Uncategorised (4996)

AkzoNobel puts on a brave face with coatings from ColorSurfaces Edition 16

AdministratorAutomotive, aerospace and consumer electronics coatings customers are discovering the latest color trends and finishes with the launch of ColorSurfaces Edition 16.

This edition of ColorSurfaces is firmly planted in AkzoNobel’s Color of the Year 2021, Brave Ground. A warm, neutral shade, it gives us the courage to embrace change. The shade is both empowering and calm, grounding and reconnecting us to the simple things in life.

“Every year, our creative team gets together with leading external design experts to discuss the global consumer trends that are expected to influence our color and material choices over the next 12 months, including an overall Color of the Year,” says Stephie Sijssens, Global Color Design Manager. “The result is ColorSurfaces, our visually stunning color trends collection. Combined with in-depth color analysis, comprehensive material research and inspiring visuals, ColorSurfaces provides unique insights to feed the inspiration of our customers.”

Four palettes – Me, Us, Time and World – have been designed around Brave Ground to show how the color can be combined to create different effects. For example, achieving a comforting look with tone-on-tone arrangements, or a sporty expression by juxtaposing Brave Ground with contrasting bright tones.

Going well beyond color, the design team explores structures, finishes, textures and patterns which they can translate into inspiring coating solutions for the automotive and consumer electronics markets. Inspiration for this year’s palettes came from natural materials like soil, clay and quartz, as well as the smooth and soothing finish of a seashell.

Brave Ground has been translated into different finishes for each of the four trend themes: refined pearls, structured terra-coat, smooth anodized effects and natural interference. Each version of Brave Ground stands strong on its own but also provides a base for other shades to shine and stand out against.

Adds Sijssens: “Our customers can use ColorSurfaces as a source of inspiration, a confirmation of design choices or as a starting point for new color development – where our design partnership with them begins.”

For more information about ColorSurfaces Edition 16, visit the ColorSurfaces web page

About AkzoNobel

AkzoNobel has a passion for paint. We’re experts in the proud craft of making paints and coatings, setting the standard in color and protection since 1792. Our world class portfolio of brands – including Dulux, International, Sikkens and Interpon – is trusted by customers around the globe. Headquartered in the Netherlands, we are active in over 150 countries and employ around 33,000 talented people who are passionate about delivering the high-performance products and services our customers expect.

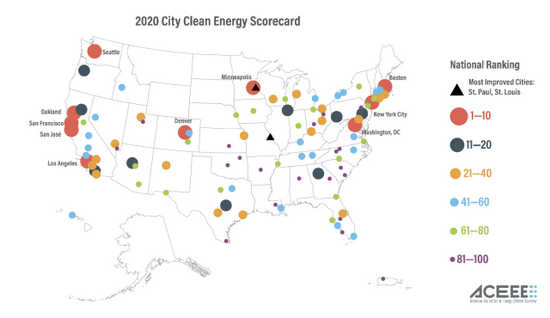

Scorecard: Leading U.S. Cities Grow Clean Energy Efforts but Many More Lag Far Behind

AdministratorLeading U.S. cities are expanding their clean energy efforts to tackle climate change, yet many more lag far behind, and only one-fifth have community-wide greenhouse gas reductions goals and are on track to meet them, according to the 2020 City Clean Energy Scorecard released Tuesday. New York City leaped to first place in the ranking—spurred in part by a new law ensuring upgrades to many inefficient buildings—followed by Boston and Seattle (tied for second place) and Minneapolis and San Francisco (tied for fourth place).

The scorecard from the American Council for an Energy-Efficient Economy (ACEEE) analyzes the efforts of 100 major U.S. cities—home to 19% of the nation’s population—to make buildings and transportation more energy efficient and scale up the use of renewable energy. It provides the most comprehensive national measuring stick for climate progress and a roadmap for future improvements. Over time, the Scorecard has adopted metrics to assess community involvement and equity as part of cities’ clean energy efforts.

The report, expanded from 75 cities last year, finds that 20 cities are now on track to meet their own community-wide greenhouse gas emission reduction goals—9 more than a year ago. Yet the remainder of the cities are not on track, haven’t provided adequate data, or have not set a goal.

“Many cities are really seizing the moment and embracing policies that help them fight climate change, while too many others are, frankly, doing very little,” said David Ribeiro, director of ACEEE’s local policy program and the lead report author. “We want to show all the cities, even the leaders, the further steps they can take to cut carbon emissions most effectively and equitably.”

Among the report’s findings:

- Washington, DC; Denver; Los Angeles; San José; and Oakland rounded out the top 10 highest-ranked cities, with San José and Oakland making the top 10 for the first time.

- The top 10 cities embraced new actions. Boston and Los Angeles updated codes to require new buildings be pre-wired for electric vehicle charging stations at more parking spaces, and San Francisco convened a network to work with marginalized communities to establish equitable zero-emissions residential building strategies.

- St. Paul (#16) was the most-improved city, taking key steps to improve efficiency of existing buildings, reduce total vehicle miles traveled, and embrace renewable energy. St. Louis (#28) was the second-most-improved city; in April, it became the third city in the country to require large existing buildings to meet a performance standard, which will drive energy efficiency upgrades.

- More cities are making efforts to increase community engagement with, and clean energy investments in, low-income communities and communities of color. Washington, DC, formed an equity advisory group to develop recommendations to be incorporated in its clean energy plans. But nearly all cities have substantial room to ramp up their efforts.

