Super User

Turmoil as Russia Invades Ukraine

Massive risk-aversion is sweeping through financial markets on Thursday in response to Russia's invasion of Ukraine.

The Russian offensive started in the early hours of the morning in Europe and has been occurring across the country. The mood turned increasingly negative as the morning progressed, with headlines and images displaying the atrocities taking place in Ukraine.

The knee-jerk reaction has been severe across the board and with the situation deteriorating by the hour, we could see further risk-aversion over the coming days. There remains huge uncertainty about how far Russia will go in Ukraine and what the knock-on effects will be across the globe, which could continue to weigh heavily on risk appetite.

The knee-jerk reaction has been severe across the board and with the situation deteriorating by the hour, we could see further risk-aversion over the coming days. There remains huge uncertainty about how far Russia will go in Ukraine and what the knock-on effects will be across the globe, which could continue to weigh heavily on risk appetite.

This comes at a time when the global economy was already facing numerous challenges as it emerges from the pandemic. There will no doubt be consequences for the global economy, with recent moves in the oil and gas market compounding those pressures that were already being felt by households and businesses this year.

It also creates enormous uncertainty for central banks around the world as, on the one hand, higher oil and gas prices will intensify the inflationary pressures that they're already trying to fight with rate hikes. But on the other hand, if they suppress economic activity and weigh on demand, it could help alleviate some of those pressures they're most concerned about.

As it stands, we're not seeing any massive shift in interest rate expectations but that could change if energy prices continue to rise in response to the Kremlin's actions in Ukraine. In many ways, Russia has passed the point of no return as painful economic sanctions are coming. Just how painful that will be for them and the rest of the world is still to be determined.

Oil above $100 and could keep going

Oil prices are soaring in response to the Russian invasion of Ukraine as traders are forced to price in sizeable risk premiums associated with the conflict. The market is already extremely tight and unable to easily contend with supply issues and, barring a shift in approach from certain producers with excess capacity, that's not going to change.

With oil prices well above $100 - up around 7% on the day - and gas prices surging once more, the question becomes just how far they will go. There's enormous uncertainty around how bad the situation will become in Ukraine and what impact that will have on supplies of oil and gas. The knee-jerk reaction has been strong and we could see prices settle if no further major escalations occur. Unfortunately, that's a massive "if" given how today has progressed.

Gold could eye highs after the invasion

Gold prices are spiking as traders are drawn to the traditional safe haven in these turbulent times. The conflict in Ukraine brings enormous uncertainty which strengthens gold's appeal as both a safe haven and an inflation hedge. The price has already hit its highest level since September 2020 and could have further levels in its sights.

The next big test will be $2,000, where it has only traded above briefly in August 2020, hitting a high that month around $2,072. The worse the situation becomes in Ukraine, the more likely it is that we'll see those levels once more.

By Craig Erlam, Senior Market Analyst, UK & EMEA, OANDA

Reinforced focus on sustainability with CSR specialist

To accelerate sustainability implementation, the Lesjöfors Group has recruited a Head of Sustainability. Anna Haesert is well experienced from several Swedish industrial companies. Reviewing the entire value chain, from purchasing to the final products, is one of the prioritized areas.

The position as Head of Sustainability is new to the group. Lesjöfors, with many manufacturing companies, is the natural organization for the position. Being a member of the executive management team gives a strong foundation as well as an overall strategic outlook for the whole Beijer Alma Group. Anna Haesert comes most recently from Boliden but has also worked for Atlas Copco and in the chemical industry. She has just finished her first month in our group and these are some of her first impressions.

What is your mission as Head of Sustainability?

“I must get to know the companies closely to fully understand their operations in order to be able to accelerate the sustainability work together with the managements. We will map the current situation, define what sustainability means for our group and set objectives based on that. Then we chart a path together how we should fulfill them. I feel a strong mandate from the Group management that this is a business-critical area where we must be one-step ahead in order to live up to current and future customer requirements and external regulations. Also for the next generation of employees, sustainability will be a decisive factor in their choice of employer. For many reasons, we must therefore make the necessary efficiencies and investments.”

