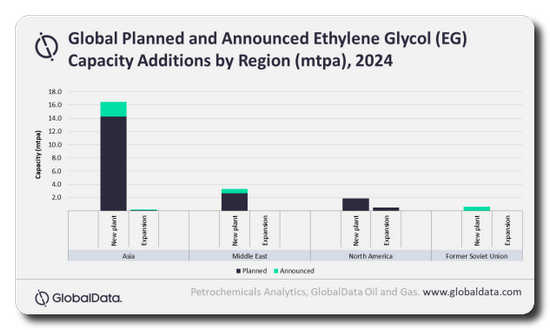

Asia to lead global ethylene glycol capacity additions by 2024, says GlobalData

AdministratorGlobal ethylene glycol (EG) capacity is poised to see considerable growth over the next five years, potentially increasing from 41.80 million tonnes per annum (mtpa) in 2019 to 65.04 mtpa in 2024, registering a total growth of 56%. Among the regions, Asia leads the capacity additions and the region’s ethylene glycol capacity is expected to increase from 23.10 mtpa in 2019 to 40.08 mtpa in 2024, at an average annual growth rate (AAGR) of 11%, says GlobalData, a leading data and analytics company.

The company’s report, ‘Global Ethylene Glycol (EG) Industry Outlook to 2024 – Capacity and Capital Expenditure Forecasts with Details of All Active and Planned Plants’ reveals that Asia is expected to have a new-build and expansion ethylene glycol capacity of 16.64 mtpa from 32 new-build and expansion projects. Out of these, 29 are new-build projects and the remaining are expansion projects.

Dayanand Kharade, Oil and Gas Analyst at GlobalData, says: “In Asia, the capacity growth of EG will be mainly from China, which accounts for around 73% of the regions’ capacity additions. New-build projects account for most of these capacity additions in China.”

GlobalData identifies India as the second highest country within the region in terms of capacity additions, with capacity increase from 2.22 mtpa in 2019 to 5.07 mtpa in 2024, at an AAGR of 16.6%. Major capacity additions will be from the plant, Haldia Petrochemicals Kakinada Ethylene Glycol Plant, with a capacity of 0.75 mtpa by 2024.

Indonesia will be the third highest country within the region in terms of capacity additions, with capacity increase from 0.22 mtpa in 2019 to 0.92 mtpa in 2024, at an AAGR of 28.9%. Major capacity additions will be from the plant, Lotte Chemical Corporation Cilegon Ethylene Glycol Plant, with a capacity of 0.70 mtpa by 2023.

Zhejiang Satellite Petrochemical Co Ltd, China Sanjiang Fine Chemicals Co Ltd and Tangshan Xuyang Petrochemical Co Ltd will be the top three companies in Asia in terms of planned and announced capacity additions over the outlook period.

- Quotes provided by Dayanand Kharade, Oil & Gas Analyst at GlobalData

- Information based on GlobalData’s report: ‘Global Ethylene Glycol (EG) Industry Outlook to 2024 – Capacity and Capital Expenditure Forecasts with Details of All Active and Planned Plants’

- This press release was written using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, technology, energy, financial and professional services sectors.

More...

Alfa Laval wins SEK 155 million off-shore orders in Brazil

AdministratorAlfa Laval – a world leader in heat transfer, centrifugal separation and fluid handling – has won two orders to supply Framo pumping systems for two FPSO (Floating Production, Storage and Offloading) vessels to operate outside the coast of Brazil. The orders have a total value of approximately SEK 155 million and are booked in the Pumping Systems unit of the Marine Division, with deliveries scheduled for 2021.

The two orders comprise marine pumping systems for firewater and sea water lift service.

The two orders comprise marine pumping systems for firewater and sea water lift service.

“I am pleased to announce these two large orders for our Framo pumping systems. These reliable and durable systems are used in a variety of duties, where they provide safe operations and optimized performance,” says Sameer Kalra, President of the Marine Division.