- Bottom-scoring cities’ policy efforts have either stagnated or not started; these cities are years behind the leaders. To scale up climate efforts across the country, more cities will need to adopt and implement effective clean energy policies.

- Many cities are encouraging electric utilities and state regulators to increase the use of renewable energy in the power system. Twenty-four cities submitted comments on public utility commission proceedings, entered into utility partnerships, enacted community choice aggregation programs, or participated in planning efforts with utilities.

The report assesses policies adopted by May 1, 2020. The public health and economic devastation wrought by COVID-19, as well as the growing outrage over racial disparities and their impacts on communities of color, could cause city policy priorities to change. The report argues that as cities focus on economic recovery in the context of COVID-19, energy efficiency and renewable energy remain a crucial strategy for creating jobs and keeping investment within local communities. Furthermore, a closer focus on equitable planning and investment can yield benefits that have historically been unavailable to communities of color.

“City budgets are under enormous strain. Clean energy policies are part of the solution because they create jobs while reducing energy costs for households, businesses, and city government,” said Ribeiro. “By keeping up and expanding clean energy efforts, cities can support the economic recovery while combatting the climate crisis.”

Mark Chambers, director of sustainability for the City of New York, said: "This recognition is meaningful for our city, and a result of determined efforts by dedicated government and community leaders. There is still urgent action needed from New York, and all cities, if we are to truly confront the climate emergency."

Seattle Mayor Jenny Durkan said: “City leadership on building energy efficiency and overall climate action is more important than ever. While the federal government has used its leverage to prop up polluting energy sectors, cities are stepping up with innovative and bold policies and programs—like our ban on heating oil—that are helping us transition away from dirty energy. Fossil fuels are damaging the health of our residents and our economy and I’m inspired by the all work happening in cities across the nation focused on reducing their use.”

St. Paul Mayor Melvin Carter said: “Clean energy is a critical part of responding to our ongoing climate crisis. We appreciate ACEEE’s important work, and its support of our efforts to build a more equitable, clean energy future in St. Paul.”

The scorecard ranks cities in five policy areas:

- Local government operations. Austin and Boston tied for the first spot. Each is on track to achieve its greenhouse gas mitigation goals for government operations and has policies to increase energy efficiency in purchasing decisions, construction practices, and asset management. Portland, San Francisco, and Washington, DC, tied for second.

- Community-wide initiatives. Washington, DC, was the leading city, adopting several greenhouse gas mitigation and clean energy goals informed by the community. Denver, Los Angeles, and Minneapolis tied for second.

- Buildings policies. New York earned the most points and was the only city to receive all possible points for city policies encouraging or requiring efficiency improvements in existing buildings. Seattle, Boston, and Chicago were the next-highest scorers.

- Energy and water utilities. Boston, Chula Vista (California), Minneapolis, and San Diego tied for the highest score. These cities and the utilities serving them scored well across metrics for efforts to help customers improve energy and water efficiency, as well as the utilities’ efforts to embrace renewable energy.

- Transportation policies. San Francisco took the top spot, earning points for efforts to increase compact, mixed-use communities, particularly near transit hubs, to reduce vehicle miles traveled. Washington, DC, New York, Portland, and Seattle followed closely behind.

The scorecard is based on data collected from cities, utilities, and numerous publicly available sources. Government staff members from all 100 cities were given the opportunity to comment on a draft of the findings.

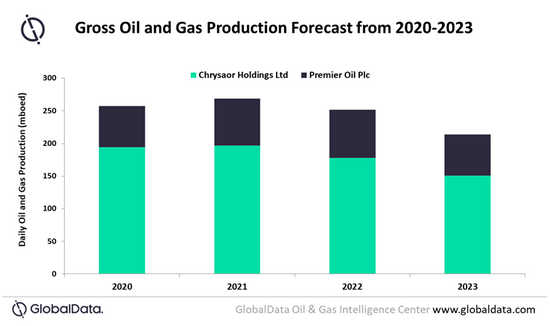

Chrysaor-Premier merger a win-win amid market challenges

AdministratorChrysaor-Premier merger a win-win amid market challenges for both private equity backed and indebted listed E&P players, says GlobalData

Following the announcement that Chrysaor Holdings and Premier Oil have proposed to merge businesses;

Daniel Rogers, Oil and Gas Analyst at GlobalData, a leading data and analytics company, offers his view on the announcement:

“With Premier Oil carrying a US$2bn debt load, and private equity players unable to execute high-value exit strategies through IPOs or divestments under current market conditions, this deal makes a lot of sense for both parties. With the stock price down over 80% from the start of the year, Chrysaor will take advantage of the depressed market value as an expansion opportunity and to list the combined businesses on the London Stock Exchange.

“The two companies will create a dominant North Sea player with production of around 250,000 barrels of oil equivalent per day and growth opportunities such as the Tolmount gas development - which GlobalData expects to boost the combined production to almost 270,000 boed in 2021. The merger will allow Chrysaor to expand its significant North Sea footprint with low-cost assets but will also gain exposure to producing assets in Indonesia and high-value development projects in South America. The combined entity will have a strengthened financial backing that should allow Premier’s pre sanctioned growth developments to move forward."