Anna Haesert

Anna Haesert

How do you think Lesjöfors has performed regarding sustainability so far?

“Both Lesjöfors and the entire Beijer Alma group have worked progressively with sustainability issues for many years. The group has taken many important steps like implementing an extensive Code of conduct and pinpointing prioritized areas. Many exciting projects for the environment and climate have been completed, such as the biogas project in Lesjöfors and the solar cell park in Värnamo. Investments in digitization and new technology streamlining operations are also examples of fruitful sustainability work.”

What sustainability objectives are possible to set for a manufacturing company?

“It is inevitable that industrial companies use a lot of energy. That is why the whole chain is important to review and streamline where we can. With great interest, we will follow the fossil-free steel production development closely with H2 Green Steel and Hybrit in the north of Sweden. Other important areas to work with are also business ethics and our contribution to the development of the local communities in which we operate.”

Have you already located prioritized focus areas for the nearest future?

“Our aim is to put effort into overseeing the entire value chain, which also will become an increasingly important customer requirement. We need to ensure that, for example, materials that we purchase and transportation meet our high sustainability demands. We also want to look deeper into the final products in which our components are used.”

Can you mention something that you bring from previous employers that Lesjöfors can benefit from?

"Important areas where I am experienced are supplier evaluation based on environmental and social aspects as well as eco-design in product development, which I think the group can benefit from."

The Lesjöfors Group provides the widest range of springs and pressings to customers in diverse industries across the world. With a unique expertise in high technological, custom-made solutions and a flexible manufacturing capacity, Lesjöfors is the premier partner for all spring requirements. Lesjöfors, owned by Beijer Alma a listed company on the Stockholm Stock Exchange, comprises almost 40 manufacturing and sales companies in many countries. As a long-term and committed spring innovator, the Group continuously grows with a good profitability, both organically and by acquisitions.

Little prospect for Europe to reduce its dependence on Russian gas in the short term, says GlobalData

Following the news that Russia has invaded breakaway territories in Ukraine;

Veronika Kustkova, Senior Oil & Gas Analyst at GlobalData, a leading data and analytics company, offers her view:

“With Nord Stream 2 coming to a halt, Germany will be losing the additional 150 million cubic metres per day of gas coming from the envisaged pipeline. Gas transit through Ukraine currently holds a yearly capacity of over 100 billion cubic metres (Bcm). As the crisis unfolds, the massive gas imports route via Ukrainian trunk pipelines may stop at any point. This brings an immediate threat to Europe while withdrawals from gas storages continue to rise, but it is doubtful they’ll reach 2018 historical lows.

“With Nord Stream 2 coming to a halt, Germany will be losing the additional 150 million cubic metres per day of gas coming from the envisaged pipeline. Gas transit through Ukraine currently holds a yearly capacity of over 100 billion cubic metres (Bcm). As the crisis unfolds, the massive gas imports route via Ukrainian trunk pipelines may stop at any point. This brings an immediate threat to Europe while withdrawals from gas storages continue to rise, but it is doubtful they’ll reach 2018 historical lows.

“European demand for gas has increased since 2020 and is expected to stay at the same level in the short term, placing Europe in an uncomfortable position as Qatar has already declared they will not be able to fulfil the supply shortage. According to Eurostat and GlobalData analysis Russian imports made up 45% of EU imports in the first 10 months of 2021. Similarly, Russian gas exports are reliant on Europe and Turkey, which made up around 78% in 2021 despite increasing volumes going to China.

“An alternative source of gas is US LNG imports, but volumes will be constrained by capacity. However, medium-term increases will depend on new projects with the likes of the Rio Grande, which has already seen a delay. However, in the past two months we have seen the US LNG imports to Europe taking over from Russian pipeline gas for the first time in history. Another offset could be from wind and solar, but we will only see a substantial 7% increase in the European energy mix in 2025.”

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

First My Energy Future LIVE attracts 100 students to build UK as leader in net zero skills

Today, (24 February 2022) OPITO, the global safety and skills organisation, hosted more than 100 students at the world’s largest subsea exhibition and conference as part of the first My Energy Future LIVE event, designed to showcase the opportunities a career in energy can offer.

