Displaying items by tag: ANDRITZ

ANDRITZ to supply another high-efficiency PowerFluid circulating fluidized bed boiler to Japan

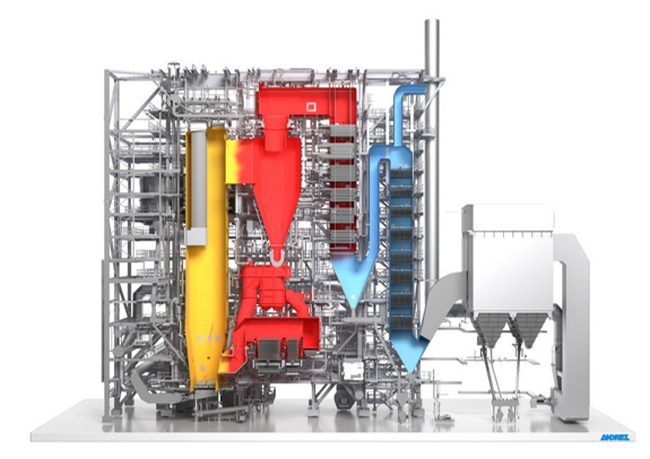

International technology group ANDRITZ has received another order from the HITACHI ZOSEN Corporation in Japan to supply a 52.7-MW PowerFluid circulating fluidized bed (CFB) boiler on EPS basis. The boiler will be part of the biomass power plant in Fukuyama, Hiroshima Prefecture, in Japan. Start-up is planned for 2025.

The ANDRITZ PowerFluid boiler will be integrated into a biomass-fired power generation facility that will be fueled by wood pellets, wood chips and palm kernel shells. With its high efficiency and state-of-the-art technology, it is the perfect solution to meet greenhouse gas reduction targets and contribute towards carbon neutrality in Japan. The biomass power plant will be capable of supplying power for roughly 110,000 Japanese households.

ANDRITZ PowerFluid circulating fluidized bed boiler. “Photo: ANDRITZ”.

ANDRITZ PowerFluid circulating fluidized bed boiler. “Photo: ANDRITZ”.

The new CFB project is the thirteenth ANDRITZ advanced CFB boiler for the Japanese market and demonstrates the excellent position ANDRITZ has in the biomass power plant market.

This order once again confirms ANDRITZ’s strong partnership with the HITACHI ZOSEN Corporation. ANDRITZ is proud to be part of this remarkable project and make another important contribution towards the Japanese power industry’s move from fossil fuel to renewable energy resources.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply new pickling and galvanizing line to Jiuquan Iron and steel (Group) Co., Ltd., China

International technology group ANDRITZ has received an order from Jiuquan Iron and Steel (Group) Co., Ltd., China, to supply a new, high-capacity pickling and galvanizing line for hot-rolled carbon steel strip.

Start-up of the line is planned for the end of 2023.

The ANDRITZ scope of supplies and services comprises the engineering, equipment supply, supervision of erection, and commissioning of the complete pickling and galvanizing line, including the electrical and automation equipment.

With ANDRITZ’s state-of-the-art, sustainable technologies, this line will produce hot-dip galvanized (GI) or ZM-coated /(zinc-aluminum-magnesium) flat steel.

Project team with customer JISCO at the ANDRITZ Shanghai Office © ANDRITZ

Project team with customer JISCO at the ANDRITZ Shanghai Office © ANDRITZ

This order confirms the good and long-lasting relationship between ANDRITZ and Jiuquan Iron and Steel (Group). In 2004, ANDRITZ delivered and successfully commissioned a hot annealing and pickling line and a cold annealing and pickling line for stainless steel for Jiuquan Iron and steel (Group). This was followed by two 20-high cold-rolling mills delivered in 2006. Additionally, ANDRITZ has performed various upgrades and modernizations on existing lines.

Established in China in 1958, Jiuquan Iron and Steel (Group) initially pursued coordinated development in six industrial sectors: iron and steel, nonferrous metals, electric energy, equipment manufacturing, producer services, and modern agriculture. The iron and steel industry has an annual production capacity of 11.05 million tons of crude steel (including 1.2 million tons of stainless steel).

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ METALS

ANDRITZ Metals is – via the Schuler Group – one of the world’s leading suppliers of technologies, plants and digital solutions in metal forming. The product portfolio also includes automation and software solutions, process know-how and service.