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

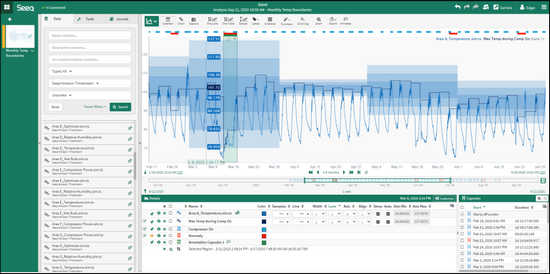

Seeq Expands AWS Cloud Services Support to Encompass Amazon Timestream

AdministratorSeeq is a launch partner for Amazon Timestream, AWS’s fully managed time series database, empowering users to create insights and improve production outcomes.

Seeq Corporation, a leader in manufacturing and industrial internet of things (IIoT) advanced analytics software, and an AWS Industry Software Competency Partner, announces expanded support for Amazon Web Services cloud services.

Seeq has been available as a SaaS application since 2018 with support for many Amazon cloud services including Amazon Redshift, DynamoDB, Aurora, and Amazon SageMaker Notebooks for machine learning integration. Seeq is now adding connectivity to Amazon Timestream, which was released for general availability on September 30, 2020. Amazon Timestream is Amazon’s fully managed time series database service for IoT and operational applications. Amazon Timestream connectivity enables Seeq users to find and publish insights on data stored in AWS from IoT sensors, industrial assets, and process variable data.

Seeq’s comprehensive set of applications for analyzing and sharing insights on process manufacturing data include Workbench for easy to use advanced analytics, Organizer for publishing reports and dashboards, and Data Lab for accessing Python libraries. Seeq applications empower engineers and subject matter experts to rapidly investigate, collaborate, and distribute insights to improve operations and business outcomes.

“Seeq connectivity to Amazon Timestream will help process manufacturers tap advanced analytics for data-based decision making at a critical time in the industry,” says Michael Risse, Cofounder of Seeq. “The need for innovation is tremendous, and our partnership with AWS will help our mutual customers unlock the value in their data.”

Seeq enables engineers and scientists in process manufacturing organizations to rapidly analyze, predict, collaborate, and share insights to improve production outcomes. Customers include companies in the oil and gas, pharmaceutical, chemical, energy, mining, food and beverage, and other process industries. Specific examples of Seeq usage include diagnostic analytics for well completions and intervention campaigns, predictive analytics on equipment failure, and sustainability and optimization efforts for energy and carbon reduction initiatives.

"Seeq continues to release compelling analytics solutions for customers in process manufacturing and Industry 4.0 engagements," comments Janice Abel, Principal Analyst at ARC Advisory Group. "The need for the faster and better insights provided by Seeq is a consistent requirement for customers investing in IIoT and Smart Manufacturing."

New Seeq support for Amazon Timestream includes the following:

- Amazon Timestream is a fast, scalable, fully managed time series database service for IoT and operational applications that makes it easy to store and analyze trillions of events per day at 1/10th the cost of relational databases. Seeq integration enables process engineers to query Timestream to support a full range of Seeq analytics types and features: predictive, descriptive, diagnostic, collaboration, etc.

- All of the browser-based Seeq applications—Organizer, Workbench, and Data Lab—connect to a shared Seeq server deployed in AWS (as SaaS or private cloud) or on premise to enable collaboration, provide access to connected data sources, and enable administrative control. For example, graphics created in Data Lab may be viewed in Organizer Topics, data modeled in Workbench may be accessed by Data Lab users, and Data Lab algorithm results are available for use in the other Seeq applications.

Seeq’s rapid growth and customer success is being fueled in part by its partnerships and commitment to cloud-based computing. Seeq is available in the AWS Marketplace, is an AWS Industrial Competency Partner, an APN Advanced Tier Technology Partner, and an AWS for Startups Partner.

In addition to AWS support, Seeq partners with many process automation vendors to support on premise deployments by connecting to systems sold by OSIsoft, Siemens, GE, ABB, Honeywell, Inductive Automation, AVEVA, AspenTech, Schneider Electric, and others.

To learn more about Seeq, visit: www.seeq.com

About Seeq Corporation

Founded in 2013, Seeq enables manufacturing organizations to rapidly find and share data insights. Oil & gas, pharmaceutical, specialty chemical, utility, renewable energy and numerous other vertical industries rely on Seeq to improve production outcomes, including yield, margins, quality, and safety. Headquartered in Seattle, Seeq is a privately held virtual company with employees and partners in the United States, Asia, Canada, Europe, and South America.

Waste salmon for biogas recognised with top aquaculture award

AdministratorThe Scottish Salmon Company (SSC) has won the Community Initiative Award at the 2020 Aquaculture Awards for its work with the Outer Hebrides Local Energy Hub (OHLEH) project on the Isle of Lewis - the first local circular economy of its kind in Scotland.

Waste salmon is fed into the Landia unit

Waste salmon is fed into the Landia unit

The success of the project, which sees fish waste (transferred from SSC’s processing plant) co-digested with household food and garden waste in an anaerobic digester (AD), is due partly to the installation of a Landia pasteurizer, as Donnie Macmillan, Plant Manager at the Comhairle nan Eilean Siar (Western Isles Council) Creed Integrated Waste Management Facility (IWMF), explains:

The Landia ensiling tank is equipped with an 18.5kW stainless steel long shaft chopper pump“Firstly, thoroughly deserved recognition must go to our partners in the OHLEH project; the Scottish Salmon Company, Pure Energy Centre (PEC), Community Energy Scotland and the funding by the Scottish Government Local Energy Challenge Fund. Behind the scenes with our very conscientious team here at Creed, we also invested in top quality, long-lasting equipment, including the Landia Pasteurizer, which allows us to process a 7-cubic ton batch per shift of waste salmon for our AD/biogas process. This is waste that would otherwise have been landfilled, so the creation instead of clean, renewable energy is a clear win-win for everybody on the Isle of Lewis and an example to the whole of Scotland and beyond as to what can be achieved with common goals”.