- 5 schools participated in My Energy Future LIVE’s inaugural event at Subsea Expo, Aberdeen

- The STEM programme is part of My Energy Future, OPITO’s interactive STEM platform which launched in 2021

- STEM challenges were led by OPITO, Global Underwater Hub, TechFest and The Royal Navy

The event, which took place during Subsea Expo, delivered by Global Underwater Hub, at the P&J Live exhibition and conference centre, was attended by students from 5 schools across the North East of Scotland.

Formerly known as Energise Your Future, My Energy Future LIVE brings together the next generation of talent and industry experts, giving pupils the chance to explore the exciting career opportunities available across the oil and gas, hydrogen, carbon capture usage and storage and offshore wind.

The inspirational event saw young people work in teams to complete various exciting STEM challenges such as building the most efficient wind turbine. Tasks were delivered by Scottish STEM education charity TechFest, STEM Ambassadors in Scotland and The Royal Navy, in partnership with OPITO and Global Underwater Hub.

Students were also given the opportunity to tour the exhibition to learn about the businesses driving the energy transition such as Motive Offshore and Prevco Subsea, try out the technologies on show including augmented reality and diving equipment, and discover emerging roles and routes into the sector.

Andy Williamson, Head of Energy Transition at OPITO, commented: “Initiatives like My Energy Future LIVE are an investment in our future. As identified in the OPITO UKCS Workforce Dynamics Review, the energy sector needs to recruit 25,000 people by 2025, with around 4,500 in roles that don’t currently exist.

“At OPITO, we are playing our part by continuing to create new products and standards to develop a skilled and competent workforce that can work across the integrated energy mix. My Energy Future LIVE events give pupils the chance to take part in hands-on STEM challenges and hear real-life experiences from industry personnel at a critical time when they are considering their future career path. It is essential we ignite passion in our young people and encourage them to pursue a career in energy to achieve our shared net zero ambitions.

“After such a positive start to our first MEF LIVE event, we are looking forward to rolling this out across the UK in the coming months.”

Trish Banks, operations director at Global Underwater Hub has been involved with the GUH STEM Challenge as well as other OPITO-led STEM initiatives for more than a decade. She said: “This year’s My Energy Future Live event has been incredibly positive and the school pupils taking part all showed a real enthusiasm for the underwater energy industry. It has been really encouraging to see so many young people considering a future career path in our sector as we continue on our journey towards Net Zero.”

The re-brand of My Energy Future LIVE (formerly Energise My Future) comes following last year’s launch of My Energy Future, OPITO’s interactive STEM platform, designed to engage young people and spark their interest in a career in the energy. The previous Energise My Future events of the same format have been held as part of major energy industry events and delivered through standalone sessions since 2008.

About OPITO

OPITO is the global skills organisation for the energy industry. Up to 375,000 people are trained to OPITO standards every year, across 50 countries through 230 accredited training centres. OPITO works to develop a safe and skilled workforce by driving global standards and qualifications, creating workforce development solutions and leading dialogue with industries and governments. With operation centres in four regions- UK and Europe, Middle East and Africa, Asia Pacific, and the Americas- OPITO is driving safety and competency improvements to benefit the industry and providing career pathways and training opportunities for the current workforce and the next generation.

About Subsea Expo

Subsea Expo is organised by industry body Global Underwater Hub and is the largest subsea-focused event in Europe, attracting over 5,000 delegates and 150 exhibitors. For more information visit: www.subseaexpo.com

Green hydrogen has potential to be a game changer for the power industry, says GlobalData

Hydrogen’s noteworthy contribution to clean energy transitions makes it a game changer for the power industry, says GlobalData. The leading data and analytics company notes that the power industry can leverage hydrogen’s potential as a cleaner burning alternative to conventional fuels in the evolving hydrogen economy.

GlobalData’s report, ‘Hydrogen in Power – Thematic Research’, notes that, while the cost of producing hydrogen from renewable energy sources is currently expensive, the momentum that has been built along the entire value chain is accelerating the cost reduction in hydrogen production, transmission, distribution, retail, and end-applications. Now is the time to scale up low-carbon technologies and lower their costs, so that hydrogen technology can be widely utilized.