In the metals processing segment, the business area offers innovative and market-leading solutions for the production and processing of flat products, for welding systems and furnaces, as well as services for the metals processing industry.

ANDRITZ’S first biomass-fired CFB boiler in Japan reaches the end of the warranty period

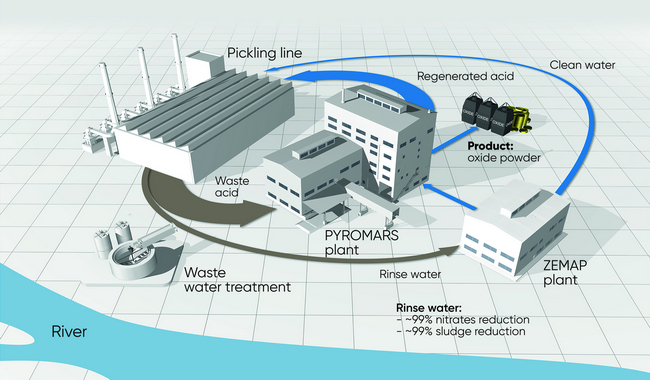

The ANDRITZ biomass-fired PowerFluid circulating fluidized bed boiler with flue gas cleaning system delivered to Mitsui Engineering and Shipbuilding for the biomass power plant in Ichihara, Chiba Prefecture, has been in commercial operation since December 2020 – after fulfilling all performance guarantee parameters in November 2020 as planned.

The Ichihara plant reached the end of the warranty period in December 2021.

The total project execution time from award of the order to the beginning of commercial operation was only 39 months, thus confirming ANDRITZ’s strong capabilities in management and timely execution of demanding projects.

Ichihara power plant is designed to produce 50 MWe electric power from biomass (wood pellets and palm kernel shells). The ANDRITZ PowerFluid boiler features high pressure and a reheat system in combination with high steam temperatures with the aim of achieving high plant efficiency and optimizing the utilization of valuable, high-grade biomass.

ANDRITZ biomass-fired PowerFluid circulating fluidized bed boiler with flue gas cleaning system for the biomass power plant in Ichihara, Japan © ANDRITZ

ANDRITZ biomass-fired PowerFluid circulating fluidized bed boiler with flue gas cleaning system for the biomass power plant in Ichihara, Japan © ANDRITZ

The ANDRITZ scope of supply comprised the engineering work, delivery, erection work, and start-up of the fluidized bed boiler, including a flue gas cleaning system with high-dust SCR and auxiliary equipment. The equipment and technologies supplied by ANDRITZ are essential parts of a high-efficiency biomass power plant for supply of green energy to the national grid.

With this biomass-fired CFB boiler, ANDRITZ has made an important contribution to the Japanese renewables initiative, supporting the Japanese power industry in the very promising transition from fossil fuel to renewable energy sources.

ANDRITZ has a strong market position for CFB boilers and is working at the moment on ten more CFB boiler projects in Japan (3 x 75 MWe and 7 x 50 MWe) that are currently in the start-up phase or will go into operation over the next few years.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ launches Turbex extractor for optimized valorization of functional nutrients

International technology group ANDRITZ has developed Turbex, a highly efficient extraction system to produce functional nutrients.

ANDRITZ Turbex helps to produce high-quality extracts from botanicals and natural products and turn waste such as orange peel or brewer’s spent grain (BSG) into revenue-generating nutrients.

This patented extraction technology works by generating high turbulence, shear, and cavitation, hundreds of times more than conventional extractors. It uses a series of rotors and stators to cause thousands of cavitation events per second, resulting in higher yields in shorter processing times. Assisted by a counter-current process, ANDRITZ Turbex delivers yields up to 50% higher than conventional systems. The low extraction temperature combined with the short processing time improves the product quality as oxidization of valuable polyphenols and antioxidants is avoided.

Requiring up to 30% less energy than conventional extraction methods, ANDRITZ Turbex has a faster return on investment and less environmental impact. The fact that it does not necessarily require ethanol as an extraction solvent but can operate using only water also reduces both costs and carbon footprint. Thanks to lower investment costs and operating expenses, Turbex also makes by-product valorization an attractive option for a broad variety of applications.

