Displaying items by tag: Metso Outotec

Metso Outotec and PT Trakindo Utama to agree on aggregates distribution in Indonesia

Metso Outotec has appointed PT Trakindo Utama as a distributor for aggregates solutions in Indonesia as of September 2021 onwards. PT Trakindo Utama will provide Metso Outotec’s track-mounted, wheel-mounted, and stationary crushers and vibrating equipment, crusher wear parts and screening media, as well as commissioning and aftermarket services including technical support and service contracts for aggregate quarries and contractors in Indonesia.

“When selecting the new aggregates distributor for this territory, we emphasized the ability, capacity and expertise to take care of the existing Metso Outotec crushing and screening customers as well as to grow the customer base,” comments Shaun Fanning, Vice President, Distribution Asia Pacific at Metso Outotec. “We are very excited to start the cooperation, as PT Trakindo Utama is well-recognized and one of the biggest construction heavy equipment dealers in the world. We believe that the partnership will enhance the availability of our solutions and elevate our service level for aggregate processing quarries and contractors in Indonesia, one of the most active construction markets in the region.” “The partnership with Metso Outotec, a prominent player in aggregate crushing and screening solutions, strengthens our position as a complete solution provider in Indonesia’s quarry and aggregate market,” says Ali R. Alhabsyi, Managing Director, PT Trakindo Utama. “Their aggregate crushing and screening solutions complements our existing heavy equipment portfolio, and helps us to expand our business, as well as become the preferred one-stop-shop for the construction industry.”

From left: Unggul Aribowo, Metso Outotec, Immawan Priyambudi and Arif Prawira, PT Trakindo Utama

From left: Unggul Aribowo, Metso Outotec, Immawan Priyambudi and Arif Prawira, PT Trakindo Utama

The scope of the contract includes for example the following Metso Outotec aggregate crushing and screening solutions; Lokotrack® and Nordtrack™ mobile crushers and screens, Nordberg© C-Series jaw crushers and Nordberg® HP™ Series cone crushers, Premier™ and Compact™ Series screens, Metso Outotec Truck Body™ and Trellex® screening media.

PT Trakindo Utama is a world-class provider of construction heavy equipment solutions in Indonesia with 50 years of experience. They have an extensive network of more than 60 branches and more than 6,000 employees throughout the country. Read more on their website at: www.trakindo.co.id

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

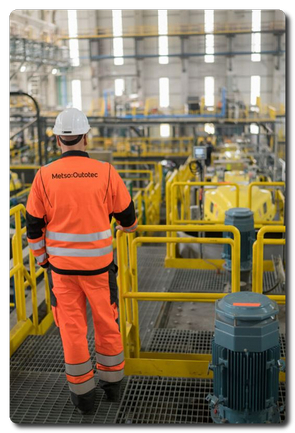

Metso Outotec awarded a major contract for supplying dewatering, flotation and automation technology to Nornickel in Russia

Metso Outotec has signed an agreement to deliver industry-leading dewatering, flotation and automation equipment for the Nornickel Talnakh processing plant expansion project in Norilsk, Russia. The order value, which is not disclosed, has been booked in Minerals’ Q2 and Q3 2021 orders received.

Metso Outotec’s delivery scope consists of the modernization of the three existing thickeners and the delivery of over 100 TankCell® flotation machines and an automation system for the new line 3 flotation area. In addition, the contract covers the supply of spare parts and consumables. Metso Outotec will also provide a metallurgical performance guarantee as well as advisory services for the installation and commissioning of the equipment. The delivery is scheduled for 2022/2023.

“We are pleased to continue our partnership with Nornickel. The supply of leading-edge equipment from Metso Outotec for the existing line 2 and the new line 3 flotation section at the Talnakh concentrator will enable an increase in the amount of ore processed. We have collaborated with Nornickel on several projects to boost the throughput rates of their processing facilities, and we are grateful for having again been selected to provide reliable solutions for a project as significant as Talnakh. Metso Outotec has previously supplied comminution and ore processing solutions and equipment for the Talnakh Concentator lines 1 and 2,” says Markku Teräsvasara, President, Minerals business area, Metso Outotec.

