Displaying items by tag: Metso Outotec

Metso Outotec introduces modular Horizontal Mill Plant Units for simple grinding circuit selection and execution

Metso Outotec is launching yet another unique solution in its range of minerals processing plant islands: the Horizontal Mill Plant Units. The pre-engineered plant units provide optimized grinding performance and simplify project management through easy circuit selection and flowsheet implementation. At the same time, they ensure safe operability and maintainability thanks to their state-of-the-art design. The plant units feature Metso Outotec’s industry-leading technologies including grinding mills, slurry pumps, hydrocyclones, conveying equipment, automation, and service support. The scope of the unit can be tailored according to project requirements (brownfield or greenfield, open or closed circuit).

“Choosing the right solution for a grinding process can be a complex task. In addition to financial and technological aspects, miners must also evaluate executional and operational factors. Our modular Horizontal Mill Plant Units have been developed to make it easier for customers to select and execute the best solution for their grinding needs. Our pre-engineered modules provide a safe and optimized solution for many grinding applications,” says Fernando Marques, Global Product Manager at Metso Outotec.

Metso Outotec Horizontal Mill Plant Unit

Metso Outotec Horizontal Mill Plant Unit

The innovative Horizontal Mill Plant Units combine Metso Outotec horizontal mills, classification, pumping and automation technologies with a wide range of services and operation support. It takes sustainability and grinding performance to a new level by optimizing the usage of energy, water, grinding media and consumables.

Benefits:

- Grinding and classification expertise to support flowsheet implementation

- Pre-engineered modules for simple and rapid execution

- Process performance guarantee

- Easy process optimization thanks to comprehensive automation and digitalization features

- Sustainable technology with safe operability and maintainability

- Lifecycle service support

Read more about Metso Outotec Horizontal Mill Plant Units on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

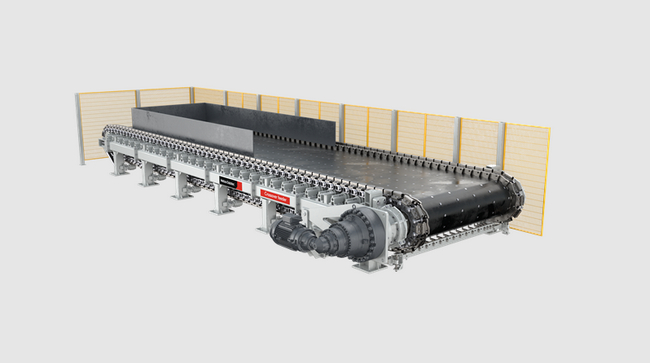

Metso Outotec complements its feeding solutions portfolio with an innovative hybrid Crossover feeder

Metso Outotec is launching the Crossover™ feeder, which is a hybrid feeding solution suitable for a wide range of greenfield and brownfield applications. Thanks to its innovative modular belt-over-apron design, the Metso Outotec Crossover™ feeder delivers unmatched levels of availability and reliability for bulk material transportation at lower overall costs.

”We are very excited to announce the launch of the Crossover™ feeder. It was developed to provide a flexible and economical solution in a wide range of applications where belt and apron feeders are not the optimal fit,” says Brian Bookamyer, Director, Bulk Materials Handling at Metso Outotec.

The Crossover™ feeder design features a reduced height of up to 50% as compared to conventional feeding technology. This lower height requirement provides an opportunity for CAPEX savings by decreasing the excavation and civil works required. For retrofit applications, the reduced height profile allows the Crossover™ feeder economically replace existing feeders, including apron and/or belt feeders by lowering modification costs.

Metso Outotec Crossover feeder

Metso Outotec Crossover feeder

Maximum productivity for any feeding application

The Crossover™ feeder complements Metso Outotec’s versatile feeding solutions portfolio, which also includes Apron feeders and Belt feeders, enabling Metso Outotec to provide our customers with the best feeding solutions to maximize performance and productivity. All Metso Outotec feeding solutions feature optimal design and dependable components to handle any duty in mining. Support through the comprehensive services network enables easy maintainability and minimal downtime.

