Displaying items by tag: shell

Wood signs global framework agreement with Shell

Wood, a global consulting and engineering company, has been awarded a multi-year enterprise framework agreement (EFA) to continue to provide services to Shell’s global projects.

Bringing specialist consulting, engineering, procurement and project management expertise to Shell’s greenfield and brownfield projects, the agreement will see Wood continue to support projects that ensure energy security and enable energy transition projects focused on carbon capture, low-carbon fuels and hydrogen. Wood will deploy expertise in decarbonisation, digitalisation and asset life extension to enhance Shell assets worldwide.

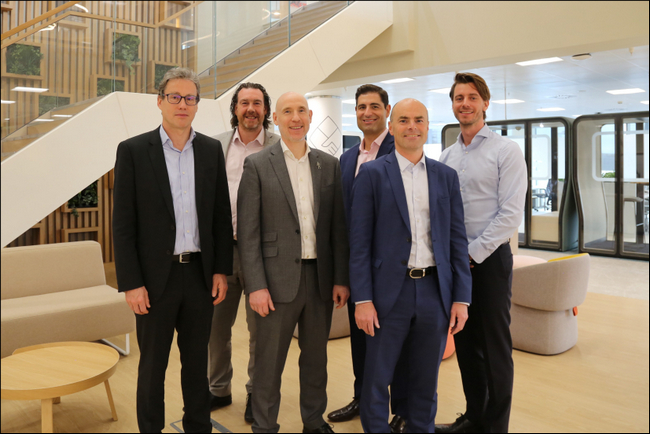

(L-R) Alistair Hope – Senior Vice President of Conventional Oil & Gas and Offshore Wind Projects, Shell; Paul Macgregor – EPC Management, Contracts & Procurement Manager, Shell; Craig Shanaghey – Executive President of Projects, Wood; Scott Commons – Vice President of Strategy & Development, Wood; Steve Nicol – Executive President of Operations, Wood; Chris Mijatovich – EPC Category Manager, Shell

(L-R) Alistair Hope – Senior Vice President of Conventional Oil & Gas and Offshore Wind Projects, Shell; Paul Macgregor – EPC Management, Contracts & Procurement Manager, Shell; Craig Shanaghey – Executive President of Projects, Wood; Scott Commons – Vice President of Strategy & Development, Wood; Steve Nicol – Executive President of Operations, Wood; Chris Mijatovich – EPC Category Manager, Shell

Under the three-year framework, with options for two one-year extensions, services will be provided by Wood’s consulting and engineering teams in Europe, North America, Latin America, South-East Asia, Australia and the Middle East.

Ken Gilmartin, Wood’s CEO, said: “This award continues a 70-year relationship between Shell and Wood, spanning more than 20 countries and numerous major projects. Complex project excellence is where we excel and we are aligned with Shell in our strategic ambitions to deliver the energy the world needs today while simultaneously delivering the energy transition at pace. We look forward to continuing to partner with Shell as we work to design a better energy future together.”

Wood is a global leader in consulting and engineering, delivering solutions to critical challenges in energy and materials markets. We provide consulting, projects and operations solutions in 60 countries, employing around 35,000 people. www.woodplc.com

Strohm supports Shell with fast-track delivery of a TCP Riser

Strohm has supplied Shell with a static Thermoplastic Composite (TCP) Riser to support operations at one of its Southern North Sea assets. The availability of TCP through Strohm’s “TCP on Demand” model and the ability to install end-fittings offshore enabled flexible, quick and easy installation.

Strohm was able to offer a fast-track delivery (January ’22) of their 2.0-inch 10ksi stock product, including all ancillaries, to support Shell’s tight schedule.

In a mature basin such as the North Sea, the pipeline infrastructure is ageing and, in some cases, pipelines are in need of replacement. For such a situation, TCP is an attractive solution. In this particular case for Shell, the TCP could be terminated above the J-tube, allowing for a smaller existing J-tube to be used, avoiding the need for any welding or curing. Strohm, together with their trusted partners, included a fast-track supply of the J-tube bellmouth, centralizer, bend restrictors, hang-off clamps, providing a full solution with a quick turnaround.

Strohm has the largest track record globally for the production and delivery of TCP. It is a strong, corrosion resistant composite pipe solution with a long, maintenance free service life. TCP is spoolable and delivered in long lengths allowing operators to use existing field support vessels on long-term charter rather than mobilising dedicated pipelay assets, making significant efficiencies and supporting lower carbon emissions targets. TCP has a 100% track record of no failures on installed pipe.

