Displaying items by tag: steel

AUTOMATION - Automated Trupunch underpins output growth at Stoke subcontractor

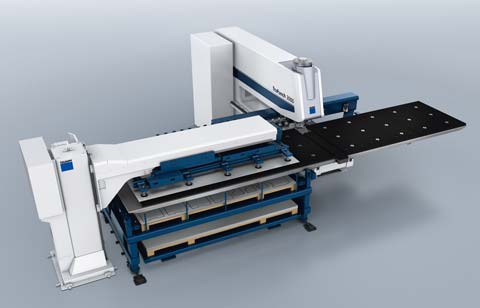

PKD Precision Sheet Metal Ltd, a leading subcontractor based in Stoke-on-Trent, has installed a new TRUMPF TruPunch 3000 S11 with SheetMaster Compact automation to help meet rising orders required for the electrical, electronic, transport and disability equipment industries.

According to PKD, there were three main reasons the company sought a new CNC punch press: increasing orders, the requirement to replace older equipment, and the need for automation to drive more efficient processing.

“We compared the TruPunch 3000 S11 with multi-turret type machines but TRUMPF won the order because, combined with the SheetMaster Compact automation, we felt it best suited what we were aiming to achieve,” explains Director, Phil Taylor. “We also saw it as a replacement for one of our older multi-turret type machines.”

The TruPunch 3000 is a resource-efficient, universal machine from TRUMPF which, for the first time ever, works without producing a scrap skeleton. With its intelligent handling of small parts, users can process sheets up to 6.4 mm thick virtually scratch-free.

Because of the diversity of industries supplied by PKD, the type of components produced by the TruPunch 3000 S11 varies considerably. However, materials are typically galvanised steel or zintec sheet up to 3.0 mm thick, with batch sizes usually in the region of 50 - 250 off. The machine has been installed alongside an existing TRUMPF TC3000 R-13 purchased in 2006.

“Comparing actual punching times, the new TruPunch 3000 S11 is quicker than our older machine, but with the addition of the SheetMaster Compact there becomes a significant increase in output,” says Mr Taylor. “The machine is already very busy and by including the TRUMPF SheetMaster Compact, we sought to create a highly efficient, stand-alone manufacturing cell that would help facilitate any unmanned staff shifts if required.”

The new TruPunch 3000 S11 is programmed offline at PKD, and highlighting the complexity of parts handled is the company’s extensive use of form tools, which include bridge, plunge and tapping, as well as other special tools to suit individual customer requirements.

“Our operators like using the machine and tell me that the touch screen controller is very user friendly,” says Mr Taylor. “They also say the TruPunch 3000 is much quieter than the TC3000, possibly due to the electric punching head, and generally cleaner to use. Furthermore, the gentle handling of the machine means we don’t encounter any issues with damage to our protective zinc coating.”

Established in 1980, PKD has enjoyed steady growth to become a 40-employee, ISO9001-accredited company with a turnover of circa £3.5 million. The company is always willing to share its expertise with customers, helping them with the design of new products, the explanation of manufacturing techniques, and with design changes to existing products to improve their effectiveness and reduce costs.

“Our aim is to not only provide customers with high quality products at competitive prices, but to deliver a service that exceeds their expectations,” says Mr Taylor. “Understandably, with globalisation, the market is leaning towards being solely price driven. However, good quality, service and delivery are still high on the customer agenda. Our philosophy has always been to make good quality products, deliver them on time and charge the right price. This, and our commitment to continual investment in new technology, enables us to compete.”

For more information please visit: www.uk.trumpf.com