The Metso Outotec Apron feeders are suitable for both light and heavy-duty applications and consist of a pre-engineered range that makes sizing and selection simple. They are best suited for feed to a primary gyratory or jaw crusher, primary gyratory discharge, secondary and tertiary stockpile reclaims, and railcar dumper discharge. The customizable Metso Outotec Belt feeders provide a reliable solution for material transport especially in large, high-capacity installations. The optimal applications range from light- to medium-duty for tertiary, reclaim and concentrate, and filter cake discharge, as well as railcar dumpers in lighter duty.

Metso Outotec also offers parts, refurbishments, and a wide range of specialized field services to help meet all maintenance, repair, training, installation, and refurbishment needs for both Metso Outotec and third-party feeders. In addition, the scalable Metso Outotec Life Cycle Services (LCS) can be tailored to cover single-event equipment shutdowns or to span over multiple years, measured against strict KPIs.

Discover more about the Metso Outotec Crossover™ feeder on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki.

Metso Outotec strengthens customer support and global network with new service center in Australia

Metso Outotec is investing in the development of its service capabilities in Australia with a new service center in the Pilbara region. The planned Pilbara service center underlines Metso Outotec’s commitment to deliver high-level services to its mining and aggregates customers, with the facility delivering enhanced productivity and shorter lead time in the region.

The construction work will begin as soon as the acquisition of the land and planning of the facility, currently subject to customary authority approvals and conditions, has been completed. Construction is planned to be completed by the end of 2022.

The location of the center will provide the agile delivery of equipment repairs, act as a base for field services, and hold inventory for customer-critical wear and spare parts. The Pilbara service center is expected to employ around 40 skilled personnel from the local communities, including service engineers and experts. The service center will handle equipment including crushers, mills, screens and car dumper repairs, as well as a customer training facility.

“The new facility location has been chosen to provide enhanced local support to our customers in the Pilbara region and represents our long-term commitment in Australia. Our customers will now have even better access to services, repairs, parts, and technical expertise to maximize their operations’ performance”, says Stuart Sneyd, President for Metso Outotec in Asia Pacific.

Martin Karlsson, Senior Vice President, Professional Services, adds: “The facility complements our global network of service centers. We will provide our customers with strong operational support and leading process knowledge to deliver high performance and safety standards for an exceptional customer experience.”

The center also supports its customers’ sustainability commitments by delivering environmentally-efficient technologies and services. Metso Outotec has high sustainability targets in its own operations and supply chain. It is committed to reducing CO2 emissions from its own operations by 50% by 2024 and targets net-zero emissions by 2030.

Metso Outotec has an extensive footprint of over 3000 field services professionals and additional support resources close to customer operations. In Australia, the company employs approximately 900 people serving mining, metals, and aggregates customers.

Further information, please contact:

Stuart Sneyd, President, Asia Pacific market area, Metso Outotec, tel. + 61 8 9420 5500, email: stuart.sneyd(at)mogroup.com

Helena Marjaranta, Vice President, Communications and Brand, Metso Outotec, Tel. +358 20 484 3212, email: helena.marjaranta(at)mogroup.com

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Metso Outotec launches innovative Concorde Cell flotation technology for fine and ultra-fine particle recovery

Metso Outotec is launching groundbreaking Concorde Cell™ flotation technology for efficient fine and ultra-fine particle recovery. This innovative Planet Positive technology sets a new benchmark in high-intensity pneumatic flotation, reducing plant operation costs and contributing to sustainability of operations through minimized energy and water consumption per tons of metal produced.

The patented Metso Outotec Concorde Cell™ technology is the first fine and ultra-fine flotation solution for more finely disseminated and complex orebodies that have previously been inaccessible.

“The need to process more finely disseminated and complex ore grades, as well as the declining ore grades and the demand for improved flotation selectivity, all bring new challenges to minerals processing flowsheets. The new Concorde Cell™ technology helps flotation circuits overcome these challenges and recover the previously unachievable ore value,” says Antti Rinne, Vice President, Flotation at Metso Outotec.

Metso Outotec Concorde Cell

Metso Outotec Concorde Cell

The Concorde Cell™ forced-air Blast Tubes treat 100% of fresh feed combined with tailings recycling for improved performance, allowing finer grinding to get extra liberation without the risk of valuable particles lost into tailings.

“Combining the well-proven TankCell® technology with Concorde Cells is a low-risk and high-benefit approach for minerals processing flowsheets. The cell produces very high shear and extremely fine bubbles, which increases recovery in particles under 20 microns,” explains Rinne.