Strohm’s TCP Flowline features Subsea Energy Solutions’ bend restrictor, topside clamps and subduct for a fast turnaround project with Shell. Image supplied courtesy of Subsea Energy Solutions

Strohm’s TCP Flowline features Subsea Energy Solutions’ bend restrictor, topside clamps and subduct for a fast turnaround project with Shell. Image supplied courtesy of Subsea Energy Solutions

The technology is increasingly being considered in the renewables sector, including offshore hydrogen and carbon capture and storage, as well as in conventional oil and gas applications. The project for Shell saw the technology being delivered on a subsea pallet.

As well as passing on cost savings for the fully installed package, in parallel, TCP also allows clients to reduce their own C02 emissions whilst contributing to an overall reduction in C02 footprint. DNV has conducted an in-depth analysis of the CO2 footprint related to the manufacture and installation of a TCP Flowline and found that it results in a 50+% reduction compared to that of a steel alternative. The company is continuing this work to assess the operational life, including assessing the impact of the non-corrosive nature of TCP which negates the need for any injection of chemicals related to inspection and pigging.

Martin van Onna, Strohm’s managing director said: “We are proud to have supported Shell with this fast-track project. This award by Shell demonstrates a growing confidence from energy companies in TCP and the benefits the product offers in terms of quick response, installation and reduced Opex. “

About Strohm:

Leading composite pipe technology company Strohm (formerly known as Airborne Oil & Gas) has the world’s largest track-record for Thermoplastic Composite Pipe (TCP) after being the first to bring the technology to the Oil & Gas industry in 2007. TCP reduces total installed and life cycle cost for subsea flowlines, jumpers and risers and has proven to reduce the CO2 footprint of pipeline infrastructures by more than 50%.

The company is committed to driving sustainability with its range of TCP solutions which enable clients towards their net-zero carbon emissions targets and supports the renewables sector.

TCP is a strong, non-corrosive, spoolable, lightweight technology which is delivered in long lengths, resulting in a significant reduction of transportation and installation costs. TCP is installed using small vessels or subsea pallets, significantly reducing CO2 emissions. It is also 100% recyclable.

Strohm’s shareholders are Chevron Technology Ventures, Shell Ventures, Evonik Venture Capital, Aker Solutions, Saudi Aramco Energy Ventures, Subsea 7, Sumitomo Corporation and the private equity investor, HPE Growth.

The firm’s manufacturing facility is located at its headquarters in IJmuiden in The Netherlands. Strohm also has offices in Houston (US), Rio de Janeiro (Brazil) and Kuala Lumpur (Malaysia).

Visit the Strohm website here

SAS, Vattenfall, Shell and LanzaTech to explore synthetic sustainable aviation fuel production

Vattenfall, SAS, Shell and LanzaTech will together investigate the production of the world’s first synthetic sustainable aviation fuel (SAF) using the LanzaJetTM “Alcohol to Jet” technology on a large scale in Sweden. Instead of using virgin fossil material in the production process, the synthetic SAF will be produced from fossil free electricity and recycled carbon dioxide from district heating.

The goal is that a new production facility will produce up to 50,000 tonnes of synthetic SAF annually, provided that an investment decision is made at a later stage. The synthetic SAF, also known as electrofuel, will be produced from fossil free electricity and recovered carbon dioxide using the LanzaJet “Alcohol to Jet” technology, developed by LanzaTech and the U.S Department of Energy’s Pacific Northwest National Laboratory (PNNL). When full production is up and running it could provide SAS with up to 25 per cent of its global demand for sustainable aviation fuel in the 2030s.

A joint study has shown promising conditions for the project, and all partner companies now agree to carry out in-depth analyses. The ambition is to commission the new production facility sometime between 2026 and 2027 near Forsmark on Sweden's east coast.

"SAS and Sustainability go hand in hand. That’s why we are incredibly proud to be part of this unique project where ambitious sustainability goals and agendas come together. Our joint commitment in finding ways to enable large-scale production of a more sustainable aviation fuel is a fantastic opportunity to accelerate the commercialization of SAF, and thus SAS’s transition towards industry-leading zero-emission flights,” says Anko van der Werff, President and CEO, SAS.

"This initiative shows the potential of cross industry partnerships to drive the decarbonization of a hard-to-abate sector. To innovate faster in order to bridge to a fossil free living within one generation. This is a really good opportunity and together we will explore further how to produce low emission electrofuel for aviation,” says Anna Borg, President and CEO, Vattenfall.