“We are pleased to continue our partnership with Nornickel. The supply of leading-edge equipment from Metso Outotec for the existing line 2 and the new line 3 flotation section at the Talnakh concentrator will enable an increase in the amount of ore processed. We have collaborated with Nornickel on several projects to boost the throughput rates of their processing facilities, and we are grateful for having again been selected to provide reliable solutions for a project as significant as Talnakh. Metso Outotec has previously supplied comminution and ore processing solutions and equipment for the Talnakh Concentator lines 1 and 2,” says Markku Teräsvasara, President, Minerals business area, Metso Outotec.

Sergey Dubovitsky, Senior Vice President Strategy, Strategic Projects, Logistics & Procurement at Nornickel, commented: “The new contract further develops the collaboration with our longstanding partner Metso Outotec, which has supplied technology to us for many years. We have an excellent track record of using the Metso Outotec machinery across the entire geography of our operations. The new equipment supply contract plays a crucial role for our expansion project – Talnakh Concentrator Line 3, which is a key step to deliver our strategy of sustainably producing metals required for the world economy to go greener”.

Metso Outotec's dewatering and flotation solutions are energy-efficient providing lower operating costs, and helping customers achieve maximum productivity and consistent recovery rates.

More information on Metso Outotec dewatering, flotation and automation technologies is available on our website

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

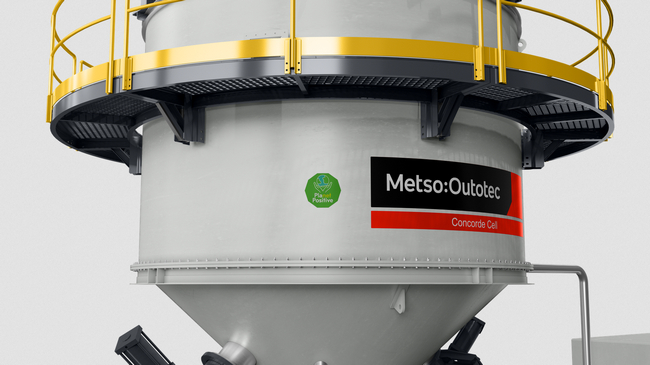

Metso Outotec provides cutting edge flotation technology for nickel concentrator in Australia

Metso Outotec will supply cutting edge flotation technology for a major nickel producer in Western Australia as part of their concentrator modernization. The site is one of the largest nickel producing sites in the world. Start-up of the new flotation cells is scheduled for 2022. The order value, which is not disclosed, has been booked in Minerals’ Q3/2021 orders received.