The Landia ensiling tank is equipped with an 18.5kW stainless steel long shaft chopper pump“Firstly, thoroughly deserved recognition must go to our partners in the OHLEH project; the Scottish Salmon Company, Pure Energy Centre (PEC), Community Energy Scotland and the funding by the Scottish Government Local Energy Challenge Fund. Behind the scenes with our very conscientious team here at Creed, we also invested in top quality, long-lasting equipment, including the Landia Pasteurizer, which allows us to process a 7-cubic ton batch per shift of waste salmon for our AD/biogas process. This is waste that would otherwise have been landfilled, so the creation instead of clean, renewable energy is a clear win-win for everybody on the Isle of Lewis and an example to the whole of Scotland and beyond as to what can be achieved with common goals”.

In addition to the continued success of its equipment on the Isle of Lewis, Landia has just been chosen to supply two of its pasteurizers for a new state-of-the-art waste-to-energy biogas plant in Romania. Set to play a crucial role in eliminating biohazards by heating biomass to a minimum of 72°C for one-hour batch processes, the Landia BioChop units will also enable the final digestate to be utilized safely as a high-quality fertilizer.

Easy to hold due to its small form factor and light weight—and includes a touchscreen, function keys, and switches—making it a good fit for machine tending and robotics applications.

IDEC Corporation introduces the new 4.3” LCD screen size HG1P handheld human-machine interface (HMI). This lightweight and robust HMI is the right-sized way to enhance operator interactions for automated machine tending and robotics applications, and it is the most cost-effective device of its type.

User-First Design

At only 500g and with contoured hand grips, a hand strap, and a wall hanging bracket, the HG1P’s ergonomic design makes it comfortable for long duration and fatigue-free use by technicians and engineers. The hardy design is tested to withstand 1.5m drops, and it uses a flush mount selector switch to prevent breakage. Competing products in this category are typically heavier, bulkier, and more prone to inadvertent damage.

Visualization and Control

A high resolution 4.3-inch TFT color LCD touch panel displays at 480x272 pixels to provide clear and informative visualization. The touchscreen is bordered with 12 physical momentary function keys (F1 to F12) with click-feedback, which write to internal memory bits within the HMI. In addition, a hardwired emergency stop button, selector switch, and a 3-position enabling switch make this unique handheld HMI flexible for designers and convenient for users.

Users will appreciate the rapid and industry-leading start-up time, which is usually less than three seconds. The usability and feature set of the HG1P combine to help users maximize productivity and minimize downtime while delivering dependable safety in any production environment, for operations such as machine setup, calibration, normal operation, and maintenance.

Easy Configuration

The HG1P is configured with the same WindO/I-NV4 software as other products offered in the IDEC HMI portfolio, which means users will be very familiar with the development environment. A common mini-USB cable or USB-A memory stick can be used to download configurations and save data. Multilingual capability is built-in, and languages can be selected and changed on the fly.

Field Friendly

Connectivity to automation platforms is via a standard 19-pin connector, using optional cables from IDEC up to 7 meters long or user-created cables up to 15 meters long, which are easily replaced if damaged. The cable transmits power, hardwired signals, and digital communications. Available in both serial and Ethernet models, the HG1P supports major industrial communication protocols such as Modbus TCP/IP, Modbus RTU, FTP client, FTP server, webserver, and user communication. In operation, the HG1P consumes only three watts, a category best.

Applications Abound

Designers can use the HG1P handheld HMI anywhere a traditional HMI is used, gaining the additional features of portability and on-board switches. It is well suited for robot teaching applications, machine tending operations, and wherever operators need to move among various locations during the course of their work. The hardwired emergency stop and enabling switch devices are crucial for implementing safety related applications where workers are near operating robots and machinery. The HG1P handheld HMI improves operator efficiency, while minimizing field hardware by eliminating the need for multiple operator interface devices on large machines.

As with all its products, IDEC offers free tech support for the HMIs, with no service or support contract required. For complete specifications or additional information, please contact IDEC Corporation at 800-262-IDEC (4332), or visit us online at http://us.idec.com/HandheldHMI .

About IDEC: IDEC Corporation is a global supplier that has provided innovative and reliable industrial automation and control products since 1945. Covering a broad range of market needs, these feature-rich and value-driven products include PLCs, human machine interfaces (HMIs), safety products and other industrial automation components. By delivering world-class products backed by personalized service and highly-rated technical support, IDEC enables design engineers to create lean, cost-effective and safe solutions to optimize their automation applications. With the recent acquisition of APEM, one of the world's leading manufacturers of operator interface panels and related components, IDEC continues to enhance our customers’ ability to create high-quality solutions. For additional information, visit www.IDEC.com/usa

Following the success of its acclaimed Separators since their launch in 2016, Borger has released a new, affordable, 25 m³/h model, suitable for dairy farmers with herds of up to 150 - and for small-scale biogas operators.

The launch of this compact new Bioselect RC 25 (which complements Borger’s existing range of up to 40 m³/h, 75 m³/h and 150 m³/h Separators), provides easy and highly effective separation of slurry.

