Displaying items by tag: Gravitricity

Slovenian coal mine looks to gravity energy storage for green future

An operational coal mine in Slovenia has become the latest mine in mainland Europe to look to underground energy storage.

The Velenje mine in the northeastern part of Slovenia is currently a fully operational lignite mine, with six working shafts and more than 1,600 mine employees.

The mine operators have now commissioned a feasibility study to examine how underground gravity energy storage – provided by Edinburgh firm Gravitricity – could offer a low carbon future as the mine winds down operations in the 2030s.

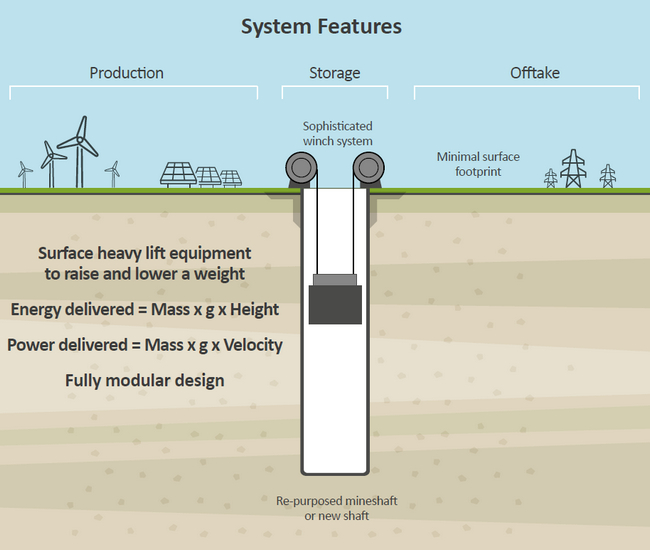

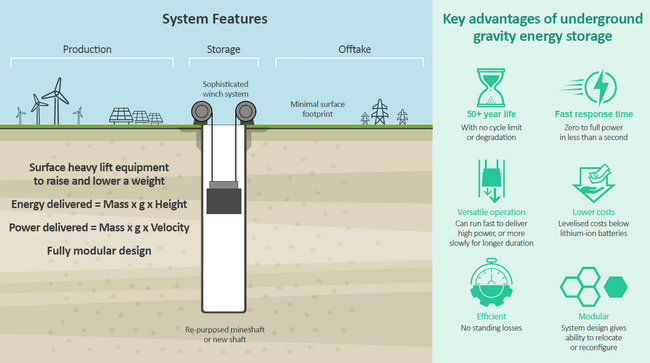

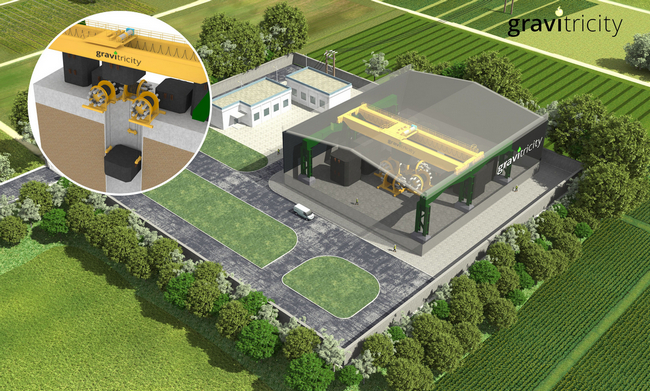

Gravitricity has developed a unique energy storage system, known as GraviStore, which raises and lowers heavy weights in underground shafts – to offer some of the best characteristics of lithium-ion batteries and pumped hydro storage.

Velenje is the latest mine to look to gravity storage, following mine sites in Finland, Germany, and the Czech Republic.

The mine’s parent company HSE Group is already Slovenia’s largest producer of renewable electricity, and any future storage scheme could potentially be combined with on-site solar generation to support the country’s transition to net zero.

Gravitricity engineers have already visited the site to assess the technical feasibility of installing systems in two specific shafts one of which is a ventilation shaft which may become available for a potential pilot project, which could start as early as next year.

Gravitricity Engineering Project Manager Nigel Voaden said:

“The Velenje mine could be very well suited to future energy storage schemes as the operational shafts are both deep and in excellent condition and we are grateful to the mine’s operators for commissioning this study. Any future project could offer a new future to many of the hundreds of people who work at the mine today.”

