Displaying items by tag: Unison Ltd

The power of three: Unison family to exhibit its latest technologies at mach 2024 and tube düsseldorf.

April 2024 is all set to be a particularly exciting time for Unison Ltd, the inventors of all-electric tube manipulation; Nukon Lasers UK, and wire bending machinery manufacturer, Pneuform Machines Ltd.

These three innovative British companies make up the Unison family – and MACH 2024 will provide the first opportunity for their respective technologies to be presented side by side since Pneuform was acquired by Unison Ltd in 2023. At the same time, over at Tube Düsseldorf, the tube and wire bending capabilities of Unison and Pneuform machines will be showcased together.

On show and operational at Stand 550 in Hall 20 at MACH 2024, will be an all-electric Unison Breeze ‘Twinhead’ tube bending machine, a Unison Synergy hybrid dual-stack tube bender, and a Pneuform 3D wire bending machine. A highly powerful European-built Nukon Rex 6kW flat sheet metal fibre laser machine from Nukon Lasers UK will also be on display.

At Stand G27 in Hall 6 at Tube Düsseldorf, visitors will be able to discover the tube and wire bending technologies offered across the Unison and Pneuform machine tool ranges. One of Unison’s manually operated, CNC-controlled EvBend machines will also be on display. Highly affordable and specially developed for low-volume precision tube bending, EvBend models are widely used across the aerospace, MRO, motorsport and oil & gas industries.

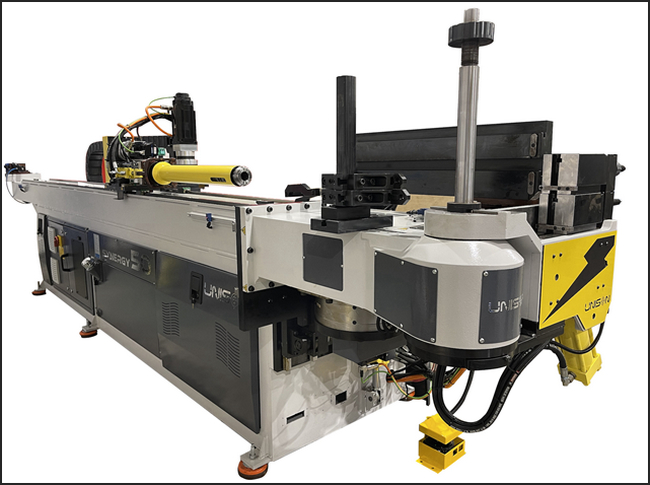

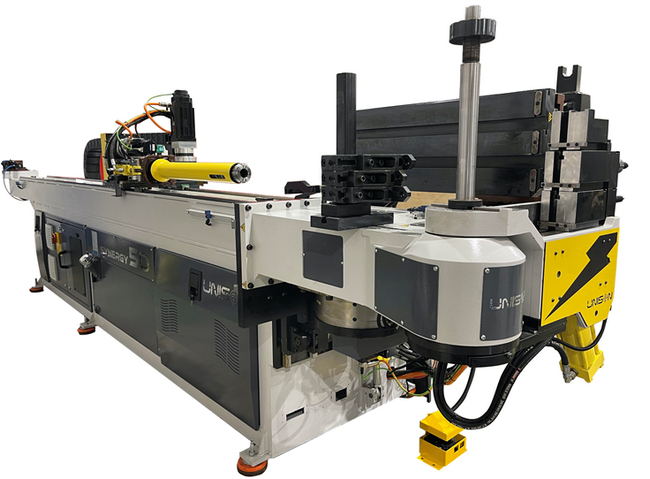

Unison Synergy, hybrid dual-stack tube bending machine.

Unison Synergy, hybrid dual-stack tube bending machine.

“We are incredibly pleased to be showcasing machines from all three Unison machine tool companies at MACH 2024, and to be presenting technologies from Unison and Pneuform at Tube Düsseldorf,” comments Unison Ltd’s joint managing director, Alan Pickering. “With our world-class, British-built Unison tube bending machines, Nukon’s highly accessible premium-quality fibre laser machines, and our recent acquisition of Pneuform, we now offer what I believe is the most comprehensive choice of quality machine tool technologies for organisations and subcontractors wanting to provide precision tube and wire bending and/or laser cutting. We have also made significant enhancements to the Pneuform model range for 2024 and are proud to support Pneuform machines with our uncompromising levels of aftersales care.”

