Administrator

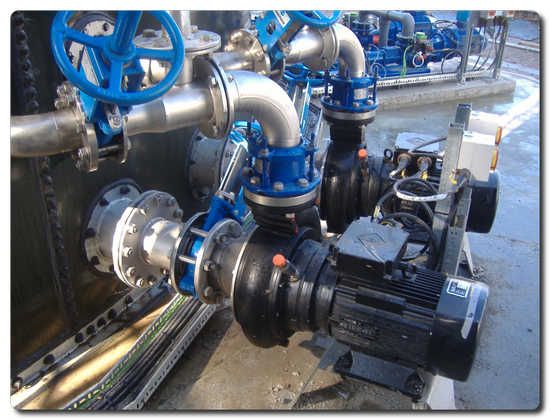

MSE Systems bring in Landia pumps and mixers to help treat potato effluent

Following the successful installation two years ago of Landia Chopper Pumps and a Landia Aeration System, MSE Systems is set to install a further three units from Landia for one of the UK’s leading supplier of potatoes.

During an upgrade to the customer’s potato processing factory, Chesterfield-based MSE Systems found that the addition of a high-efficiency Dissolved Air Flotation (DAF) plant would improve the activated sludge process by reducing oxygen demand. To ensure that the plant could meet future needs, a new chemical addition system was introduced to remove suspended solids, free emulsified oils, grease and elevated residual phosphorus.

For odour control, an 11kW Landia AirJet system was installed to mix, aerate and control odours of screened potato effluent in a balance tank. In addition, two submersible Landia Chopper Pumps were brought in to pump screened potato effluent from a 4.5m deep pit (500m away), which included an additional 4m lift.

Andy Neal, Design Manager at MSE Systems, said: “Our challenge, which meant utilising a very small footprint between the existing plants, was to help our customer meet and maintain a stringent Environment Agency discharge consent, so that they remain fully compliant. The Landia AirJet and Chopper Pumps have proved very reliable and cost-effective, so it gave us the confidence to invest further in this equipment as the best, long-term solution.

He added: “For a new packing line, two submersible Landia Chopper Pumps will pump potato effluent, whilst a Landia Jet Mix system will mix organic sludge (dissolved solids 3-5%) in a 60m3 tank”.

MSE Systems ensured that the initial installation proceeded with the minimal amount of disruption, in order for their customer to reopen on schedule. Despite the tight time frame, the new wastewater treatment plant was delivered by MSE Systems ahead of deadline and within budget.

Growing digitalization makes the oil and gas industry more vulnerable to cyberattacks

The oil and gas industry is increasingly relying on digital technologies to transform itself in the 21st century. As increasing volumes of data are being stored on networked servers, there is a higher probability of this data getting targeted by hackers, says GlobalData, a leading data and analytics company.

GlobalData’s latest thematic report, ‘Cybersecurity in Oil & Gas (2020)’ highlights the importance of cybersecurity technologies in the industry, in order to protect oil and gas assets against internal as well as external threats.

The oil and gas industry is expanding the use of digital technologies to optimize daily activities. Widespread deployment of the IoT is generating huge volumes of data. Each node in a company’s network, whether a computer terminal, a cell phone, sensors, or a networked camera, can become an entry point for hackers.

Ravindra Puranik, Oil and Gas Analyst at GlobalData, comments: “Hackers can exploit these nodes and gain access to a wealth of information, including business plans, project designs, supplier details, contracts, financing, and other critical information. Loss or theft of such data can prove financially and operationally detrimental for an oil and gas company.

Ravindra Puranik, Oil and Gas Analyst at GlobalData, comments: “Hackers can exploit these nodes and gain access to a wealth of information, including business plans, project designs, supplier details, contracts, financing, and other critical information. Loss or theft of such data can prove financially and operationally detrimental for an oil and gas company.

“The frequency and sophistication in cyberattacks has increased over the years, as seen in the case of the Shamoon attack that has targeted Saudi Aramco on multiple instances. Hence, it is imperative that oil and gas companies adopt a proactive approach in handling cybersecurity. Broad scale coordination among industry players, government agencies, and technology vendors is essential to tackle such complex and persistent menace.”