"Sustainable aviation fuel offers the greatest potential to reduce emissions from aviation. It is only by working together today across the aviation ecosystem to drive the technologies and infrastructure needed to produce SAF at scale that the aviation sector can achieve net zero by 2050. This is why I am excited for this collaboration to explore one more pathway for SAF production,” says Anna Mascolo, President, Shell Aviation.

“The aviation sector faces incredible challenges getting the volumes of SAF needed for sustainable flight. This project is the start of delivering on these volumes and by reusing carbon dioxide and fossil free power we have an opportunity for unprecedented scale. We need to rethink carbon and together with fossil free power, harness it to create a new climate safe future for all,” says Jennifer Holmgren, CEO LanzaTech.

The aim of the project is to get the production of electrofuel started in Sweden. The companies have signed a Memorandum of Understanding and agreed that Vattenfall will investigate fossil free electricity supply, hydrogen production and carbon dioxide recovery. Shell will investigate fuel production, logistics and be the electrofuel buyer. LanzaTech will provide its gas fermentation expertise to make ethanol from the input gas streams and parties will license the LanzaJet “Alcohol to Jet” technology to convert the ethanol to electrofuel. SAS will participate as a potential buyer of the electrofuel.

Facts:

- Electrofuel is one type of SAF (Sustainable Aviation Fuel).

- In contrast to fossil feedstock, fossil free electricity, recycled carbon dioxide and water will be the only inputs to the process of making electrofuel. Electricity will mainly be used to make hydrogen via electrolysis. Carbon dioxide plus hydrogen can be converted by LanzaTech’s process into ethanol which is then converted via the LanzaJet Alcohol to Jet process to the aviation electrofuel.

- Rather than be released, the carbon dioxide from a district heating facility will be captured and used for electrofuel production. When electrofuel is combusted by aircraft engines, the captured carbon dioxide is released into the atmosphere after being utilized a second time. The raw materials planned to be used are fossil free electricity from the Swedish electricity grid and carbon dioxide collected from Vattenfall’s combined heat and power plant in Uppsala, where approximately 200,000 tonnes of carbon dioxide can be recovered per year.

- Today’s aircraft are certified to fly with a maximum of 50% SAF depending on production pathway and the remainder with traditional aviation fuel.

- Our annual planned SAF production of 50,000 ton would strongly contribute to the Swedish national targets of a fossil free domestic air travel and corresponds to about 30% of the needed Jet fuel to reach that target.

About Vattenfall

Vattenfall is a leading European energy company, which for more than 100 years has electrified industries, supplied energy to people’s homes and modernised our way of living through innovation and cooperation. We now want to make fossil-free living possible within one generation. That's why we are driving the transition to a sustainable energy system through initiatives in renewable production and climate smart energy solutions for our customers. We employ approximately 20,000 people and have operations mainly in Sweden, Germany, the Netherlands, Denmark and the UK. Vattenfall is owned by the Swedish state. For more information: corporate.vattenfall.se

About SAS

SAS, Scandinavia’s leading airline, with main hubs in Copenhagen, Oslo and Stockholm, flies to destinations in Europe, the USA and Asia. Spurred by a Scandinavian heritage and sustainable values, SAS aims to be the global leader in sustainable aviation. To achieve net zero carbon emissions on its domestic markets in 2030 and on a global level before 2050, SAS will, over the coming years, source a growing share of SAF, both through its self-supply at the main hubs but also through into-plane suppliers at the locations from which SAS operates. Further information is available at www.sasgroup.net

About Shell

Shell is an international energy company with operations divided across Upstream, Integrated Gas and Renewable and Energy Solutions and Downstream. We are partnering with customers, businesses, and others to address emissions, including in sectors that are difficult to decarbonise such as aviation, shipping, road freight and industry. Shell aims to produce around 2 million tonnes of SAF by 2025, and by 2030, it aims to have at least 10% of global aviation fuel sales as SAF.

About LanzaTech

LanzaTech harnesses the power of biology and big data to create climate-safe materials and fuels. LanzaTech has created a platform that converts waste carbon into new everyday products that would otherwise come from virgin fossil resources. LanzaTech’s first commercial scale gas fermentation plant has produced over 27M gallons of ethanol which is the equivalent of keeping over 130,000 metric tons of CO2 from the atmosphere. Additional plants are under construction globally. Further information is available at www.lanzatech.com.

Kongsberg Digital and Shell International Exploration & Production enter into a Strategic Partnership Agreement

The objective of the agreement is to collaborate and accelerate digital solutions and transformation for well delivery and performance.