Reducing storage volume and creating effective fertilization with the liquid phase or use of solids as bedding material, the Borger Separator can be fully installed or used as a mobile unit, consistently achieving Dry Solids (DS) content up to 38%.

The Borger Separator range now includes its smallest model yet.

The Borger Separator range now includes its smallest model yet.

The Borger Bioselect 25 m³/h model also benefits from a new feature that enables the user to adjust the length of the dewatering chamber to their specific requirements for enhanced separation efficiency.

To ensure optimal utilization of the Separator, as well as a long service life, Borger manufactures ready-to-connect, complete units with Separator, Borger rotary lobe pump and control unit that synchronizes the operation of the components. Upon request, Borger can also take care of the construction of the frame or the trailer.

In addition, Borger has developed a new frame concept for its separators – customized, using a modular principle depending on the amount of space available at the customers’ premises. For the new Bioselect RC 25, the frame can be equipped with a three-point-hitch frame. This makes it possible to relocate the entire unit easily and quickly by using a tractor.

For More Information:

Borger UK

01902 798977

This email address is being protected from spambots. You need JavaScript enabled to view it.

Emerson Offers Industry’s First ‘Four-in-One’ Compact Flow Meter

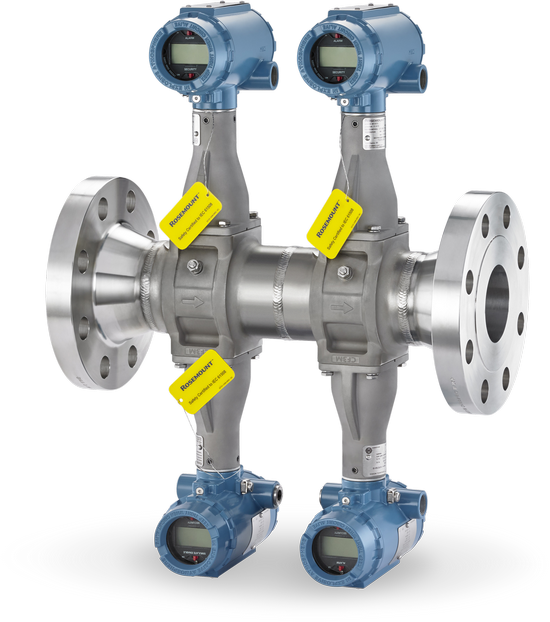

AdministratorNew Rosemount™ 8800 Quad Vortex meter is designed with built-in redundancies for SIL 3 safety requirements along with basic process control, and fits into less than half the space of four traditional redundant flow meters, offering easy, cost-effective installation

Emerson has introduced the Rosemount™ 8800 Quad Vortex flow meter specifically designed to meet stringent safety standards in environments and applications that require safety instrumented systems (SIS). The flow meter is the first in the industry with quadruple sensors and transmitters to meet safety integrity level (SIL) requirements. Comprised of multiple independent sensors in an all-welded meter body, the meter provides a compact flow solution with built-in redundancies for added safety without introducing intentional leak points. The meter reduces piping needs threefold by eliminating the additional flanges and pipe runs required for the installation of multiple flow meters in a redundant flow measurement solution.

With the ability to meet measurement challenges in industries such as chemical, power, refining, and offshore oil and gas applications, particularly where space is limited, and safety is crucial, the Rosemount 8800 Quad Vortex flow meter can take the place of multiple individual flow meters. The Rosemount 8800 Quad Vortex flow meter accomplishes the same task as four separate meters, without needing impulse lines that might clog. The meter saves money by reducing installation costs as a simple all-in-one drop-in solution.

The Rosemount 8800 Quad Vortex flow meter is designed to meet stringent safety standards in environments and applications that require safety instrumented systems.

The Rosemount 8800 Quad Vortex flow meter is designed to meet stringent safety standards in environments and applications that require safety instrumented systems.

The Rosemount 8800 Quad Vortex flow meter’s design and configuration allows for a SIL 3-capable solution and protects against spurious trips using a two out of three (2oo3) voting method. The 2oo3 voting method ensures that at least two of the sensors must read ‘good’ for a process to continue, which means one poor reading does not trip a complete process shutdown.

“Our refining and chemical customers who have tested this new flow meter have found tremendous value from this unique and differentiated flow solution,” said Julie Valentine, refining industry flow solutions director for Emerson’s Automation Solutions business. “The 8800 Quad Vortex flow meter has made the specification, purchase and installation of a SIS/SIL application with reduced piping and space requirements easier than ever before.”

For more information, visit www.Emerson.com/RosemountQuadVortex.

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and engineering company providing innovative solutions for customers in industrial, commercial and residential markets. Our Automation Solutions business helps process, hybrid and discrete manufacturers maximise production, protect personnel and the environment while optimising their energy and operating costs. Our Commercial & Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency and create sustainable infrastructure. For more information visit Emerson.com.

More data, at quicker speeds: Serial communication to TCP/IP

AdministratorIn a data-driven world, turning data into actions is the best way to boost efficiency. As businesses become more global and complex, operational data must travel across greater distances, at faster speeds and in larger quantities. Here, Jürgen Resch, industry manager at COPA-DATA, examines why manufacturers should move their information systems from serial communication to TCP/IP.

Generally, serial communication is a widely used method to transfer data between processing equipment and peripherals. Every device, might it be your computer or mobile, runs on serial protocol which serves as a reliable form of communication.

