Super User

Siemens to build a world-leading 2-pole electric motor

Siemens LDA has received an order from a Chinese customer to deliver a special machine with dual shaft extension. It can be used in motor operation with a power of 105 MW and as generator with up to 129 MVA in power generation mode. The motor will have an efficiency of beyond 98 percent and will be a world-leading 2-pole electric motor.

Beside the motor, the contract includes the delivery of a 40 MW Sinamics GL150 starting frequency converter. This LCI-converter (load commutated inverter) is designed for single-motor applications with variable and constant torque characteristics. As a result of the low switching losses and the low loss thyristor technology, the efficiency of the LCI converter is extremely high and lies at 99 percent.

- Siemens Large Drives Applications (LDA) to deliver a high voltage (HV) motor with 105 MW and a 40 MW starting frequency converter for an energy storage project in China

- The motor will have an efficiency of beyond 98 percent

The drive system will be part of an energy storage project. Energy storage technologies have been viewed as a supporting key technology for the energy revolution and a national strategic emerging technology in China. This kind of technology holds decisive advantages such as high capacity, low costs, high efficiency, and environmental friendliness.

The drive system will be part of an energy storage project. Energy storage technologies have been viewed as a supporting key technology for the energy revolution and a national strategic emerging technology in China. This kind of technology holds decisive advantages such as high capacity, low costs, high efficiency, and environmental friendliness.

The plants operate by using motors to drive compressors, whose energy will be stored in suitable storage vessels. The stored energy can be released to drive an expander, which in turn drives a generator to produce electricity. Compared with other energy storage technologies, the plants have a very large power rating and storage capacity, low self-discharge, and a long lifetime. These attributes generally make it the most promising and cost-effective method for bulk energy storage grid services.

The motor will be manufactured at the Siemens Dynamowerk Berlin, Germany, which is the oldest manufacturing plant of Siemens and has existed for 115 years.

“Once completed, this project will be the largest and most efficient energy storage station in the world. We are happy to support our customer in the energy transition and this project with a drive system that sets a benchmark – a world-leading 2-pole electric motor with an efficiency of above 98 percent”, says Hermann Kleinod, CEO of Siemens Large Drives Applications (LDA).

For further information please see https://sie.ag/3fusEHz

KAZAKHSTAN EXPORT SUCCESS FOR NORTH SEA VENTILATION & INDEX ENCLOSURES

IndEx Enclosures, the Kent-based manufacture of Hazardous Area and Industrial control gear enclosures has just dispatched the latest consignment of Activated Isolation, Modulation, Fire & Gas Damper junction boxes bound for the huge Tengiz oilfields of Kazakhstan.

The custom-designed ATEX Zone 1 certified and Industrial Standard enclosures, were ordered by North Sea Ventilation (NSV) Ltd of Hull.

Andrew Sully, NSV’s Project Manager, commented, “We originally began working with IndEx Enclosures on this contract back in 2016 leading to the supply of some 3,200 off ATEX-certified and Industrial Standard Junction Box enclosures destined for Kazakhstan which were delivered on time and as agreed. The ventilation systems on the various modules are obviously vital to the whole operation of the facility with the Actuated Dampers regulating the flow of air and extremely important parts of the systems which have to operate in potentially explosive atmospheres.”

Kazhak Ventilation Damper.jpg The IndEx Enclosures ventilation damper control Junction Boxes are fitted with tri-langauge signage for Kazakhstan.

Kazhak Ventilation Damper.jpg The IndEx Enclosures ventilation damper control Junction Boxes are fitted with tri-langauge signage for Kazakhstan.

“After the supply of these enclosures over two years, during which time there had been no delays nor failures of ATEX testing, the scope of our contract was then extended to include another 3,000 off Junction Boxes for field buildings which is just completing.”

“What steered us towards IndEx Enclosures was their willingness to design and manufacture non-standard enclosures to our exact specification which includes their population with electrical terminals and supply of tri-language signage and certification. The products and service has been excellent and we now consider them as a primary preferred source of supply, not only for Kazakhstan, but all similar projects.”

