Displaying items by tag: AMADA WELD TECH EUROPE

AMADA WELD TECH EUROPE Offers Universal Spot Welding Heads

Provide a narrow footprint enabling high-density mounting in confined areas.

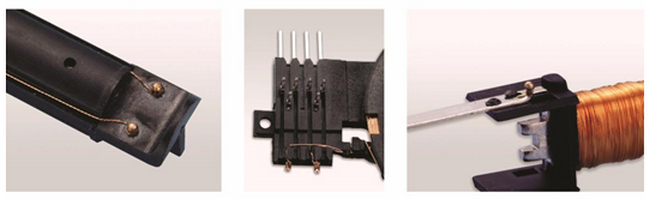

AMADA WELD TECH EUROPE highlights its Universal Spot Welding Heads, a modular weld head system that offers flexibility, simplicity, and high performance for micro joining applications. The precision ultra-low inertia weld head modules can be used either as a standalone system mounted on a third party product or as bench mounted units with fixed or variable height back supports.

The Universal Spot Welding Heads feature very low inertia, which delivers fast process response and rapid settling. They are suitable for motor, pneumatic, and manual drive systems. With a proven, rugged design ideal for automation, the Universal Spot Welding Heads provide a narrow footprint that enables high-density mounting in confined areas.

Available in a wide range of custom and standard electrode holders, the precision modules combine an integral force adjustment control with options to fit built-in force and displacement sensing monitoring transducers for use with process feedback based power supplies.

The Spot Welding Heads are ideal to use for micro joining applications, like coin cell tabs or engine components and many more.

About AMADA WELD TECH:

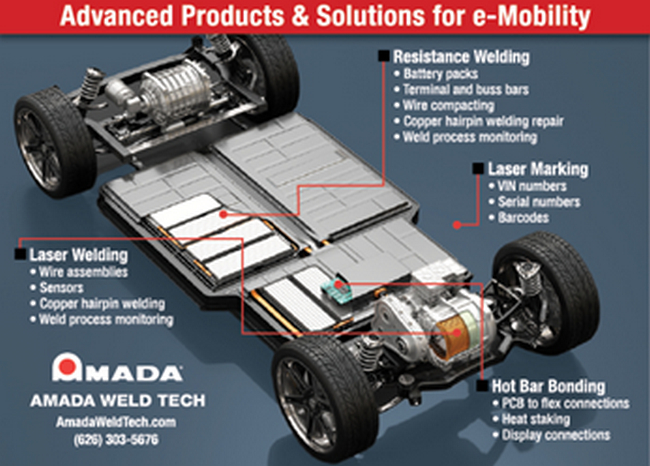

AMADA WELD TECH is a leading manufacturer of equipment and systems for Laser Welding, Laser Marking, Laser Cutting, Resistance Welding, Hermetic Sealing and Hot Bar Reflow Soldering & Bonding. We design and manufacture industry-leading product families for the global market and customize our products around specific micro-joining applications for all our customers. AMADA WELD TECH product markets include medical devices, battery, automotive, solar industry, electronic components and aerospace. AMADA WELD TECH Europe is headquartered in Germany and has additional production facilities in The Netherlands and UK, as well as sales offices in France, Hungary and Italy. And is part of the worldwide AMADA Group, with about 8.500 employees worldwide. More about our products and services: www.amadaweldtech.eu

AMADA WELD TECH Highlights Welding and Process Monitoring Technology at The Battery Show

AMADA WELD TECH announces that it will promote its battery and EV welding technologies at The Battery Show, September 12-14, 2023, at the Suburban Collection Showplace in Novi, Michigan. On display in Booth 2537 will be the WL-P300A laser processing workstation, and the UB-4000A linear DC welding power supply paired with the TL-188B-EZ weld head and WM-200A IIoT-ready networked resistance weld monitor.

WL-P300A is a Class 1 laser processing workstation optimized for marking on a range of metals (CRS, Copper, and Aluminum). Integrated with a IR fiber laser, it is ideal for making permanent, machine-readable marks on a variety of materials. The laser may also be used for welding of small components and has proven to connect battery tab to cylindrical Li-ion cells. Standard options include an XY table, rotary stage, cover gas module, fume extraction, bar code reader, and camera systems to tailor the machine to your specific processing needs.

The UB-4000A is a 200-4000 Amp linear DC resistance welding control that features four feedback modes, precise waveform control, and fast rise time. Weld energy may be programmed in current, voltage, power, or V-A in increments as short as 0.1 milliseconds. The power supply will be paired with the TL-188B-EZ pneumatic weld head, which operates at speeds exceeding 3600 welds per hour. This precise, low-inertia, force-fired weld head has a narrow vertical profile that exerts 5 to 100 lb (22-445 N) of force.

Complementary to the resistance welding system will be a live demonstration of the new WM-200A IIoT-ready, networked monitor. The monitor will collect high-resolution waveform data from the UB-4000A/TL-188B-EZ, which can be used for instantaneous comparison of good/bad signals, for statistical analysis of the process, and provide a means for manufacturing traceability. AMADA WELD TECH will also show a range of handheld and desktop weld process monitoring solutions to aid in production.

