Displaying items by tag: Konecranes

First Konecranes Gottwald Generation 6 Mobile Harbor Crane to Italy

Terminal San Giorgio S.r.l. (TSG) has ordered an eco-efficient Konecranes Gottwald ESP.8 Mobile Harbor Crane for its terminal in Genoa, Italy. Booked in November 2021, it is the very first Generation 6 crane to go to Italy. It will be delivered in June 2022.

Established in 2006, TSG has become the largest multipurpose terminal in Genoa, the busiest port in Italy. It is equipped to handle all kinds of freight including containers, breakbulk, project cargo, yachts, steel, and Ro-Ro.

Part of the Autosped/Gavio Group, a leading Italian logistics company, the terminal includes a number of intermodal rail and road connections to destinations around the country.

“We already operate two Generation 5 Konecranes Gottwald Mobile Harbor Cranes in Genoa, and they’ve always performed above and beyond our expectations, so we’re proud to be the first customer in Italy to order a new Generation 6. With its improved performance and additional features, we can’t wait to see how it handles containers and project cargo at our terminal,” says Maurizio Anselmo, Managing Director of TSG.

Innovative digital features and a fuel-optimized diesel generator set bring the crane in line with EU Stage V emission standards and Italy’s National Industry 4.0 Plan, a state strategy that encourages industrial innovation. The crane also has built-in readiness for an external power supply, so conversion to electric operation will be easy when resources allow. An additional service agreement will ensure that the cranes stay in good condition and provide TSG with maximum uptime.

“Our partnership with TSG is strong. With this new order, TSG will be able to experience the full potential of the Generation 6 crane in their operations. The order also shows the value of our sustained product development, as we continue to improve the productivity, reliability and fuel efficiency of our cranes,” says Gino Gherri, Regional Sales Manager for Konecranes Port Solutions.

The Generation 6 crane on order is a Konecranes Gottwald ESP.8 Mobile Harbor Crane, with a working radius of 54 m and a capacity of 150 t. A natural successor to the two Generation 5 cranes already on-site, it features stronger lifting capacity curves for improved performance and a higher classification for container handling, which doubles its service life in container handling operations.

A strong focus on customers and commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2020, Group sales totaled EUR 3.2 billion. The Group has around 16,500 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

Eurotransit orders Konecranes RMGs for new intermodal terminal in Kazakhstan

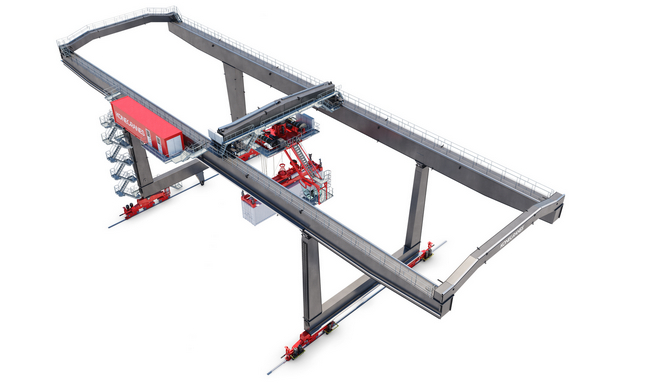

Eurotransit Group of Companies (Eurotransit) in Kazakhstan has ordered two Konecranes Rail-Mounted Gantry (RMG) cranes for its new intermodal terminal under construction in Dostyk, near the border with China. The order was booked in August 2021 and the cranes will be delivered in Q4 2022.

In addition to the intermodal terminal under construction, Eurotransit operates a terminal in Altynkol, Kazakhstan. The two Konecranes RMGs on order will transship containers on trains running between Kazakhstan and China.

Mr Erlan Dikhanbaev, Director of Eurotransit, said: “The Konecranes RMGs are central to our ambitious growth plans. We have very demanding environmental requirements – we often have to deal with strong winds and very low temperatures. We also had very demanding requirements for container handling productivity and reliability. Konecranes convinced us with their reliable technology and service support.”