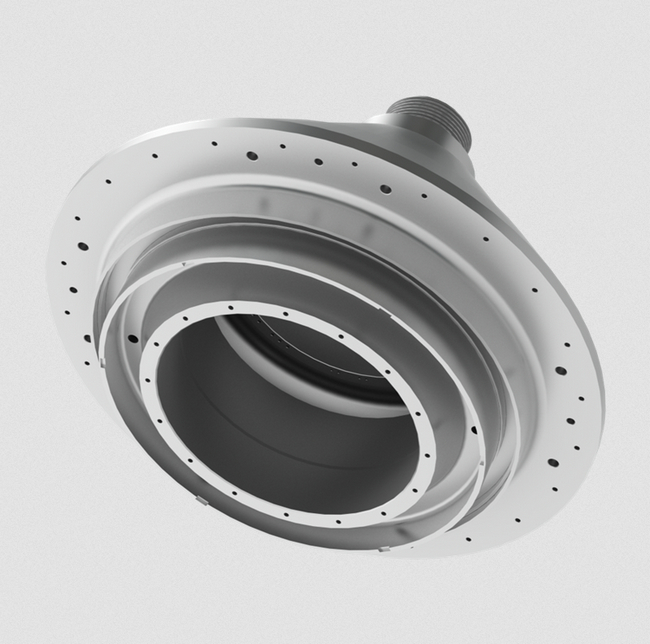

Metso Outotec’s delivery includes nickel rougher and cleaner flotation technology based on new and proprietary Concorde Cell™ flotation technology. The Concorde Cell™ uses a high-pressure aerated slurry jet through a choke to force the bubbles and particles to attach. This technology was originally invented by Laureate Professor Graeme Jameson to improve ultrafine particle flotation. Metso Outotec will be launching the Concorde Cell™ technology this fall.

Concorde Cell™

Concorde Cell™

“Metso Outotec is a leading provider of flotation technology. Thanks to intensive R&D efforts, we have successfully developed the new Concorde Cell™ flotation technology for superior performance in fine and ultrafine particle recovery. This is in response to the global industry trend towards efficient use of the Earth’s resources with more environmentally efficient technologies for more finely disseminated and complex orebodies,” says Paul Sohlberg, Vice President, Separation business line at Metso Outotec.

The Concorde Cell™ technology is a part of Metso Outotec’s Planet Positive portfolio.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki.

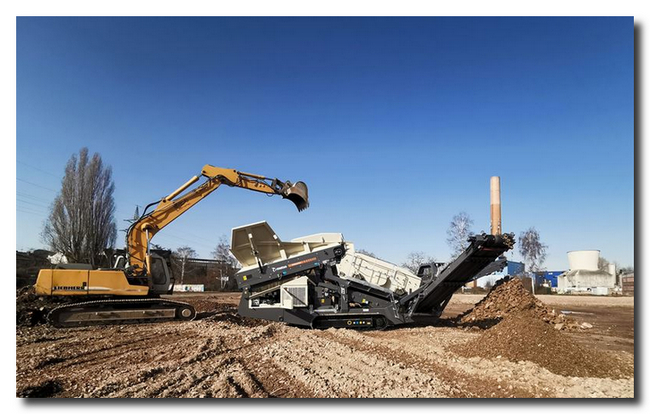

Metso Outotec and Ascendum Makina to cooperate in Turkey

Metso Outotec and Ascendum Makina Tic A.S. have started the cooperation to provide crushing and screening solutions for companies in the aggregate industry in Turkey. As of August 2021, Ascendum will sell Metso Outotec’s mobile and stationary crushers, vibrating equipment, and track- and wheel-mounted crushers and screens for aggregate processing. In addition, Ascendum will provide related Metso Outotec’s crusher wear parts and provide services, such as commissioning, service contracts and technical support.

Metso Outotec Nordtrack S25 jobsite

Metso Outotec Nordtrack S25 jobsite

“Ascendum has a strong reputation in providing earth moving equipment and services,” says Olli-Pekka Oksanen, Senior Vice President, Distribution Management Office at Metso Outotec. “We expect that the cooperation enables us to reach out to new aggregate crushing and screening customers more efficiently, as well as to provide our existing customers with faster access to parts, support and services.”

“The cooperation broadens our aggregate crushing and screening product offering,” says Mahir Hocaoglu, the CEO of Ascendum Makina. “Metso Outotec is a premium brand, and combined with our dedicated local expertise, our aim is to increase the customer satisfaction and to continue to be the preferred choice what it comes to aggregate crushing and screening solutions.”

Ascendum Makina Tic. A.S. is a Turkish distributor of equipment and services that are used in infrastructure projects, road construction projects, construction, and mining sectors. They have three main branches and three sub-dealer locations around Turkey with more than 600 employees. Read more at: http://www.ascendum.com.tr/

Metso-Outotec-Lokotrack-LT200HP-2018

Metso-Outotec-Lokotrack-LT200HP-2018

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Metso Outotec and Donum to provide aggregate solutions in the Philippines

Metso Outotec and Donum Industrial Corporation have signed a distribution contract concerning aggregate crushing and screening solutions in the Philippines. The contract covers Metso Outotec’s track-mounted Lokotrack® and Nordtrack™ equipment, the Nordberg® NW Series wheel-mounted equipment, Metso Outotec crusher wear and spare parts and Trellex® screening media. Donum will also provide related commissioning and aftermarket services including technical support and service contracts. The contract has come into effect in July, 2021.“The contract with Donum improves the availability of our equipment, crusher wears and spare parts via local inventory and experts,” says Shaun Fanning, VP, Distribution Asia Pacific at Metso Outotec. He continues: “Donum is locally recognized as one of the reputable and reliable suppliers and service providers. Their presence will help us to attain new quarrying and construction clients, and to support the customers throughout the solution lifecycle with dedicated local resources.”

Metso Outotec and Donum to provide aggregate solutions in the Philippines

Metso Outotec and Donum to provide aggregate solutions in the Philippines

“We are very proud to be the exclusive distributor of Metso Outotec’s mobile crushing and screening solutions for the aggregates industry in the Philippines,” comments Arlene Abata, President, Donum Industrial Corporation. “Customers value our expertise, the ability to transact locally and to have local support on day-to-day business. We believe that the partnership enables us to grow the business further through an expanded product offering. ”Donum Industrial Corporation serves a versatile clientele including aggregate industry through its head office in Taytay, Rizal, and three fabrication sites with 62 employees currently. Read more at: https://donumcorp.com.ph

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

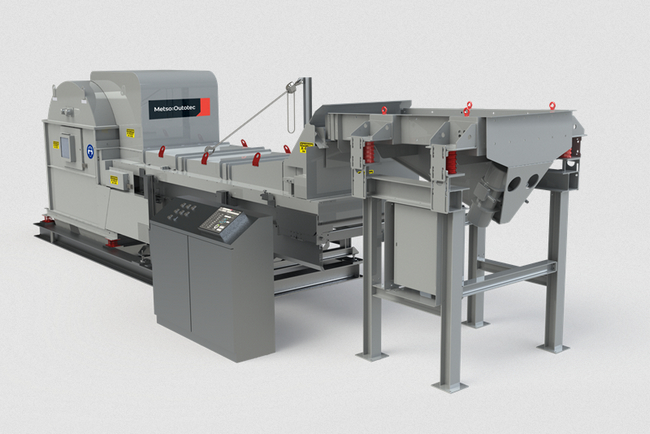

Metso Outotec continues to provide mining industry particle ore sorting solutions supported by TOMRA technology

Metso Outotec and TOMRA Mining have agreed to continue the non-exclusive cooperation to supply particle ore sorting solutions for the mining and metallurgical industries. The collaboration expands Metso Outotec’s and TOMRA’s capability to offer leading-edge solutions that help increase the overall value of ore deposits by reaching new levels of energy efficiency and productivity, decreasing costs, and extending the life of mining operations.

“Separating ore from waste rock as early and as efficiently as possible is essential in minerals processing. The best result can be achieved by combining state-of-the-art crushing systems with advanced ore sorting. The combination of Metso Outotec’s crushing know-how and TOMRA’s particle ore sorting expertise is an excellent match, providing substantial benefits to our customers,” says Guillaume Lambert, Vice President, Crushing at Metso Outotec.

TOMRA’s sensor-based sorting has been a proven concept in minerals processing, recycling, and the food industry for nearly 50 years. It can reduce specific energy consumption by 15 percent, as well as the amount of water used by three to four cubic meters per tonne of ore. This makes it an extremely cost-effective and sustainable solution that can benefit both mining operations and the environment.

