Displaying items by tag: optima

Cybersecurity at the highest level

OPTIMA collaborates with LANCOM Systems to develop a novel VPN solution for machines

The Optima Group from Schwaebisch Hall, Germany, has joined forces with cybersecurity specialist LANCOM Systems to develop a new type of VPN solution for machines and systems. As a result, it is now possible to establish an even more secure connection with the systems installed at the customer's site and maintain them remotely. The solution, which is the only one of its kind on the market, allows for VPN connections monitoring, protects the machine network at the customer's site with a firewall and is particularly user-friendly.

Markus Irle, Vice President Firewall & Security at LANCOM Systems, and Dr. Eng. Benjamin Haefner, Group Leader Industrial IT at Optima, presenting the new VPN solution. (Source: Optima. All photos were taken in compliance with the strictest infection control measures.)

Markus Irle, Vice President Firewall & Security at LANCOM Systems, and Dr. Eng. Benjamin Haefner, Group Leader Industrial IT at Optima, presenting the new VPN solution. (Source: Optima. All photos were taken in compliance with the strictest infection control measures.)

"With LANCOM Systems, we have found the ideal partner to take our cybersecurity to the next level," says Dr. Eng. Benjamin Haefner, Group Leader Industrial IT at Optima. In the future, every machine built by the special-purpose machine manufacturer will be equipped with an edge firewall from LANCOM that has been specially developed for Optima. "In addition to the highest security VPN routing functionality, the edge firewall functions as a kind of central doorman in the machine. As a result, uncoordinated data flows with potential risks can be systematically reduced and controlled," explains Haefner.

Unparalleled functionalities for maximum security

In addition, the VPN connection between Optima and the machines at the customer's site can be permanently monitored with what is known as a central firewall. "These functionalities are one-of-a-kind on the market and ensure maximum IT security," says Haefner. The structure of the entire VPN solution is strictly aligned with standards relevant to cybersecurity, such as IEC 62443 or CPwE reference architecture.

With the new VPN connection and its special security features, Optima and LANCOM Systems offer Optima’s customers a particularly secure and user-friendly solution. In the future, every machine manufactured by this special-purpose machine builder will be equipped with it. (Source: Optima)

With the new VPN connection and its special security features, Optima and LANCOM Systems offer Optima’s customers a particularly secure and user-friendly solution. In the future, every machine manufactured by this special-purpose machine builder will be equipped with it. (Source: Optima)

User friendliness increases IT security

The LANCOM solution is also user-friendly and easy to operate. In addition, the automated solution can be configured for the customer's network faster than previous applications. There is plenty of freedom for making flexible adjustments to the customer's individual IT infrastructure, which facilitates harmonious integration. Retrofitting can be carried out on existing machines at any time. "Usability is a particularly important issue for us," adds Markus Irle, Vice President Firewall & Security at LANCOM Systems. "This is because a large proportion of cybersecurity incidents are due to errors in use, not the security technologies themselves." Such a challenge can be overcome by making the system less complex. The development partnership with LANCOM Systems is part of an extensive series of measures Optima has taken to further enhance cybersecurity.

Highly respected manufacturer of secure, reliable and future-proof network and security solutions

High-tech in action: An Optima employee checks the correct configuration of the VPN solution using a tablet. (Source: Optima) Based in Wuerselen, Germany, LANCOM Systems is a highly respected manufacturer of secure, reliable and future-proof network and security solutions (WAN, LAN, WLAN & firewalls) for business and government. For the fifth time in a row, the German network infrastructure provider has topped the Professional User Rating Security Solutions (PUR-S) user survey conducted by the analyst firm techconsult and boasts an excellent reputation among experts. LANCOM Systems is a wholly owned subsidiary of the Rohde & Schwarz technology group.

High-tech in action: An Optima employee checks the correct configuration of the VPN solution using a tablet. (Source: Optima) Based in Wuerselen, Germany, LANCOM Systems is a highly respected manufacturer of secure, reliable and future-proof network and security solutions (WAN, LAN, WLAN & firewalls) for business and government. For the fifth time in a row, the German network infrastructure provider has topped the Professional User Rating Security Solutions (PUR-S) user survey conducted by the analyst firm techconsult and boasts an excellent reputation among experts. LANCOM Systems is a wholly owned subsidiary of the Rohde & Schwarz technology group.