“The survey includes an all-site assessment looking at energy demand, production, and storage, provides an initial calculation of the potential energy storage capacity for each of the six shafts on site, and completes a technical feasibility assessment for the installation of two GraviStore systems,” Voaden says.

Following submission of Gravitricity’s findings, the Velenje mine operators will have the opportunity to consider a second phase of the feasibility study prior to any final decision on a pilot scheme.

Gravitricity is currently fundraising on the Crowdcube platform and has already passed its £500,000 funding target.

Gravitricity is raising £500,000 investment on Crowdcube. Capital At Risk.

About Gravitricity

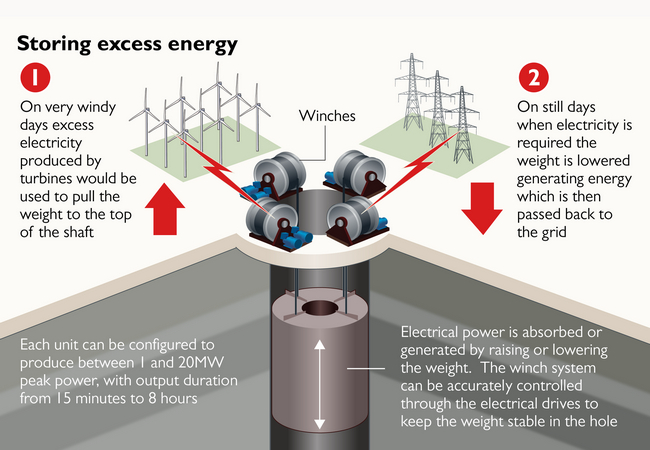

Gravitricity uses heavy weights suspended in a deep shaft by cables attached to winches. When there is excess electricity, for example on a windy day, the weight is winched to the top of the shaft ready to generate power. This weight can then be released when required – in less than a second – and the winches become generators, producing either a large burst of electricity quickly, or releasing it more slowly depending on what is needed.

See short (30 second) ‘how it works’ animation here.

Unlike batteries, the Gravitricity system can operate for decades without any reduction in performance. Gravitricity has an expanding portfolio of intellectual property in underground energy storage including eight granted patents and a further two pending. The idea of using gravity to store energy is not new. Britain already relies on a number of pumped storage hydro schemes, such as Cruachan Power Station, where water is pumped uphill to be released when required.

Gravitricity is advancing a number of full-scale GraviStore projects, including a plan to transform state owned mine infrastructure in the Czech Republic into an energy store.

About Velenje coal mine

Despite the national and global trends aiming to transition to a low-carbon or carbon-neutral society, Premogovnik Velenje (Velenje Coal Mine), an associated company of Holding Slovenske Elektrarne, is still an important and indispensable pillar of the Slovene energy industry. Together with Termoelektrarna Šoštanj (Šoštanj Thermal Power Plant), it has been striving for decades to ensure undisturbed and reliable power supply for one third of Slovenia.

We are immensely proud that the foundations of today's image of the Šaleška dolina Valley are based on mining, as the Velenje Coal Mine has been the main driving force of development of the entire region since 1875, and its impact is often seen beyond the valley, as well.

We have extracted over 259 million tonnes of coal from the depths of the Šaleška dolina Valley. From the initial 3,500 tonnes in 1887, the biggest breakthrough in production happened in the 1980s, when mechanised mining equipment was gradually introduced, which helped us achieve the milestone of over 5 million tonnes of extracted coal per year. Nowadays, our production, which is primarily dependent on the consumption by the Šoštanj Thermal Power Plant, is around 2-2.5 million tonnes of coal per year.

Our story is based principally on tradition and our know-how, technological equipment, and technologies that we developed. We participate in some key development and research projects, co-financed by the European funds, which support high-technology development. Every year, our innovations are among the recipients of the highest regional and national awards. For years, we have been spreading knowledge, experience, technology, and equipment abroad.