“We are very excited to enter into this new strategic partnership agreement with Shell International and enable the digital transformation of their well business. We believe the partnership approach is a significant reason why we have successfully created tools for digital transformation that work for our customers, and that have broad application across the industries they are in. We already have a strong relationship with Shell on energy production and look forward to replicating that model to enable transformation of another segment”, says Hege Skryseth, President of Kongsberg Digital and EVP KONGSBERG.

Kongsberg Digital has, during the previous few years, put together a substantial digital roadmap for oil and gas companies, supporting digitalization within the industry. This strategy has been founded on agile methodologies, open ecosystems, data integration, and people centric solutions. Shell has utilized Kongsberg Digital’s real-time data products in their global wells portfolio for several years. Now, they are undertaking a digital transformation of their wells business with a strong need for digital solutions.

Shell and Kongsberg both have a long track record of innovations over 100 years. We are excited to formalize our collaboration on the next generation projects in Wells IoT and Shells wider Digital transformation. Advances in cloud technology, ML delivery and visualization techniques open up opportunities to improve operational safety and decision making. This will position both companies at the forefront of drilling and wells digital journey, says Jon Crane, Vice President of Wells Digital in Shell International.

The agreement is to align initiatives across the overall life cycle for well deliveries, through planning, execution and reporting by shared visibility into each other’s roadmap and to increase the creation of market driven applications.

The Strategic Partnership Agreement was signed June 2021.

KONGSBERG DIGITAL

Kongsberg Digital, a subsidiary of KONGSBERG, is a provider of next-generation software and digital solutions, to customers within maritime, oil and gas, and renewables and utilities. The company consists of more than 500 software experts with leading competence within the internet of things, smart data, artificial intelligence, maritime simulation, automation and autonomous operations. Kongsberg Digital is the group-wide center of digital expertise for the KONGSBERG group. www.kongsbergdigital.com

KONGSBERG

KONGSBERG (OSE-ticker: KOG) is an international, leading global technology corporation delivering mission-critical systems and solutions with extreme performance for customers that operate under extremely challenging conditions. We work with nations, businesses and research environments to push the boundaries of technology development in industries such as space, offshore and energy, merchant marine, defence and aerospace, and more. KONGSBERG has about 11,000 employees located in more than 40 countries, creating a total revenue of NOK 25.6bn in 2020.

CONTRACT - Dutch oil and gas producer NAM renews HSE contract with Royal HaskoningDHV

Risk management for all 175 onshore and offshore NAM oil and gas facilities

Nederlandse Aardolie Maatschappij (NAM) – the joint venture between Shell and ExxonMobil – has renewed and extended its Health, Safety and Environmental (HSE) contract with Royal HaskoningDHV. The three year contract covers risk above the ground on all NAM’s 175 onshore and offshore oil and gas exploration and production sites.

The multi-million euro contract encompasses all of NAM’s offshore and onshore assets in the Netherlands and the North Sea area. Royal HaskoningDHV will support NAM to achieve the safest, most efficient and sustainable gas exploration and production.

NAM is the leading producer of natural gas in the Netherlands. Mr Eric Dorenbos, NAM’s HSE Regulatory Affairs Manager, said: “Royal HaskoningDHV’s understanding of the oil and gas industry and strong presence in the north of the Netherlands means they understand local sensitivities. They have acquired extensive knowledge of NAM’s assets and operations over recent years, and demonstrated they are a reliable and trusted partner. For this reason we want to continue our relationship with them and have therefore renewed and extended their contract for a period of three years.”

Mr Arthur Groot, Account Manager of the NAM at Royal HaskoningDHV, said: “We are helping NAM to achieve their objectives of conducting their operations in a safe, sustainable and efficient way. Our work will focus on Hazard and Effect Management, Compliance Management and Impact Assessment. This will include preparation of key documents, safety management studies, operation and contingency manuals, technical safety support and legal support.”

The delivery of Royal HaskoningDHV’s extensive range of HSE services – currently unrivalled in the Netherlands – will help NAM achieve their goals for the next three years and beyond.

Royal HaskoningDHV is an independent, international engineering and project management consultancy with more than 130 years of experience in aviation, buildings, energy, industry, infrastructure, maritime, mining, rural and urban areas, and water. Backed by the expertise and experience of 6,500 colleagues from 100 offices in 35 countries, our professionals combine global expertise with local knowledge to deliver a multidisciplinary range of consultancy services for the entire living environment. By showing leadership in sustainable development and innovation, together with our clients, we are working to become part of the solution to a more sustainable society now and into the future.

See for more information our website royalhaskoningdhv.com.

For more information:

This email address is being protected from spambots. You need JavaScript enabled to view it., Press Officer Royal HaskoningDHV, +31 88 3482026 / +31 6 29098238