Did you know that… Framo pumping systems are used in four main areas: cargo, offshore, environmental and aquaculture?

This is Alfa Laval

Alfa Laval is active in the areas of Energy, Marine, and Food & Water, offering its expertise, products, and service to a wide range of industries in some 100 countries. The company is committed to optimizing processes, creating responsible growth, and driving progress – always going the extra mile to support customers in achieving their business goals and sustainability targets.

Alfa Laval’s innovative technologies are dedicated to purifying, refining, and reusing materials, promoting more responsible use of natural resources. They contribute to improved energy efficiency and heat recovery, better water treatment, and reduced emissions. Thereby, Alfa Laval is not only accelerating success for its customers, but also for people and the planet. Making the world better, every day. It’s all about Advancing better™.

Alfa Laval has 17,500 employees. Annual sales in 2019 were SEK 46.5 billion (approx. EUR 4.4 billion). The company is listed on Nasdaq OMX.

NUM launches digital twin technology for CNC machine tools

AdministratorCNC specialist NUM has launched digital twin technology that enables machine tool manufacturers to reduce their time to market dramatically, by using powerful Industry 4.0 simulation techniques.

Originally known as pairing technology, and first used by NASA in the early days of space exploration, digital twin technology is now rapidly gaining industry acceptance as one of the most cost-effective means of accelerating the development of products, processes and services.

- Provides virtual model of physical machine mechatronics

- Significantly reduces machine development time and cost by allowing design analysis, testing and performance enhancement to take place before construction

For automation products such as machine tools, a digital twin is a virtual model that uses simulation, real-time data acquisition/analysis and machine learning techniques to allow full evaluation of a machine’s dynamic performance before constructing a physical prototype. The same technology can also be employed for customer presentations, virtual commissioning and operator training purposes – and all well before the actual machine itself has even been built.

NUM offers two versions of digital twin technology, to best suit customers’ needs. Both versions are designed for use with NUM’s powerful, open-architecture Flexium+ CNC platform. One version uses a naked Flexium+ controller and resident virtualisation software running on the system’s industrial PC to simulate the twinned machine automation. The other version uses the actual Flexium+ controller that will eventually be incorporated in the machine, linked via EtherCAT to a standalone PC running specialist high speed hardware simulation software to represent the mechatronics of the twinned machine.

The virtual controller version includes a software development kit for creating the software model of the machine. The model is a standalone PLC program that uses predefined components to simulate individual machine elements, such as sensors, spindles, pneumatic cylinders, etc. It is loaded into the integrated PLC of the Flexium+ controller. The Flexium NCK in the controller executes the NC programs and simulates the changing position values of the machine’s axes. To help users visualise the process, NUM’s package includes the CODESYS Depictor software tool produced by CODESYS GmbH, which is used to produce 3D visualisations from the IEC 61131-3 code created by the simulation.

The other version of NUM’s digital twin technology package accommodates real-time data acquisition and analysis. It is based on the ISG-Virtuous hardware simulation software produced by Industrielle Steuerungstechnik GmbH (ISG). The Flexium+ controller that is intended to be used in the physical machine is connected via an EtherCAT network to a standard PC, and interacts with the simulation software in real-time. The PC acts as the twinned virtual machine – with all simulated, virtual components behaving like real components in terms of their interfaces, parameters and operating modes – to accurately replicate the structure and dynamic performance of the real machine. The movements of the machine are displayed realistically on the PC, using the supplied 3D simulation software.

NUM’s new digital twin technology provides machine tool manufacturers with a very powerful and cost-effective means of reducing their developments costs and accelerating their time to market. The virtual controller version is especially useful for the early development stage of a project, before the CNC system has been finalised, while the real-time hardware simulation version has the advantage that all sequencing (PLC) and motion control (CNC) programs that are created during development can simply be transferred to the real machine as soon as it becomes available.