Manufactured from 316 Stainless Steel for its superior corrosion resistance qualities, the 140mm x 140mm enclosures are the latest export success for the company who have developed a high degree of brand recognition and a first class reputation for the design and manufacture of hazardous area control, instrumentation and connection products at their Ashford facility. The company have established a global reputation for customisation and service within the energy, chemical processing, food, pharma and rail sectors with a client base of over 200 active companies.

Mark Popple, General Manager of IndEx Enclosures, added, “We’ve enjoyed a very successful relationship with NSV and look forward to continue to be of service to them. We are slightly unusual in the sector for designing and manufacturing totally in-house which gives us the ability to supply non-standard items for both Hazardous Area and normal Industrial use. Constant investment in our personnel and plant has given us the flexibility to compete with far larger suppliers of enclosures and our clients appreciate our ability to rapidly supply both standard and bespoke items at cost-effective rates.”

Founded in 2010, IndEx Enclosures was purchased by Kent Business Investors earlier this year who have continued investing to build on the company’s manufacturing excellence.

SinnovaTek Announces Nomatic Precision Processing System

Provides advanced technology for smooth food and beverage products

SinnovaTek, a leading developer and integrator of advanced food processing equipment and technology, announces the availability of the Nomatic Precision Processing System, ideal for smooth food and beverage products produced on a small scale. With a throughput range of 1-3 liters per minute (lpm), Nomatic ensures retention of nutrients, quality, color, and flavor. It is a good choice for producing baby food, sauces, fruit and vegetable purees, as well as coffee and smoothies. Featuring a portable design and small footprint, Nomatic is easy to move and can fit through a standard door. The integrated clean-in-place (CIP) system means the system is easy to clean and the user-friendly control panel ensures simple operation and control.

Configurable for extended shelf-life (ESL), hot fill, or aseptic processing, Nomatic enables the testing of numerous product types. It can replicate a range of processes and process a wide range of viscosities, offering operators tremendous flexibility in product categories. Nomatic’s size makes it a good choice for producing small batches, as little as 5 gallons for trial purposes.

Up to six controllable heating sections enables Nomatic to replicate the thermal processing parameters of large scale systems. The system runs on microwave energy, an electric energy source offering minimal thermal degradation of product. The entire processing system is under positive pressure during processing so there is no loss of volatile and sensitive flavors.

To learn more, schedule a trial, or purchase a Nomatic, contact us at https://www.sinnovatek.com/contact.html.

About SinnovaTek

SinnovaTek is a leading developer and integrator of advanced food processing equipment and technology through its family of companies including SinnoVita and FirstWave. As a certified B corporation, SinnovaTek’s mission is to promote worldwide health and wellness by fostering the delivery of high quality, healthy foods through sustainable methods.

The SinnovaTek family of companies provides several pathways to service its customers' needs:

- Provides high-quality continuous flow microwave processing systems and pumps to food manufacturers along with the engineering and R&D support to make them successful.

- SinnoVita: Provides science-backed VITERO ingredient technologies to reduce food waste and increase nutrient delivery.

- Provides a platform for companies to launch and test new products in a high quality aseptic format without the minimum order quantities that are normally required for a launch, enabling SinnovaTek to service customer production needs before they are ready to move to a larger scale.

SinnovaTek is passionate about finding the best solution for its customers. Learn more at www.sinnovatek.com.

DIALIGHT LAUNCH ProSite LED FLOODLIGHT RANGE

Dialight Group, the leader in industrial LED lighting innovation, has launched its new ProSite LED floodlight range for the EMEA and APAC markets.

Launched today at the Offshore Technology Conference (OTC) in Houston, the floodlights are designed for industrial applications providing superior visibility to external worksites with crisp, near daylight illumination to ensure the safety and security of a diverse range of facilities including Oil & Gas, Petrochemical, Transport and other external storage areas.

The new ProSite series is currently available in 12,000 – 65,000 lumen models, reaching up to 165 Lumens Per Watt (LPW), for mounting heights of up to 30metres. The floodlights integrate highly efficient precision optics, offering a wide range of beam patterns from narrow-spot to very wide, symmetric or asymmetric, and are capable of withstanding harsh environments. The in-house designed optical surfaces precisely distribute the light over the target area with minimum light spill for optimal illumination without wasted light or unnecessary light pollution.

Dialight ProSite Floodlight.jpg Dialight’s new ProSite LED Floodlights are available in 12k to 65k lumen models.

Dialight ProSite Floodlight.jpg Dialight’s new ProSite LED Floodlights are available in 12k to 65k lumen models.

Offering maximum protection against water, dust, debris, vibration and impact with IP66/67, and IK10 (integrated polycarbonate optic/lens or lens cover) or IK08 (glass lens cover) ratings, the floodlights come with corrosion-resistant 316 stainless steel mounting hardware as standard. The ProSite can withstand a variety of environmental conditions and has a wide operating temperature range of -40°C to +65°C.

With just four screws to access wiring, installation is quick and easy. Several mounting options are available as well as a variety of accessories including wire guards, visors and bird spikes. The ProSite series comes with Dialight’s industry-leading 10 year warranty.

Launching the ProSite range, Fariyal Khanbabi, Dialight Group Chief Executive, commented, “The ProSite series features Dialight’s hallmark dependability and efficiency in an innovative, compact new design that provides a brighter, safer and more secure work environment. As a company, it is our priority to provide industry with products that perform to the highest standards, while also being cost-effective, easy to install and virtually maintenance free over their 10 year lifespan so that nothing is wasted - whether that be money, time, or unnecessary environmental impact.”

The new ProSite floodlights are now available. To learn more about them and Dialight’s other market-leading industrial LED lighting solutions, visit www.Dialight.com

About Dialight

Dialight is a global leader in improving sustainability, safety and operational efficiency for its customers by providing high-efficiency, long-lasting LED lighting technology for industrial applications. With over a million fixtures installed worldwide, Dialight’s class-leading technology reduces energy use, cost and environmental impact for customers and is certified to a broad range of international standards. The company’s operations are headquartered in the U.S., and it is listed on the main market of the London Stock Exchange under the ticker DIA. Further information on Dialight and its products is available at www.dialight.com.

ACWA Power announces financial close for 1500 MW Sudair Solar plant and Aramco joining the consortium under PIF renewables program

ACWA Power, a leading developer, investor and operator of power generation and desalinated water plants, has announced today the financial close for the 1500 MW Sudair Solar plant, a key project under the Public Investment Fund (PIF) renewable energy program.

The launch of the Sudair Solar project was announced at the inauguration of Sakaka PV project in April 2021, under the patronage of HRH Prince Mohammed bin Salman bin Abdulaziz, Crown Prince, Deputy Prime Minister, Chairman of the Supreme Committee for Energy Mix Affairs for Electricity Production and Enabling Renewable Energy Sector, and in the presence of HRH Prince Abdulaziz bin Salman bin Abdulaziz Al Saud, Minister of Energy.

A specialized Saudi technical team at the Ministry of Energy selected the Sudair project site and carried out the engineering requirements and preliminary studies of the project with the aim of achieving the highest levels of efficient energy production and contributing to shaping the circular carbon economy, which the Kingdom adopted during its presidency of the G20 last year. Sudair solar is testament to the Kingdom's continuous efforts to reduce emissions resulted by the energy sector. Additionally, the Ministry of Energy utilises its Renewable Energy Program and Local Content Development Program to enable the prosperity of this promising sector and its supply chains through various initiatives such as mobilizing private sector investments and encouraging partnerships between the public and private sectors to create a competitive national market for renewable energy.

ACWA Power also announced that SAPCO, a fully owned company of Aramco, have joined the consortium with ACWA Power and Badeel, a company fully owned by PIF. The consortium, led by ACWA Power, embodies the strategic importance of the Sudair Solar PV project, the first project under PIF’s renewable energy program. The program aims to support Saudi Arabia’s ongoing energy transition and diversification, and to deliver 70% of the country’s renewable energy under the National Renewable Energy Program (NREP).

ACWA Power - in which PIF holds a 50% stake - and Badeel will each own 35% in the special purpose vehicle “Sudair One Renewable Energy Company”, which was incorporated for the project; with SAPCO holding a 30% stake.

Renewables and Utilities sector is one of the 13 priority sectors that PIF identified as a key focus area in its Strategy 2021-2025. The strategy focuses on unlocking the capabilities of the private sector, and aims to increase local content contribution to 60% Including PIF and its portfolio companies, in addition to expanding opportunities for local companies to partake in the Fund's projects.