Benefits of the Concorde Cell™ flotation technology:

- Superior recovery of fine and ultra-fine particles

- Very high shear environment with increased bubble surface area flux for faster flotation kinetics

- Optimized froth recovery and improved selectivity

- Forced air allowing wider process control and stability for further flotation optimization

The offering also includes Blast Tube retrofit kits for upgrading the metallurgical performance of self-aspirated pneumatic flotation cells to the Concorde Cell™ technology. In addition, Metso Outotec can provide a complete slurry handling package for the Concorde Cell, including pumps, spare parts, as well as optimization and maintenance services.

Discover more about the innovative Metso Outotec Concorde Cell™ technology on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki.

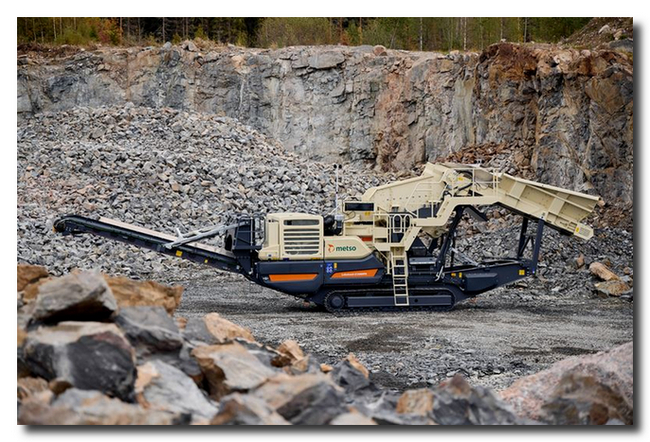

Metso Outotec expands Lokotrack mobile series for aggregates

Metso Outotec is launching two new models to the Lokotrack® mobile crushing and screening series. The new Lokotrack LT200HPX and Lokotrack LT220GP mobile cone crushers are compact but efficient units ideal for aggregate contractor customers, bringing up to 30% more capacity and added flexibility compared to earlier models. The new models will be premiered during Metso Outotec’s virtual studio events on 27th October, and in the new Lokotrack Liveroom 360 online experience together with services and parts offerings for Lokotrack. The new Lokotrack models are available globally as of 27th October.

Metso Outotec Lokotrack LT200HPX-3D

Metso Outotec Lokotrack LT200HPX-3D

More efficient aggregate operations

The launch models have many new features that are designed to improve the efficiency of customer’s operations. They are built on the same new chassis, allowing customers to choose between the two cone crusher types and various optional features based on their specific needs. The Lokotrack LT200HPX is equipped with an efficient two-deck pre-screen providing more capacity. Heavy duty chassis and wide conveyors facilitate high throughput, and a direct v-belt crusher drive ensures high fuel efficiency. Service and transportation are facilitated with extensive service platforms that fold down for transport. LT200HPX can be combined with Lokotrack LT106 and LT116 jaw crushers and Lokotrack ST3.8 and ST4.8 mobile screens.

The Lokotrack LT220GP provides additional crushing power and can be equipped with a pre-screen or with a belt feeder. LT220GP fits well with Lokotrack LT120/LT120E mobile jaw crushers and ST4.10 mobile screen for high-capacity aggregate production.

“The new models and our end-to-end offering displayed in the Lokotrack Liveroom, demonstrate our focus on improving aggregates customers’ operations and bottom line,” says Kimmo Anttila, Vice President, Lokotrack Solutions at Metso Outotec. “With these new models of 300 metrics tons per hour capacity and 40 metrics ton transport weight, the customers have even more choice and flexibility to select from our cone crusher range. Lokotrack is a sustainable and future-proof choice for any type of aggregate production.”

Metso Outotec Lokotrack LT200HPX

Metso Outotec Lokotrack LT200HPX

Extensive service and support portfolio

Metso Outotec offers extensive services and parts support for Lokotrack, including for example spare and wear parts recommendation lists and kits, full container load parts service, inspections and extended warranties and the Metrics remote monitoring solution. The service portfolio showcased in the Liveroom addresses the needs of aggregates customers in terms of equipment protection, availability, performance, and upgrades. These services are aimed at helping Lokotrack crushing and screening assets operate at their optimal levels.