The Konecranes RMGs on order will have a railspan of 32 m and will serve 6 train tracks, lifting containers 1-over-2. They will be equipped with an intuitive GUI, with extra visibility provided by video cameras on the spreader and under the trolley. They will also be equipped with the Konecranes DGPS Skew Control System, and the smart features Auto-positioning and Auto-TOS Reporting.

A strong focus on customers and commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2020, Group sales totaled EUR 3.2 billion. The Group has around 16,500 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

www.konecranes.com

LOGISTEC USA orders two Konecranes Gottwald Generation 6 Mobile Harbor Cranes to reduce marine carbon footprint in Florida

Leading North American terminal operator LOGISTEC USA Inc. (LOGISTEC) has ordered two new eco-efficient Generation 6 Konecranes Gottwald Mobile Harbor Cranes for their terminal at the Port of Manatee in Tampa Bay, Florida, USA. The order, booked in August, will be handed over by February 2022.

LOGISTEC operates 80 terminals in 54 ports across North America. The company handles all kinds of cargo, and their terminal at the Port of Manatee deals mostly with containers, pallets, steel and break-bulk. In the light of their continued commitment to the port, they are anticipating increasing levels of container traffic.

“With the arrival of our two new electric drive cranes from industry-leader Konecranes, we will be serving our customers in an eco-friendly way. These new additions to our fleet of cargo handling equipment are well aligned with our focus on reducing our marine carbon footprint in support of our Green Marine initiatives. This is great news for our customers, our community and the environment in Port Manatee,” said Rodney Corrigan, President of LOGISTEC USA Inc.

“2021 marks 50 years of Konecranes presence in the Americas, and this order from LOGISTEC is a good illustration of the strength of our long-term partnerships in the region,” says Alan Garcia, Sales Manager, Port Solutions, Region Americas for Konecranes. “The order also shows clearly that our new Generation 6 cranes are living up to their potential in the market, offering high performance and reliability while lowering fuel costs and reducing emissions.”

The two new Generation 6 cranes will be Konecranes Gottwald ESP.7 Mobile Harbor Cranes, with a working radius of up to 51 m and a lifting capacity of 125 t. These cranes are the natural successors of the two Generation 5 cranes already on-site. They feature a higher tower cab for a better view of the vessels in port and stronger lifting capacity curves for improved handling performance and a higher classification, which doubles their service life in container handling operations. Their on-board drive follows the strict EPA Tier 4 final standards. It’s a smart hybrid drive combining a diesel engine with optimized fuel consumption and an ultracap. This allows for both eco-efficient operation and peak performance when necessary.

A strong focus on customers and commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2020, Group sales totaled EUR 3.2 billion. The Group has around 16,500 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

Nemport in Turkey orders fleet of Konecranes Noell RTGs to handle growing demand

NEMPORT LÌMAN ÌŞLETMELERI (Nemport) in Izmir, Turkey, has ordered 10 Konecranes Noell Rubber-Tired Gantry (RTG) cranes to handle growing container traffic. The order was booked in July and the cranes will be delivered in October 2022.

Nemport said: “Nemport is experiencing growing container traffic. We are building a new container yard and a new berth for mega container vessels, and the new RTGs will be fundamental to its productivity. As usual, Konecranes was very proactive in providing the solution, carefully evaluated by Nemport. We are confident that the Konecranes Noell RTGs will give us the performance and reliability we need. From the beginning, we have been operating Konecranes RTGs and Konecranes Gottwald Mobile Harbor Cranes with great success.”

Nemport terminal

Nemport terminal

Adel Issa, Sales Manager Region EMEA, Konecranes Port Cranes, said: “Konecranes is committed to meeting Nemport’s needs in every way. We are a good fit with Nemport’s entrepreneurial spirit. The Konecranes Noell RTGs on order will help Nemport to expertly serve its customers as the growing trade gateway of the Aegean region.”

A strong focus on customers and commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2020, Group sales totaled EUR 3.2 billion. The Group has around 16,500 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

Konecranes’ sustainability work rewarded with first Gold rating from EcoVadis

Konecranes has received a Gold rating from EcoVadis for its ambitious sustainability work, its highest-ever placing. The company’s actions, policies and reporting put it in the top 4% of all rated companies globally, and it is in the top 1% of its general-purpose machinery peers.