GlobalData’s thematic research identifies BP, Chevron, ConocoPhillips, Eni, ExxonMobil, Gazprom, Royal Dutch Shell and Saudi Aramco, among the leaders in the cybersecurity theme in the oil and gas industry. It also highlights some of the cybersecurity technology providers for oil and gas industry, namely BlackBerry, Broadcom, Cisco Systems, Fortinet, IBM, Microsoft, Palo Alto Networks, and Verizon.

More recently, the COVID-19 pandemic has increased cyber risk significantly. Employees working on personal computers and using public networks are especially vulnerable to phishing and other types of cyberattacks.

Puranik concludes: “The industry needs a clear strategy and then subsequent delivery to address these vulnerabilities and protect against data loss, denial of service, and other forms of disruption to operations.”

- Quotes provided by Ravindra Puranik, Oil & Gas Analyst at GlobalData

- Information based on GlobalData’s thematic report: ‘Cybersecurity in Oil & Gas (2020)’

- This press release was written using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis, and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, technology, energy, financial and professional services sectors.

Renewable energy in Chile gets more attractive with its major capacity build-up during 2019-30

The Chilean renewable market stands to reap the benefits of its renewables’ potential and intent to lower the price of electricity for the customers. The country has put in gigantic efforts to promote renewable expansion to contribute to its decarbonization plan and achieving the target of attaining carbon neutrality by 2050. The Chilean renewable capacity, including hydropower, presently contribute to around 47% of the capacity mix while Fossil fuel rules the remaining 53%. Chile’s capacity mix is estimated to witness a major upside by 2030, with renewables (including hydropower) accounting for more than 70% of the power capacity mix, says GlobalData, a leading data and analytics company.

Somik Das, Senior Power Analyst at GlobalData, comments: “The country is firmly planning to retire its coal power generation fleet and to prioritize renewable energy (RE) sources that would not require damming or diverting water resources impacting the environment. Due to Chile’s vulnerability to future changes in the climatic conditions, GlobalData estimates that during 2019-2030, almost 30GW of new power generation capacity will be built. Out of this, 90% of the new capacity will be renewable in nature. Solar PV and Wind will lead the renewable capacity built together contributing more than 70% of the capacity.

Somik Das, Senior Power Analyst at GlobalData, comments: “The country is firmly planning to retire its coal power generation fleet and to prioritize renewable energy (RE) sources that would not require damming or diverting water resources impacting the environment. Due to Chile’s vulnerability to future changes in the climatic conditions, GlobalData estimates that during 2019-2030, almost 30GW of new power generation capacity will be built. Out of this, 90% of the new capacity will be renewable in nature. Solar PV and Wind will lead the renewable capacity built together contributing more than 70% of the capacity.

“GlobalData’s projects database defines the robust market attractive with more than 8.9GW of wind projects and 21.9GW of solar PV projects under various stages of development.”

Chile has a plan to phase out coal-fired power plants by 2040 and achieve carbon neutrality by 2050. To provide an unwrinkled road to a smooth transition and risk-free environment to the investors would need an established supply chain, policy support, and continuous visibility of the market. During the H1 2020, the country’s renewable sector has already witnessed a high number of M&A and ‘Asset Transaction’ financial deals compared to the same period last year. Solar PV technology saw three times more financial deals amounting to US$4bn, followed by wind at US$1.2bn and hydropower at US$0.3bn.

Das concludes: “Chile has been particular about the environment and its resources, in the generation front, it is trying to reduce coal-based power generation which formed as high as 45.6% in 2013 to 5-15% of the generation blend, in 2030. The current Chilean energy transition vision and trajectory towards an increasingly clean and efficient matrix has provided the investors with the confidence of a stable and lasting market with good returns.”

- Comments provided by Somik Das, Senior Power Analyst at GlobalData

- This insight was based upon data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

Emerson Introduces Industry’s First Pneumatic Valve System with Embedded Wireless Connectivity

New automatic recovery module enables easy valve system commissioning and configuration

Emerson has introduced a wireless automatic recovery module (ARM) for its AVENTICS™ G3 electronic fieldbus platform that makes it easy for technicians to perform pneumatic valve system commissioning and diagnostics from a mobile phone, tablet or laptop computer.

“The AVENTICS G3 fieldbus platform is the first in the industry to offer wireless technology that puts valve system configuration and diagnostics at the control engineer’s fingertips,” said Enrico De Carolis, vice president of global technology, fluid control and pneumatics, at Emerson. “This offering furthers our quest to help manufacturers reduce production downtime and simplify valve system commissioning, while creating a path for using diagnostics/prognostics for analytics and advancing our offering of intelligent devices with IIoT capability.”