About AMADA WELD TECH

Since 1948, AMADA WELD TECH has worked to achieve one goal: to solve customer’s manufacturing challenges. Knowing there is no one solution that fits all, the company strives to provide customers with innovative and reliable manufacturing technology solutions in an effort to be their single source provider. AMADA WELD TECH manufactures equipment and systems for resistance welding, laser welding, laser marking, laser cutting, hermetic sealing and hot bar reflow soldering and bonding. The company serves a wide range of markets including medical devices, battery, aerospace, automotive and electronic components. AMADA WELD TECH is an ISO9001 certified company. Contact AMADA WELD TECH at This email address is being protected from spambots. You need JavaScript enabled to view it.. Learn more about the company’s products and services at www.amadaweldtech.com.

AMADA WELD TECH Announces Pulsed Arc Welding Solutions for Coil Termination

AMADA WELD TECH offers a full range of pulsed arc welding power supplies for precision joining applications, ensuring exact control and repeatability. These supplies range from lab models with customizable options, to production machines offering streamlined features to match the customer’s exact needs. Every item is designed and built in-house, from equipment for small-scale manual production to fully automated systems.

With a specialist product portfolio developed for precision joining of materials and spanning many industrial sectors, AMADA WELD TECH Europe can uniquely offer the correct technology to suit customers’ specific needs. Each system solution is available with easy-to-program PLC or industrial PC software. Also, each system benefits from SPC integration, automatic alignment, advanced user interfaces, remote diagnostics, CNC motion, robotics, and product transport systems, as required.

The systems are available in 1, 2, 3, and 4 output models to allow for a single power supply in high-speed production automation. Single output standard models include the PA-60P and PA-200P. Multiple output models are available from 20-60 amps.

Each unit produces a pulse of accurately controlled current. A specially developed arc start system incorporates a high voltage DC impulse, operating with a stabilizing power supply. This ensures consistent arc ignition with minimal radiated interference. All models offer gas flow control and voltage monitoring, to detect arc failure.

Closed loop techniques ensure stable outputs independent of temperature, cable lengths, and mains supply variations. AMADA WELD TECH Europe accomplishes this through transistorized output control and an analogue feedback and drive circuit. This control system responds rapidly to process changes and stabilizes output, ensuring consistency.

About AMADA WELD TECH

AMADA WELD TECH is a leading manufacturer of equipment and systems for Laser Welding, Laser Marking, Laser Cutting, Resistance Welding, Hermetic Sealing and Hot Bar Reflow Soldering & Bonding. We customize our products around specific micro-joining applications for all our customers around the globe. AMADA WELD TECH product markets include medical devices, battery, automotive, solar industry, electronic components and aerospace. We are an ISO9001 certified company. Contact AMADA WELD TECH at This email address is being protected from spambots. You need JavaScript enabled to view it.. Find out more about the company’s products and services at www.amadaweldtech.eu.

AMADA WELD TECH EUROPE announces the DC-H3000A High Duty DC Spot Welding Power Supply for High Precision Applications

AMADA WELD TECH announces the availability of the DC-H3000A High Duty cycle, DC Spot Welding Power Supply for high precision micro-joining applications. This power supply is designed for use in the medical device industry and other applications where the highest level of accuracy, process control and traceability is required.

The switching system architecture of the DC-H3000A provides unsurpassed levels of DC current purity, with ultra-low ripple and fast loop response, which enables it to react to, and control challenging applications, achieving a stated accuracy of +/- 1% of the controlled parameter set point. The precise pulsed output delivered to the weld, is controlled in terms of either the peak voltage, current or power.

The DC-H3000A also features an exceptional user interface and system connectivity capabilities. A modern, intuitive Touch Screen display allows easy access to the weld settings, data logging and communications functionality. The DC-H3000A is equipped with USB, Ethernet, RS232 and conventional I/O communication ports for interfacing with control systems and/or capture of all welder performance data, which allows for simple automation and machine integration.

For a complete solution, the DC-H3000A can interface directly with the high-performance AMADA WELD TECH WH-L090A Linear Motor Weld Head or pneumatically driven weld heads for improved process control.

The DC-H3000A (formerly known as DC2013-T) is suited to any micro-joining application requiring a current of less than 3,000 Amps.

Learn more on our website: https://www.amadaweldtech.eu/products/resistance-welding/mid-high-frequency-inverter-power-supplies/dc-h3000a-high-duty-dc-spot

About AMADA WELD TECH

AMADA WELD TECH is a leading manufacturer of equipment and systems for Laser Welding, Laser Marking, Laser Cutting, Resistance Welding, Hermetic Sealing and Hot Bar Reflow Soldering & Bonding. We customize our products around specific micro-joining applications for all our customers around the globe. AMADA WELD TECH product markets include medical devices, battery, automotive, solar industry, electronic components and aerospace. We are an ISO9001 certified company. Contact AMADA WELD TECH at This email address is being protected from spambots. You need JavaScript enabled to view it.. Find out more about the company’s products and services at www.amadaweldtech.eu.