Energy is the means for achieving our goals. By innovative thinking and professional and efficient work, we can improve the competitive position of the entire Velenje Coal Mine Group

Green future for former coal mines - Gravitricity and Czech state enterprise DIAMO commit to cooperate on full scale gravity energy store

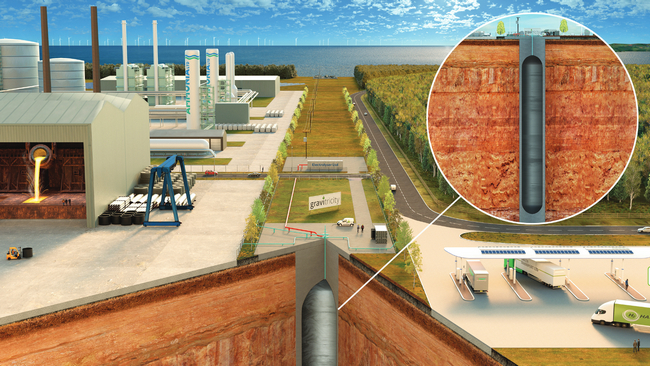

A former coal mine in the Czech Republic could become the first full scale gravity energy store in Europe.

- Opportunity to transform Darkov deep mine into underground energy store

- Gravitricity and Czech state company DIAMO sign memorandum of understanding

- Commitment to seek EU funds for first full scale 4MW / 2MWh scheme

- New future for mining communities as countries move to net zero

Underground energy storage specialists Gravitricity have signed a memorandum of understanding with DIAMO, the Czech state enterprise charged with mitigating the consequences of uranium ore and coal mining in the republic.

The memorandum will see the partners work together to seek EU funds to transform the former Darkov deep mine into a massive energy store – which could be a pathfinder for projects Europe-wide.

Yesterday, at a formal signing ceremony at the British Embassy in Prague, the two parties committed to work in tandem to seek funds to turn the decommissioned mine into a 4MW / 2MWh energy store – capable of powering more than 16,000 homes.

Gravitricity also signed a memorandum with VSB Technical University of Ostrava, whose specialist mining expertise will support the implementation of Gravitricity’s technology into the existing mine.

The Darkov mine is located in the coal-rich Moravian-Silesian region of the Czech Republic, near the city of Karviná. Construction started in 1972, to access thick seams of coal more than 700 metres below the surface, and at its peak it employed around 4000 people.

Gravitricity plans to store energy by lowering and raising a single massive weight suspended in the Darkov mine shaft.

The Edinburgh firm has already demonstrated a scale version of their technology in Edinburgh – built in partnership with Dutch winch specialists Huisman – and now plans to build full-scale schemes in the UK and worldwide. Future multi-weight systems could have a capacity of 25MWh or more.

Speaking at the ceremony, Gravitricity Managing Director Charlie Blair said:

“A low carbon world will require vast amounts of energy storage, and at Gravitricity we have developed a long-life energy storage technology which can delivery super-fast energy and offers some of the best characteristics of lithium batteries and pumped hydro storage.

“We hope our collaboration with DIAMO will allow us to demonstrate this technology at scale and offer a potential future for coal mines that are approaching the end of their original service life.”

The British Ambassador to the Czech Republic Matt Field said:

“It is a great honour to host this Memorandum of Understanding signing ceremony. We truly appreciate that Gravitricity, DIAMO and Technical University Ostrava plan to cooperate on Gravitricity’s first prototype project. It would be the first full-scale installation of this renewable energy technology, a project that is unique, transformative and green.”

Ludvík Kašpar, CEO of DIAMO said:

“Our main task is to provide the liquidation of mines, but at the same time we are looking for new uses for the mine sites according to the needs of the region. The Gravitricity project is an opportunity for mines and also for our experts, who can try working on new projects and cooperation with a foreign entity. We have a lot of work ahead of us, we need to check all aspects and risks related to with operation of the mine.”

At Darkov, DIAMO is also planning to build a photovoltaic power plant and is considering the production of green hydrogen. The site will also be home to an experimental greenhouse project – called EDEN Silesia – managed by the Silesian University.

Worldwide, Gravitricity estimates there are around 14,000 mines which could be suitable for gravity energy storage.

About Gravitricity

Gravitricity uses heavy weights – totalling up to 12,000 tonnes – suspended in a deep shaft by cables attached to winches.

When there is excess electricity, for example on a windy day, the weight is winched to the top of the shaft ready to generate power.