Aramco’s investment in the Sudair Project is its first participation with PIF in its renewable energy program; reflecting the company’s efforts to advancing sustainable energy solutions within its operations and Saudi Arabia, where a variety of low-carbon energy solutions are being deployed.

With an investment value of SAR 3.4 billion, Sudair Solar PV project, which is located at Sudair Industrial City, is set to become one of the largest single-contracted Solar PV plants in the world and the largest of its kind in Saudi Arabia. A 25-year power purchase agreement for the plant was signed with the Saudi Power Procurement Company, with the tariff being among the lowest for solar PV projects globally. Using bi-facial modules with tracking technology, the plant is set to deliver highly efficient performance and be capable of powering 185,000 homes, while offsetting nearly 2.9 million tons of emissions per year.

The financing for the project is based on the principles of limited recourse project financing, with the senior debt structured as a soft mini perm facility with a tenor of 28 years and both conventional as well as Islamic tranches. The financing structure also features a set of equity bridge facilities provided by local and international banks supporting the sponsor group’s equity investment in the project.

The financing group includes Mizuho Bank, Ltd., Riyad Bank, Korea Development Bank, Arab Petroleum Investments Corporation (APICORP), Al Rajhi Banking & Investment Corporation, and Standard Chartered Bank as senior lenders and Mandated Lead Arrangers. The equity bridge facilities are provided by Bank Al Bilad, Saudi British Bank and SMBC International Plc.

Underpinned by our ambition and determination to continue driving the transformation of the Kingdom’s energy sector, I would like to extend my sincere gratitude and pride following the signing of agreements for the first project under the PIF Renewable Energy Program. Today’s milestone marks progress in achieving the goals of Vision 2030 and the requirements of the National Renewable Energy Program launched by the Custodian of the Two Holy Mosques, King Salman bin Abdulaziz Al Saud; guided by the directives of His Royal Highness the Crown Prince, Mohammed bin Salman bin Abdulaziz; and reinforced by the unparalleled support of His Royal Highness Prince Abdulaziz bin Salman, Minister of Energy, to accomplish this ambitious vision

Mohammad Abunayyan, ACWA Power Chairman

Abunayyan continued, “The launch of Sudair Solar embodies a pivotal foundation for diversifying the energy mix and accelerating energy transition in the Kingdom, as well as transferring ACWA Power’s international expertise, knowledge and capabilities in the global renewable sector back to the Kingdom. The project will encourage Saudi companies to participate in the implementation of renewable energy projects and support local talent in cultivating the skills and competencies needed in this thriving sector, which constitutes one of the Kingdom’s key pillars for sustainable socioeconomic development."

“The Sudair Solar project is also testament to the leadership and foresight shown by PIF in bringing together various stakeholders to create tangible impact in the renewables sector by integrating robust public-private partnerships (PPP), one of the cornerstone policies of Vision 2030. We are honoured to work hand-in-hand with the Kingdom's greatest national champions, including PIF, Aramco and leading local and international financial institutions; to bring the largest solar PV plant in Saudi Arabia to fruition,” Abunayyan added.

This milestone demonstrates the potential for solar power in Saudi Arabia and the expertise that this consortium has to deliver it. The landmark renewable energy project is a significant step and key part of PIF’s commitment to develop 70% of Saudi Arabia’s renewable energy capacity outlined in the Saudi Vision 2030. It also helps fulfill the aims of the Saudi Green Initiative to chart a path for Saudi Arabia and the broader region to protect the planet by clearly defining an ambitious roadmap that rallies the region and will significantly contribute to achieving global targets in confronting climate change

Our involvement in the Sudair Solar PV plant reflects our efforts to advancing sustainable energy solutions, both within our own operations and the broader energy network. While hydrocarbons will continue to be a vital part of the energy mix for decades to come, renewables like solar have an important role to play in helping achieve the world’s climate goals. Sudair will support Saudi Arabia’s ambition to generate part of the nation’s power needs from renewable energy by 2030, and is one of several low-carbon energy options being deployed by Aramco

The EPC agreement for the construction of the Sudair Solar PV was signed with Larsen & Toubro in April 2021. The first phase of the project is expected to begin producing electricity during the second half of 2022, contributing towards the Saudi Green Initiative.