Konecranes’ rating improved from 2020 thanks to the implementation of additional policies, increased transparency and additional certifications, business sustainability rating provider EcoVadis said, declaring the company’s overall sustainability performance to be on an advanced level in activities related to the environment, labor and human rights, ethics and sustainable procurement.

Since the 2020 survey, Konecranes has committed to set science-based climate targets, its digital services received information security certification (ISO 27001), it started third-party supplier sustainability audits and it reported on its human rights risks and ways to mitigate them. Please see Konecranes’ 2020 Sustainability Report for an overview of its activities.

“Sustainability is at the core of our business. We strive to make a positive impact on society and the environment, and are making excellent progress on a number of fronts: EcoVadis Gold follows the CDP climate change performance leadership rating we received last year, and we plan to publish our science-based carbon reduction targets by end of the 2021. We will not stop in our drive to improve our performance even further,” said Konecranes President and CEO Rob Smith.

Konecranes has five sustainability cornerstones: Climate action and resource efficiency; eco-optimized offering and circularity; a safe workplace and products; a diverse, inclusive and engaging workplace; and responsible business conduct.

Together with its customers and business partners, Konecranes makes lifting and material flows more productive and sustainable. Our culture is rooted on uncompromised safety, high ethics and diversity and inclusion. We work for a decarbonized and circular world for customers and society.

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2020, Group sales totaled EUR 3.2 billion. The Group has around 16,500 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

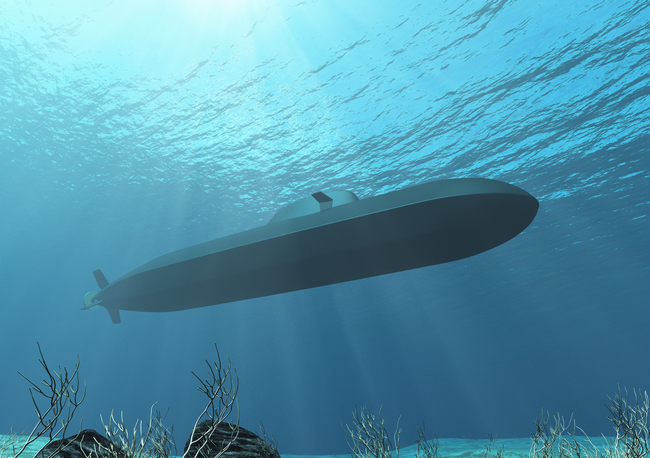

Konecranes wins 14-crane order from thyssenkrupp Marine Systems for Kiel shipyard

Konecranes has won an order from the thyssenkrupp Marine Systems shipyard to supply 14 process cranes for a shipbuilding hall now being built in Kiel, Germany. The order was booked in July 2021.

The double-girder crane systems, which will be built by Konecranes’ Demag Cranes & Components unit, will be installed in the new production halls in Kiel, which is being developed into an international center of excellence for submarine production. The cranes will have been manufactured, delivered and commissioned by the time work begins in 2023.

The cranes will come with numerous features to increase performance, service life and, in particular, precision. These include optimized rope lead-off on the hoists (to extend the service life of the hoist ropes), extended monitoring of the hoist brake (to improve safety), electronic overload protection with a load spectrum recorder (to determine the remaining service life of the hoists) and 24/7 online support.

Thomas Bönker, Senior Vice President for Process Cranes at Konecranes, said: “This is a demanding project, with the high travel and positioning accuracy of the cranes required, for example, when two submarine segments weighing over 100 t each have to be precisely positioned by two cranes and four travelling hoist units to assemble the hull. We are pleased to support thyssenkrupp Marine Systems with our process crane technology for this exciting and forward-looking project.”

A strong focus on customers and commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity.

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2020, Group sales totaled EUR 3.2 billion. The Group has around 16,500 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

Brazilian terminal orders three new Konecranes Generation 6 Mobile Harbor Cranes to increase capacity, competitiveness

Konecranes has won an order to deliver three of its new eco-efficient Generation 6 Konecranes Gottwald cranes to Super Terminais Comercio e Industria Ltda (Super Terminais) in Brazil. The order, booked in June 2021, makes Super Terminais the first customer for the new cranes, and will help it sustainably meet growing demand for containers and general cargo in the Port of Manaus.