Join the studio events and visit the Lokotrack Liveroom at live.mogroup.com.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

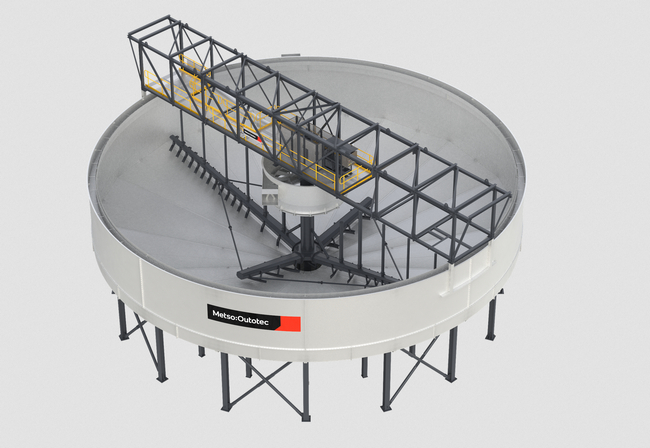

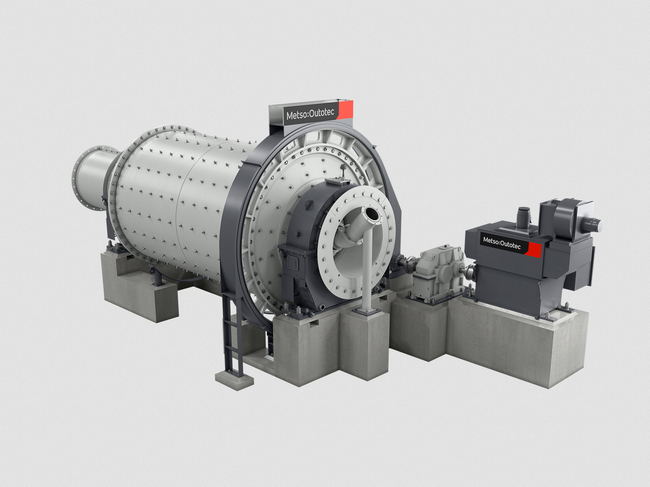

Metso Outotec to deliver grinding mills and thickeners to a nickel plant in Indonesia

Metso Outotec has been awarded a contract for the delivery of several horizontal grinding mills and thickeners to a greenfield nickel project in Indonesia.The value of the order is approximately EUR 24 million, and it has been booked in Minerals’ Q3/2021 orders received.

Metso Outotec’s scope of delivery includes five grinding mills with a total installed power of 10.6MW, as well as 13 HCT high-compression thickeners, which are part of the company’s Planet Positive offering.

Metso Outotec HCT thickner

Metso Outotec HCT thickner

“We are pleased to have been chosen as the supplier of this key equipment for this major project. A diligent verification process with the customer confirmed that Metso Outotec grinding mills and thickeners will provide significant added value to their process. The customer selected our grinding mills based on robust, proven technology, and industry leading availability. The HCT thickeners are proven to provide the best washing efficiency, thus reducing the loss of nickel metal in leaching residue,” says Markku Teräsvasara, President, Minerals and Deputy CEO of Metso Outotec.

Discover more about Metso Outotec thickening and clarification solutions here. For more information about our grinding mills, please visit the related product pages on our website.