CODESYS® is a trademark of CODESYS GmbH.

ISG-virtuos is a trademark of Industrielle Steuerungstechnik GmbH.

COSEL announces 1.2 kW high power density, low profile, onboard AC/DC power module for industrial and medical applications

AdministratorCOSEL Co, Ltd (6905: Tokyo) has just announced the addition of a 1.2 kW, compact and low profile, onboard AC/DC power module. Designed for demanding worldwide applications, the TUNS1200 has an input voltage range of 85VAC to 305VAC and is certified to meet industrial and medical standards. Packaged in a sealed plastic case with aluminum baseplate the TUNS1200 has a height of just 12.7 mm (0.5”) and weighs less than 280 grams. Compared to existing 1kW onboard AC/DC modules, the TUNS1200’s footprint is 36% smaller while delivering 21% more power. The unit can be operated from -40C to +100C baseplate temperatures. TUNS1200 modules can be paralleled up to nine units (up to 9,750W), their output voltage can be adjusted down to zero volts, and is easily set to constant voltage or constant current operating modes.

- Low profile with baseplate 12.7 mm (0.5 inch)

- High power density 152 W/In3 - 9.3 W/cm3

- 36% smaller footprint than current 1kW industry standard

- Wide input voltage 85VAC to 305VAC

- Active current sharing and easy paralleling - up to 9 units

- CVCC with easy constant current mode for battery charger

- High reliability and 5-year warranty

Thanks to COSEL’s high efficiency topology, the TUNS1200 delivers 21% more power in a 36% smaller footprint than existing AC/DC modules.

Packaged in sealed housing with an aluminum baseplate, the TUNS1200 is the latest member of COSEL’s TUNS series, which includes a 50W ¼ brick, 100W ½ brick and 300, 500 and 700W full brick units. Designed with the latest technology, the TUNS1200 delivers its full power up to +85 degrees centigrade baseplate temperature, and is able to operate safely at up to +100 degrees centigrade with a derating.

Designed for worldwide applications, TUNS1200 power supplies have an input voltage range of 85VAC to 305VAC single phase, and conform to the safety standards input voltage range of 100-277 VAC (50/60Hz).

The TUNS1200 series embraces three output voltages versions: TUNS1200F12 (12V / 84A), TUNS1200F28 (28V / 43A) and the TUNS1200F48 (48V / 25A). Output voltage can be adjusted +/- 20% (-20% /+10% for the 48V) using the trimming pin, though the TUNS1200 series include an active Voltage Trimming input (VTRM) making it possible to adjust the output voltage down to zero by applying an external voltage source. Using the latest technology, the TUNS1200 has a power efficiency of 92% typical and a power factor of 0.98 at 100V.

COSEL TUNS1200 series - 1.2 kW high power density, low profile, onboard AC/DC power module for industrial and medical applications

COSEL TUNS1200 series - 1.2 kW high power density, low profile, onboard AC/DC power module for industrial and medical applications

For applications such as battery chargers requiring constant current (CC), the TUNS1200 includes a dedicated pin (ITRM) and by applying a DC voltage or connecting a resistor to the –S terminal it is possible to set the constant current from just above zero to the desired current.

In applications where more power is required and physical height is an issue it is possible to connect up to nine TUNS1200s in parallel, delivering up to 9,750W in conduction cooling mode. When connected units in parallel and utilizing the Current Balance (CB) pin, the COSEL active current sharing ensures that each module delivers the correct amount of current to the load.

Optimized for conduction cooling, the TUNS1200 series can be operated within a temperature range of -40 to +100C baseplate, 20 - 95%RH (Non condensing). Depending on cooling and assembly method, a power derating may apply.

Housed in a sealed plastic case with aluminum baseplate, the TUNS1200 measures 117.3 x 86.8 x 12.7 mm (4.62 x 3.42 x 0.5 inch). The unit includes four mounting holes for fixing the unit to a cold plate or an additional heatsink. The standard unit comes with M3 threaded mounting holes, and a 3.4 millimeter non-threaded mounting insert option is available (option T).