- Contract marks first order for new, revamped Konecranes Gottwald’s mobile harbor crane portfolio

- New Generation 6 is engineered for electric power and can run on battery power, cutting fuel and maintenance costs and helping customers meet their low-carbon targets

Super Terminais, a new customer for Konecranes, needs the extra lifting capacity to handle the megaships in use today at Manaus, an important commercial center and transport hub for the upper Amazon basin. The ESP.10 cranes are the largest models in the new Generation 6 portfolio and will be built on a new floating pier which can accommodate a recent influx of larger vessels coming down the Amazon River.

“Konecranes has been able to provide us with a specially tailored, holistic solution consisting of reliable, high-performance cranes that fit perfectly onto our unusual quay,” says Marcello Di Gregorio, Managing Director of Super Terminais. “This equipment will significantly expand our capacity and give opportunities for future growth and development. The choice of this equipment brought the perfect solution that goes in line with our philosophy of environmental preservation and sustainability, uniting productivity, technology and reliability.”

“We consulted closely with Super Terminais, and our new Generation 6 electric cranes overcame the special challenges that a hot climate and the floating pier presented us. This demonstrates the importance of a solid partnering relationship with customers and the flexibility of our equipment in a range of applications and working environments,” says Andreas Moeller, Senior Sales Manager, Mobile Harbor Cranes, for Konecranes Port Solutions.

The cranes will be connected to an external power supply on shore, to increase efficiency and fully comply with regional emission standards. Electric cranes provide comprehensive lifting solutions that support customers in helping them to move closer to their low-carbon targets. Konecranes calls this Ecolifting. You can read more on the new Generation 6 here.

A strong focus on customers and commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2020, Group sales totaled EUR 3.2 billion. The Group has around 16,500 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

Konecranes wins first customer for EPA-approved new diesel-to-hybrid conversion technology

Konecranes has won a contract with South Carolina Ports to supply 12 Rubber Tire Gantry (RTG) retrofit hybrid power packs, a milestone contract for new technology that offers significant carbon emission reductions and lower operating costs – without compromising performance.

The US Environmental Protection Agency (EPA) approved Konecranes’ new hybrid technology in April 2021 after a comprehensive testing protocol conducted by West Virginia University (WVU) at South Carolina Ports’ Wando Welch Terminal. Konecranes partnered with WVU to test and measure RTG exhaust emissions using the new hybrid power packs, with WVU concluding: “Carbon monoxide emissions were observed to reduce by over 95% compared with conventional Tier 3 Diesel-electric RTG cranes.” *

The approval means that South Carolina Ports, and other US ports, are assured of the efficacy and sustainability of Konecranes’ technology, and it comes at a time when the agency is offering companies the chance to apply for grants like the DERA (Diesel Emissions Reduction Act) as they convert to more sustainable equipment. Funding for this retrofit is partially provided through a 2019 DERA grant that was awarded to the South Carolina Department of Health and Environmental Control, in partnership with South Carolina Ports.

The conversion of the 12 20-year-old Charleston-based Konecranes diesel RTG cranes will begin in January 2022. The contract complements Konecranes’ momentum in the region, with over 30 new hybrid RTGs delivered to ports across America since 2020.

Konecranes Hybrid RTG Retrofit

Konecranes Hybrid RTG Retrofit

“The decision of South Carolina Ports to opt for Konecranes’ new technology is an indicator of things to come in an industry where the focus is increasingly on finding sustainable ways to stay ahead of growing demand. We have worked with South Carolina Ports for over 24 years and look forward to extending that relationship as we optimize their RTG fleet,” said Scott Lane, VP of Konecranes’ US Port Services.

“Anyone can add a battery to an engine and call it ‘hybrid’, but because we manufacture our own drive and control systems, we are the only company that can conduct a full upgrade on a turnkey basis without compromising crane performance. This agreement shows the global strength of Konecranes, involving engineers in the US and Finland, including our RTG pioneer Jorma Merimaa, and the results have been sensational,” Lane added.