This weight can then be released when required – in less than a second – and the winches become generators, producing either a large burst of electricity quickly, or releasing it more slowly depending on what is needed.

Unlike batteries, the Gravitricity system can operate for decades without any reduction in performance.

See a short (30 second) explainer animation here.

The idea of using gravity to store energy is not new. Europe already relies on a number of pumped storage hydro schemes, mostly focused in mountainous regions in Switzerland, Austria and Germany, where water is pumped uphill to be released when required.

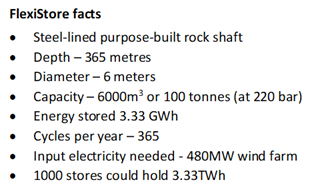

Underground green hydrogen stores offer ‘goldilocks’ solution to UK’s future hydrogen needs

The UK could see the construction of hundreds of new purpose-built underground hydrogen stores to help fuel the green economy of the future.

- Gravitricity signs MoU with infrastructure major VSL to build prototype green hydrogen FlexiStore

- Purpose built lined rock shafts can be located where required

- Each shaft can hold 100 tonnes – sufficient to refuel 1000 HGVs

- 1000 stores could meet a quarter of UK’s predicted hydrogen storage needs

- ‘Goldilocks’ solution is bigger than above ground storage and more flexible than salt caverns

- Fleets of FlexiStores could utilise vast and growing amounts of unused (‘constrained’) wind

Underground energy storage specialists Gravitricity have signed a memorandum of understanding (MoU) with infrastructure major VSL Systems UK to complete the design of the purpose-built underground lined rock shafts which could be rolled out nationwide. They plan to build a scale demonstrator in the next 24 months ahead of commercial rollout.

VSL is part of the French Bouygues Construction group and is a specialist contractor for the construction, preservation and repair of major engineered structures and infrastructure. Gravitricity is an Edinburgh based energy storage company which is developing below ground gravity energy storage systems in the UK and mainland Europe.

Gravitricity believes their storage technology – known as FlexiStore – is a ‘goldilocks’ solution to the future challenge of green hydrogen storage – offering a system that is larger and more secure than above ground hydrogen storage, and more flexible than subterranean salt caverns, the two most commonly-proposed alternatives.

Each rock shaft would be six metres in diameter and 365 metres deep and lined with steel. A single store would hold up to 100 tonnes of green hydrogen – sufficient to refuel more than 1000 HGVS, or to power 500 buses for a week.

Gravitricity calculates that construction of just 1000 FlexiStores would meet a quarter of the UK Government’s predicted 2050 hydrogen storage needs[i].

Crucially, the stores can be constructed wherever required and are not dependent upon specific geological locations (a drawback of salt caverns). This means single or multiple FlexiStores can be built close to renewable-powered green hydrogen production facilities where they can fuel hydrogen-powered industrial hubs and commercial hydrogen filling stations.

A single FlexiStore would store the green hydrogen generated by a 460 MW offshore wind farm and could be emptied and refilled daily, whilst multiple stores could soak up vast amounts of otherwise wasted or ‘constrained’ wind – which amounted to 3.6TWh in 2020[ii].

The Edinburgh firm is now seeking funds along with VSL to build their first scale demonstrator project in the UK. Once complete Gravitricity then plans the rollout of hundreds of purpose-built green hydrogen FlexiStores nationwide. The company is also in advanced discussions with Cumbrian steel specialists Bendalls Engineering to fabricate the linings for the rock shafts.

[i] National Grid’s ‘Future Energy Scenarios 2021’ suggest that between 12TWh and 51TWh of hydrogen storage will be required in 2050 across varying net zero compliant scenarios. UK Hydrogen Strategy, August 2021: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/1011283/UK-Hydrogen-Strategy_web.pdf

[ii] Storage could ‘slash curtailment of British wind’ - reNews - Renewable Energy News

“Green hydrogen will be a vital fuel of the future in industrial applications and in heavy transport, where electrification is just not feasible, or where industrial grey hydrogen is already used,” says Charlie Blair, Managing Director of Gravitricity.

“Green hydrogen will be a vital fuel of the future in industrial applications and in heavy transport, where electrification is just not feasible, or where industrial grey hydrogen is already used,” says Charlie Blair, Managing Director of Gravitricity.