More information: www.optima-packaging.com/cybersecurity

About OPTIMA

Optima supports companies worldwide with flexible and customer-specific filling and packaging machines for pharmaceuticals, consumer goods, paper hygiene and medical devices markets. As a provider of solutions and systems, Optima accompanies these companies from the product idea through to successful production and throughout the entire machine life cycle. Over 2,650 experts around the globe contribute to Optima's success. 19 locations in Germany and abroad ensure the worldwide availability of services.

Technologies to power the vehicles of the future

OPTIMA packaging group expands portfolio to include fuel cell production lines

Fuel cell vehicles are considered a potential solution in the battle against climate change. The Optima Group has now developed machine solutions to increase the production capacity of fuel cells. As a result, the required production steps – coating, cutting, assembling the individual layers, and stacking – have been automated. This establishes the Schwaebisch Hall-based family-owned Group as a leading supplier of complete solutions, offering fuel cell production worldwide. More information will be available on September 14 and 15, 2021 at the f-cell trade show at the Haus der Wirtschaft conference and congress center in Stuttgart – or by contacting Optima directly.

According to experts, we must significantly increase our efforts in the fight against climate change. Hydrogen is attracting attention as a propulsion technology. Many hybrid buses have been equipped with fuel cells to generate electric power. This significantly increases the range of an electrically-powered vehicle.

Furthermore, the refueling process is considerably faster than charging a lithium-ion battery. These advantages are particularly effective for vehicles used for long periods with minimal breaks, for example trucks, autonomous transport systems, and industrial trucks in large logistics centers.

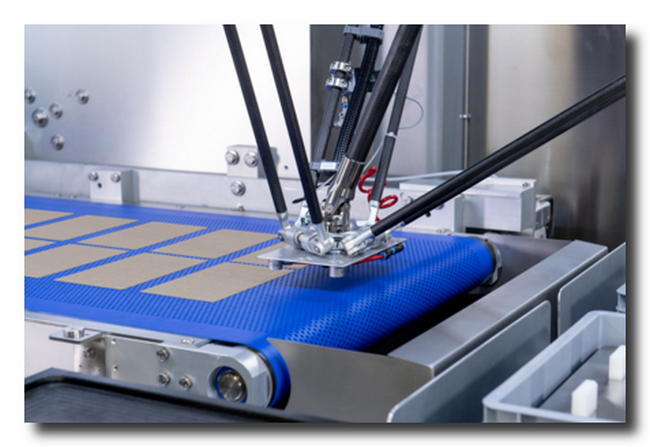

The extremely sensitive gas diffusion layers (GDLs) are a component of the membrane electrode assembly (MEA). They are cut and moved to the next process stage with the aid of a robotic gripper arm. (Source: Optima)

The extremely sensitive gas diffusion layers (GDLs) are a component of the membrane electrode assembly (MEA). They are cut and moved to the next process stage with the aid of a robotic gripper arm. (Source: Optima)

Growing demand for fuel cells

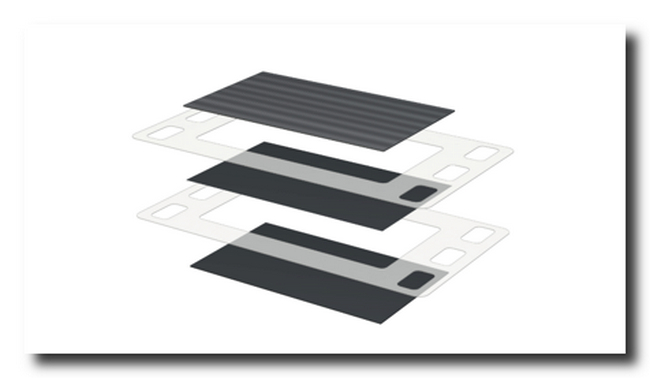

Greater use increases the need to produce fuel cells and drives demand for faster production. At the same time, extensive automation of the manufacturing process is essential to reduce production costs. At the heart of the fuel cell is the membrane electrode assembly, or MEA for short. This is permeated by hydrogen and oxygen, which react with each other within the MEA. This electrochemically generates the electric current required for propulsion of the vehicle. An MEA basically consists of an ion-conducting electrolyte membrane with a catalyst layer on the anode and cathode side (catalyst coated membrane, CCM) and gas diffusion layers (GDLs). These layers are delivered to the fuel cell or the MEA manufacturer as rolled goods or produced by the manufacturer itself. Here they need to be cut into the size required, assembled, and bonded.