“In partnership with Konecranes and through the support of our grant funding, SC Ports will upgrade 12 RTG cranes with hybrid battery/genset engine systems, making them both high performing and energy efficient,” SC Ports Chief Operating Officer Barbara Melvin said. “Konecranes’ technology aligns well with our efforts to invest in equipment that both enhances terminal operations and offers environmental benefits.”

The hybrid power pack retrofit is part of Konecranes’ suite of Ecolifting™ products that have been engineered from the ground up to deliver dramatically reduced carbon exhaust emissions. Ecolifting™ in turn is part of the company’s overall vision of a low-carbon, sustainable future.

A strong focus on customers and commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.

Further Technical or Commercial Information:

Scott Lane, Vice President, Port Services, Konecranes Inc. USA

Email: This email address is being protected from spambots. You need JavaScript enabled to view it. or phone +1 912 704-7797

Further South Carolina Ports Information:

Kelsi Brewer, SC Ports General Manager of Public Relations & Digital Media

This email address is being protected from spambots. You need JavaScript enabled to view it., 843-577-8676

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2020, Group sales totaled EUR 3.2 billion. The Group has around 16,500 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

Konecranes launches new generation of energy-efficient mobile harbor cranes as global trade accelerates

Konecranes today launched its sixth generation of mobile harbor cranes, refreshing and reinforcing its industry-leading portfolio as global trade accelerates and the industry seeks more sustainable lifting solutions to reduce its climate impact.

- New Generation 6 high-performance model portfolio targets growing global bulk and general cargo handling market demand as COVID-19 pandemic eases

- Engineered for electric power, new cranes can also run on battery power, cutting fuel and maintenance costs and helping Konecranes’ customers meet their low-carbon targets

- New interactive MHC Product Advisor lets customers configure the right crane for their requirements, easing the impact of COVID-19 restrictions on face-to-face meetings

- Sales of the new products have now started

Generation 6 marks the first comprehensive revamp of Konecranes Gottwald’s mobile harbor crane portfolio in 15 years, and comes as growth in the global bulk and general cargo handling market accelerates. Research from Drewry Maritime Advisors forecasts the global bulk and general cargo handling market, excluding RoRo and vehicle traffic, to grow 6.8% year-on-year in 2021 to 7.4 billion tonnes. Drewry expects growth to continue in coming years, reaching 8.5 billion tonnes by 2025, a compound annual growth rate of 3.5%.

Konecranes, which launched the world’s first mobile harbor crane in 1956 and is a pioneer in Ecolifting™, has worked closely with customers around the world while developing the new cranes. The result is a range of products that can eco-efficiently service essentially any type of vessel and any kind of cargo – containers, general cargo, project cargo and bulk – in any location, either on the quay or on a barge. Sales are now underway.

“Konecranes is a pioneer and leader in high-performance mobile harbor cranes, and today’s launch underscores that pedigree at a time when growth in the global bulk and cargo handling market gathers pace and customers are seeking more sustainable solutions,” said Konecranes President and CEO Rob Smith.

“These cranes represent the best of Konecranes in terms of technology and durability, and thus also strongly support our commitment to sustainability. The carbon footprint of our customers is just as important as our own, and we aim to reduce it through low-carbon, eco-efficient solutions and by extending product lifecycles in ports, factories and everywhere our products and services are used,” Smith said.

Freedom to move – with lower emissions

Reflecting Konecranes’ commitment to a decarbonized and circular world for customers and society at large, Generation 6 is designed for electrical power use; power can be sourced from an onshore grid, meaning no direct carbon emissions during operation. Operators can also choose a new battery solution that also reduces emissions and gives greater flexibility by permitting crane operation independent from the grid. For quays without a power supply, a common occurrence in developing markets, the cranes come with fuel-saving diesel generators and Konecranes’ latest hybrid drives.

“Stevedores globally, big and small, are increasingly focused on reducing the carbon footprint of their operations in the near term. Growing trade and the need to replace old equipment will likely mean increased demand from ports around the world for more efficient cargo handling equipment to support increases in productivity, reduction of costs and CO2 emissions,” said Dinesh Sharma, Director at Drewry Maritime Advisors.