“Purpose-built lined rock shafts will be the safest and most affordable way to store large volumes of hydrogen near to where it will be required. It is difficult to transport hydrogen. It therefore makes sense to locate hydrogen storage systems close to sources of renewable power – which can generate green hydrogen – and to potential users.

“At present, the main proposals for storage are underground salt caverns and above ground storage. Salt caverns offer scale, but very little flexibility – they only exist in certain locations; whilst above ground systems lack scale.

“We believe we have a ‘Goldilocks’ solution which can be delivered safely and affordably to meet the growing hydrogen economy’s needs,” Blair says.

Commenting on the MoU, Peter Hughes, Managing Director of VSL UK said:

“VSL is delighted to partner with Gravitricity to develop and deliver these pioneering ground engineering solutions for renewable energy generation and storage. This project is fully aligned with the VSL vision to focus our engineering capabilities and solutions on the global transition to a low carbon future.”

The UK Government has highlighted a number of electrolytic hydrogen projects across the UK which will require hydrogen storage alongside renewable powered electrolysers[iii].

Gravitricity has already identified a number of sites for the UK pilot project and is in discussion with site owners, including utilities, regarding the pilot project and future commercial schemes.

Gravitricity recently completed a £300,000 feasibility study, conducted with ARUP and funded by the UK Government’s BEIS HySupply programme, which showed it is technically and commercially feasible to store large amounts of compressed hydrogen in an underground lined rock shaft.

“If green hydrogen is to become a mass market fuel of the future then we need to find ways to store it safely and in large quantities close to where it is needed,” Blair says.

[iii] Page 11, UK Hydrogen Strategy, August 2021: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/1011283/UK-Hydrogen-Strategy_web.pdf

About Gravitricity

At Gravitricity we are developing long-life, below-ground technologies which store energy safely and deliver it on demand at a lower lifetime cost than current alternatives.

Our gravity and hydrogen storage technologies each offer unique attributes, ideally suited to the fast-evolving energy markets of tomorrow.

About VSL Ltd

As a specialist in post-tensioned and cable-stayed structures, foundations and ground engineering, VSL contributes to the design and construction of transport infrastructure (bridges, tunnels, roads), buildings, and industrial & energy-producing structures, and it maintains, repairs and upgrades all structural systems that guarantee performance, safety and durability.

VSL is part of Bouygues Construction group. It has 3,800 employees in 25 countries, mainly located in Asia, Oceania, the Middle East, Europe, Canada and Latin America.

Gravitricity and Arup secure £300k BEIS HySupply 2 grant to develop below ground hydrogen storage

The towns and cities of the future may be able to rely on green hydrogen stored below ground, if a newly funded UK project succeeds.

- Purpose-built shafts could store large quantities of hydrogen

- Feasibility study could lead to first of a kind UK project

- Potential to build hydrogen stores wherever required

Gravitricity and Arup have together secured £300,000 from the Department of Business Energy & Industrial Strategy (BEIS) to study the feasibility of storing hydrogen in purpose-built underground shafts.

Edinburgh-based energy storage specialists Gravitricity and global built environment consultancy Arup will collaborate to deliver a complete system design and commercial feasibility report for the novel idea, as well as identifying a potential site for their underground hydrogen store. The design will also include integration with gravity energy storage and inter-seasonal heat.

The parties been awarded £299,985 in Phase 1 of the BEIS Low Carbon Hydrogen Supply 2 [HySupply 2] Competition which aims to support innovation in the supply of hydrogen, reducing the costs of supplying hydrogen, bringing new solutions to the market, and ensuring that the UK continues to develop world leading hydrogen technologies for a future hydrogen economy.

If successful, the project could be selected to enter Phase 2, where the partners would build a £multi-million scale demonstrator in the UK.

This would involve sinking a purpose-built concrete lined vertical underground shaft with a domed cap, to create a demonstration pressurised hydrogen storage vessel. [Pictured.]

Commenting on the project, Gravitricity’s Hydrogen and Thermal Storage Lead, Sally Molyneux says:

“If green hydrogen is to become a mass market fuel of the future – for example for providing heat to industry or powering heavy vehicles – then we need to find ways to store it safely and in large quantities close to where it is needed.

“Storing hydrogen in underground shafts is intrinsically safer and less obtrusive than above ground options and is a solution that does not require unique geology such as salt caverns. We believe Gravitricity’s innovation is a scalable storage method which is cost effective, extremely durable, and can be implemented everywhere.”

Gravitricity Managing Director Charlie Blair adds:

“Our partnership with Arup creates a combined team with all of the expertise and experience required to build and deliver Gravitricity underground energy stores.

“In the past, our cities relied on huge gasometers to store the gas they required. In the future, our towns can look to purpose-built shafts to safely store the green hydrogen they will need.”

Mark Neller, Arup’s Energy Leader for the UK, India, Middle East and Africa, said:

“Working with Gravitricity and BEIS on this innovative approach to hydrogen storage has the potential to play an important role in the future of the UK’s energy systems. This project will draw on Arup’s extensive skills and experience, as part of our wider efforts to help the UK meet its ambitious target of reaching net-zero by 2050.”

UK Energy Minister Greg Hands said:

“The UK is truly leading the world in hydrogen innovation thanks to the exciting efforts of companies like Gravitricity. The government support which they have received today will help to boost the development of hydrogen as the clean, affordable, homegrown superfuel of the future.”

Longer term, the partners believe the shafts can also be used for fast response electricity storage, using Gravitricity’s solid weight technology which raises and lowers heavy weights in a shaft.

In addition, the shaft’s gastight lining will in future incorporate heat exchangers for inter-seasonal heat storage. Adding heat exchangers to the shaft lining, at marginal cost, creates a very large ground source capable of feeding a network of heat pumps in the surrounding area.

This sharing of infrastructure means the cost per unit of energy stored (as electricity, heat and hydrogen) will be very competitive.

Last summer Gravitricity successfully commissioned and operated a grid-connected 250kW demonstrator in Leith, Edinburgh, and now plan to build a full-scale project in a decommissioned mine shaft in mainland Europe.

About Gravitricity

Gravitricity uses heavy weights – totalling up to 12,000 tonnes – suspended in a deep shaft by cables attached to winches.

When there is excess electricity, for example on a windy day, the weight is winched to the top of the shaft ready to generate power. This weight can then be released when required – in less than a second – and the winches become generators, producing either a large burst of electricity quickly, or releasing it more slowly depending on what is needed.

Unlike batteries, the Gravitricity system can operate for decades without any reduction in performance.

See a short (30 second) explainer animation here.

Gravitricity has applied for seven patents in total, with five granted and two pending.

The idea of using gravity to store energy is not new. Britain already relies on a number of pumped storage hydro schemes, such as Ben Cruachan, where water is pumped uphill to be released when required.

About Arup

Arup is a world class firm of more than 16,000 designers, planners, engineers, architects, consultants and technical specialists, working in 140 countries across the world on every aspect of today's built environment. For more information, see: https://www.arup.com/our-firm.

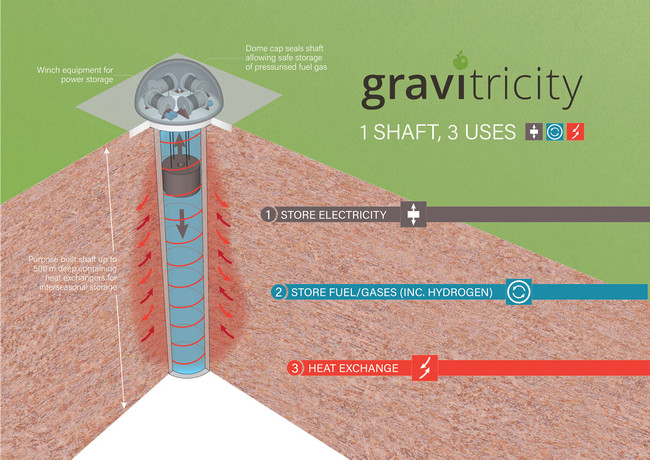

Gravitricity secures £912k BEIS grant to develop UK multi-weight energy store

Gravitricity has secured a £912,000 grant from the Department of Business Energy & Industrial Strategy (BEIS) to develop plans for a multi-weight energy storage system – to be built on a brownfield site in the UK.