The units have a 3,000VAC input to output isolation voltage (2MOOP), 2,000VAC input to ground (1MOOP) and 500VAC output to ground. Overcurrent, overvoltage and thermal protection are included as standard.

Suitable for industrial and medical applications, the TUNS1200 complies with the safety agency approvals: UL62368-1, EN62368-1, C-UL (equivalent to CAN/CSA-C22.2 No.62368-1 ), ANSI/AAMI ES60601-1, EN60601-1 3rd, C-UL (equivalent to CAN/CSA-C22.2 No.60601-1), and complies with IEC60601-1-2 4th. The TUNS1200 includes an active filter, complying with the harmonic attenuation IEC61000-3-2 (Class A).

Benefiting from a design optimized for conduction cooling, the TUNS1200 is suitable for applications requiring a silent power solution such as in a surgery room. Equally, it is suitable for industrial applications when forced air ventilation is impossible due to environmental constraints. Attached to a chassis or cold plate, the TUNS1200 can deliver impressive power with a high level of reliability.

The power supply complies with the RoHS directive and is CE marked in accordance with the Low Voltage Directive.

Related URL:

COSEL TUNS series

https://www.coseleurope.eu/Products/AC-DC/TUNS

About COSEL:

Established in Japan 1969, COSEL is one of the world’s leading designers and manufacturers of high performance AC-DC Power Supplies, DC-DC Converters and EMI Filters. With quality, reliability & flexibility as our main focus, we pride ourselves on developing some of the highest quality and most reliable products seen anywhere in the world today. The Cosel Group is a $253m global company employing some 810 staff with sales offices throughout Japan, Asia, Europe and North America. Our product range is aimed mostly at demanding applications within the Industrial, Factory Automation, Medical, Telecoms, Lighting, Audio/Broadcast & Renewable Energy sectors. A flexible approach with full in-house design means we deliver products using the very latest technology meeting the growing demands of our customers.

Rotork intelligent electric actuators with gearboxes used to provide flood protection in Texas

AdministratorThese sluice gates were constructed following discussions caused by Hurricane Harvey in 2017, which caused over $125 billion dollars’ worth of damage in the Houston area. During this time many locations in the 7-county region experienced serious flooding.

Storm water facilities were upgraded throughout the billion dollar golfing community and in other areas within the surrounding development. As the area is very flat, possible flooding can be a concern, as storm water flows into these facilities and down to the sluice gates, connecting to the nearby river. The gates remain open at all times so that water can flow into the river. However, during periods of excessive rainfall and heavy storms, when the river itself poses a flood risk, the actuators close the gates and seal the development from the river. The runoff water is then pumped away over the top of a nearby levee, allowing it to eventually run back into the river.

Intelligent electric IQ actuators with IB gearboxes on top of the sluice gate, ready to close it in order to prevent flooding.

Intelligent electric IQ actuators with IB gearboxes on top of the sluice gate, ready to close it in order to prevent flooding.

The installation of the actuators helps to ensure that the people of this community remain safe from the damage which could otherwise be caused by water infiltration into the development.

Rotork Site Services was responsible for commissioning the actuators with gearboxes and the start-up, ensuring that all products were fully operational.

Intelligent electric IQ actuators were chosen for this application due to the remote location of the sluice gates, which would have prohibited an hydraulic or pneumatic solution. Additionally, the close proximity of an electrical generator meant that a power supply was readily available.

Rotork’s IB gearboxes are suitable for use on sluice gates and for the most demanding motorised applications. They’re made with cast steel and when combined with the IQ actuator they can reach a torque of up to 44,000 Nm (32,452 lbf.ft).

Read more about IQ actuators

Read more about IB gearboxes

Read more about Rotork Site Services