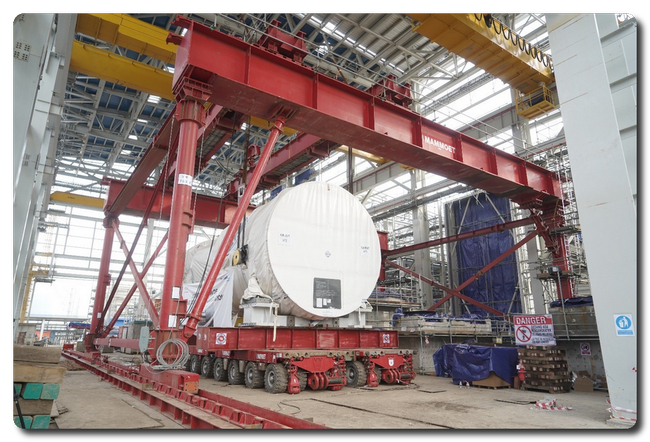

Mammoet completes replacement of power plant equipment in Indonesia

Purpose-built gantry system completes precise maneuver

Mammoet has successfully completed a heavy transportation and installation project in Indonesia. On behalf of General Electric, the team transported a 430t gas turbine and a 445t gas turbine generator at Tambak Lorok Power Plant, located in Semarang, Central Java. The loads were moved one-by-one a distance of 200m from their storage area to the power block building, using 10 axle-lines of SPMT in 4 file configuration.

At the installation area, the two pieces of equipment were maneuvered adjacent to their foundation and aligned centrally with it using SPMTs. Four strand jacks then slowly lifted the slings placed around the lifting trunnions to a sufficient height, raising the loads from the SPMTs. Next, the loads were slowly moved transverse to the center line of the foundations using a hydraulic system on top of the beams.

Mammoet transported and installed a gas turbine and gas turbine generator for General Electric’s Tambok Lorok power plant project.

Mammoet transported and installed a gas turbine and gas turbine generator for General Electric’s Tambok Lorok power plant project.

Once the loads were aligned on the foundation lines to the customer’s satisfaction using self-propelled skid beams, they were slowly lowered onto the foundation. With the full weight of the equipment on the foundation, the slings were then removed from the lifting trunnions of the turbine and generator. This gantry system used was in-house designed and comprised four 200t strand jacks, 500t self-propelled skid beams, 150t skidding systems and customized lifting gantries.

This methodology was used so that operations could be completed within the customers’ given time frame and for the installation to still take place despite the tight space restrictions on site. Moreover, even though Mammoet had limited time available for transportation and installation, the team completed the scope of work promptly and with efficiency, due to its experts’ detailed project planning.

This gantry system used was in-house designed and comprised four 200t strand jacks, 500t self-propelled skid beams, 150t skidding systems and customized lifting gantries.

This gantry system used was in-house designed and comprised four 200t strand jacks, 500t self-propelled skid beams, 150t skidding systems and customized lifting gantries.

Mammoet’s work to install the generator and turbine will see an increase in electricity supplied to the Java-Bali grid. General Electric’s Tambok Lorok Power Plant is part of Indonesia’s 35,000MW grid expansion project, and will power over five million Indonesian homes upon its completion.

Mammoet

Mammoet helps clients with Smarter, Safer and Stronger solutions to any heavy lifting or transport challenge. We aim to develop long term relationships in order to understand their businesses and challenges best, so we can realize the most efficient and cost-effective approaches. We have a unique global network and an unparalleled fleet of equipment. Through deep and longstanding engineering expertise and the highest quality and safety standards in execution we bring an intelligent and flexible approach to projects across a wide breadth of industry sectors. Clients trust us to help them achieve feats that were once considered impossible, and we have often broken records in doing so.

For more information, visit www.mammoet.com

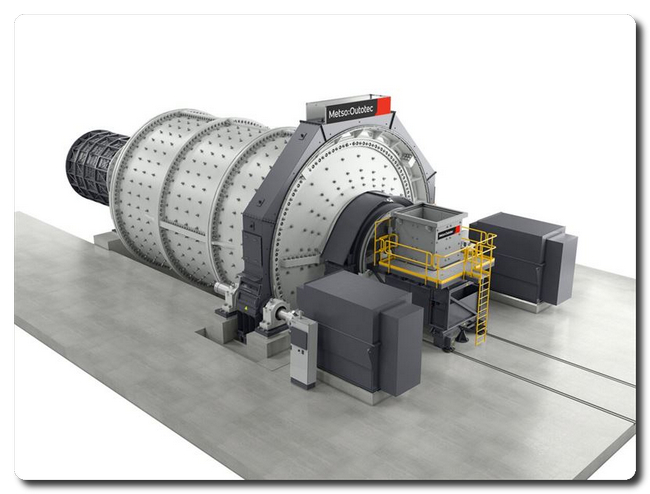

Metso Outotec to supply a high-capacity Premier™ SAG mill to Northern Star Resources in Australia

Metso Outotec will deliver a high-capacity, high-powered Premier™ SAG mill to Northern Star Resources Limited’s Thunderbox gold mine expansion located in Yandal Belt, north of Kalgoorlie in Western Australia. The typical value of such a delivery is approximately 15 million depending on the final scope. The order has been booked in Minerals’ first half of 2021 orders received.

On award of Northern Star Resources’ largest mill to date, Northern Star’s General Manager Processing, Mr Simon Tyrrell, said: “The Thunderbox expansion increases the operation’s hard rock processing capacity to 6.0Mtpa from the current 3.0Mtpa, and decreases processing costs as outlined in our 2021 Investor Day Presentation. Northern Star’s selection of Metso Outotec for the mill supply is supported by their locally based expertise, large mill supply history and ongoing collaboration with Northern Star.”

“We are pleased to be chosen as a supplier for the Thunderbox expansion. The gear-driven Premier™ SAG mill to be delivered will feature 18MW of motor power. With the Premier™ mill range we advance our unrivaled innovation legacy providing our customers with most reliable technology, engineered to exceed their specific requirements. We are looking forward to continue the collaboration with Northern Star Resources and to be part of their success story,” says Christoph Hoetzel, Head of Grinding business line at Metso Outotec.

Metso Outotec Premier Ball Mill

Metso Outotec Premier Ball Mill

Metso Outotec offers the industry's widest range of horizontal grinding mills consisting of the Premier™ and Select™ mills. They can be easily integrated with Metso Outotec mill reline equipment and are supported by the company’s extensive services network to ensure optimization during the mills’ lifetime. Metso Outotec also offers the market’s most comprehensive mill linings range and relining services with materials and designs optimized for each specific application.

Discover more about Metso Outotec grinding technology and Planet Positive approach.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Regulation-ready software at 3P Innovations

Pharmaceutical compliance is no easy feat. To support 3P Innovation in its development of production equipment for life sciences, COPA-DATA provided flexible, regulation-proof software for the creation of an ultra-compact fill-finish platform.

3P is a life sciences engineering and custom automation company. The organization works collaboratively with pharmaceutical and medical device businesses to develop new products through the design, manufacture and support of production equipment.

Based in a brand-new purpose-built facility in Warwick, UK, 3P services a multi-national customer base with machines installed right across the world.

3P‘s offering includes aseptic processing machines, powder and liquid filling technologies, custom device manufacture, as well as assembly and testing. For this project, 3P used zenon to develop an automated, ultra-compact and highly flexible fill-finish platform.

Fill-finish platform

As a life sciences organization, regulatory compliance is high on 3P’s agenda, and a project to create a new fill-finish platform was no exception.

The project’s desired outcome was the creation of an improved fill-finish platform — fill-finish platforms are used to manage the process of filling vials, syringes, cartridges, and bottles with a vaccine, medicine or ingredient. Naturally, these platforms must be aseptic, precise and in an ideal world, fully automated.

The goal was an automated fill-finish process that could be used in either single or multi-container formats. The technology would help 3P’s customers to manufacture pre-clinical and GMP clinical batches quickly and cost effectively and crucially, would reduce end user’s engineering time.

As a product for the life sciences sector, this technology also needed to comply with FDA 21 CFR Part 11 and EudraLex Annex 11 — regulations covering the pharmaceutical industries in both the United States and Europe.

Meeting industry standards

In the pharmaceutical sector, regulatory compliance is largely reliant on accurate record keeping and audit trails. However, as many pharmaceutical and life sciences organizations move away from paper-based records, compliance against FDA 21 CFR Part 11 also has specific requirements for electronic record keeping.