Werner Volk, Director New Applications/Concepts at Optima Life Science (left) and Juergen Bareiss, Head of Optima Life Science, with membrane electrode assemblies (MEAs). (Source: Optima)

Werner Volk, Director New Applications/Concepts at Optima Life Science (left) and Juergen Bareiss, Head of Optima Life Science, with membrane electrode assemblies (MEAs). (Source: Optima)

Complete solutions for all manufacturing stages

"After spending several years in development, we are pleased that we can offer suitable machine solutions for all process stages involved in manufacturing MEAs, despite the high barriers to entry," says Juergen Bareiss, Head of the Optima Life Science business unit where the manufacturing technologies for fuel cells were developed. In cooperation with Coatema Coating Machinery GmbH, total solutions that include unwinding, coating, and cutting GDLs as well as combining the GDL and CCM to form the finished MEA are now available. Stacking the finished MEAs into a fuel cell stack occurs in the final stages of development. This machine solution will also be market-ready by the end of the year.

"This was mainly possible due to synergy effects within the broad-based Optima Group, the courage to innovate, and preexisting technologies as well as know-how in web converting," explains Bareiss. Technologies previously used for manufacturing and packaging processes in the medical technology, consumer goods, and paper hygiene industries have proven to be extremely valuable. This makes Optima a leading supplier of complete solutions for fuel cell production.

"With our solutions, we strive to become the market leader in the field of complete solutions for fuel cell production and contribute to a more environmentally-friendly mobility," says Bareiss. "In addition to sustainable business and machinery, developing environmentally friendly and future-proof solutions for our target markets is also important to us as part of our overall sustainability strategy," adds Dominik Broellochs, Group Sustainability Manager at the Optima Group. The fuel cell, he explains, is precisely the kind of solution that will enable sustainable mobility.

Structure of a membrane electrode assembly (MEA). The gas diffusion layers (GDLs) are on the outside, while the electrolyte membrane (catalyst coated membrane, CCM) is on the inside. Optima combines these layers together. (Source: Optima)

Structure of a membrane electrode assembly (MEA). The gas diffusion layers (GDLs) are on the outside, while the electrolyte membrane (catalyst coated membrane, CCM) is on the inside. Optima combines these layers together. (Source: Optima)

Market with great growth potential

"In contrast to lithium-ion batteries, German companies could become technological leaders in fuel cell development and manufacturing," says Werner Volk, Director New Applications/Concepts at Optima Life Science, who has been leading the developments. Optima is a global company that can supply machine solutions on an international scale along with the support required by producers who are interested in increasing their capacity. Anyone who is looking to switch from timed, piece-based production to continuous processes with higher outputs will find the right partner in Optima, says Volk. He will be on hand to answer questions regarding this subject at the f-cell trade show on September 14 and 15, 2021, at the Haus der Wirtschaft in Stuttgart (List hall, booth no. 46).

More about this topic at: www.optima-packaging.com/fuel-cell

About OPTIMA

Optima supports companies worldwide with flexible and customer-specific filling and packaging machines for pharmaceuticals, consumer goods, paper hygiene and medical devices markets. As a provider of solutions and systems, Optima accompanies these companies from the product idea through to successful production and throughout the entire machine life cycle. Over 2,650 experts around the globe contribute to Optima's success. 19 locations in Germany and abroad ensure the worldwide availability of services.

Joachim Dittrich, new Chief Representative, will assume his responsibilities in February

Joachim Dittrich will be the Chief Representative of Optima, as of February 2018.

Joachim DittrichThe 53-year old machine engineer will be responsible for the development and internationalization, particularly for Optima Consumer, as well as for additional subsidiaries and holdings nationwide and internationally.

Joachim DittrichThe 53-year old machine engineer will be responsible for the development and internationalization, particularly for Optima Consumer, as well as for additional subsidiaries and holdings nationwide and internationally.

The area of responsibility includes the strategic orientation and development of these business sections, and the development of prospects and synergies. Mr. Dittrich will assume a large part of Hans Bühler’s (CEO) tasks for the Optima Consumer division. Hans Bühler will dedicate more of his time to overall tasks and topics regarding the consortium.

Joachim Dittrich returns to his former domain: he worked for Optima Consumer from 2010 to 2011 as Commercial Director. Due to family matters, he switched to a well-known packaging machine manufacturer to take on the responsibilities of General Manager.

“Team orientation, highest motivation and commitment” are his top priorities for a corporation, says Joachim Dittrich. “Agility, enjoyment of work and the common success are also of fundamental importance to me.”