The new wireless ARM module and AVENTICS G3 fieldbus platform are ideal for pneumatic valve system applications in the automotive, food and beverage, tire, packaging and metalworking industries.

The wireless ARM module provides easy access to the AVENTICS G3 fieldbus platform’s diagnostic and commissioning capabilities via an internal Wi-Fi access point and mobile website — even when the valve system is located inside a machine or on a ceiling. It offers the visual benefits of a hard-wired human machine interface (HMI) at lower cost and with higher flexibility. The wireless ARM module generates error notification for alarms, voltage levels, short circuits, module errors, open load errors and distribution errors to reduce system downtime.

The device has a small footprint that connects easily to the AVENTICS G3 fieldbus platform in the space of a jumper clip. It features three power settings for low-, medium-, or high-distance signals to ensure safe and secure access to data — regardless of where the valve system is mounted. Additional security benefits include wireless signal that can be turned off during configuration, multiple password options, and diagnostic and commissioning information provided with no control capability.

The wireless ARM module is compatible with Ethernet/IP DLR, and PROFINET protocols. Additional protocols are targeted for future release.

The wireless ARM module also protects the AVENTICS G3 fieldbus platform’s configuration information from a critical failure, including all settable node and attached I/O module parameters.

Emerson also has introduced an upgraded ARM clip for the AVENTICS G3 fieldbus platform that is backwardly compatible to existing ARMs and G3 fieldbus platforms. The ARM clip improves system reliability by protecting configuration information from critical valve system failure.

The AVENTICS G3 fieldbus platform’s electronic parameters and settings are automatically stored in the ARM’s nonvolatile memory and then the ARM is automatically disconnected from power, to ensure stored information is not erased during a power spike or critical failure. “A replacement G3 fieldbus communication node can automatically download the required parameters from the ARM module,” said De Carolis. “This enables the valve system and production line to quickly resume operation without the need for re-commissioning by a controls engineer, offering true ‘plug and play’ capability.”

The compact ARM module is easy to install in the space of an AVENTICS G3 fieldbus platform’s jumper clip without having to change the mounting.

For more information, visit www.Emerson.com/AVENTICS.

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and engineering company providing innovative solutions for customers in industrial, commercial, and residential markets. Our Emerson Automation Solutions business helps process, hybrid, and discrete manufacturers maximize production, protect personnel and the environment while optimizing their energy and operating costs. Our Emerson Commercial and Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency, and create sustainable infrastructure. For more information visit www.Emerson.com

Crowley Completes Challenging Over-the-Shore Fuel Delivery to U.S. Military in the Arctic

Crowley successfully lightered and delivered nearly four million gallons of military specification fuel to Eareckson Air Station on the Aleutian Island of Shemya in Alaska, overcoming challenges that included Mother Nature’s destruction of the island’s shoreside dock, remote location and challenging weather and sea conditions.

Shemya’s radar and aircraft refueling station, Eareckson Air Station, and the 180 service members, contractors and civilians who operate it rely on Crowley’s twice-yearly fuel deliveries to supply fuel required for incoming aircraft for the Defense Logistics Agency, U.S. Coast Guard, Air Force and other state and federal agencies. With this season’s delivery, Crowley continued its nearly uninterrupted service record, which dates to 1956.

Shemya’s radar and aircraft refueling station, Eareckson Air Station, and the 180 service members, contractors and civilians who operate it rely on Crowley’s twice-yearly fuel deliveries to supply fuel required for incoming aircraft for the Defense Logistics Agency, U.S. Coast Guard, Air Force and other state and federal agencies. With this season’s delivery, Crowley continued its nearly uninterrupted service record, which dates to 1956.

This year’s fueling, while similar in outcome, differed in complexity and execution. The operation, carried out in partnership between Crowley’s government solutions and Alaska fuels team, utilized the company-owned tug Sea Prince and 52,000-barrel barge DBL-289 to execute multiple vessel-to-vessel lighterages, followed by multiple over the shore deliveries in lieu of a traditional alongside delivery.

