Displaying items by tag: moxa

Bundled Know-How for IIoT Applications: Cooperation Between Moxa Europe and Robotron

Objective: Fast provision of easy-to-use and scalable IIoT solutions – with focus on four application areas.

Moxa Europe GmbH and Robotron Datenbank-Software GmbH announce their collaboration in the configuration and provision of IIoT platforms. The two partners are focusing on the "Industrial Internet of Things" – applications in demanding industries such as process technology, oil & gas and energy technology. The first joint IIoT projects have already been realized for customers in the energy sector.

Most industrial companies have the use of IIoT solutions on their agenda. Some face the challenge of needing to see the first results quickly and with as few resources of their own as possible in order to determine whether the creation of an IIoT infrastructure is even worthwhile. Others have already invested time and money and have initial results – but no scalable platform to be able to efficiently undertake the next roll-outs and further projects.

Moxa Europe GmbH and Robotron Datenbank-Software GmbH are addressing precisely these challenges. They have combined their activities in the field of Industrial IoT and, effective immediately, are preparing complete solutions that lead to quickly installed, easy-to-operate and broadly scalable IIoT platforms.

Moxa contributes the reliable industrial hardware with which the sensors, machines and other components are integrated. At the heart of this IIoT infrastructure are industrial-grade IIoT gateways and edge computers. For these components, Moxa also makes an operating system available with Moxa Industrial Linux. Major releases of this operating system will be provided with security updates over a period of ten years. This ensures a long service life and stability of the installed hardware – including the ever-increasing cyber-security requirements.

As a specialist for the collection and evaluation of large quantities of data, Robotron offers various software solutions and platforms for high-performance IIoT applications. For the area of industrial production, focus is on current edge and cloud technologies as well as artificial intelligence for intelligent process control and optimization. These solutions can be adapted over a broad spectrum to the individual and widely varying requirements of the industrial users.

Together, Moxa and Robotron are focusing their collaboration on four application cases:

1. General IIoT platforms in demanding industries and applications, for which Moxa provides hardware components: Transportation (especially railway technology), oil & gas industry.

2. IIoT solutions for the energy sector – a particular strength of the partnership. The first projects have already been implemented here: using affordable IIoT hardware and innovative data analysis and visualization, insights into the distribution network can be generated that were previously only possible with considerably more expensive traditional solutions.

3. Energy efficiency and management in industry. Here, the industrial experience of Moxa and the data analytics expertise from Robotron (based on, among other things, the robotron*IPEA platform) form an ideal combination.

4. Real-time applications based on Robotron's Realtime Computer Vision platform (RCV). Together with the hardware from Moxa's appropriately certified edge-computing technology, this platform is also suitable for use in demanding industrial applications (e.g., in industries such as oil & gas, mining / extraction technology, rail technology, etc.).

With this well-prepared collaboration, both partners see great potential for offering their customers clear additional benefits as well as opportunities for opening new application fields. Hermann Berg, Head of Industrial IoT at Moxa Europe: "The collaboration with Robotron puts us in the position of also being able to very confidently offer complex IIoT projects with high requirements on software and cloud technology." Those responsible at Moxa are certain they have found the right software partner with just the right solution portfolio. Hermann Berg: "I am impressed how well developed and stable the Robotron platform is and with how much attention to detail the pre-processing of the data on the gateway has been implemented."

From Robotron's perspective, the combination of hardware and software expertise for IIoT applications creates the ideal condition for being even more successful together. Michael Baling, Head of Division Industry at Robotron: With the broad industrial-grade and robust portfolio from Moxa, we have found a partner to whom we can simply leave discussions regarding topics such as environmental requirements, longevity, and hardware-based security. In the area of logistics as well, Moxa – together with the German distribution partner Sphinx Computer – has relieved us of all complexity, allowing us to concentrate fully on our core competencies of software and data analysis."

You can learn more about the application cases and joint solutions on a new website created together by Robotron and Moxa: www.moxa-iiot.eu.

Robotron specializes in the effective management and evaluation of very large quantities of data. With its solutions, the company creates added value for clients from the energy sector, industry and public administration – efficiently and with focus on the customer. Today, there are more than 570 employees in the company and its subsidiaries, 450 of whom work at the headquarters in Dresden. Robotron has, for many years, accompanied industrial companies on the road to Industry 4.0. Innovative solutions with current edge and cloud technologies as well as artificial intelligence successfully contribute to the optimization of processes as well as to improvements in quality and efficiency with renowned customers from the field of industrial manufacturing, particularly the automotive and semiconductor industries. For more information, visit www.robotron.de/en/industry.