“TOMRA, as an original equipment manufacturer, can add significant value to the process and engineering optimization of sensor-based sorting inclusive solutions when engaging with our customers within a cooperation agreement framework,” says Mathilde Robben, Key Account Manager at TOMRA Mining.

Find out more about Metso Outotec particle ore sorting solutions at mogroup.com.

More information about TOMRA Sorting is available on their website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Metso Outotec complements the crusher head portfolio with the robust solution for large Nordberg crushers

Metso Outotec introduces a new crusher head to complete the portfolio for Nordberg® MP800, MP1000, MP1250, HP800, and HP900 crushers. The Xtreme (forged) head is the most robust head on the market designed to handle the most demanding applications.

“Metso Outotec now has a complete range of crusher heads in the portfolio and our customers can choose the level of durability based on their application and needs. The new Xtreme forged head is the most reliable crusher head in the industry. The OEM design ensures optimal crushing even where equipment may be pushed beyond design limits,” says Chad Smallwood, SVP Crushing Products at Metso Outotec.

New Xtreme crusher head for large Nordberg crushers

New Xtreme crusher head for large Nordberg crushers

Increased reliability for the most extreme conditions

The new Xtreme head provides customers with an option for the most extreme conditions. The Xtreme head complements the Enhanced (heavy duty) head and the Elect (traditional cast) head in this comprehensive range of crusher heads.

The customer can match their price point and duty level to get the most life out of their components. Maximizing and extending the life of the components allows for a more sustainable operation overall.

Key benefits of the Xtreme head

- Advanced geometrical features to assure consistent bearing loading within machine design parameters

- Complete one-piece forged material

- A sustainable design and capabilities to provide safe and reliable operations

- Offers a 3-year warranty

Discover more about the Xtreme head and other crusher head alternatives at https://www.mogroup.com/portfolio/cone-crusher-upgrades/.

Metso Outotec has experience from hundreds of applications around the world and has an installed base of more than 10 000 crushers.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

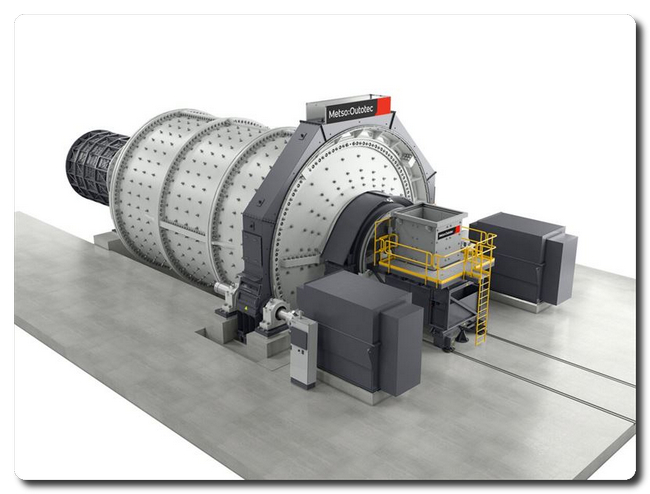

Metso Outotec to supply a high-capacity Premier™ SAG mill to Northern Star Resources in Australia

Metso Outotec will deliver a high-capacity, high-powered Premier™ SAG mill to Northern Star Resources Limited’s Thunderbox gold mine expansion located in Yandal Belt, north of Kalgoorlie in Western Australia. The typical value of such a delivery is approximately 15 million depending on the final scope. The order has been booked in Minerals’ first half of 2021 orders received.

On award of Northern Star Resources’ largest mill to date, Northern Star’s General Manager Processing, Mr Simon Tyrrell, said: “The Thunderbox expansion increases the operation’s hard rock processing capacity to 6.0Mtpa from the current 3.0Mtpa, and decreases processing costs as outlined in our 2021 Investor Day Presentation. Northern Star’s selection of Metso Outotec for the mill supply is supported by their locally based expertise, large mill supply history and ongoing collaboration with Northern Star.”

“We are pleased to be chosen as a supplier for the Thunderbox expansion. The gear-driven Premier™ SAG mill to be delivered will feature 18MW of motor power. With the Premier™ mill range we advance our unrivaled innovation legacy providing our customers with most reliable technology, engineered to exceed their specific requirements. We are looking forward to continue the collaboration with Northern Star Resources and to be part of their success story,” says Christoph Hoetzel, Head of Grinding business line at Metso Outotec.

Metso Outotec Premier Ball Mill

Metso Outotec Premier Ball Mill

Metso Outotec offers the industry's widest range of horizontal grinding mills consisting of the Premier™ and Select™ mills. They can be easily integrated with Metso Outotec mill reline equipment and are supported by the company’s extensive services network to ensure optimization during the mills’ lifetime. Metso Outotec also offers the market’s most comprehensive mill linings range and relining services with materials and designs optimized for each specific application.

Discover more about Metso Outotec grinding technology and Planet Positive approach.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Nornickel awards major contract for processing equipment supply to Metso Outotec

Nornickel, the world’s largest producer of palladium and high-grade nickel and a major producer of platinum and copper, has awarded a major contract for the supply of some of the key industry-leading equipment used in mining operations to Metso Outotec, further extending the partnership with Finland’s technology solutions provider.

Nornickel and Metso Outotec have signed an agreement to deliver industry-leading dewatering, flotation and automation equipment for Nornickel’s Talnakh concentrator expansion project in Russia’s Arctic city of Norilsk. The contract value is a commercially sensitive matter and therefore may not be disclosed publicly.

Nornickel and Metso Outotec have signed an agreement to deliver industry-leading dewatering, flotation and automation equipment for Nornickel’s Talnakh concentrator expansion project in Russia’s Arctic city of Norilsk. The contract value is a commercially sensitive matter and therefore may not be disclosed publicly.

Metso Outotec’s delivery scope consists of modernization of three existing thickeners and delivery of over 100 TankCell® flotation machines and an automation system for the new Talnakh concentrator Line 3 flotation area. In addition, the contract covers the supply of spare parts and consumables. Metso Outotec will also provide a metallurgical performance guarantee as well as advisory services for the installation and commissioning of the equipment. The delivery is scheduled for 2022-23.

Sergey Dubovitsky, Nornickel Senior Vice President Strategy, Strategic Projects, Logistics & Procurement, commented: “The new contract further develops the collaboration with our longstanding partner Metso Outotec, which has supplied technology to us for many years. We have an excellent track record of using the Metso Outotec machinery across the entire geography of our operations. The new equipment supply contract plays a crucial role for our expansion project — Talnakh Concentrator Line 3, which is a key step to deliver our strategy of sustainably producing metals required for the world economy to go greener”.

Markku Teräsvasara, Metso Outotec President, Minerals business area, commented: “We are pleased to continue our partnership with Nornickel. The supply of leading-edge equipment from Metso Outotec for the existing Line 2 and the New Line 3 flotation section at the Talnakh concentrator will enable an increase in the amount of ore processed. Our company has collaborated with Nornickel on several projects to boost the throughput rates of their processing facilities, and we are grateful for having again been selected to provide reliable solutions for a project as significant as Talnakh. Metso Outotec has already supplied equipment and solutions for comminution and ore processing for Talnakh concentrator Line 1 and Line 2”.

ABOUT THE COMPANY

MMC Norilsk Nickel is a diversified mining and metallurgical company, the world’s largest producer of palladium and high-grade nickel and a major producer of platinum and copper. The company also produces cobalt, rhodium, silver, gold, iridium, ruthenium, selenium, tellurium, sulphur and other products.

The production units of Norilsk Nickel Group are located at the Norilsk Industrial District, on the Kola Peninsula and Zabaykalsky Krai in Russia as well as in Finland and South Africa.

MMC Norilsk Nickel shares are listed on the Moscow and on the Saint-Petersburg Stock Exchanges, ADRs are traded over the counter in the US and on the London, Berlin and Frankfurt Stock Exchanges.

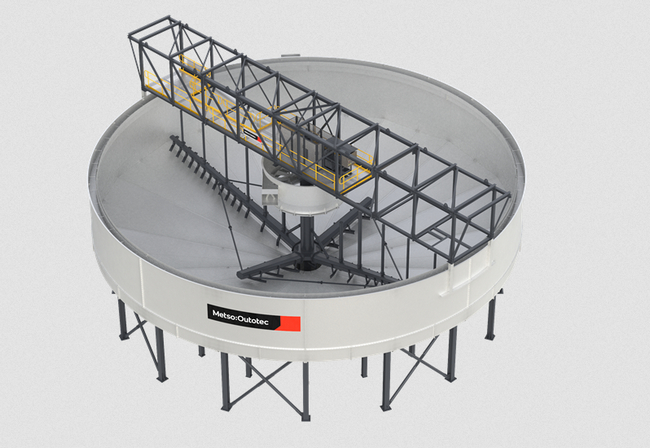

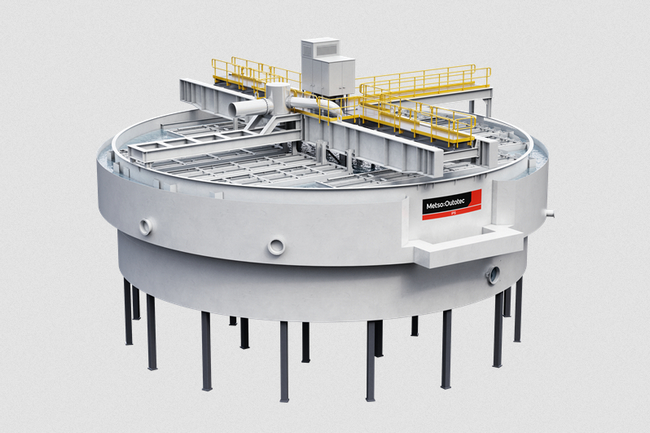

Metso Outotec launches thickening and clarifying solutions to enable clear performance improvements and sustainable profits

Metso Outotec is introducing a comprehensive portfolio of thickening and clarifying solutions to achieve new levels of operational reliability and performance in minerals and metals processing. The solutions continue to set the industry standard with state-of-the-art High-Rate Thickeners, High-Compression Thickeners, Paste Thickeners, Inclined Plate Settlers, and Clarifiers.

“We are excited to launch our combined thickeners and clarifiers portfolio to the market. This portfolio is designed to help our customers unlock the full potential of their dewatering process. Our solutions provide high process performance, facilitate efficient operation, and feature a robust design, enabling increased uptime,” says Brian Berger, Vice President, Thickening and Clarifying solutions at Metso Outotec. “With the combination of these features in the portfolio, our customers can align their profitability and sustainability targets.”

HCT 925

HCT 925

The thickeners and clarifiers offering is supported by a global network of service experts to ensure that maximum efficiency is continuously delivered by the equipment and plants. Metso Outotec's services offering includes everything from comprehensive onsite tailings management audits, engineering, spare and wear parts, maintenance services, and remote operation capabilities.

The solutions feature a sustainable design and capabilities to provide safe and reliable operations. They also comply with the highest safety standards, are easy to operate and maintain, and can easily be combined with a complementary automation offering to improve performance by controlling key variables of the thickening process.

MO IPS 02

MO IPS 02

Key benefits

- High-performance, robust solutions to meet a wide range of applications

- Industry-leading innovation in thickening and clarification equipment

- Exceptional experience in meeting and exceeding customer expectations in all phases of the equipment buying, operation, and decommissioning lifecycle

Discover more about Metso Outotec thickening and clarification solutions on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com, twitter.com/metsooutotec