The regulation requires organizations to provide evidence that electronic documents and signatures are authentic. FDA 21 CFR Part 11 compatible software is the most effective way to ensure compliance and COPA-DATA’s pharmaceutical automation software, zenon, provides this reassurance.

zenon is an industrial software platform with specific advantages to the life sciences sector. While it can be used at the application level for operating projects, it can also be used in the engineering environment to create projects. Most importantly, for 3P, zenon is developed specifically to meet the FDA 21 CFR Part 11 criteria and carries compliance against the regulation throughout all its modules.

For 3P, choosing zenon as a software platform could ensure compliance for the fill-finish process through built-in recipe management, accurate audit trails and user administration functionality.

Developing new tech

The objective of 3P’s new fill-finish technology was to minimize the risk involved in filling and finishing processes. The new platform needed to be flexible, scalable and allow end users to integrate a wide variety of different pump brands and technologies.

Notably, 3P needed the platform to be compatible with both rotary piston and peristaltic pumps to ensure it was suitable for different types of end users.

“At 3P, many of our machines are uniquely configured for a client application or are even a completely bespoke machine,“ explained Chris Webber, control systems manager at 3P Innovation. “This requires us to generate new HMI screens for each project and all of those must enable operators to intuitively operate a complex piece of automation. COPA-DATA‘s zenon software allows us to quickly evolve our HMI designs during the development phase, synchronising our in-house design styles with the new functionality needed on each machine and incorporating feedback from operators.”

By choosing to develop an ultra-compact platform, 3P’s technology also needed to fit easily into existing insulators, bio-safety cabinets and other containment equipment. The design of the platform also included multiple tools on the same machine; liquid fill, nitrogen flush, check-weigh, stopper and cap.

Developing such a multifaceted platform required software that facilitated this level of diversity. zenon was ideal for this.

As a truly independent software platform, zenon does not limit users to specific equipment manufacturers or communication protocols. In fact, zenon allows for communication with a wide variety of manufacturers and technologies, making it truly flexible and scalable. For customers like 3P, this ensures the platform is versatile and future proof.

Regulatory compliance is key for the life sciences industry, as well as the machinery deployed in pharmaceutical plants. Thankfully though, it needn’t cause a headache. New technology is providing easier, faster, and more effective ways to adhere to the industries regulatory hurdles.

Highlights:

[e.g. technical details or main customer benefits; 4-10 bullet points]

- FDA 21 CFR Part 11 compatibility

- Seamless communication with other technologies

- Built-in recipe management

- Scalable technology

- Flexible user administration

Emerson Helps Alaska’s Largest Wind Farm Provide Reliable, Affordable Clean Energy

Sustainable grid solutions reduce costs by 65% and support the delivery of low-cost, renewable power.

Emerson (NYSE: EMR) today announced the completion of a digital transformation project to increase the reliability of clean energy generation at Golden Valley Electric Association’s (GVEA) Eva Creek wind farm. The project improves the management of Alaska’s largest wind farm.

Rural Alaskan communities are on the front line of climate change, given the region’s extreme weather. As the largest electric utility serving northern Alaska, GVEA and its Eva Creek wind farm supply nearly 25MW of reliable, low-cost electricity to customers, while reducing fossil fuel usage.

Emerson’s sustainable grid solutions have delivered fast results, increasing the reliability of GVEA’s wind turbines and contributing to a 65% reduction in operations and maintenance costs.

Emerson’s modernisation of Golden Valley Electric Association’s Eva Creek wind farm automation technology and software increases the reliability of low-cost, clean energy generation for customers in northern Alaska. Image courtesy of GVEA.

Emerson’s modernisation of Golden Valley Electric Association’s Eva Creek wind farm automation technology and software increases the reliability of low-cost, clean energy generation for customers in northern Alaska. Image courtesy of GVEA.

“Emerson is a key collaborator in our goal to increase access to clean energy for our customers in northern Alaska,” said Frank Perkins, GVEA vice president of power supply. “Our investment in a common automation platform helps us efficiently incorporate more renewable energy and minimise our carbon footprint.”