ANDRITZ Turbex extractor © ANDRITZ

ANDRITZ Turbex extractor © ANDRITZ

The Turbex extractor is an efficient method of extracting vegetable proteins, polyphenols, essential oils, extra virgin olive oil, antioxidants and (dietary) fiber from waste products such as spent brewer’s grain or coffee grounds, botanicals, tea leaves, citrus peel, or cannabis leaves. With the right extraction sequence and process parameters, the valorization process can be optimized in terms of purity and product composition to obtain products with maximum commercial value.

ANDRITZ Turbex can be installed as a retrofit to improve existing process line performance thus making a useful addition to process line solutions such as those in the ready-to-drink-tea market.

ANDRITZ will present the innovative Turbex at the Anuga FoodTec in Cologne, Germany from April 26-29, 2022 in hall 5.1 at booth D-088.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ SEPARATION

ANDRITZ Separation provides mechanical and thermal technologies as well as services and the related automation solutions for solid/liquid separation, serving the chemical, environmental, food, mining and minerals industries. The customized, innovative solutions focus on minimizing the use of resources and achieving highest process efficiency, thus making a substantial contribution towards sustainable environmental protection. In addition, the business area offers technologies and services for the production of animal feed and biomass pellets.

ANDRITZ to supply the 12th high-efficiency PowerFluid circulating fluidized bed boiler to Japan

International technology group ANDRITZ has received another order from Toyo Engineering Corporation in Japan to supply a 50-MWe PowerFluid circulating fluidized bed (CFB) boiler on EPS basis. The boiler will be part of the biomass power plant in Tahara-shi, Aichi Prefecture, in Japan. Start-up is planned for 2025.

The ANDRITZ PowerFluid boiler will be integrated into a biomass-fired power generation facility that will be fueled by wood pellets. With its high efficiency and state-of-the-art technology, it is the perfect solution to meet greenhouse gas reduction targets and contribute towards carbon neutrality in Japan. The biomass power plant will be capable of supplying power for roughly 110,000 households in Japan.

This order once again confirms ANDRITZ’s strong partnership with Toyo Engineering Cooperation. ANDRITZ is proud to be part of this remarkable project and make another important contribution towards the Japanese power industry’s move from fossil fuel to renewable energy resources.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ to supply complete electro- and hydro-mechanical equipment for the Nenggiri hydropower station, Malaysia

International technology group ANDRITZ – as part of a consortium – has signed a contract with TNBPG Hydro Nenggiri Sdn. Bhd. (a wholly owned subsidiary of TNB Power Generation Sdn Bhd.) to supply the complete electro- and hydro-mechanical equipment for the new Nenggiri Hydroelectric Project in Kelantan, the northeastern state of the Malay Peninsula.

Commissioning is scheduled for the middle of 2026. The contract value for ANDRITZ is more than 100 million euros.

The scope of supply of the consortium includes two Francis turbine generating units including complete mechanical and electrical balance of plant and hydro-mechanical equipment as well as the high voltage switchyard.

Once completed, the Nenggiri Hydroelectric Project will provide 300 MW of peak load coverage to significantly stabilize the national power grid. Flood mitigation benefits for the downstream areas are another important target of the hydropower station.

The Nenggiri Hydroelectric Project is one of several government-approved projects to meet the growing energy demand of Malaysia and to increase the share of renewable energy in its energy mix to 40 percent by 2035.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ HYDRO

ANDRITZ Hydro is one of the globally leading suppliers of electromechanical equipment and services for hydropower plants. With over 180 years of experience and an installed fleet of more than 470 GW output, the business area provides complete solutions for hydropower plants of all sizes as well as services for plant diagnosis, refurbishment, modernization, and upgrade of existing hydropower assets. Pumps for irrigation, water supply and flood control as well as turbo generators are also part of this business area’s portfolio.

ANDRITZ successfully starts up pressurized refining system at Biyang Huifeng, China

International technology group ANDRITZ has successfully completed the start-up of a pressurized refining system supplied to Biyang Huifeng Wood Industry Board Co., Ltd. at its MDF production plant in Biyang, Henan province, China.

With the new ANDRITZ pressurized refining system, the customer is capable of processing poplar wood chips as raw material. The heart of the new system is the innovative ANDRITZ 54-1CP refiner, which features high energy efficiency. The scope of supply also included a maintenance-friendly 20” discharger with the latest C-feeder concept, a compensator and a proven 20” ribbon feeder.