In fact, it was not until the 1990’s that fibre optics were implemented to guarantee immunity against electromagnetic interferences, which not only prevented interruptions but helped save tons of copper that were laid in cable conduits.

So, when ethernet became cheaper and new network topologies — the arrangement in which computer systems or network devices are connected to each other — were made possible, such as the Transmission Control Protocol/Internet Protocol (TCP/IP).

COP471 - Secure in the knowledge – BP.jpg: Industrial software can be vital in preventing the rising number of Distributed Denial of Service (DDoS) attacks against businesses.

COP471 - Secure in the knowledge – BP.jpg: Industrial software can be vital in preventing the rising number of Distributed Denial of Service (DDoS) attacks against businesses.

TCP/IP protocol

TCP/IP is responsible for managing the connection between a client and a server, making sure the data that needs to be transferred is split into several packets, which will eventually reach their destination. Unlike serial communication, if data corrupts or does not reach its destination TCP/IP defines how the missing data will be retransmitted, while controlling the flow of data to the right place.

TCP/IP technologies have received much stronger development efforts than serial, due to the vast number of users currently utilising it. For example, TCP/IP is used for the internet, which obviously demands fast communication speeds and flexibility in topologies.

TCP/IP is also widely used in industrial settings, unless the facility has opted for fast Ethernet protocols. In these environments, TCP/IP can help support network protocols within substations and manufacturing plants, such as DNP3 and IEC 60870-5-104. These protocols are commonly used for wide area communication between the substation and the supervisory control and data acquisition (SCADA) master.

With this in mind, TCP/IP is essential for the plethora of new current remote working situations the industry finds itself in. This is due to its ability to control locations separated between long distances. That being said, TCP/IP is not without its downfalls.

Considerations

Because they are so widely used, TCP/IP protocols can be vulnerable to attack. Today, hacking tools for TCP/IP related protocols are easier to find than serial protocols, so it is essential to ensure systems are secure.

Consider the consequences of this risk for an energy network, for example. While TCP/IP provides data communication for distributed assets, such as multiple substations and energy generation sites, this widespread infrastructure is at serious threat of cyber-attack. In fact, since the infamous discovery of Stuxnet in 2010, there has been an increase in attacks on the energy sector, with attacks rising by 380 per cent between 2014 and 2015.

When using TCP/IP protocols, the energy sector must be extra vigilant. When choosing technology, the energy industry involve options like Virtual Private Networks, coupled with standards like the IEC 62351 series, that provide the required levels of security. COPA-DATA’s energy grid software, zenon, for instance, meets the IEC 62351 standard for security in energy management systems and is developed using a security by design approach.

There are, of course, some instances where serial communication is used for security. In the power industry, this is only present in rare cases where a dedicated communication link is used serially for security reasons. This provides more protection against hackers, but security by obscurity is not a viable way to protect critical infrastructure. Instead, opting for secure TCP/IP is recommended.

TCP/IP ensures data can travel across greater distances, at faster speeds and in larger quantities. And, although TCP/IP might be at some risk to attack, by combining this with secure communication technology, like COPA-DATA’s zenon, we can protect data and in turn, the grid.

COPA-DATA

COPA-DATA is the manufacturer of the zenon® software platform, used in the manufacturing and energy industries for the automated control, monitoring, and optimization of machines, equipment, and power supplies. Founded by Thomas Punzenberger in 1987 and headquartered in Salzburg, Austria, the independent, family-owned company employs approximately 285 workers around the globe. The distribution of software on an international scale is made possible through the company’s eleven subsidiaries and numerous distributors. In addition, more than 270 certified partner companies ensure efficient software implementation for end users in the food & beverage, energy & infrastructure, automotive, and pharmaceutical industries. In 2019, COPA-DATA generated turnover of EUR 51 million.

About zenon

zenon is a software platform from COPA-DATA for manufacturing and the energy industry. Machines and equipment are controlled, monitored and optimized. zenon’s particular strength is open and reliable communication in heterogeneous production facilities. Open interfaces and over 300 native drivers and communication protocols support the horizontal and vertical integration. This allows for continuous implementation of the Industrial IoT and the Smart Factory. Projects with zenon are highly scalable.

zenon is ergonomic, both for the engineer and for the end user. The engineering environment is flexible and can be used for a wide range of applications. The principle of “setting parameters instead of programming” helps engineers to configure projects quickly and without errors. Complex functions for comprehensive projects are supplied out-of-the-box to create intuitive and robust applications. Users can thereby contribute to increased flexibility and efficiency with zenon.

Emerson’s New Full-Bore Ball Control Valve Combats Vibration, Cavitation and Noise

AdministratorEmerson has introduced the Fisher™ V280 full-bore trunnion-mounted ball control valve for severe and specialty pressure, flow and process control applications. The valve provides excellent dynamic process control by utilising a robust drive train unique to the market that is designed to guide the shaft and properly absorb energy. Available attenuators for liquid and gas process fluids offer an effective solution for combatting the negative consequences of cavitation, such as vibration, erosion and noise.

The body connections of the V280 valve have been re-engineered to significantly simplify the design and reduce the number of parts, while utilising the same construction for the inlet and outlet. This allows an easy retrofit of single or dual ball seals with standard or customised noise attenuating aerodomes or anti-cavitation hydrodomes on the inlet, outlet or both. Typical applications include midstream oil and gas, particularly compressor anti-surge service.

Fisher™ V280 ball valve with attenuator, 1061 piston actuator and FIELDVUE™ DVC6200.