“The successful completion of the Shemya fuel delivery, despite the environmental and infrastructure challenges, is representative of the reliable, flexible solutions that Crowley consistently delivers to government and commercial energy customers,” said Sean Thomas, vice president. “It’s a credit to our men and women at sea and ashore, who ensure safe and quality product can be delivered in the most difficult conditions in order for our service members to carry out their mission.”

Lightering operations to this island 1,200 miles from Anchorage are challenged by the “tyranny of distance,” converging at a location where tide and wave action, combined with drastic and sudden weather changes, create very narrow windows of opportunity for marine operations. After coordinating government, contractor and Crowley personnel, afloat and ashore, for the most appropriate operational timing, Crowley successfully lightered fuel from a contracted articulated tug-barge (ATB) offshore, then delivered it over the shore and into Eareckson’s shoreside tanks and trucks.

“Even with a relatively calm three- or four-foot swell, it's very much a contact sport and a very active sea out there,” said Crowley Fuels' long-time Cargo Operations Manager, Anthony Morris, who leads the delivery activities.

Crowley’s crews have lightered fuel to Shemya for decades, but this latest delivery marks the end of an era of line-haul vessel delivery to the island. Starting in 2021, Crowley’s new, 55,000-barrel ATB Aurora/Qamun, soon to enter sea trials, will serve Crowley’s customers throughout western Alaska and the Arctic. The ATB is specifically designed to improve efficiency, maneuverability and operational capability in the challenging waters found surrounding Alaska. Pending the award of a new contract, the vessel will assume service to Shemya as well, continuing Crowley’s commitment to the mission at this remote and austere location.

Crowley’s crews have lightered fuel to Shemya for decades, but this latest delivery marks the end of an era of line-haul vessel delivery to the island. Starting in 2021, Crowley’s new, 55,000-barrel ATB Aurora/Qamun, soon to enter sea trials, will serve Crowley’s customers throughout western Alaska and the Arctic. The ATB is specifically designed to improve efficiency, maneuverability and operational capability in the challenging waters found surrounding Alaska. Pending the award of a new contract, the vessel will assume service to Shemya as well, continuing Crowley’s commitment to the mission at this remote and austere location.

Morris welcomes the change. “The crew of the ATB will be able to go into the harbor, turn, look at the weather and decide whether they can actually make it to the dock and exit without having to get alongside. It gives us a bigger window of opportunity, improves our operational efficiency and most importantly, further improves upon the already safe methods developed by Crowley,” he said.

That window of opportunity extends beyond the island of Shemya to the many remote villages of Western Alaska that also depend on Crowley’s capabilities and people who know how to get fuel over the shore in some of the most austere environments on earth.

About Crowley Solutions

Crowley Solutions, the company's government services group, provides energy services including petroleum storage, distribution by sea and land, fuel over the shore and liquified natural gas solutions; global supply chain solution services including truck, rail, air, and ocean transportation as well as global freight forwarding; maritime solutions comprised of naval architecture and marine engineering services, vessel management, chartering, towing, port and range operations, and foreign military sales; and technology solutions that move customers to the forefront of transportation management, data analysis, automation and cyber security.

About Crowley Fuels

Crowley Fuels is a leader in Alaska’s fuel industry, providing safe, dependable transportation, distribution and sales of petroleum products to more than 280 communities across the state. The company is the state’s largest wholesaler of quality fuel products, including diesel, heating fuel, propane, gasoline, aviation fuels, marine fuels and packaged petroleum products. Crowley has 18 petroleum terminals across the state with a combined 76 million gallons of storage capacity, and the company utilizes its diverse distribution channels – on land, over water and occasionally through the air – to deliver the fuel Alaskans need to live, work and play throughout the state.

For information on Jacksonville-based Crowley Holdings Inc., a holding company of the 128-year-old Crowley Maritime Corporation, visit www.crowley.com.

Kemira announces long-term polymer supply agreement extension with Ithaca Energy

Kemira, a global leader in the manufacture and supply of high-quality polymers, has signed a multiyear extension to the current polymer supply agreement with Ithaca Energy. The new contract is an extension to a contract signed in 2018 to supply polymers in order to enhance oil extraction performance on one of Ithaca Energy’s operated assets in the UK North Sea.

In 2017, Kemira expanded the polymer manufacturing capacity for Chemical Enchanced Oil Recovery (CEOR) in its Botlek site in the Netherlands. The now announced multiyear supply agreement extension with Ithaca Energy will ensure good utilization of the investment at Botlek.

In 2017, Kemira expanded the polymer manufacturing capacity for Chemical Enchanced Oil Recovery (CEOR) in its Botlek site in the Netherlands. The now announced multiyear supply agreement extension with Ithaca Energy will ensure good utilization of the investment at Botlek.

Pedro Materan, SVP Global Oil & Gas at Kemira: ”We are very pleased to continue our partnership with Ithaca Energy long-term. Kemira’s fully tailored polymers for CEOR offer excellent opportunities to improve resource efficiency and sustainable operations as well as profitability.”

Kemira is a global chemicals company serving customers in water intensive industries. We provide best suited products and expertise to improve our customers’ product quality, process and resource efficiency. Our focus is on pulp & paper, oil & gas and water treatment. In 2019, Kemira had annual revenue of around EUR 2.7 billion and over 5,000 employees. Kemira shares are listed on the Nasdaq Helsinki Ltd. www.kemira.com

Ithaca Energy’s strategy is centered on building a highly profitable, leading North Sea oil and gas company. The Company is an experienced North Sea operator focused on the delivery of lower risk growth through the appraisal and development of UK undeveloped discoveries and the exploitation of its UK producing asset portfolio. The Company was founded in 2004 and has grown through the execution of both new field development activities and acquisitions. Ithaca is a wholly owned subsidiary of the Tel Aviv stock exchange listed Delek Group Limited (TASE: DLEKG, US ADR: DGRLY), Israel’s leading integrated energy company. For further information please consult the Company’s website www.ithacaenergy.com.

Konecranes wins order for two more mobile harbor cranes from ZHD Stevedores in the Netherlands

In July 2020, ZHD Stevedores (ZHD) ordered two eco-efficient Konecranes Gottwald Model 6 Mobile Harbor Cranes for their operations in the Netherlands – one for Dordrecht and one for Moerdijk. With delivery in February and commissioning by the end of March 2021, the cranes will handle dry bulk, steel coils, breakbulk and containers.

Established in 1968, ZHD Stevedores is a privately owned, independent stevedoring company with over 50 years of stevedoring experience. Active in the so-called Rotterdam-Rijnmond area, ZHD operates terminals (including open and covered storage) in the ports of Dordrecht and Moerdijk. ZHD also renders floating stevedoring services in the Port of Rotterdam.

Today, this fourth-generation family business handles cargo from ships of all sizes. In order to maintain its continuing success in one of the largest port regions in the world, ZHD regularly renews its equipment to improve their technology and competitiveness. ZHD is already operating several Konecranes Gottwald mobile harbor cranes. The present investment is made to both further improve services towards customers as well as to further comply with future environmental requirements.

Today, this fourth-generation family business handles cargo from ships of all sizes. In order to maintain its continuing success in one of the largest port regions in the world, ZHD regularly renews its equipment to improve their technology and competitiveness. ZHD is already operating several Konecranes Gottwald mobile harbor cranes. The present investment is made to both further improve services towards customers as well as to further comply with future environmental requirements.

“Exactly 20 years ago, we ordered our first legacy Gottwald mobile harbor crane – a HMK 300 EG,” says Alain Bornet, Managing Director of ZHD Stevedores. “This crane has served us well, but it’s time to get a replacement. We already have two Model 6 cranes, one of which is placed on a self-propelled pontoon and has been constructed and engineered as a one-of-a-kind 50-ton floating crane called “Ahoy 50”. We believe an investment in two more cranes is the right answer to our growing operations. The cranes have proven to be durable, high-performance machines and have really helped to build our business. So, it was logical for us to rely on Konecranes again to expand our capacity.”

The two new Konecranes Gottwald Model 6 mobile harbor cranes are the G HMK 6407 B variant in a four-rope grab configuration for dry bulk handling. With a maximum lifting capacity of 100 tons, they are suitable to handle steel coils, breakbulk and containers. Both cranes will be prepared for operations on a pontoon, a modification that provides the versatility needed for multiterminal and multimodal operations. Furthermore, they have different propping bases allowing the crane to be placed and operated in narrow spaces.

Both cranes feature advanced mobile harbor crane drive technology from Konecranes that meets EU Stage V emission standards. Additionally, the cranes are prepared for connection to an external power supply, providing ZHD maximum flexibility in terms of energy source and points of operation.

The cranes are also equipped with the latest Konecranes digital services such as web reporting and bidirectional remote access that allows ZHD to share crane data in order to improve performance and maintenance work.

“We have been collaborating very intensively to achieve as much operational flexibility as possible. The outcome is very impressive. This joint effort proves the strength of our customer relationship with ZHD,” says Alexandros Stogianidis, Director Sales Benelux for Konecranes Port Solutions. “They use our equipment to boost their productivity, improve their eco-efficiency and add flexibility to their stevedoring business. We look forward to their future success as we continue to work together.”

With this transaction, ZHD and Konecranes have further consolidated their cooperation into the future and are therefore confident that they will further optimize their mutual services.

Further information:

Alexandros Stogianidis, Director Sales Benelux, Konecranes Port Solutions

Email: This email address is being protected from spambots. You need JavaScript enabled to view it. or phone: +32 3 546 4508

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2019, Group sales totaled EUR 3.33 billion. Including MHE-Demag, the Group has around 17,300 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

Metso Outotec wins two orders for high-capacity copper anode casting shops

Metso Outotec has won two orders for its Outotec® Anode Casting Shops, which are to be delivered to copper production plants in China and Bulgaria. Yangxin Hongsheng Copper Co., Ltd., which is constructing its greenfield copper smelter in Huangshi, Hubei, China, expects to start its operations in 2021. Aurubis Bulgaria AD’s copper production plant in Pirdop, Bulgaria, has been operating since the end of the 1950s and is a longtime customer of Metso Outotec.

Both anode casting shops are equipped with fully electric systems to improve maintainability, energy efficiency and safety. The shops are expected to be commissioned in 2021. Typically, the combined value for two shops of this type would be close to EUR 10 million. The orders have been booked in Metso Outotec’s Q3 2020 orders received.

Anode Casting Shop

Anode Casting Shop

“We are extremely pleased to have won these two important orders. Both shops will feature two casting wheels for high capacity and yield. They will also be equipped with advanced automation to ensure high availability and high casting accuracy to produce high quality anodes,” says Jari Ålgars, President, Metals business area at Metso Outotec.

World-leading copper processing technology

Metso Outotec is a global leader in anode casting technology, which is used to produce a significant proportion of the world’s copper anodes.

Metso Outotec has delivered more than 90 anode casting shops around the world, and its offering features all the technology and expertise required for the end-to-end copper production process and its lifetime servicing.

More information on Metso Outotec’s Anode Casting Shop

For further information, please contact:

Jyrki Makkonen, Vice President, Smelting, Metso Outotec, Tel. +358 20 529 4022, E-mail: jyrki.makkonen(at)mogroup.com

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing, metals refining and recycling industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its illustrative combined sales for 2019 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

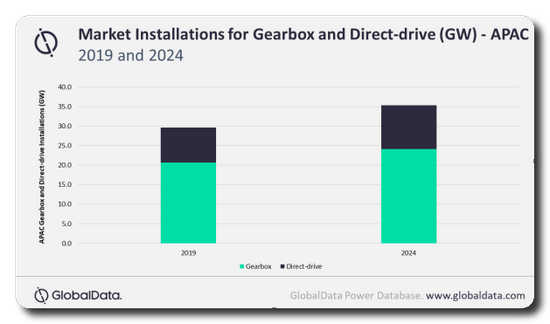

APAC to lead global wind gearbox and direct-drive equipment markets over next four years, says GlobalData

Asia-Pacific (APAC) is expected to continue to lead the global wind gearbox and direct-drive equipment markets between 2020 and 2024 with a projected market share of 50.7% and 64%, respectively, says GlobalData, a leading data and analytics company.

GlobalData’s latest report, ‘Wind Gearbox and Direct-Drive, Update 2020 - Global Market Size, Competitive Landscape and Key Country Analysis to 2024’, reveals that the dynamic shift towards low carbon modes of power generation, improvements along the supply chain and technology maturity are creating viable business opportunities within the wind power sector.

Emerging economies are beginning to embrace wind, which is driving new installations while prominent markets such as China, the US and EU, with their legacy installations, are creating a significant market for gearbox refurbishments.

The global installations of wind gearbox and direct-drive equipment are estimated to aggregate 221.2GW and 78.1GW, respectively, over the forecast period.