Weng Duansheng, Vice General Manager at Biyang Huifeng, says, “The excellent operation of our first pressurized refining system installed by ANDRITZ in our Jiangsu mill convinced us to trust once more in the know-how of ANDRITZ’s panelboard experts. The successful and timely start-up of our new line has proven that our decision was the right one.”

From left to right: Huang Yongli, MDF Technology Manager, ANDRITZ; Li Xingfeng, Vice General Manager, Biyang Huifeng; Weng Duansheng, Vice General Manager, Biyang Huifeng; Yu Hongsheng, Process Control Engineer, ANDRITZ; and Wang Hongren, Workshop Manager, Biyang Huifeng.

From left to right: Huang Yongli, MDF Technology Manager, ANDRITZ; Li Xingfeng, Vice General Manager, Biyang Huifeng; Weng Duansheng, Vice General Manager, Biyang Huifeng; Yu Hongsheng, Process Control Engineer, ANDRITZ; and Wang Hongren, Workshop Manager, Biyang Huifeng.

Michael Rupp, Vice President for Panelboard Systems at the ANDRITZ Paper, Fiber and Recycling Division, adds, “We always aim to continuously optimize our technology and services for our customers. Thus, it’s a pleasure to work with a forward-thinking customer like Biyang Huifeng, who values our efforts.”

Successful start-up of the new pressurized refining system in Biyang once again demonstrates ANDRITZ’s strong position in the Chinese panelboard industry, with more than 180 installations.

Biyang Huifeng Wood Industry Board was established in 2017 and is mainly active in the wood-working and panelboard industry.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient, and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power production, flue gas cleaning plants, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

ANDRITZ to supply new pickling line for aluminum strip to AMAG Rolling GmbH

International technology group ANDRITZ has received an order from AMAG Rolling GmbH, a member of the Austrian company AMAG GROUP, to supply a new strip pickling line for its facility in Ranshofen.

The new strip pickling line #2, with planned annual production of 30,000 tons (gross), will go into operation in mid-2023.

ANDRITZ will supply the complete strip pickling line as well as a new, integrated wastewater treatment plant, including design, engineering, delivery, installation, start-up, and optimization of production.

An autonomous coil transport brings the coils to the line and then collects the coils produced. Metris Intelligent Coil, an innovative, digital solution developed by ANDRITZ Automation, logs all coil-specific production data and provides support in optimizing quality and productivity as well as in achieving and verifying sustainability goals (CO2 footprint, consumption of resources).

AMAG Rolling and ANDRITZ: group photo at the contract signing ceremony © AMAG Rolling

AMAG Rolling and ANDRITZ: group photo at the contract signing ceremony © AMAG Rolling

The new equipment technology with a highly efficient spray pickling system is designed for both hot-rolled and cold-rolled strip in order to cover the broad product portfolio of AMAG Rolling. Special focus lies on careful production of bright products. The new strip pickling line allows fast product changes and hence, very flexible production planning.

The award of this order to ANDRITZ underlines the many years of successful collaboration between these two prestigious Austrian companies. Following several plant modernization and production expansion projects, this new strip pickling line with its special wastewater treatment plant is now the next step in this long-term business relationship.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ METALS

ANDRITZ Metals is – via the Schuler Group – one of the world’s leading suppliers of technologies, plants and digital solutions in metal forming. The product portfolio also includes automation and software solutions, process know-how and service.

In the metals processing segment, the business area offers innovative and market-leading solutions for the production and processing of flat products, for welding systems and furnaces, as well as services for the metals processing industry.

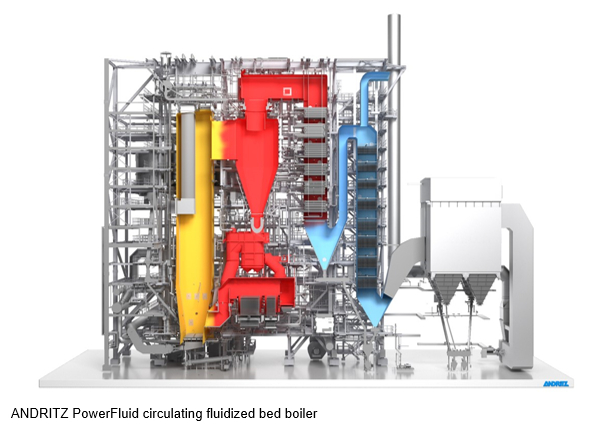

ANDRITZ to supply two new mixed acid recovery systems (Pyromars) to Walsin Lihwa

International technology group ANDRITZ has received an order from Walsin Lihwa, Taiwan, to supply two Pyromars plants with capacities of 4,500 l/h and 6,500 l/h for their wire rod production sites in Yantai, China, and Yenshui, Taiwan.