Fisher™ V280 ball valve with attenuator, 1061 piston actuator and FIELDVUE™ DVC6200.

The V280 is a fully rated ANSI class 900 valve, available in 6”, 8”, 10”, 12” and 16” sizes. A variety of high-performance packing materials are available, including ENVIRO-SEAL™ live-loaded packing. Optional special materials and constructions are available to accommodate specialty applications. The valve comes standard as a single-seal construction but is available with optional dual-seal construction, allowing bi-directional flow and double block-and-bleed operation.

The standard offering V280 complies with the NACE MR0175/ISO 15156 Sour Service/Sour Crude oil standard, carries the full ASME B16.5 Class 900 flange rating, and can handle fluid temperature ranges from -20 to 180 degrees F. Alternate seal options can handle temperatures from -50 to 400 degrees F. The valve can be fitted with a number of different positioners or auxiliary devices to suit hazardous or challenging environments.

Together with the Fisher V260 and V270 valves, the V280 provides users with a complete portfolio of full bore ball control valves.

To learn more about the Fisher V280 full-bore severe and specialty ball control valve, please visit: www.Emerson.com/FisherV280.

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and engineering company providing innovative solutions for customers in industrial, commercial, and residential markets. Our Emerson Automation Solutions business helps process, hybrid, and discrete manufacturers maximise production, protect personnel and the environment while optimising their energy and operating costs. Our Emerson Commercial & Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency, and create sustainable infrastructure. For more information visit Emerson.com

More...

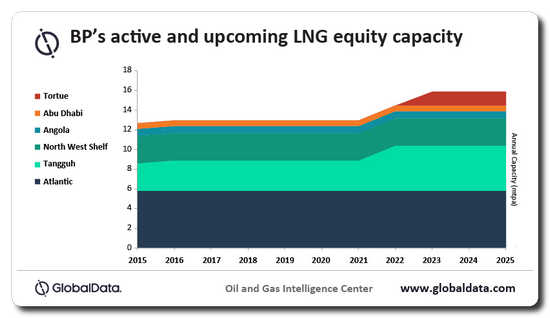

BP’s low carbon energy ambitions will be impacted by market weakness, says GlobalData

AdministratorBP will need to commit to significant investments in the renewable energy and liquefied natural gas (LNG) space in order to meet its 2030 target of 50GW in renewables capacity and 30MPTA in LNG. Capital available for investment activity will be challenged as market weakness dents cashflow from BP’s core hydrocarbons business, says GlobalData, a leading data and analytics company.

Daniel Rogers, Oil and Gas Analyst at GlobalData, comments: “BP has proven its willingness to invest big outside its core business, but will continue to rely on hydrocarbons as the cash cow for future investments. The current market fundamentals reduce the profitability of BP’s core business, potentially shrinking its pool of capital available for future low-carbon acquisitions.”

LNG will continue to play a major role in BP’s low-carbon energy and electricity goals and is targeting significant growth in the sector. In its current equity LNG portfolio, BP is forecast to reach 16MTPA in capacity by 2025, while relying on merchant volumes for the rest of the targeted amount.

Rogers continues: “The delay of the Tortue LNG project was a major blow and further delays could hinder BP’s 2025 target from being achieved. Future developments in Mauritania and Senegal will be the cornerstone of the company’s growth opportunities, but will hinge on investment decisions going ahead in spite of a potentially oversupplied LNG market going into the late 2020s.”

BP currently holds 2.3GW of installed renewable power capacity, leading the way for the major international oil companies (IOCs) and its recent deal with Equinor secures entry into the offshore wind sector with a capacity addition of 2.2GW once complete. BP’s current project pipeline will increase its capacity by 6.5GW, but this is still short of its target of 20GW by 2025.

Rogers concludes: “As BP will leverage off its core hydrocarbons business to fund its investment strategy, weakened oil and gas prices will put pressure on the company’s capital availability necessary to meet its low-carbon energy ambitions.”

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

The new NordtrackTM mobile equipment range from Metso Outotec breaks the milestone of 100 sold units

AdministratorThe new mobile crushing and screening range from Metso Outotec, NordtrackTM, has passed the milestone of 100 units sold worldwide. The volume sales of the range started during 1Q2020.

“This is a remarkable achievement for a new product range; especially considering how the pandemic has impacted the construction industry around the world,” says Vesa Tuloisela, Director, Nordtrack offering at Metso Outotec. “It strengthens our expectation that the potential Nordtrack customers appreciate the reliability and support of a premium brand. We believe that the demand for aggregate recycling equipment is on a steady path.”

Sales and deliveries have started globally and the biggest demand so far is coming from North America and Europe. Customers have ordered Nordtrack crushers for C&D (concrete and demolition) waste sites and aggregate quarries, and Nordtrack screens for aggregate screening and industrial applications, such as mulch screening and top-soil pre-screening. Mobile conveyors are used as auxiliary equipment to complete the crushing and screening plants.

“It is a range which meets the needs of the small and medium sized contractors who are looking to expand their business in aggregates, whether it is recycling or small-scale virgin aggregate production,” Vesa Tuloisela describes. “The features and options of the range have been selected in a way that the equipment is easy to use and to move between worksites. We have plans to announce new features and range extensions in the near future.”

“I want to express my warmest gratitude to all our customers and distributors who have welcomed Nordtrack. We continue to develop both the Nordtrack range and our Lokotrack mobile equipment portfolio to reach a more diverse customer base,” he concludes.

See the Nordtrack equipment in action at metso.com/nordtrack.

For further information, please contact:

Vesa Tuloisela, Director, Nordtrack Offering, Aggregates Business area, Metso Outotec, Tel. +358 50 385 1871 email: vesa.tuloisela(at)mogroup.com

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing, metals refining and recycling industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its illustrative combined sales for 2019 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

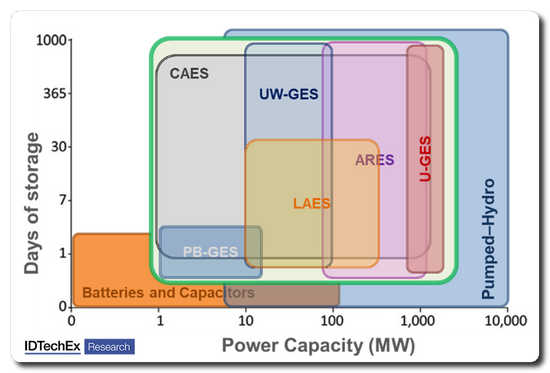

The Next Stage of the Electricity Grid Investigated by IDTechEx Research

AdministratorThe electricity market is evolving to allow a higher integration of variable energy sources and a new class of devices is approaching the market to satisfy this necessity.

In the new report released by IDTechEx: “Potential Stationary Energy Storage Device to Monitor”, the emerging class of energy storage devices, characterized by long storage duration and MW size power output, are investigated.

While existing energy storage devices are already populating the market, from Li-ion batteries to pumped-hydro energy storage, this new class of storage technologies will aim to complete the puzzle of the energy storage market.

Pushed from the electrification of the automotive sector, Li-ion batteries have been deeply investigated in the last decades and are currently the standard choice for short and medium-duration storage.

On the other end of the storage market, pumped hydro energy storage (PHES) are the main energy storage systems supporting the grid. These systems have a power capacity of GW scale (1000s of MW), and long storage time, from days upwards.

In between these two storage systems, a new group of storage devices is now approaching the market, with an intermediate power range, between MW to GW scale and an energy storage capacity that is almost indefinite.

Power and storage capacity comparison of different technologies. Source: IDTechEx Research report “Potential Stationary Energy Storage Device to Monitor”

The devices investigated by IDTechEx include:

- Gravitational Energy Storage (GES):

- Piston-Based GES (PB-GES)

- Underground PHES (U-PHES)

- UnderWater GES (UW-GES)

- Advanced Rail Energy Storage (ARES)

- Compressed Air Energy Storage (CAES)

- Liquid Air Energy Storage (LAES)

The market addressed by these systems aims to improve the quality, and resiliency of the electricity grid, and distribution networks. Therefore, it is aiming to address the Front-the-Meter (FTM) section of the electricity grid.

These devices, as investigated in IDTechEx’s new report “Potential Stationary Energy Storage Device to Monitor”, support the electricity grid providing peak-shaving service, grid deferral, and frequency regulation, among other possible services.

Moreover, because some of these technologies involved the use of several turbines, some of these devices can address more than one service at the time, therefore increasing the value stacking of these technologies.

Although they come with high capital costs, and are in their initial demonstration phase, these devices are a promising solution to stabilize the electricity grid and reach a high level of integration of variable renewable energy sources.

For more information on this report, please visit www.IDTechEx.com/PotentialSES or for the full portfolio of Energy Storage research available from IDTechEx please visit www.IDTechEx.com/Research/ES.

IDTechEx guides your strategic business decisions through its Research, Consultancy and Event products, helping you profit from emerging technologies. For more information on IDTechEx Research and Consultancy, contact This email address is being protected from spambots. You need JavaScript enabled to view it. or visit www.IDTechEx.com.

Alfa Laval – a world leader in heat transfer, centrifugal separation and fluid handling – has won three orders to supply Framo pumping systems for three FPSO (Floating Production, Storage and Offloading) vessels to be built in China. The orders have a combined, total value of approximately SEK 275 million and are booked in the Pumping Systems unit of the Marine Division, with deliveries scheduled for 2021.

The orders comprise marine pumping systems for crude oil offloading, produced water, slop and ballast duties.

The orders comprise marine pumping systems for crude oil offloading, produced water, slop and ballast duties.

“I am pleased to announce these large orders for our Framo pumping systems. These three orders confirm our systems reliability and ability to provide safe and optimized performance,” says Sameer Kalra, President of the Marine Division.

Did you know that… Framo was acquired by Alfa Laval in 2014 and is now part of the company’s worldwide organization?

This is Alfa Laval

Alfa Laval is active in the areas of Energy, Marine, and Food & Water, offering its expertise, products, and service to a wide range of industries in some 100 countries. The company is committed to optimizing processes, creating responsible growth, and driving progress – always going the extra mile to support customers in achieving their business goals and sustainability targets.

Alfa Laval’s innovative technologies are dedicated to purifying, refining, and reusing materials, promoting more responsible use of natural resources. They contribute to improved energy efficiency and heat recovery, better water treatment, and reduced emissions. Thereby, Alfa Laval is not only accelerating success for its customers, but also for people and the planet. Making the world better, every day. It’s all about Advancing better™.

Alfa Laval has 17,500 employees. Annual sales in 2019 were SEK 46.5 billion (approx. EUR 4.4 billion). The company is listed on Nasdaq OMX.