A team of students from Eindhoven University of Technology has succeeded in developing an all-electric, ultra-fast charging prototype race car. Set to roar into action at the Le Mans 24-hour endurance racing event in France, the team leveraged the advantages of Danfoss technology to solve its fluid conveyance challenges.

All-electric racing cars are not new, but how does the endurance motorsport segment join the green revolution, where events require the rapid recharging of race cars? Enter InMotion, a student team from Eindhoven University of Technology in the Netherlands which set out to develop an all-electric race car with ultra-fast charging capabilities.

Electric refueling

To help take InMotion’s fast charging technology (called electric refueling) from concept to reality, the team reached out for technology sponsors. PowerFlex, an expert supplier of hose solutions based in Weesp, Netherlands, stepped up to the challenge. The company is a long-term Danfoss Power Solutions distribution partner.

“We saw huge potential in their ambitious project,” said Ruggero Grillo, marketeer at PowerFlex. “We believed in their goal, their underlying technology and their passion, so we were proud to support them and help accelerate the motorsport sector’s transition to a green energy future.”

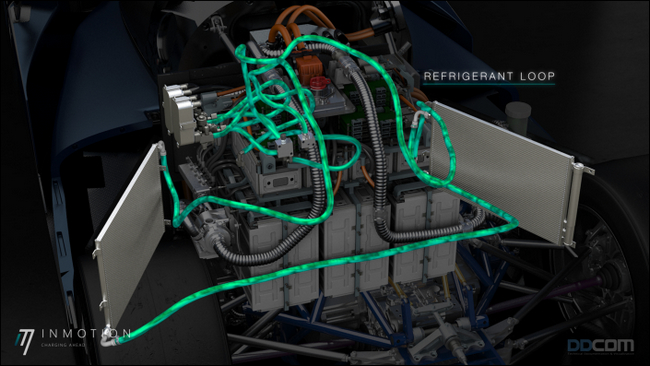

The PowerFlex team was tasked with helping InMotion identify the optimal fluid conveyance solutions to meet several of The Revolution race car’s key challenges. These included minimizing heat buildup in the 58 kilowatt-hour battery pack during fast charging, enabling quick battery disconnection, and delivering efficient cooling.

Battery pack cooling

To maintain the optimal battery pack temperature during fast charging, PowerFlex recommended the Danfoss Evercool GH001 multi-refrigerant hose and fittings due to advantages that include near-zero permeation, tight bend radius, wide temperature range, and compatibility with many refrigerants.

In addition, the Danfoss EZ Clip system for hose assemblies gave the InMotion team flexible installation options without the need to invest in costly crimp tooling, while Danfoss Hansen aluminum dry-break ADB couplings were chosen for quick and easy battery connection and disconnection without fluid loss or air infiltration.

Finally, to optimize heat distribution from the race car’s battery pack, PowerFlex provided various Aeroquip by Danfoss Performance Products, including hoses, fittings, and adapters. Throughout the project, the knowledge and experience of PowerFlex was a crucial asset in The Revolution race car’s successful development, providing InMotion with on- and off-site technical guidance, testing, servicing, and more.

“Offering a low weight-to-power ratio, high performance, and racing-level quality, the Danfoss components we chose were designed for exactly this kind of challenge — and they delivered,” stated Grillo.

12-minute charge

InMotion’s prototype race car is now able to reach an 80% state of charge from near depletion in just 12 minutes. The installed solutions keep the vehicle as lightweight as possible, while also making it easier for InMotion to assemble or reconfigure systems. Importantly, The Revolution endurance race car remains on course to showcase the game-changing potential of fast charging at the world-famous Le Mans.

For further details, please view the full case study.

About Danfoss

Danfoss engineers solutions that increase machine productivity, reduce emissions, lower energy consumption and enable electrification. Our solutions are used in such areas as refrigeration, air conditioning, heating, power conversion, motor control, industrial machinery, automotive, marine, and off- and on-highway equipment. We also provide solutions for renewable energy, such as solar and wind power, as well as district-energy infrastructure for cities. Our innovative engineering dates back to 1933. Danfoss is family-owned, employing more than 40,000 people, and serving customers in more than 100 countries through a global footprint of 95 factories.