Metso Outotec Select mill

Metso Outotec Select mill

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

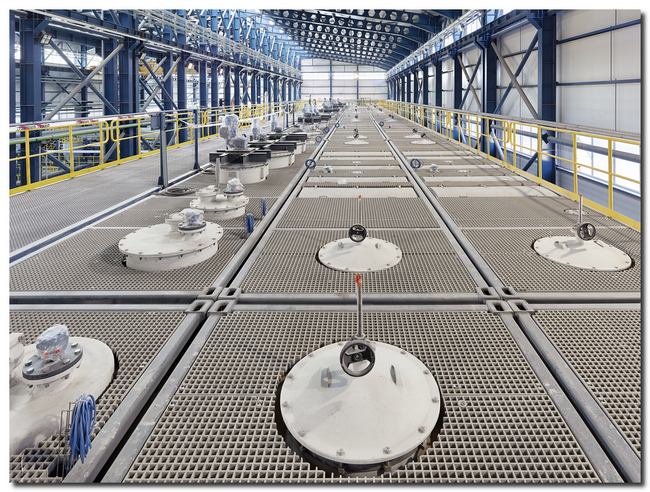

Metso Outotec to deliver modular cobalt solvent extraction technology to Canada

Metso Outotec has signed an agreement with the Canadian battery materials company First Cobalt Corporation to deliver Planet Positive solvent extraction technology to their cobalt refinery expansion in Ontario. The value of the order is approximately EUR 10 million, and it has been booked into Metals’ Q4/2021 orders received.

Metso Outotec’s scope of delivery includes the engineering and supply of a modular VSF®X solvent extraction plant. First Cobalt aims at producing 25,000 tonnes of traceable, high-quality, battery-grade cobalt sulfate annually. Their refinery in Ontario is currently the only permitted producer of battery-grade cobalt for the North American electric vehicle market.

“We are happy to be moving forward with Metso Outotec, an industry-leading business partner. Metso Outotec was selected based on its competitive pricing and technically superior bid. The contracted solution involves the latest advancements in solvent extraction in terms of modular design, process control, and ease of installation and start up,” explains Trent Mell, President & CEO of First Cobalt.

Metso Outotec VSF x solvent extraction lines

Metso Outotec VSF x solvent extraction lines

“We are excited to start working on this ambitious project with First Cobalt. To date, we have sold almost 50 solvent extraction plants worldwide, 11 of which represent the proven modular VSF®X technology. This will be our first VSF®X solvent extraction plant in Canada,” says Mikko Rantaharju, Vice President, Hydrometallurgy, at Metso Outotec.

Read more about our solvent extraction technologies on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

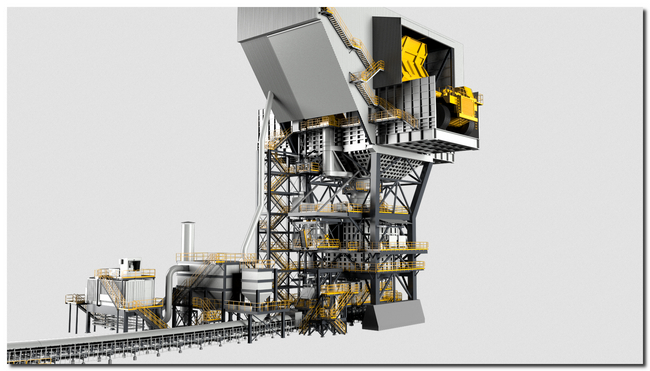

Metso Outotec wins order for Foresight™ semi-mobile primary gyratory crushing plant at Codelco’s Radomiro Tomic operation

Metso Outotec has signed an agreement with Codelco in Chile to design and supply a Foresight™ semi-mobile primary gyratory (SMPG) crushing plant for Codelco’s Radomiro Tomic operation. The value of the order is not disclosed. It has been booked in Minerals’ Q3/2021 orders received.

Equipped with a Superior™ MKIII 60-110 primary gyratory crusher, apron feeder discharge and dust collection, the Foresight™ SMPG meets the highest demands in productivity and sustainability. It is part of Metso Outotec’s in-pit crush and convey solutions (IPCC) portfolio.

“We have extended our Planet Positive offering in June of this year, launching our IPCC solutions, combining the right team, technology, and services to redefine productivity in this space. We highly appreciate Codelco’s continued trust in us to deliver significant crush and convey infrastructure to meet Codelco’s demanding operational and sustainability goals,” says Markku Teräsvasara, President, Minerals.

Foresight™ semi-mobile primary gyratory crushing plant

Foresight™ semi-mobile primary gyratory crushing plant

“We are honored Codelco has chosen us to deliver this significant project in Radomiro Tomic and extend the fleet of Superior™ primary gyratory crushers at that site. With more than 1,300 employees and integrated fabrication of wear materials in Chile, we service our fleet of crushers wholistically and look forward to supporting this plant as well,” says Eduardo Nilo, President, South America Market Area.