Start-up of the plants is scheduled for the first quarter of 2023.

ANDRITZ Pyromars plant © ANDRITZ

ANDRITZ Pyromars plant © ANDRITZ

The ANDRITZ scope of supply includes the mechanical and electrical equipment as well as supervision of erection work and commissioning.

The ANDRITZ mixed acid recovery systems will significantly reduce the nitrates in the wastewater and enable nitric and hydrofluoric acids to be recovered, thus saving consumption of fresh acid in Walsin Lihwa’s wire rod pickling plants. In addition, this investment in sustainable operation will strongly reduce the amounts of wastewater and sludge produced.

Walsin Lihwa is a strong business partner of ANDRITZ and is already operating a Pyromars plant and two ZEMAP systems that ANDRITZ has supplied.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.

ANDRITZ METALS

ANDRITZ Metals is – via the Schuler Group – one of the world’s leading suppliers of technologies, plants and digital solutions in metal forming. The product portfolio also includes automation and software solutions, process know-how and service.

In the metals processing segment, the business area offers innovative and market-leading solutions for the production and processing of flat products, for welding systems and furnaces, as well as services for the metals processing industry.

ANDRITZ to supply two fiber preparation systems for insulation material to Naturheld, Germany

International technology group ANDRITZ has received orders from Naturheld GmbH to supply two fiber preparation systems for its new production line in Grafenwöhr, Germany. With this project, Naturheld is also entering the insulation material sector. Start-up is scheduled for the second half of 2022.

ANDRITZ’s scope of supply comprises two lines with a state-of-the-art pressurized refining system, each featuring a capacity of up to 10 t/h and including the following technological highlights:

- Plug Screw Feeder for optimum dewatering prior to refining and advanced wear protection for longer screw lifetime

- C-Feeder for constant feeding of wood chips to the HC refiner and stable operation over the entire capacity range

- 44-1CP refiner for production of high-quality fibers with lowest possible energy consumption

From left to right: Reinhard Schlager, Manager R&D, ANDRITZ; Andreas Sandner, General Manager, Naturheld; Christian Rosypal, Sales Engineer, ANDRITZ; Robert Friedl, General Manager, Naturheld; Michael Rupp, Vice President for Panelboard Systems, ANDRITZ; Sebastian Forster, Project Manager, Naturheld; and Stephan Lohmeyer, General Manager, Scantec “Photo: ANDRITZ”.

From left to right: Reinhard Schlager, Manager R&D, ANDRITZ; Andreas Sandner, General Manager, Naturheld; Christian Rosypal, Sales Engineer, ANDRITZ; Robert Friedl, General Manager, Naturheld; Michael Rupp, Vice President for Panelboard Systems, ANDRITZ; Sebastian Forster, Project Manager, Naturheld; and Stephan Lohmeyer, General Manager, Scantec “Photo: ANDRITZ”.

The systems will process a mixture of spruce and pine wood chips from Naturheld’s own wood processing plant, producing premium fiber material for flexible and hard insulation board as well as for blown-in insulation.

Robert Friedl, General Manager of Naturheld says: “The meetings with ANDRITZ headed in the right direction from the very beginning! The clear focus on ecological and economical production and the technical competences convinced us that we should enter the insulation material sector with ANDRITZ as our partner. Their experience in machine construction and customer-oriented approach to collaboration were both impressive and enjoyable!”

Michael Rupp, Vice President for Panelboard Systems in the ANDRITZ Paper, Fiber and Recycling Division, adds: “We are very impressed by Naturheld’s holistic approach, such as their regional wood supply or highly energy-saving and zero-wood-waste production process. We are looking forward to seeing ANDRITZ technology providing top performance in Naturheld’s new insulation material production facility.”

Naturheld is part of the Ziegler Group, an owner-managed company with more than 20 locations throughout Germany and almost 2,000 employees. The group has its origins in the wood industry and is also active in logistics, house construction, mechanical engineering, interior decoration, and the restaurant trade.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.