Emerson’s solutions simplify management of the Eva Creek wind farm and provide more accurate equipment diagnostics and analytics for forecasting and dispatch. The end-to-end solution incorporates Emerson’s Ovation™ automation platform and OSI monarch™ software to expertly help utilities achieve a more resilient, responsible and smarter power grid.

“Increased visibility into Eva Creek operations enables GVEA to further safeguard the reliable operation of this critical source of renewable energy for northern Alaska,” said Bob Yeager, president of Emerson’s power and water solutions business. “With Emerson’s comprehensive portfolio of sustainable grid solutions, GVEA is well positioned to optimise operations across its entire power system, from generation to meter.”

Emerson has been ranked as the leading distributed control systems provider for the global power generation industry, according to Omdia.1

1Omdia, Distributed Control Systems Report, 2020. Market share based on revenue. Results are not an endorsement of Emerson. Any reliance on these results is at the third-party’s own risk.

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and engineering company providing innovative solutions for customers in industrial, commercial, and residential markets. Our Automation Solutions business helps process, hybrid, and discrete manufacturers maximise production, protect personnel and the environment while optimising their energy and operating costs. Our Commercial & Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency, and create sustainable infrastructure. For more information visit Emerson.com

Nornickel awards major contract for processing equipment supply to Metso Outotec

Nornickel, the world’s largest producer of palladium and high-grade nickel and a major producer of platinum and copper, has awarded a major contract for the supply of some of the key industry-leading equipment used in mining operations to Metso Outotec, further extending the partnership with Finland’s technology solutions provider.

Nornickel and Metso Outotec have signed an agreement to deliver industry-leading dewatering, flotation and automation equipment for Nornickel’s Talnakh concentrator expansion project in Russia’s Arctic city of Norilsk. The contract value is a commercially sensitive matter and therefore may not be disclosed publicly.

Nornickel and Metso Outotec have signed an agreement to deliver industry-leading dewatering, flotation and automation equipment for Nornickel’s Talnakh concentrator expansion project in Russia’s Arctic city of Norilsk. The contract value is a commercially sensitive matter and therefore may not be disclosed publicly.

Metso Outotec’s delivery scope consists of modernization of three existing thickeners and delivery of over 100 TankCell® flotation machines and an automation system for the new Talnakh concentrator Line 3 flotation area. In addition, the contract covers the supply of spare parts and consumables. Metso Outotec will also provide a metallurgical performance guarantee as well as advisory services for the installation and commissioning of the equipment. The delivery is scheduled for 2022-23.

Sergey Dubovitsky, Nornickel Senior Vice President Strategy, Strategic Projects, Logistics & Procurement, commented: “The new contract further develops the collaboration with our longstanding partner Metso Outotec, which has supplied technology to us for many years. We have an excellent track record of using the Metso Outotec machinery across the entire geography of our operations. The new equipment supply contract plays a crucial role for our expansion project — Talnakh Concentrator Line 3, which is a key step to deliver our strategy of sustainably producing metals required for the world economy to go greener”.

Markku Teräsvasara, Metso Outotec President, Minerals business area, commented: “We are pleased to continue our partnership with Nornickel. The supply of leading-edge equipment from Metso Outotec for the existing Line 2 and the New Line 3 flotation section at the Talnakh concentrator will enable an increase in the amount of ore processed. Our company has collaborated with Nornickel on several projects to boost the throughput rates of their processing facilities, and we are grateful for having again been selected to provide reliable solutions for a project as significant as Talnakh. Metso Outotec has already supplied equipment and solutions for comminution and ore processing for Talnakh concentrator Line 1 and Line 2”.

ABOUT THE COMPANY

MMC Norilsk Nickel is a diversified mining and metallurgical company, the world’s largest producer of palladium and high-grade nickel and a major producer of platinum and copper. The company also produces cobalt, rhodium, silver, gold, iridium, ruthenium, selenium, tellurium, sulphur and other products.

The production units of Norilsk Nickel Group are located at the Norilsk Industrial District, on the Kola Peninsula and Zabaykalsky Krai in Russia as well as in Finland and South Africa.

MMC Norilsk Nickel shares are listed on the Moscow and on the Saint-Petersburg Stock Exchanges, ADRs are traded over the counter in the US and on the London, Berlin and Frankfurt Stock Exchanges.