Unison Breeze ‘Twinhead’ machines

The UK’s leading manufacturer of tube bending machinery, Unison Ltd pioneered ultra-precise, all-electric tube manipulation and today offers the largest range of all-electric tube and pipe bending machines for diameters from 4 mm to 275 mm. Unison’s range of ‘Twinhead’ machines has been developed for the high-speed manufacture of symmetrical tubular shapes, such as those typically used in automotive, agricultural, transport and furniture applications. Models include a 5-axis machine with optional weld-seam detection, end forming, tube marking and barcode batch reading, and an 11-axis multi-stack, multi-radius option for more complex shapes.

Unison Synergy hybrid machines

Developed to make Unison quality and reliability accessible to organisations that typically carry out repetitive tube bending tasks and don’t require the rapid setup time and all-electric operation of Unison’s Breeze tube bending machines, Unison Synergy models combine electric control with advanced hydraulic operation. Available in 50 mm and 80 mm (maximum tube diameter) versions, Synergy models offer exceptional power and robust design with user-friendly touchscreen control and a choice of industry leading motors and drives.

Pneuform wire bending machines

Pneuform was a pioneer of CNC 3D wire bending. Today its wire and small diameter tube bending machines have become the industry standard with many manufacturers of beer coolers, drink dispensers, HVAC equipment, and small diameter automotive parts. Pneuform’s range of wire bending machines includes rotary head models, flat rotary line bending machines and enamelled wire bending machines. Available in 2-axis and 3-axis versions, Pneuform machines cater for outside tube diameters ranging from 3 mm to 11 mm in stainless steel and 3 mm to 15 mm in copper.

Nukon Lasers UK

The Nukon Rex fibre laser machine that will be on display at MACH 2024 combines powerful 2D flat sheet metal cutting capability with optional pipe and tube cutting and marking features. Developed primarily for subcontractors and organisations cutting small batches of varying shapes and sizes, Nukon Rex machines have an extremely compact footprint and are available with power outputs ranging from 2kW to 6kW. Nukon Rex fibre lasers offer high-spec features that are standard across the wider Nukon range. These include advanced Lantek Expert CAD/CAM nesting software and American-made nLIGHT fibre lasers. Nukon Lasers UK is the exclusive UK and Ireland distributor for Nukon’s European-built 2D, 3D and tube fibre laser cutting machines and loading & unloading solutions. Nukon fibre lasers combine high speed and high precision with exceptional value and build quality, as well as exceptionally low running costs.

www.unisonltd.com

www.nukonlasers.co.uk

www.pneuform.com

‘BIG BIRTHDAY BASH’ MARKS UNISON’S 50 YEARS OF INTELLIGENT TUBE TECHNOLOGY

Unison Ltd, the UK-based inventors of all-electric tube manipulation, celebrated their 50th anniversary with a big birthday bash at their Scarborough HQ on Wednesday, 24th May 2023.

Just short of 100 customers, colleagues, friends and members of the ‘Made In Yorkshire’ trade group attended the event, which began with a hearty brunch and a warm welcome by Unison’s joint managing director, Alan Pickering.

Technology talks and machine tool presentations followed. These included demonstrations of Unison’s ultra-precise, all-electric Breeze range of tube bending machines, as well as fibre laser cutting machines from Unison’s sister company, Nukon Lasers UK. Unison’s newly released Opt2Sim Scan hand-held 3D tube scanning system - the latest addition to the company’s advanced Opt2Sim Suite of tube simulation software - also attracted a great deal of attention. The event concluded with a buffet lunch, followed by ice creams in the glorious Scarborough sunshine that graced the day.

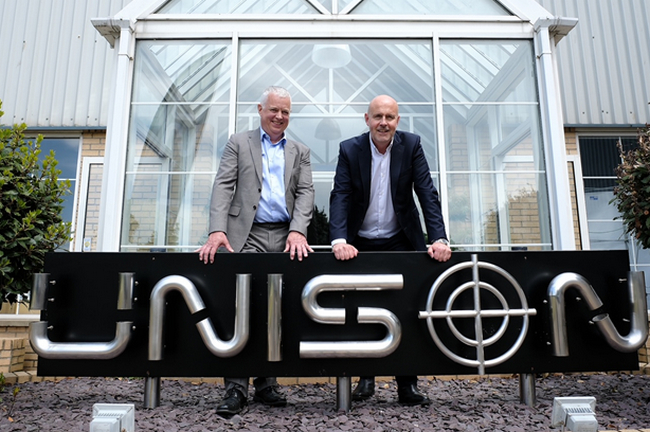

From left: Alan Pickering and Julian Kidger – Unison Ltd’s joint managing directors.

From left: Alan Pickering and Julian Kidger – Unison Ltd’s joint managing directors.

“I’d like to thank everyone who attended and helped make our 50th anniversary celebrations such a resounding success,” comments Alan Pickering. “It was fantastic to meet customers and friends old and new – many of whom had travelled a considerable distance to celebrate with us. I’d also like to thank every member of the incredible Unison team for the hard work they put into making the day possible. Here’s to another 50 years of intelligent tube technology!”

Unison Ltd: intelligent tube technology

Established in 1973, Unison Ltd is the UK’s leading manufacturer of tube and pipe bending machines and continually innovates the tube and pipe bending marketplace. The company manufactured the world’s first all-electric tube bender in 1994, followed by the world’s first all-electric multi-stack tube

bender, then the world’s largest all-electric tube bender for the shipbuilding industry. Available in single-stack, multi-stack and right/left varieties, Unison machines are delivered to more than 20 countries globally. Unison’s tube bending software is recognised as the most user-friendly control system for tube bending machines. The software is written and supported by Unison, ensuring complete control of its evolution, with no need for third party support.

www.unisonltd.com

PRESENTING UNISON’S TUBE BENDING INNOVATIONS AT FABTECH 2023

Unison Tube LLC, the North American division of UK-based Unison Ltd, will present a number of innovative tube manipulation technologies at FABTECH – North America’s largest metal forming, fabricating, welding, and finishing event. Unison machines on show at FABTECH Booth D41930 will include an all-electric Unison Breeze 100 mm (maximum tube diameter) multi-stack tube bender and one of the company’s manually operated, CNC-controlled EvBend 1000 models.

The all-electric Unison Breeze 100 mm machine

Unison Ltd invented ultra-precise, all-electric tube and pipe bending, and the Breeze 100 mm machine is one of the company’s flagship models. Like all Unison Breeze tube bending machines, the 100 mm Breeze offers rapid setup, fast tooling changes, exceptional power, rigid mechanical design, and all-electric control for right-first-time repeat sub-contract work, or immediately after producing a single trial part. These are all attributes that Unison Ltd believes make its Breeze models the ultimate tube manipulation machines for businesses specializing in small batch production runs. Equipped with Unison’s recently upgraded Unibend software, all-electric Breeze machines also offer cycle time speed improvements in the region of 25% compared to earlier models and incorporate new teach routine and simulation features.

The Unison EvBend range

Unison’s EvBend 1000 is a high-precision 3-axis machine that was developed to reduce the entry cost to precision rotary draw tube bending. The machine combines manually operated feed, tube rotation and bending force, with CNC-controlled braking on the carriage feed, rotation and bend arm axes. Typically used for low-volume, high-accuracy production and prototyping, Unison EvBend machines provide accurate multi-plane bending at a much lower cost than many CNC benders. Two models are currently available – the EvBend 1000 for bending tube of up to 16 mm in diameter, and the EvBend 2000, a machine featuring power-assisted operation and capable of bending tube of up to 50 mm in diameter. The EvBend CNC control includes a PC-based 15” touchscreen and is capable of processing up to 100 bends per component. Unison EvBend machines are widely used across the aerospace and motorsport sectors for bending precision components.

“FABTECH 2022 was an incredibly successful event for us,” comments Unison Tube LLC’s Vice President, Stuart Singleton. “With that in mind, we are looking forward to attending this year’s event with a larger booth and an even more exciting line up of tube bending machines. To arrange to meet me or another member of the Unison Tube team at FABTECH, simply email This email address is being protected from spambots. You need JavaScript enabled to view it..”

About Unison Tube LLC

Unison Tube LLC is the North American division of Unison Ltd, the UK’s leading manufacturer of tube and pipe bending machines, offering the largest range of all-electric benders for diameters from 5/32” (4 mm) to 10” (275 mm) schedule pipe. With a reputation for building highly powerful, highly robust machines that deliver uncompromising levels of accuracy and repeatability, Unison Ltd continually innovates the tube and pipe bending marketplace. The company manufactured the world’s first all-electric tube bender in 1994, followed by the world’s first all-electric multi-stack tube bender, then the world’s largest all-electric tube bender for the shipbuilding industry. Available in single-stack, multi-stack and right/left varieties, Unison machines are delivered to more than 20 countries globally. Unison’s tube bending software is recognized as the most user-friendly control system for tube bending machines. The software is written and supported by Unison, ensuring complete control of its evolution, with no need for third party support.

www.unisonltd.com

For more product information, please contact:

Stuart Singleton – Unison Tube LLC (North America)

T: +1 (828) 808 4286 E: This email address is being protected from spambots. You need JavaScript enabled to view it.

BRINGING NEW LEVELS OF TUBE BENDING INNOVATION TO FABTECH 2022

Unison Tube LLC, the North American division of UK-based Unison Ltd, will present a number of innovative tube manipulation technologies at FABTECH – North America’s largest metal forming, fabricating, welding, and finishing event.

Unison machines on show at Booth C10217 will include an all-electric Breeze Twin Head tube bending machine and one of the company’s all-new Synergy hybrid, multi-stack tube benders. Unison will also use FABTECH to launch the most advanced version ever of its industry leading Opt2Sim tube bending simulation software, with several free software licenses up for grabs.

Unison all-electric Twin Head machine

Equipped with Unison’s recently upgraded Unibend control - an operating system offering speed enhancements of up to 25% - all-electric Unison Twin Head 1 ½” (maximum tube diameter) machines will precision bend two ends of a tube simultaneously. This capability makes them well suited to the high-speed manufacture of symmetrical tubular shapes typically found in automotive, agricultural and furniture applications.

Unison Synergy hybrid tube bending machine.

Unison Synergy hybrid tube bending machine.

New Unison Synergy hybrid machine

Officially launched at the MACH machine tool show earlier this year, Unison’s new Synergy machines combine electric and hydraulic operation with exceptional levels of control. Developed for organisations that aspire to Unison quality but carry out repetitive tube bending tasks, Synergy models provide a highly accessible entry point into the Unison range. Available in 2” (50 mm) and 3” (80 mm) versions, Synergy machines feature a servo-driven bend arm, carriage, plane of bend and carriage side shift, with a hydraulically controlled mandrel, pressure die and clamping system. This is a combination that Unison believes make its Synergy range perfect for high volume, repetitive tube manipulation operations.

New Opt2Sim tube manipulation software – a complete end-to-end solution

Continuous innovation has ensured that Unison Opt2Sim remains a favourite tube manipulation software program among users of Unison and other brands of tube bending machines. In this latest iteration of Opt2Sim, Unison makes it easier than ever to import and extract tube data and includes software versions that take simulating the bending process, creating batch files and scanning tube coordinates to the next level. Opt2Sim provides users with a complete end-to-end solution, from taking 3D STEP files to bending tube within a single software suite. Delegates visiting Unison’s FABTECH booth will have the chance to win one of several Opt2Sim software licenses.

“We are delighted to be returning to FABTECH with such inspiring tube bending technologies,” comments Unison Tube’s Vice President, Stuart Singleton. “As industry returns to pre-pandemic levels, our aim is to help as many manufacturers and subcontractors as possible accelerate their efficiency, ingenuity and productivity. We are particularly excited to be unveiling our latest Opt2Sim software, as this really will revolutionise tube bending simulation for organisations of all sizes.”