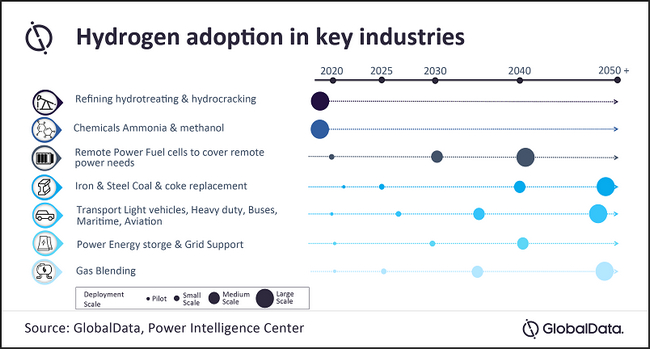

Sectors such as oil refining and ammonia, methanol, and steel production have been using hydrogen extensively. Hydrogen will play a critical role in the transition to clean energy with the advancement of its applications in sectors such as transportation (fuel cell vehicles), buildings (hydrogen blending), and power generation.

Sneha Susan Elias, Power Analyst at GlobalData, comments: “Currently, in the power industry, hydrogen plays a minimal role and accounts for less than 0.2% of electricity generation, according to the International Energy Agency. However, a change is highly possible in the near future, as the mixing of ammonia can decrease the impact of carbon in existing conventional coal-fired power plants, hydrogen gas turbines, and combined-cycle gas turbines (CCGT). When it comes to long-term and large-scale energy storage, hydrogen (in the form of compressed gas, ammonia [NH3], or synthetic methane) has a role to play in balancing seasonal variations in electricity supply and demand from renewable energy sources.”

Hydrogen is becoming popular as a low or zero-carbon energy source. The major growth markets for green hydrogen include green hydrogen replacing grey hydrogen and new markets such as energy storage, buildings, and transportation. Several countries have begun to consider a hydrogen-based economy as a solution to increasing carbon emissions, energy stability, and climate change issues. Green hydrogen presently has a small share in the production mix but is poised to increase, given the ambitious targets announced by countries. Through the Hydrogen Strategy for a Carbon Neutral Europe (EU Green Deal), the EU targets for a renewable hydrogen electrolyzer capacity of 6 GW by 2024 and 40 GW by 2030. India unveiled its National Hydrogen Mission in 2021 and aims for 5 million tonne (MT) green hydrogen production by 2030. Australia’s National Hydrogen Strategy plans to set up hydrogen hubs regions wherein users of hydrogen are co-located to take advantage of existing users or potential hydrogen markets.

Elias concludes: “With global leaders in the energy industry in search of solutions that will help them to achieve decarbonization or enhance energy security, hydrogen is on track to becoming an energy vector and its use is gathering momentum.”

- Quotes provided by Sneha Susan Elias, Power Analyst at GlobalData

- Information based on GlobalData’s thematic report: ‘Hydrogen in Power - Thematic Research’

- This press release was written using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

Brammer Buck & Hickman and SKF release range of informative resources on bearings in food & drink applications

Brammer Buck & Hickman, the UK’s leading supplier of industrial maintenance, repair and overhaul (MRO) products and services, has released a range of valuable resources on bearings aimed specifically at engineers operating in the food and drink sector; these include a webinar, a dedicated website section, a product brochure, a guide to the challenges faced in this sector, and several case studies.

In the food and drink industry, bearings are faced with some of the most demanding environments to be found, required to perform across a very wide range of temperatures, subject to frequent washdowns and guided by regulations that are becoming ever more stringent; and, of course, there are cost considerations. The choice of bearings therefore requires careful consideration. Brammer Buck & Hickman, which has extensive experience of working with some of the biggest names in the food and drink sector, has come together with bearings manufacturer SKF to produce a range of resources to assist food and drink producers improve the performance and service life of their bearings.

A recorded webinar, hosted by Brammer Buck & Hickman and presented by SKF, is available on YouTube on the RubixTube channel. In under 40 minutes, the webinar examines the key issues that impact on bearings in the food & drink sector, with a focus on reducing risk when it comes to food safety. It also identifies bearings that are best suited to this industry and includes a preview of the latest products and technologies due to be released.

For those that prefer to digest information in a different format, Brammer Buck & Hickman has produced two new brochures. The first is a product brochure on SKF bearing solutions for the food & drink sector, which covers the Food Line Blue Range, Food Line Deep Groove ball bearings and SKF Fryer bearing technology. The brochure looks at the key attributes of these bearing units and how they could benefit your production process. The second PDF is a guide: ‘Top 3 Challenges in the Food & Drink Sector…and how to ensure your bearings meet them’. It looks in more detail at the issues surrounding safety, cost control and sustainability in the food and drinks processing sector. Just as importantly, it provides guidance on how to meet those challenges. Both brochures are available to download from the food & drink industry page on Brammer Buck & Hickman’s dedicated SKF bearings section on its website: uk.rubix.com/supplier/skf/foodandbeverage.

Case studies on real world usage of SKF bearings in the food and drink sector have also been produced.

Brammer Buck & Hickman is an SKF Authorised Distributor across Europe and has an in-depth knowledge of the manufacturer’s product range, along with early access to its latest technologies.

Brammer Buck & Hickman is part of the Rubix group. With turnover of more than €2.3 billion in 2018, Rubix is Europe’s largest supplier of industrial maintenance, repair and overhaul (MRO) products and services. For more information, go to uk.rubix.com

About Brammer Buck & Hickman

Brammer Buck & Hickman is the UK’s leading technical specialist distributor of maintenance, repair and overhaul (MRO) products, as well as supplying multiple value-added services. Branches across the breadth of the UK provide customers with quick and easy access to more than 5 million products, from bearings, power transmission and fluid power through to tools and health & safety products. This extensive product portfolio is underpinned by specialist engineering services as well as condition monitoring. At the heart of Brammer Buck & Hickman’s service is a commitment to providing customers with cost savings through:

- reducing total acquisition costs

- improving production efficiency

- reducing working capital.

Brammer Buck & Hickman is part of the Rubix group, Europe’s largest supplier of industrial MRO products and services.

Endress+Hauser Introduces Netilion Water Networks Insights

The innovative, cloud-based monitoring solution from Endress+Hauser paves the way to comprehensive optimization and automation for water networks—from anywhere at any time.

Netilion Water Network Insights (NWNI) enables full transparency for water networks around the clock by providing reliable monitoring of flow, pressure, temperature, level, water quality, and other measurements. This software service connects all levels of water supply systems, empowering service providers and water associations to manage multiple control and data sources through a single interface. These sources include field devices, industrial controllers, data transfer components, data recording and archiving devices, analysis and forecasting tools, and others.

NWNI provides access to all measurement data gathered in a water network and transmitted to the cloud, whether its users are accessing the system from a control room computer, via a laptop at home, on a tablet in the field, or from a smartphone on the move. The web-based interface provides users with complete system monitoring, and when limit values are exceeded, or in the event of failure, it delivers alarms to users via e-mail, SMS, or push notifications.

The software system includes many evaluation tools, including time curves, diagrams, tables, and trends, and by incorporating external data sources—such as weather prediction systems—users can also create trend analyses and forecasts. These tools help inform characteristics, like run-off during heavy rainfall, consumer water demand, and expected availability.

Secure and flexible connectivity options are critical for modern facilities, and NWNI provides these with cutting-edge data exchange technologies. All communication is encrypted and secure, even in remote regions with a self-sufficient power supply, providing data reliability and integrity.

NWNI provides facility personnel with systemwide views, reducing required rounds and verifying functional operation of remote spring taps, elevated reservoirs, pipelines, pumping and distribution stations, and more. This makes it possible to keep close tabs on a broad range of system values and quality parameters including:

- Comprehensive water quantity and quality monitoring around the clock

- Accurate custody transfer allocation and cost accounting

- Reliable leak locating

- Weather impacts

- Energy efficiency and optimization

NWNI for wastewater – complying with environmental regulations

Industrial, commercial, and municipal wastewater regulatory agencies mandate many water quality parameters to protect the environment, so facilities must treat wastewater in several stages prior to discharge. To maintain compliance, these facilities must carefully monitor water quality, substance concentrations, pollution loads, and other parameters.

NWNI ensures wastewater treatment organizations meet or maintain these requirements at all times of the day, by assisting operations with:

- Reliable forecasts of in/outflows and water quality by leveraging current weather data and state-of-the-art analysis algorithms

- Optimal sizing of wastewater treatment plants through the comprehensive knowledge of effluent substance concentration and material loads in catchment areas

- Reliable substance concentration control by using data from liquid analysis devices

- Precise flow and concentration measurement to ensure accurate billing of wastewater charges

- Biological process risk mitigation by monitoring influent substance concentrations

Heartbeat Technology provides safety in custody transfer

In water custody transfer, infinitesimal inaccuracies in flow measurement can create significant billing discrepancies. Although frequent testing can reduce the occurrence of these errors, it historically required removing flowmeters from service for testing and calibration. Frequent removal is often impractical, particularly on large water pipelines over a few feet in diameter.

Addressing this challenge, Endress+Hauser’s integrated Heartbeat Technology testing functionality provides verification of flow meter measurements with the push of a button. Users can view these automatically generated verification records in NWNI.

NWNI provides systemwide visualization and recordkeeping, improving regulatory, reporting, and custody transfer accuracy. These tools help water agencies streamline operations, improve decision-making, and increase revenue streams.

To learn more about NWNI visit: https://eh.digital/3gTSZyG

About Endress+Hauser in the U.S.

Endress+Hauser is a global leader in measurement instrumentation, services and solutions for industrial process engineering. Endress+Hauser provides sensors, instruments, systems and services for level, flow, pressure and temperature measurement as well as analytics and data acquisition. We work closely with the chemical, petrochemical, food & beverage, oil & gas, water & wastewater, power & energy, life science, primaries & metal, renewable energies, pulp & paper and shipbuilding industries. Endress+Hauser supports its customers in optimizing their processes in terms of reliability, safety, economic efficiency and environmental impact. The Group employs nearly 15,000 personnel worldwide and generated [net sales of] more than 2.9 billion euros (3.3 billion U.S. dollars) in 2021. For more information please visit, us.endress.com.

The Endress+Hauser Group

Endress+Hauser is a global leader in measurement and automation technology for process and laboratory applications. The family company, headquartered in Reinach, Switzerland, achieved net sales of approximately 2.9 billion euros in 2021 with a total workforce of more than 15,000.

Endress+Hauser devices, solutions and services are at home in many industries. Customers thus use them to gain valuable knowledge from their applications. This enables them to improve their products, work economically and at the same time protect people and the environment.

Endress+Hauser is a reliable partner worldwide. Its own sales companies in more than 50 countries as well as representatives in another 70 countries ensure competent support. Production facilities on four continents manufacture quickly and flexibly to the highest quality standards.

Endress+Hauser was founded in 1953 by Georg H Endress and Ludwig Hauser. Ever since, the company has been pushing ahead with the development and use of innovative technologies, now helping to shape the industry’s digital transformation. 8,600 patents and applications protect the Group’s intellectual property.

For further information, please visit www.endress.com/media-center or www.endress.com.

Emerson Technologies Selected for Geothermal Clean Energy Production

Geological modeling software will help HITA increase safety and reliability of sustainable geothermal energy sources

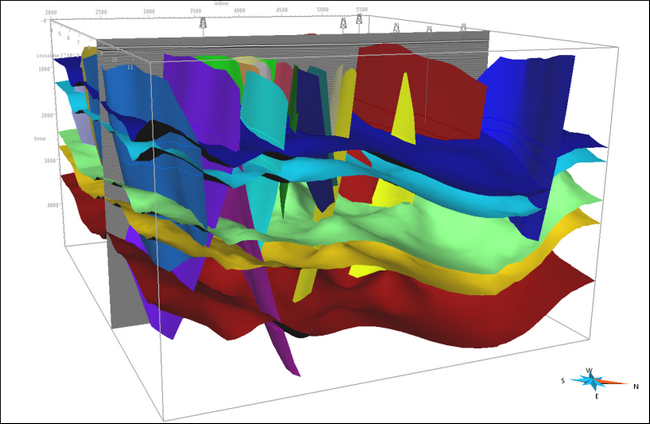

HITA, a deep geothermal energy company in Belgium, has selected global software and technology leader Emerson (NYSE: EMR) as a key technology provider in the discovery and development of geothermal energy sources in Northern Belgium. Emerson’s geological and reservoir modeling software will help reduce risk in selecting locations for renewable geothermal energy projects, increasing the safety and reliability of construction and operation while enabling long-term sustainable energy production from the earth’s heat.

Climate change policies are driving growth of geothermal energy—an industry forecasted to grow as much as eightfold in the European Union by 2050, according to the International Renewable Energy Agency. Emerson’s geological modeling software will help HITA locate the most suitable subsurfaces for drilling deep geothermal wells to unlock sustainable energy sources for corporate and municipal use.

“A highly accurate and realistic picture of subsurface geology is critical for the safe development of sustainable energy sources,” said Stijn Bos, chief operating officer and senior project geologist at HITA. “Emerson technologies use seismic, geologic and other data to generate detailed models that can determine the best location for geothermal plants.”

Emerson’s SKUA-GOCAD modeling software will help HITA more easily identify drilling locations by creating highly realistic models designed for easy interpretation.

“Geological exploration and production software, including Emerson’s SKUA-GOCAD modeling software, has traditionally been used in the oil and gas industry. But it’s also well suited for geothermal energy, as well as carbon capture and storage,” said Mark Bulanda, executive president of Emerson’s Automation Solutions business. “Emerson’s advanced, science-based applications will help move society toward a safer and more sustainable future.”

For more information about Emerson’s exploration and processing software solutions, please visit www.emerson.com/skua-gocad.

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and engineering company providing innovative solutions for customers in industrial, commercial, and residential markets. Our Automation Solutions business helps process, hybrid, and discrete manufacturers maximize production, protect personnel and the environment while optimizing their energy and operating costs. Our Commercial and Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency, and create sustainable infrastructure. For more information visit Emerson.com.

Outokumpu receives the highest Platinum level sustainability recognition from EcoVadis

Outokumpu has received the highest Platinum level recognition for the second year in a row from the sustainability rating platform EcoVadis. The Platinum level rating indicates that Outokumpu is among the top 1% of the over 85,000 companies evaluated.

“We are happy to continue on the highest Platinum level in the EcoVadis rating and to be among the top 1% sustainability performers. We have made good progress in sustainability and launched our more ambitious sustainability strategy and targets last year. We are pleased to see that our total score in the assessment increased from last year reflecting our strong commitment to sustainability. We aim to continue improving our scores even further and strengthen our position as the industry leader in sustainability”, says Juha Erkkilä, Vice President, Group Sustainability at Outokumpu.

“We are happy to continue on the highest Platinum level in the EcoVadis rating and to be among the top 1% sustainability performers. We have made good progress in sustainability and launched our more ambitious sustainability strategy and targets last year. We are pleased to see that our total score in the assessment increased from last year reflecting our strong commitment to sustainability. We aim to continue improving our scores even further and strengthen our position as the industry leader in sustainability”, says Juha Erkkilä, Vice President, Group Sustainability at Outokumpu.

EcoVadis assesses companies in respect to environment, labor and human rights, ethics and sustainable procurement. EcoVadis assesses companies in line with global standards such as GRI and UN Global Compact. As a part of its sustainable sourcing initiative, Outokumpu partnered with EcoVadis in 2021 to evaluate the sustainability performance of its raw material suppliers.

Outokumpu has recently improved its performance in other ESG ratings as well. In February 2022, Outokumpu was included in the S&P Global’s Sustainability Yearbook and in the latest Carbon Disclosure Project's (CDP) assessment in 2021, Outokumpu received the second highest B rating for its climate action and upgraded to grade C in CDP’s water assessment. Outokumpu has improved its ratings also in MSCI and Sustainalytics ESG ratings.

“At the same time, when we have put in place a more ambitious sustainability agenda and improved our ESG ratings, we see increasing need for more robust processes especially in assessing our own supply chain. This will be one of our key focus areas in 2022”, says Juha Erkkilä.

As the leader in sustainable stainless steel production, sustainability is at the core of Outokumpu. Outokumpu updated its sustainability strategy and climate targets in 2021 committing to the Business Ambition for limiting global warming to 1.5°C.

Smart approach loads-out modules three days early

2,200t moves engineered in short timeframe, protecting project schedule

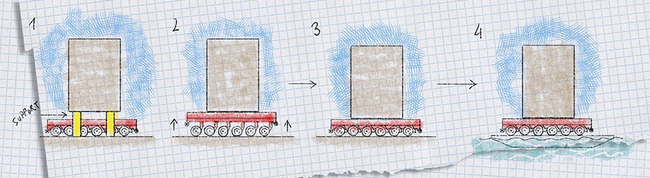

Offshore construction specialists Estaleiros do Brasil Ltda. (EBR) needed the load-out of seven modules to be engineered, planned, and executed in the space of just a few weeks. These modules were being built in Brazil destined for FPSO integrations abroad; the challenge was on to have the modules in active production as soon as possible.

The modules – some weighing up to 2,200t each and over 30m by 18m in size – were to be transferred from the quay to a waiting ship. Phase one of the project would transfer the first four such modules, and phase two the remaining three.

The work was not straightforward, however. A challenge presented itself during the first phase, as there were limited feasible jacking points available underneath the module. These are strengthened areas, built into a module’s design, that allow it to be lifted from underneath by large jacking systems.

As there was not sufficient time to reinforce the structure of each module so that they could be jacked down using other points, an alternative solution had to be found. It came through innovative use of standard lifting equipment.

Mammoet teams use trailers for 2,200t module load-out.

Mammoet teams use trailers for 2,200t module load-out.

Hydraulic trailers used for transport projects have the ability to raise and lower mechanically, so it was decided that each module would be lowered sequentially, using the hydraulic course of the trailers rather than traditional jacking equipment. In turn, each module was weighed, jacked-down to the correct grillage height, then loaded-out onto the ship within a precise timeframe.

Despite the novel approach, this methodology allowed the first four modules to be loaded-out in just twelve days instead of the allotted 15.

Phase two of the operation, which included the three final modules, was successfully completed a few months later. During this phase, only the weighing and load-out was required. To complete this scope, Mammoet's team mobilized the same 96 axle-lines of PST/THP trailers as previously used, a large selection of weighing and auxiliary equipment, and it could mobilize staff from every corner of the Americas to ensure the job was done on time.

During phase two, the largest module measured over 29.9m (around 98,000 ft) long and 37.488m (122.9 ft) tall. Again, each module’s weight aligned with expectations, at around 2,200t each.

Mammoet Project Manager, Alvaro Campos, explains, “One of Mammoet’s greatest challenges was the mobilization time since we were asked to deliver with very short notice and the required equipment was in various locations across Brazil.

We managed to get everything to site on time thanks to the hard work of a very professional crew and we pulled out a safe execution which was praised many times by our final clients and brought them much relief.”

Both phases were effectively delivered for end customers Modec and Cameron/SBM respectively, and all tasks were executed while complying with our customer’s and Mammoet's high safety standards. Mammoet’s team has vast experience in loading out large modules onto vessels across the globe, most recently a nearly 4,000t topside in Turkmenistan.

Mammoet

Mammoet helps clients with Smarter, Safer and Stronger solutions to any heavy lifting or transport challenge. We aim to develop long term relationships in order to understand their businesses and challenges best, so we can realize the most efficient and cost-effective approaches. We have a unique global network and an unparalleled fleet of equipment. Through deep and longstanding engineering expertise and the highest quality and safety standards in execution we bring an intelligent and flexible approach to projects across a wide breadth of industry sectors. Clients trust us to help them achieve feats that were once considered impossible, and we have often broken records in doing so.

For more information, visit www.mammoet.com