In addition to lower emissions, the design of the crane advances circularity through a more durable design: its robust construction doubles the cranes’ service life in container operation compared to earlier generations, and more powerful lifting capacity curves and high working speeds ensure greater efficiency and faster cargo turnaround times. The long-lasting design not only saves the resources needed to build new cranes – it supports resale values when customers choose to renew their fleets.

A truly connected fleet, designed by the customer

The new products also reflect Konecranes’ technology leadership. The new cranes will be equipped with smart crane features for safe, ergonomic and efficient crane operation, and will come equipped with TRUCONNECT remote monitoring, which collects condition, usage and operating data from control systems and sensors to help with maintenance planning and predicting possible component or equipment failure. Customers will also get access to the yourKONECRANES customer portal for a comprehensive view of equipment maintenance needs and performance.

These capabilities reflect Konecranes’ investment in the growing opportunities of data. The company has a data science laboratory in Lyon, France, as part of its continuing drive to digitalize products, services, and operations, and has tapped the real-time insights from its tens of thousands of connected devices and pieces of equipment around the world to balance demand and supply in real time and navigate through the COVID-19 pandemic.

Konecranes today also launched its online self-service Product Advisor, which gives customers the chance to configure their own cranes, facilitating the purchasing process at a time when face-to-face meetings – the main way the industry has done business for decades – can be difficult due to the pandemic.

To read more about these Electric, Smart and Powerful (ESP) mobile harbor cranes and their new genetic code for the future, please click here for a release with technical details

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2020, Group sales totaled EUR 3.2 billion. The Group has around 16,600 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

Georgia Ports Authority orders 28 Konecranes container cranes as larger ship traffic grows

The Georgia Ports Authority (GPA) has ordered 20 eco-efficient Konecranes Rubber Tired Gantry (RTG) cranes and 8 Konecranes Ship-to-Shore (STS) cranes for the Port of Savannah in the US. Six of the STS cranes will be the largest ever made by Konecranes. The RTG order was booked in Q1 2021, and the STS order was booked in Q4 2020.

The GPA placed the order as it prepares to serve the world’s largest container vessels such as the HMM Algeciras class and Maersk’s Triple-E class, which have capacities of 24,000 TEU or more – meaning they can carry 24,000 containers either 20 or 40 feet in size. The STS cranes will be delivered in two batches, the first in June 2023 and the second in October 2023. The diesel-electric RTG cranes will be delivered in four batches of five cranes in 2021-2022.

Griff Lynch, Executive Director of the GPA, said: “The GPA is always preparing for the next evolution of global trade. The new high-performance and long-lasting STS cranes on order are part of the Big Ship/Big Berth program. Six of the new cranes will be very large, enabling us to serve the New-Panamax container ships, which will reach us thanks to the dredging of the final portion of Savannah’s shipping channel, which will be done by late 2021.”

Mika Mahlberg, Executive Vice-President, Konecranes Port Solutions, said: “Konecranes has been working with the GPA since the early 1990s. We have always worked closely with them to improve efficiency and stay ahead of industry trends, and today’s announcement marks the latest step in that relationship. Six of the new STS cranes will be the largest that Konecranes will have ever made, and the new RTGs will help the GPA reach their growth and performance targets.”

When the new Konecranes STS cranes enter service, Konecranes will have delivered 45 STS cranes to the GPA, Port of Savannah, since 1990. The GPA also operates a large fleet of Konecranes RTG cranes; when the latest 20 RTGs are delivered and in service the GPA will operate a fleet of 201 Konecranes RTGs.

A strong focus on customers and a commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.

Further information:

Jussi Suhonen, Regional Sales Director Americas, Konecranes Port Solutions

Email: This email address is being protected from spambots. You need JavaScript enabled to view it. or phone: +1-281-610-2576

Further information for investors and analysts:

Kiira Fröberg, Vice President, Investor Relations, Konecranes

Email: This email address is being protected from spambots. You need JavaScript enabled to view it. or phone: +358 20 427 2050

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2020, Group sales totaled EUR 3.2 billion. The Group has around 16,900 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).