About Unison Tube LLC

Unison Tube LLC is the North American division of Unison Ltd, the UK’s leading manufacturer of tube and pipe bending machines, offering the largest range of all-electric benders for diameters from 5/32” (4 mm) to 10” (275 mm) schedule pipe. With a reputation for building highly powerful, highly robust machines that deliver uncompromising levels of accuracy and repeatability, Unison Ltd continually innovates the tube and pipe bending marketplace. The company manufactured the world’s first all-electric tube bender in 1994, followed by the world’s first all-electric multi-stack tube bender, then the world’s largest all-electric tube bender for the shipbuilding industry. Available in single-stack, multi-stack and right/left varieties, Unison machines are delivered to more than 20 countries globally. Unison’s tube bending software is recognised as the most user-friendly control system for tube bending machines. The software is written and supported by Unison, ensuring complete control of its evolution, with no need for third party support.

www.unisonltd.com

Proof that engineering careers still appeal to UK youngsters!

Scarborough's annual Engineering Week event aimed at encouraging youngsters to consider careers in engineering has just held its most successful event - attracting over 2700 schoolchildren and young students.

Scarborough's annual Engineering Week event aimed at encouraging youngsters to consider careers in engineering has just held its most successful event - attracting over 2700 schoolchildren and young students.

Almost 30 organisations - most from the Yorkshire region - put on educational and fun displays about jobs in engineering today. Many exhibits were hands-on and interactive and ranged from touch-screen computer-aided design software, to remote operated vehicles for subsea oil and gas work, robot arms, and even an ingenious piece of food processing automation - a rustic potato cleaning machine developed for a McCain Foods' oven chips TV commercial.

"Great Britain was built on the engineering revolution, and still today it's engineering prowess that is largely defining the growth and success of economies and nations," says Peter Wilkinson from the lead organiser Unison - the Scarborough-based manufacturer of tube bending machines. "As a country, the UK urgently needs to invest in engineering, and attracting more youngsters to enter the profession is critical to that purpose. This event is about just that - we set out to show just how interesting and rewarding engineering is - and it's making a big difference in our region."

Over three days, more than 2700 schoolchildren and teachers - plus many more at evening public sessions - toured the exhibition. Among these was the guest of honour, HRH Prince Richard The Duke of Gloucester, representing Queen Elizabeth II. Prince Richard has a strong technical background, having trained as an architect and worked as a partner in a London practice before taking up Royal and family duties. The Duke identifed wholeheartedly with the ambititons of the event - to attract UK youngsters to become the engineers of tomorrow - and said he'd like to come back next year. As might be expected, he took particular interest in Atlas Ward Structures' exhibit - which demonstrated CAD software the Scarborough-based company uses to design steelwork for world-renowned projects such as The Shard and the Queen Elizabeth Olympic Park.

The Scarborough Engineering Week event was conceived by the directors of the metalworking machinery builder Unison Ltd, and they led the organisation of this year's event. They were aided by the regional education business partnership NYBEP who organised the student attendance from regional primary, secondary, sixth form and further education schools and colleges. The event was made possible by sponsorship from York Potash who want to develop a mine in the Scarborough area to produce potash fertilizer - a very large scale enterprise which could create hundreds of high quality engineering jobs.

Schoolchildren were treated to an array of engineering products and technology from Atlas Ward Structures, Bluebird Vehicles, Castle Employment, Castle Group, Deep Sea Electronics, Dale Power Solutions, Derwent Training Association, F1 in Schools, Fanuc, Festo, Firmac, Forum Subsea Technologies, Hunprenco, Joy Global, McCain Foods, Moog, North Sea Winches, NYBEP, Osprey, Plaxton, Sainsbury's, Schneider Electronic, Unison, University of Hull, University of Sheffield Advanced Manufacturing Research Centre (AMRC), Wilfrid Scruton, Yorkshire Coast College, and York Potash.

Some 130 representatives from all of the organisations involved in the exhibition, as well as the attending schools and colleges, attended a celebratory dinner during the event at The Spa in Scarborough. Adrian Allen OBE of the Advanced Manufacturing Research Centre gave the keynote speech.

Scarborough Engineering Week ran from 14-16 October 2013, at The Spa in Scarborough.