The Edinburgh-based energy storage specialists will work alongside control and simulation experts Industrial Systems and Control (ISC), winch specialists Huisman and Careys Civil Engineering to deliver the front-end engineering design (FEED) for a 4MWh, multi-weight system using a custom-built shaft.

They will also work closely with a site partner to secure the planning consents required to develop and build their multi-weight gravity energy store at a grid-connected site in northern England.

The Gravitricity system stores electricity by raising and lowering heavy weights in a shaft. Analysts at Imperial College predict the firm’s patented multi-weight concept will offer long duration energy storage at a lower levelized cost than alternative technologies, including lithium ion batteries.

The feasibility project will complete in late 2022 and will provide the information required to commence build of the full-scale commercial prototype multi-weight gravity energy store immediately thereafter, subject to securing planning permission and the necessary funds.

The £1.5 million feasibility project follows the success of the company’s 250kW demonstrator, which was commissioned and operated in Leith, Edinburgh, during summer last year.

The company is also advancing plans to build a full-scale single-weight project in a disused mine shaft in mainland Europe, to commence this year.

The FEED study is being supported by the BEIS Longer Duration Energy Storage Competition, a competitive funding scheme to accelerate the commercialisation of innovative energy storage projects which can contribute to net zero. Gravitricity secured a grant of £912,410 towards the £1,520,684 project cost (representing 60 percent funding intensity for SMEs).

Gravitricity Managing Director Charlie Blair says:

“Finding low-cost, long-life ways to store renewable power will be crucial in the world’s journey to net zero. Our multi weight concept has been proven by our Leith demonstrator where two 25 tonne weights were configured to run independently, delivering smooth continuous output when lowered one after the other. We were able to demonstrate a roundtrip efficiency of more than 80 percent and the ability to ramp up to full import or export power in less than a second.

“A Gravitricity system with multiple weights offers a lower cost per MWh of energy stored – more weights give more mass (or MWhs) whilst the number of hoisting systems (which forms a substantial part of asset cost) does not increase.

“This project will demonstrate multi-weight use and control using a single set of hoisting equipment and will pave the way to custom projects which can be built wherever they are required,” Blair says.

The project has been welcomed by UK Government Energy and Climate Change Minister Greg Hands who said:

“Driving forward energy storage technologies will be vital in our transition towards cheap, clean and secure renewable energy.

“It will allow us to extract the full benefit from our home-grown renewable energy sources, drive down costs and end our reliance on volatile and expensive fossil fuels. Through this competition we are making sure the country’s most innovative scientists and thinkers have our backing to make this ambition a reality.”

The second phase of the project will see Gravitricity commence construction of a first of kind commercial

prototype system at a grid-connected site in the north of England. The company anticipate that a substantial amount of the mechanical design and optimisation of hoisting equipment for fast response applications will be directly transferable from this project to all future applications, as will the control systems being developed.

Latest Gravitricity Explainer - Extended Animation - Spring 2020 from Gravitricity Team on Vimeo.

As future production ramps up, Gravitricity and its partners intend to produce modular systems which will bring fabrication costs down considerably. At the point where multiple schemes are being implemented, the consortium will be able to purchase and operate their own shaft sinking equipment using, offering substantial savings and further improvements to the levelized cost of energy storage.

About Gravitricity

Gravitricity has built strong relationships with Glasgow-based control and simulation experts Industrial Systems and Control Ltd (ISC) and already have a collaboration in place. The multi-weight gravity energy store project will bring together the knowledge gained through the execution of the concept demonstrator project and build on the combined expertise to generate valuable new controls software. ISC work scope will include the simulation of the multi-weight system.

The model will provide a realistic estimate of efficiencies, performance and power delivery profile. This will ensure optimal energy storage with the potential for lowering levellised cost of storage (LCOS) and progress to full commercialisation. ISC will also provide the software to control the subsystems that will provide the overall functionality of the system.

Huisman Equipment have been working closely with Gravitricity under a collaboration agreement since 2018. Huisman supplied the design and hardware for the winch system in the successful Leith demonstrator project and will supply the design and winch system for the Project.

Gravitricity have been working with Careys Civil Engineering since the beginning of 2021. Careys bring more than 50 years expertise in civils engineering design and shaft construction to the project.