In 2019, the global total installation of wind gearbox stood at 41.2GW as compared to 13GW for direct-drive. Although gearbox will continue leading the market over the forecast period in absolute terms, the direct-drive market is projected to witness higher growth, as they offer lower system weight, higher reliability due to fewer parts, and reduced maintenance, with higher power ratings. The direct-drive market is expected to witness an annual installation of 17.5GW, i.e., 27% of the total installation in 2024.

Nirushan Rajasekaram, Power Analyst at GlobalData, says: “Within APAC, major countries such as China, India and Australia are significantly driving the direct-drive market, with other countries such as Japan, South Korea and Taiwan playing a minor role in supporting the market. Similarly, for wind gearbox equipment, trends in the major markets of China and India will underpin the regional gearbox market, which is estimated to grow at a compound annual growth rate (CAGR) of 7%, over the forecast period.”

China accounted for approximately 38% of the global gearbox market value in 2019. The country is committed towards enhancing its renewable portfolio, to sustain its development agenda and the growing electricity demand, while reducing power sector emissions. However, the market is projected to decline over the forecast period, due to policy changes instituted by the government.

Rajasekaram adds: “India is estimated to be the fastest growing market for gearbox, growing at a CAGR of 19.5% over the forecast period. Similar to China, the government has proposed ambitious renewable energy targets, which are expected to drive the wind equipment market. With respect to the refurbishment market, the large-scale historical installations of wind turbines in China will drive the regional market value for gearbox refurbishment, which is projected to grow significantly over the forecast period.”

However, despite the positive outlook for wind gearbox and direct-drive markets, certain market uncertainties exist. The emergence of other technologies, changing regulatory landscape, and financial constraints threaten the market. Major countries such as China and the US are likely to experience a market slowdown. Nevertheless, opportunities for refurbishment are plenty, owing to legacy turbine installations in the aforementioned countries.

Rajasekaram concludes: “The growing role of smart technologies and other low carbon modes of power generation could result in wind power becoming uncompetitive and thereby limiting its growth prospects. Countries with significant wind capacities are exploring other clean power generation sources, while emerging markets will require the construction of sufficient grid infrastructure to support new generation capacity addition, which could slow the overall market deployment of wind power.”

Konecranes wins order for fleet of Konecranes Noell Sprinter Carriers

The HDC Hyundai Development Company of Korea has ordered a fleet of 28 Konecranes Noell Sprinter Carriers for Busan New Port 2-4 in Busan, Korea. The Sprinter Carriers will be delivered as part of the port’s expansion project 2-4. The order was booked in August 2020.

“The HDC Hyundai Development Company is a renowned developer of container terminals and we are proud to have received this repeat order as Busan New Port continues to expand,” said Peter Kania, Head of Sales for Straddle Carriers, Konecranes Port Cranes. “We delivered Sprinter Carriers as part of Busan New Port’s earlier growth phase. This further order is a vote of confidence and trust in the performance and reliability of these machines as horizontal transport vehicles from the quayside, working closely with the automated stacking cranes in the container yard,” continued Kania. When the Sprinter Carriers on order are delivered and working, Busan New Port will have a Konecranes Noell Sprinter Carrier fleet of 64 machines.

The Sprinter Carriers on order are man-driven, diesel-electric machines stacking containers 1-over-1 as part of swift container transfer between the quayside and container yard. The order will be delivered in three batches starting at the end of 2021 and ending by July 2022. All of the machines will be equipped with Stage IV diesel engines, and they will all have 8 wheels by special customer request to reduce ground pressure. The standard Konecranes Noell Sprinter Carrier has 6 wheels.

All of these Konecranes Noell Sprinter Carriers will have built-in readiness for automation. This puts Busan New Port on Konecranes’ path to port automation, where container terminals improve productivity and safety in manageable steps. The path to port automation applies to all container handling equipment brands. Full automation can be the final goal but it doesn’t have to be. Flexibility is the key.

Further information:

Peter Kania, Head of Sales for Straddle Carriers, Konecranes Port Cranes

Email: This email address is being protected from spambots. You need JavaScript enabled to view it. or phone: +499312053216

Further information for investors and analysts:

Kiira Fröberg, Director of Investor Relations, Konecranes

Email: This email address is being protected from spambots. You need JavaScript enabled to view it. or phone: +358 20 427 2050

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2019, Group sales totaled EUR 3.33 billion. Including MHE-Demag, the Group has around 17,300 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).