Metso Outotec’s integrated modular in-pit crush and convey solutions consist of crushing, conveying, and stacking equipment combined with IPCC planning and life cycle services. The offering is designed to ensure the highest productivity, energy efficiency, and maintainability. Metso Outotec IPCC solutions with their improved energy efficiency are part of the company’s Planet Positive portfolio. In-pit crush and convey operations also reduce haulage related energy consumption and CO2 emissions.

Discover more about in-pit crush and convey technology at mogroup.com/ipcc

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Metso Outotec and Phu Thai Cat to start distribution cooperation

Metso Outotec and Phu Thai Cat (PTC) have signed a distribution contract for Metso Outotec’s aggregates solutions in Vietnam, Laos, and Cambodia. The agreement includes a wide choice of Metso Outotec’s mobile, portable, and stationary crushing and screening equipment, crusher wear parts, screening media and parts. The contract has come into effect in September 2021.

The demand for aggregates in the territory is estimated to grow significantly in the coming few years thanks to the implementation of major infrastructure projects. Because of the development, aggregates customers are focusing more on production efficiency and output material quality that Metso Outotec’s premium crushers are perfect for.

“We are very pleased to start the cooperation with Phu Thai Cat,” says Shaun Fanning, Vice President, Distribution Management Asia Pacific in Metso Outotec. “The combination of high market demand for aggregates solutions in the region and a professional partner like Phu Thai Cat, we look forward to an effective cooperation to grow our business. Most importantly we expect that with the cooperation our aggregates customers will enjoy better availability of our aggregates solutions and products, complemented by PTC’s strong local resources and support.”

“The cooperation allows us to provide alternative, high-efficiency solutions to aggregates customers,” comments Trinh Duc Thang, General Director, Phu Thai Cat. “The combination of high quality Metso Outotec aggregates solutions and our already proven product support capability will benefit the customers and help us to develop another profitable business by expanding the customer base while finding new opportunities with existing clients.”

The contract covers Metso Outotec’s Lokotrack® and Nordtrack™ track-mounted equipment, NW Series wheel-mounted equipment, Nordberg® C-Series jaw crushers, GP- and HP-Series cone crushers, NP-Series and Barmac® impact crushers, HRC grinding rolls, vibrating equipment, and conveyor belts. It also includes related wear parts and parts, such as crusher wears, O-Series wears, Trellex® screening media and Contender™ Series parts.

Phu Thai Cat provides construction and mining equipment, genuine parts, maintenance, repair, warranty and value solutions for aggregates, mining, and construction industries. They have five branches and 368 employees. Read more at their website: https://www.phuthaicat.com.vn/

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Metso Outotec introduces versatile portfolio of magnetic separators for improved recovery

Metso Outotec is introducing its versatile magnetic separators portfolio consisting of wet and dry Low Intensity Magnetic Separators and High Gradient Magnetic Separators. The portfolio caters to a wide variety of applications with the separators’ flexible modular design, enabling superior separation selectivity and improved recovery of fine and ultra-fine particles.

"We have a long history in magnetic separation, and we delivered the first separator back in the 1890s. Since then, we've developed and delivered thousands of magnetic separators worldwide. We are continuously developing our products securing our position at the forefront of the magnetic separation industry.” says Jan Jirestig, Product Manager, Magnetic Separators, Metso Outotec.

Metso Outotec High Gradient Magnetic Separators (HGMS) are designed to recover weakly magnetic material from non-magnetic matter and can be used for many applications including the processing of iron ores, rare earths and other weakly magnetic minerals, which are not normally treatable by ordinary magnetic separators.

Metso Outotec Magnetic Separator

Metso Outotec Magnetic Separator

The Low Intensity Magnetic Separators (LIMS), which are designed to recover magnetic material from non-magnetic matter, are part of Metso Outotec’s Planet Positive product offering. The separators use physical separation and don’t require chemicals in the process. The Low Intensity Magnetic Separators feature modular design with several frames and process tank designs and use a common magnetic drum for ease of selection of the best machine for each individual application.

Metso Outotec’s offering also includes the SLon® Vertically Pulsating High-Gradient Magnetic Separator (VPHGMS), which effectively processes fine, weakly-magnetic minerals. The units are wet, high-intensity magnetic separators that use a combination of magnetic force, pulsating fluid, and gravity to process minerals.

Discover more about Metso Outotec magnetic separators on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki.