Administrator

Emerson Offers Industry’s First ‘Four-in-One’ Compact Flow Meter

New Rosemount™ 8800 Quad Vortex meter is designed with built-in redundancies for SIL 3 safety requirements along with basic process control, and fits into less than half the space of four traditional redundant flow meters, offering easy, cost-effective installation

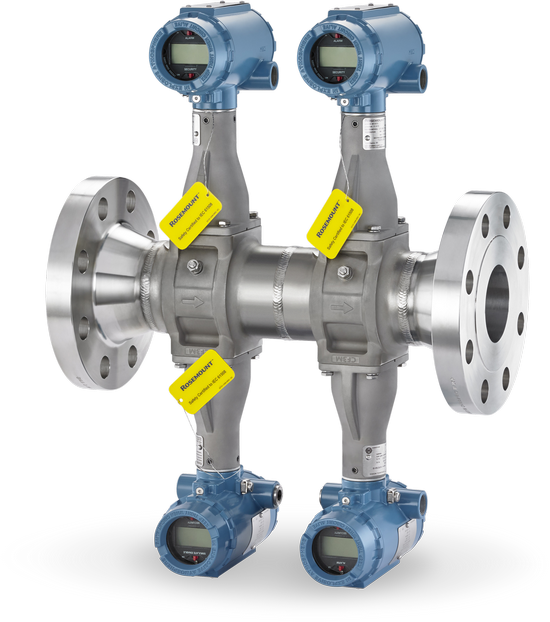

Emerson has introduced the Rosemount™ 8800 Quad Vortex flow meter specifically designed to meet stringent safety standards in environments and applications that require safety instrumented systems (SIS). The flow meter is the first in the industry with quadruple sensors and transmitters to meet safety integrity level (SIL) requirements. Comprised of multiple independent sensors in an all-welded meter body, the meter provides a compact flow solution with built-in redundancies for added safety without introducing intentional leak points. The meter reduces piping needs threefold by eliminating the additional flanges and pipe runs required for the installation of multiple flow meters in a redundant flow measurement solution.

With the ability to meet measurement challenges in industries such as chemical, power, refining, and offshore oil and gas applications, particularly where space is limited, and safety is crucial, the Rosemount 8800 Quad Vortex flow meter can take the place of multiple individual flow meters. The Rosemount 8800 Quad Vortex flow meter accomplishes the same task as four separate meters, without needing impulse lines that might clog. The meter saves money by reducing installation costs as a simple all-in-one drop-in solution.

The Rosemount 8800 Quad Vortex flow meter is designed to meet stringent safety standards in environments and applications that require safety instrumented systems.

The Rosemount 8800 Quad Vortex flow meter is designed to meet stringent safety standards in environments and applications that require safety instrumented systems.

The Rosemount 8800 Quad Vortex flow meter’s design and configuration allows for a SIL 3-capable solution and protects against spurious trips using a two out of three (2oo3) voting method. The 2oo3 voting method ensures that at least two of the sensors must read ‘good’ for a process to continue, which means one poor reading does not trip a complete process shutdown.

“Our refining and chemical customers who have tested this new flow meter have found tremendous value from this unique and differentiated flow solution,” said Julie Valentine, refining industry flow solutions director for Emerson’s Automation Solutions business. “The 8800 Quad Vortex flow meter has made the specification, purchase and installation of a SIS/SIL application with reduced piping and space requirements easier than ever before.”

For more information, visit www.Emerson.com/RosemountQuadVortex.

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and engineering company providing innovative solutions for customers in industrial, commercial and residential markets. Our Automation Solutions business helps process, hybrid and discrete manufacturers maximise production, protect personnel and the environment while optimising their energy and operating costs. Our Commercial & Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency and create sustainable infrastructure. For more information visit Emerson.com.

More data, at quicker speeds: Serial communication to TCP/IP

In a data-driven world, turning data into actions is the best way to boost efficiency. As businesses become more global and complex, operational data must travel across greater distances, at faster speeds and in larger quantities. Here, Jürgen Resch, industry manager at COPA-DATA, examines why manufacturers should move their information systems from serial communication to TCP/IP.

Generally, serial communication is a widely used method to transfer data between processing equipment and peripherals. Every device, might it be your computer or mobile, runs on serial protocol which serves as a reliable form of communication.

In fact, it was not until the 1990’s that fibre optics were implemented to guarantee immunity against electromagnetic interferences, which not only prevented interruptions but helped save tons of copper that were laid in cable conduits.

So, when ethernet became cheaper and new network topologies — the arrangement in which computer systems or network devices are connected to each other — were made possible, such as the Transmission Control Protocol/Internet Protocol (TCP/IP).

COP471 - Secure in the knowledge – BP.jpg: Industrial software can be vital in preventing the rising number of Distributed Denial of Service (DDoS) attacks against businesses.

COP471 - Secure in the knowledge – BP.jpg: Industrial software can be vital in preventing the rising number of Distributed Denial of Service (DDoS) attacks against businesses.

TCP/IP protocol

TCP/IP is responsible for managing the connection between a client and a server, making sure the data that needs to be transferred is split into several packets, which will eventually reach their destination. Unlike serial communication, if data corrupts or does not reach its destination TCP/IP defines how the missing data will be retransmitted, while controlling the flow of data to the right place.

TCP/IP technologies have received much stronger development efforts than serial, due to the vast number of users currently utilising it. For example, TCP/IP is used for the internet, which obviously demands fast communication speeds and flexibility in topologies.

TCP/IP is also widely used in industrial settings, unless the facility has opted for fast Ethernet protocols. In these environments, TCP/IP can help support network protocols within substations and manufacturing plants, such as DNP3 and IEC 60870-5-104. These protocols are commonly used for wide area communication between the substation and the supervisory control and data acquisition (SCADA) master.

With this in mind, TCP/IP is essential for the plethora of new current remote working situations the industry finds itself in. This is due to its ability to control locations separated between long distances. That being said, TCP/IP is not without its downfalls.

Considerations

Because they are so widely used, TCP/IP protocols can be vulnerable to attack. Today, hacking tools for TCP/IP related protocols are easier to find than serial protocols, so it is essential to ensure systems are secure.

Consider the consequences of this risk for an energy network, for example. While TCP/IP provides data communication for distributed assets, such as multiple substations and energy generation sites, this widespread infrastructure is at serious threat of cyber-attack. In fact, since the infamous discovery of Stuxnet in 2010, there has been an increase in attacks on the energy sector, with attacks rising by 380 per cent between 2014 and 2015.

When using TCP/IP protocols, the energy sector must be extra vigilant. When choosing technology, the energy industry involve options like Virtual Private Networks, coupled with standards like the IEC 62351 series, that provide the required levels of security. COPA-DATA’s energy grid software, zenon, for instance, meets the IEC 62351 standard for security in energy management systems and is developed using a security by design approach.

There are, of course, some instances where serial communication is used for security. In the power industry, this is only present in rare cases where a dedicated communication link is used serially for security reasons. This provides more protection against hackers, but security by obscurity is not a viable way to protect critical infrastructure. Instead, opting for secure TCP/IP is recommended.

TCP/IP ensures data can travel across greater distances, at faster speeds and in larger quantities. And, although TCP/IP might be at some risk to attack, by combining this with secure communication technology, like COPA-DATA’s zenon, we can protect data and in turn, the grid.

COPA-DATA

COPA-DATA is the manufacturer of the zenon® software platform, used in the manufacturing and energy industries for the automated control, monitoring, and optimization of machines, equipment, and power supplies. Founded by Thomas Punzenberger in 1987 and headquartered in Salzburg, Austria, the independent, family-owned company employs approximately 285 workers around the globe. The distribution of software on an international scale is made possible through the company’s eleven subsidiaries and numerous distributors. In addition, more than 270 certified partner companies ensure efficient software implementation for end users in the food & beverage, energy & infrastructure, automotive, and pharmaceutical industries. In 2019, COPA-DATA generated turnover of EUR 51 million.

About zenon

zenon is a software platform from COPA-DATA for manufacturing and the energy industry. Machines and equipment are controlled, monitored and optimized. zenon’s particular strength is open and reliable communication in heterogeneous production facilities. Open interfaces and over 300 native drivers and communication protocols support the horizontal and vertical integration. This allows for continuous implementation of the Industrial IoT and the Smart Factory. Projects with zenon are highly scalable.

zenon is ergonomic, both for the engineer and for the end user. The engineering environment is flexible and can be used for a wide range of applications. The principle of “setting parameters instead of programming” helps engineers to configure projects quickly and without errors. Complex functions for comprehensive projects are supplied out-of-the-box to create intuitive and robust applications. Users can thereby contribute to increased flexibility and efficiency with zenon.

Emerson’s New Full-Bore Ball Control Valve Combats Vibration, Cavitation and Noise

Emerson has introduced the Fisher™ V280 full-bore trunnion-mounted ball control valve for severe and specialty pressure, flow and process control applications. The valve provides excellent dynamic process control by utilising a robust drive train unique to the market that is designed to guide the shaft and properly absorb energy. Available attenuators for liquid and gas process fluids offer an effective solution for combatting the negative consequences of cavitation, such as vibration, erosion and noise.

The body connections of the V280 valve have been re-engineered to significantly simplify the design and reduce the number of parts, while utilising the same construction for the inlet and outlet. This allows an easy retrofit of single or dual ball seals with standard or customised noise attenuating aerodomes or anti-cavitation hydrodomes on the inlet, outlet or both. Typical applications include midstream oil and gas, particularly compressor anti-surge service.

Fisher™ V280 ball valve with attenuator, 1061 piston actuator and FIELDVUE™ DVC6200.

Fisher™ V280 ball valve with attenuator, 1061 piston actuator and FIELDVUE™ DVC6200.

The V280 is a fully rated ANSI class 900 valve, available in 6”, 8”, 10”, 12” and 16” sizes. A variety of high-performance packing materials are available, including ENVIRO-SEAL™ live-loaded packing. Optional special materials and constructions are available to accommodate specialty applications. The valve comes standard as a single-seal construction but is available with optional dual-seal construction, allowing bi-directional flow and double block-and-bleed operation.

The standard offering V280 complies with the NACE MR0175/ISO 15156 Sour Service/Sour Crude oil standard, carries the full ASME B16.5 Class 900 flange rating, and can handle fluid temperature ranges from -20 to 180 degrees F. Alternate seal options can handle temperatures from -50 to 400 degrees F. The valve can be fitted with a number of different positioners or auxiliary devices to suit hazardous or challenging environments.

Together with the Fisher V260 and V270 valves, the V280 provides users with a complete portfolio of full bore ball control valves.

To learn more about the Fisher V280 full-bore severe and specialty ball control valve, please visit: www.Emerson.com/FisherV280.

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and engineering company providing innovative solutions for customers in industrial, commercial, and residential markets. Our Emerson Automation Solutions business helps process, hybrid, and discrete manufacturers maximise production, protect personnel and the environment while optimising their energy and operating costs. Our Emerson Commercial & Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency, and create sustainable infrastructure. For more information visit Emerson.com

BP’s low carbon energy ambitions will be impacted by market weakness, says GlobalData

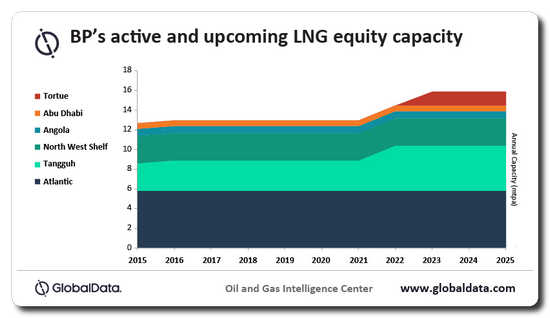

BP will need to commit to significant investments in the renewable energy and liquefied natural gas (LNG) space in order to meet its 2030 target of 50GW in renewables capacity and 30MPTA in LNG. Capital available for investment activity will be challenged as market weakness dents cashflow from BP’s core hydrocarbons business, says GlobalData, a leading data and analytics company.

Daniel Rogers, Oil and Gas Analyst at GlobalData, comments: “BP has proven its willingness to invest big outside its core business, but will continue to rely on hydrocarbons as the cash cow for future investments. The current market fundamentals reduce the profitability of BP’s core business, potentially shrinking its pool of capital available for future low-carbon acquisitions.”

LNG will continue to play a major role in BP’s low-carbon energy and electricity goals and is targeting significant growth in the sector. In its current equity LNG portfolio, BP is forecast to reach 16MTPA in capacity by 2025, while relying on merchant volumes for the rest of the targeted amount.

Rogers continues: “The delay of the Tortue LNG project was a major blow and further delays could hinder BP’s 2025 target from being achieved. Future developments in Mauritania and Senegal will be the cornerstone of the company’s growth opportunities, but will hinge on investment decisions going ahead in spite of a potentially oversupplied LNG market going into the late 2020s.”

BP currently holds 2.3GW of installed renewable power capacity, leading the way for the major international oil companies (IOCs) and its recent deal with Equinor secures entry into the offshore wind sector with a capacity addition of 2.2GW once complete. BP’s current project pipeline will increase its capacity by 6.5GW, but this is still short of its target of 20GW by 2025.

Rogers concludes: “As BP will leverage off its core hydrocarbons business to fund its investment strategy, weakened oil and gas prices will put pressure on the company’s capital availability necessary to meet its low-carbon energy ambitions.”

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

The new NordtrackTM mobile equipment range from Metso Outotec breaks the milestone of 100 sold units

The new mobile crushing and screening range from Metso Outotec, NordtrackTM, has passed the milestone of 100 units sold worldwide. The volume sales of the range started during 1Q2020.

“This is a remarkable achievement for a new product range; especially considering how the pandemic has impacted the construction industry around the world,” says Vesa Tuloisela, Director, Nordtrack offering at Metso Outotec. “It strengthens our expectation that the potential Nordtrack customers appreciate the reliability and support of a premium brand. We believe that the demand for aggregate recycling equipment is on a steady path.”

Sales and deliveries have started globally and the biggest demand so far is coming from North America and Europe. Customers have ordered Nordtrack crushers for C&D (concrete and demolition) waste sites and aggregate quarries, and Nordtrack screens for aggregate screening and industrial applications, such as mulch screening and top-soil pre-screening. Mobile conveyors are used as auxiliary equipment to complete the crushing and screening plants.

“It is a range which meets the needs of the small and medium sized contractors who are looking to expand their business in aggregates, whether it is recycling or small-scale virgin aggregate production,” Vesa Tuloisela describes. “The features and options of the range have been selected in a way that the equipment is easy to use and to move between worksites. We have plans to announce new features and range extensions in the near future.”

“I want to express my warmest gratitude to all our customers and distributors who have welcomed Nordtrack. We continue to develop both the Nordtrack range and our Lokotrack mobile equipment portfolio to reach a more diverse customer base,” he concludes.

See the Nordtrack equipment in action at metso.com/nordtrack.

For further information, please contact:

Vesa Tuloisela, Director, Nordtrack Offering, Aggregates Business area, Metso Outotec, Tel. +358 50 385 1871 email: vesa.tuloisela(at)mogroup.com

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing, metals refining and recycling industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its illustrative combined sales for 2019 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

The Next Stage of the Electricity Grid Investigated by IDTechEx Research

The electricity market is evolving to allow a higher integration of variable energy sources and a new class of devices is approaching the market to satisfy this necessity.

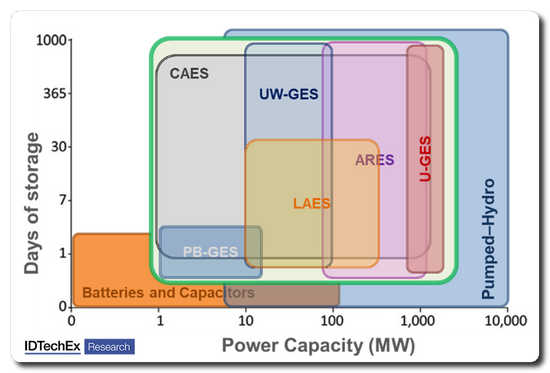

In the new report released by IDTechEx: “Potential Stationary Energy Storage Device to Monitor”, the emerging class of energy storage devices, characterized by long storage duration and MW size power output, are investigated.

While existing energy storage devices are already populating the market, from Li-ion batteries to pumped-hydro energy storage, this new class of storage technologies will aim to complete the puzzle of the energy storage market.

Pushed from the electrification of the automotive sector, Li-ion batteries have been deeply investigated in the last decades and are currently the standard choice for short and medium-duration storage.

On the other end of the storage market, pumped hydro energy storage (PHES) are the main energy storage systems supporting the grid. These systems have a power capacity of GW scale (1000s of MW), and long storage time, from days upwards.

In between these two storage systems, a new group of storage devices is now approaching the market, with an intermediate power range, between MW to GW scale and an energy storage capacity that is almost indefinite.

Power and storage capacity comparison of different technologies. Source: IDTechEx Research report “Potential Stationary Energy Storage Device to Monitor”

The devices investigated by IDTechEx include:

- Gravitational Energy Storage (GES):

- Piston-Based GES (PB-GES)

- Underground PHES (U-PHES)

- UnderWater GES (UW-GES)

- Advanced Rail Energy Storage (ARES)

- Compressed Air Energy Storage (CAES)

- Liquid Air Energy Storage (LAES)

The market addressed by these systems aims to improve the quality, and resiliency of the electricity grid, and distribution networks. Therefore, it is aiming to address the Front-the-Meter (FTM) section of the electricity grid.

These devices, as investigated in IDTechEx’s new report “Potential Stationary Energy Storage Device to Monitor”, support the electricity grid providing peak-shaving service, grid deferral, and frequency regulation, among other possible services.

Moreover, because some of these technologies involved the use of several turbines, some of these devices can address more than one service at the time, therefore increasing the value stacking of these technologies.

Although they come with high capital costs, and are in their initial demonstration phase, these devices are a promising solution to stabilize the electricity grid and reach a high level of integration of variable renewable energy sources.

For more information on this report, please visit www.IDTechEx.com/PotentialSES or for the full portfolio of Energy Storage research available from IDTechEx please visit www.IDTechEx.com/Research/ES.

IDTechEx guides your strategic business decisions through its Research, Consultancy and Event products, helping you profit from emerging technologies. For more information on IDTechEx Research and Consultancy, contact This email address is being protected from spambots. You need JavaScript enabled to view it. or visit www.IDTechEx.com.

Alfa Laval wins SEK 275 million off-shore orders

Alfa Laval – a world leader in heat transfer, centrifugal separation and fluid handling – has won three orders to supply Framo pumping systems for three FPSO (Floating Production, Storage and Offloading) vessels to be built in China. The orders have a combined, total value of approximately SEK 275 million and are booked in the Pumping Systems unit of the Marine Division, with deliveries scheduled for 2021.

The orders comprise marine pumping systems for crude oil offloading, produced water, slop and ballast duties.

The orders comprise marine pumping systems for crude oil offloading, produced water, slop and ballast duties.

“I am pleased to announce these large orders for our Framo pumping systems. These three orders confirm our systems reliability and ability to provide safe and optimized performance,” says Sameer Kalra, President of the Marine Division.

Did you know that… Framo was acquired by Alfa Laval in 2014 and is now part of the company’s worldwide organization?

This is Alfa Laval

Alfa Laval is active in the areas of Energy, Marine, and Food & Water, offering its expertise, products, and service to a wide range of industries in some 100 countries. The company is committed to optimizing processes, creating responsible growth, and driving progress – always going the extra mile to support customers in achieving their business goals and sustainability targets.

Alfa Laval’s innovative technologies are dedicated to purifying, refining, and reusing materials, promoting more responsible use of natural resources. They contribute to improved energy efficiency and heat recovery, better water treatment, and reduced emissions. Thereby, Alfa Laval is not only accelerating success for its customers, but also for people and the planet. Making the world better, every day. It’s all about Advancing better™.

Alfa Laval has 17,500 employees. Annual sales in 2019 were SEK 46.5 billion (approx. EUR 4.4 billion). The company is listed on Nasdaq OMX.

Nexans umbilicals to play vital role in Senegal’s first offshore oil development

Nexans has signed a contract with Subsea 7 to design and manufacture 46 km of umbilicals for the Sangomar field, offshore Senegal. The umbilicals, produced by Nexans’ specialized facility in Halden, Norway, will provide vital hydraulic, control and instrumentation services for a stand-alone floating production storage and offloading (FPSO) facility and associated subsea infrastructure.

- Nexans will supply 46 kilometers of umbilicals as well as accessories and testing services to Subsea 7, the contractor responsible for the integrated subsea production systems serving the Sangomar Field Development project.

- Nexans’ Halden facility will provide both static and dynamic umbilicals for each phase of the project, with deliveries commencing in 2022.

- The Sangomar field, containing both oil and gas, is located 100 kilometers south of Dakar and will be Senegal’s first offshore oil development.

Nexans will deliver 13,471 m of dynamic umbilicals which will be installed from north to south. Nexans will also provide 9.503m of main static umbilicals, 8,719 m of production infield umbilicals, and 14,650 m of injection infield umbilicals in the subsequent four phases of development.

Ragnvald Graff, Sales Director Oil&Gas says: ‘We are delighted to be designing and manufacturing the umbilicals for Senegal’s first offshore oil development. Nexans continues to lead the industry on umbilical technology, and we are excited to contribute our expertise and world-class products to this promising endeavor. Offshore oil development in West Africa has immense potential, and we’re thrilled to be a part of this important journey.’

The Sangomar Field Development was discovered in 2014. Located 2 km below the seabed floor, the field is spread over 400km2, in water depths of 700 to 1400 meters. The phased development includes the installation of a stand-alone floating production storage and offloading (FPSO) facility and subsea infrastructure that will be designed to facilitate subsequent development phases. These options include potential gas export to Senegal and future subsea tie-backs to other fields.

About Nexans

Nexans is a key driver for the world’s transition to a more connected and sustainable energy future. For over 120 years, the Group has brought energy to life by providing customers with advanced cable technologies for power and data transmission. Today, Nexans goes beyond cables to offer customers a complete service that leverages digital technology to maximize the performance and efficiency of their critical assets. The Group designs solutions and services along the entire value chain in three main business areas: Building & Territories (including utilities and emobility), High Voltage & Projects (covering offshore wind farms, subsea interconnections, land high voltage), and Industry & Solutions (including renewables, transportation, oil and gas, automation, and others).

Corporate Social Responsibility is a guiding principle of Nexans’ business activities and internal practices. In 2013 Nexans was the first cable provider to create a Foundation supporting sustainable initiatives bringing access to energy to disadvantaged communities worldwide. The Group’s commitment to developing ethical, sustainable and high-quality cables also drives its active involvement within leading industry associations, including Europacable, the NEMA, ICF and CIGRE.

Nexans employs nearly 26,000 people with an industrial footprint in 34 countries and commercial activities worldwide. In 2019, the Group generated 6.7 billion euros in sales.

Nexans is listed on Euronext Paris, compartment A.

For more information, please visit www.nexans.com

Aramco delays major investment as COVID-19 has longer term impacts, says GlobalData

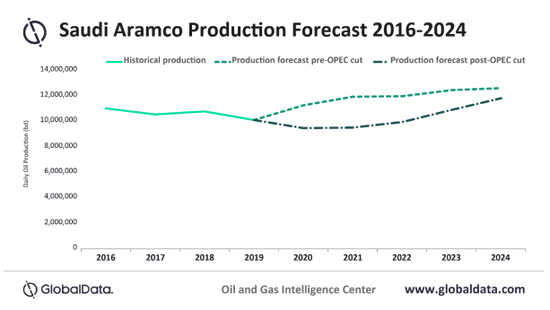

Aramco has faced a tough time in 2020 so far. Just months after its long-awaited IPO in December 2019, the impacts of COVID-19 on the company are clear to see. Aramco has been forced to delay two large expansion projects at the Marjan and Berri Complexes as the virus’ impacts have been far reaching and damaging for the global economy, oil prices, and demand, according to GlobalData, a leading data and analytics company.

Conor Ward, Oil & Gas analyst at GlobalData, comments: “These expansion projects aimed to add a significant amount of production to the company’s portfolio. However, the impacts of COVID-19 now represent a long-term impact and along with the OPEC+ production cuts, Saudi Arabia is likely to see significantly reduced output than would have been planned.”

In commitment with the agreed OPEC+ production cuts, Saudi Arabia has cut 2.5 million barrels of oil per day (Mmbd) in May, June, and July. In further efforts to rebalance oil prices, Saudi Arabia, UAE, and Kuwait agreed to a further 1.18 mmbd production cut of which Saudi Arabia will bare 1 million. Aramco will experience an approximately 18% cut in its originally planned 2020 production and with these OPEC cuts along with the impacts of COVID-19, it is unlikely that production levels will rebound before 2022.

The upcoming expansion plans have been delayed and Aramco will become increasingly more strict with its capital spending due to the uncertainty which COVID-19 has brought to the market. H1 spending for the company has already been 15% lower than 2019 and this trend is expected to continue into 2021 as the company continues to re-evaluate its spending habits amid a global demand reduction.

Ward concludes: “Going forward, the company will remain the largest single energy company in the world with above industry average profit margins however, continued weakness in global oil prices will put pressure on the company and in turn, the government’s fiscal budgeting.”

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors. PR10913.

Metso Outotec to supply energy efficient Vertimill grinding technology to a gold mine in Australia

Metso Outotec will deliver two energy-efficient Vertimill® VTM-4500 stirred mills to a gold mine in Australia 2021. These vertical grinding mills will be the largest of their kind to be installed in Australia. Typical value for this type of an order is in the range of EUR 10 to 15 million, depending on the scope of delivery. The order has been booked in Metso Outotec’s orders received in Q3, 2020.

Metso Outotec to supply energy efficient VertimillMetso Outotec’s Vertimill provides the lowest total cost of ownership compared to other grinding mills in many applications thanks to its high energy efficiency, reduced media consumption, low installation cost as well as minimal liner wear and maintenance. It is capable of handling feed sizes up to 6mm and grinding to products less than 20 microns and it is available in standard mill sizes ranging from 15HP (11kW) to 4500HP (3352kW).

Metso Outotec to supply energy efficient VertimillMetso Outotec’s Vertimill provides the lowest total cost of ownership compared to other grinding mills in many applications thanks to its high energy efficiency, reduced media consumption, low installation cost as well as minimal liner wear and maintenance. It is capable of handling feed sizes up to 6mm and grinding to products less than 20 microns and it is available in standard mill sizes ranging from 15HP (11kW) to 4500HP (3352kW).

Metso Outotec is the only manufacturer worldwide than can offer multiple stirred mill technologies (Vertimill®, HIGTM mill and SMD) enabling to support their customers with the most suitable and efficient mill for their application.

Discover more about Vertimill®

Christoph Hoetzel, Head of Grinding Business Line, Metso Outotec, E-mail: christoph.hoetzel(at)mogroup.com, Tel. +61 477 330 679

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing, metals refining and recycling industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its illustrative combined sales for 2019 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki.mogroup.com