About Moxa

Moxa is a leading provider of edge connectivity, industrial computing, and network infrastructure solutions for enabling connectivity for the Industrial Internet of Things. With over 30 years of industry experience, Moxa has connected more than 71 million devices worldwide and has a distribution and service network that reaches customers in more than 80 countries. Moxa delivers lasting business value by empowering industry with reliable networks and sincere service for industrial communications infrastructures. Information about Moxa’s solutions is available at www.moxa.com.

The MOXA logo is a registered trademark of Moxa Inc. All other trademarks herein are the property of their respective owners.

Moxa Launches Wireless Add-on Module for MXview to Overcome the Wi-Fi Network Management Challenges in Smart Manufacturing

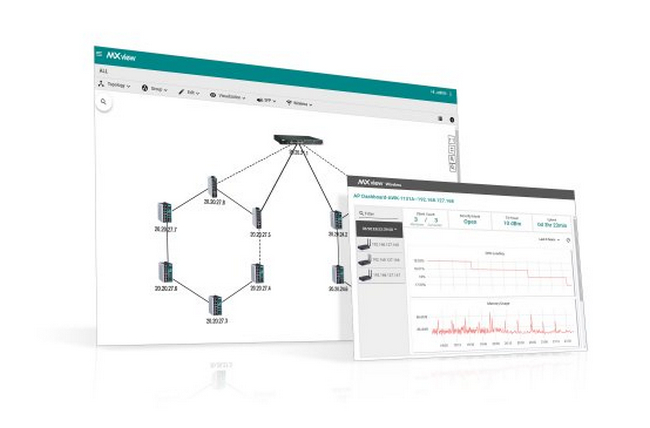

Moxa, a leading provider of network infrastructure solutions, has released the MXview Wireless add-on module for our MXview industrial network management software. MXview streamlines network management by visualizing networks, helping non-IT staff simplify operations and improve network uptime.

This software has successfully helped many customers from around the world in different industries, such as in power, intelligent transportation, and manufacturing. Today, with the rise of smart manufacturing, intelligent and reliable industrial network communication has become the cornerstone for nearly every smart application. In response to the transformation of the industrial environment and increasing number of Wi-Fi applications, the new MXview Wireless add-on module fulfills the different requirements of both static and dynamic wireless applications in smart manufacturing. With reliable network communications as a foundation and real-time network management from a single pane of glass, business owners can focus on improving operational efficiency and achieving maximum system uptime.

Visualize Wi-Fi Networks for Optimal Operational Efficiency

Intelligent process control is a typical static wireless application in smart manufacturing where customers use Wi-Fi to establish the communication between the clients installed at production lines and the control center. However, an unstable wireless connection might lead to wrong decision-making due to incomplete on-site information or dropped connections, affecting optimal production processes. It’s often difficult to know the exact status of the Wi-Fi connection and fix issues immediately the moment they occur. The MXview Wireless add-on module simplifies network management by allowing users to get detailed device information and performance indicator charts for individual AP and client devices from the device dashboard. “A major benefit of this module is that users can now view the wireless and wired network status from a single main control dashboard. This feature not only lets you quickly understand the network conditions of the factory, but also makes network management much easier.” says Lyra Li, product manager at Moxa. Furthermore, users can monitor connectivity patterns and customize alert settings to immediately notify you of any problems. In turn, this allows engineers to perform on-site troubleshooting quickly and efficiently, ensuring maximum network availability.

Intelligent process control is a typical static wireless application in smart manufacturing where customers use Wi-Fi to establish the communication between the clients installed at production lines and the control center. However, an unstable wireless connection might lead to wrong decision-making due to incomplete on-site information or dropped connections, affecting optimal production processes. It’s often difficult to know the exact status of the Wi-Fi connection and fix issues immediately the moment they occur. The MXview Wireless add-on module simplifies network management by allowing users to get detailed device information and performance indicator charts for individual AP and client devices from the device dashboard. “A major benefit of this module is that users can now view the wireless and wired network status from a single main control dashboard. This feature not only lets you quickly understand the network conditions of the factory, but also makes network management much easier.” says Lyra Li, product manager at Moxa. Furthermore, users can monitor connectivity patterns and customize alert settings to immediately notify you of any problems. In turn, this allows engineers to perform on-site troubleshooting quickly and efficiently, ensuring maximum network availability.

Easy Troubleshooting for Maximum System Uptime

In automated material handling (AMH) systems, the Wi-Fi connections must be able to dynamically adapt to the constantly moving vehicles. An unstable wireless signal could easily disrupt the operation of these systems. However, wireless connections are invisible and affected by a lot of different factors. The MXview Wireless add-on features a dynamic topology view to let users see the status of wireless links and connection changes at a glance. Moreover, since automated vehicles constantly roam between different APs around the facility, users can overlay the network topology on top of a floor map of the facility to easily locate the vehicle by just checking the client’s wireless connection. This helps save a great deal of time when trying to identify a malfunctioning client device. “The roaming playback function lets users review a client’s roaming history of the past 30 days to repeat an incident. Users can leverage this function to find and address the root cause more efficiently, instead of having to consolidate and examine individual device logs.” says Lyra. Exclusively developed by Moxa, these two functions are specially designed to fulfill the growing requirements of automated factories, smart logistics, and other intelligent applications. To learn more about our wireless AMH solutions.

Leveraging our experience in wired network management with MXview, the newly released MXview Wireless add-on module was created to get the most out of your Wi-Fi applications. To encourage everyone to experience the power of this industrial network management software, Moxa is also launching a special promotion program. From now until December 31, 2021, users can fully enjoy the MXview Wireless add-on for free for one year by simply activating the MXview Wireless add-on module for MXview. For more information about the product and details regarding this ongoing promotion, please visit the product page or the microsite at www.moxa.com/MXview.

MXview and MXview Wireless Add-on Module Highlights

√ Automatically discovers and visualizes network devices and physical connections

√ Instant alerts with customizable trigger thresholds

√ Easily embedded into OT/IT systems

√ Single, integrated dashboard for wired and wireless network status overview

√ Detailed device information and performance indicator charts

√ Dynamic topology view shows the status of wireless links and connection changes at a glance

√ Visual, interactive roaming playback function to review the roaming history of clients

Learn how MXview was endorsed by our ITS customer by reading our City of Lancaster, USA case study.

Moxa Demonstrates Its Commitment to Securing Industrial Networks By Becoming IEC 62443-4-1 Certified

Moxa Inc., a leader in industrial communications and networking, with a focus on securing industrial networks, is delighted to announce it has obtained the IEC 62443-4-1 certification pertaining to cybersecurity standards. The certification testing and audit was performed by LCIE Bureau Veritas and issued by the IECEE certification body. Moxa has always been involved in the cybersecurity industry and was one of the first companies globally to become IEC 62443-4-1 certified by the world-leading conformity assessment and certification services provider.

The IEC 62443 standard Part 4-1 defines a secure development lifecycle for the purpose of developing and maintaining secure products used in industrial automation and control systems. The IEC 62443-4-1 certificate confirms that Moxa has implemented a secure by design methodology from the first day of the product development process, which includes complete security lifecycle management and patch management. This certificate also demonstrates Moxa’s capability to identify and respond to vulnerabilities and work with customers to mitigate their risks.

According to IDC’s latest worldwide IT and OT Convergence survey in 2020, the key motivations for IT/OT convergence are enhancing operational safety and performance, reducing costs, and improving quality. Another important observation from the report is that globally, 48.8% of IT and OT management owners consider security to be the top barrier to IT/OT convergence. This point highlights the importance OT enterprises place on security when embracing Industry 4.0 or the Industrial Internet of Things (IIoT) in order to significantly enhance operational efficiency and productivity.

According to IDC’s latest worldwide IT and OT Convergence survey in 2020, the key motivations for IT/OT convergence are enhancing operational safety and performance, reducing costs, and improving quality. Another important observation from the report is that globally, 48.8% of IT and OT management owners consider security to be the top barrier to IT/OT convergence. This point highlights the importance OT enterprises place on security when embracing Industry 4.0 or the Industrial Internet of Things (IIoT) in order to significantly enhance operational efficiency and productivity.

“In response to our customer’s concerns, Moxa has been actively looking into the security requirements of IEC 62443 standards dating back to when they were still under development in 2016,” said Samuel Chiu, General Manager of Moxa Networking Co. Ltd. “By adhering to the strict verification process of IEC 62443 standards, Moxa not only provides industrial-grade solutions, but also ensures that security is part of the DNA of its reliable networking solutions throughout the product development process. We provide our customers with the assurance that they can connect their valuable assets with Moxa’s solutions and be confident that they can keep their operations running smoothly.”

Moxa has also been following the evolving cybersecurity best practices in order to ensure our solutions work harmoniously with the latest technological innovations of edge devices while mitigating the latest cyberthreats. One of the best practices is shared in Enhancing ICS Cybersecurity in the Software Development Lifecycle. This article, which features on the ISA Global Cybersecurity Alliance blog, was contributed to by SZ Lin, Assistant Project Manager at the Technology and Research Corporate Division of Moxa. Lin was the first person in Taiwan to be awarded the ISA/IEC 62443 Cybersecurity Expert Certificate. In addition to Lin, Felipe Sabino Costa, whose current roles include ISA cybersecurity instructor and Moxa LATAM Industrial Cybersecurity Expert, also pointed out some key criteria in his article Can a Solution Provider Handle Industrial Cybersecurity? 8 Questions to Ask. His article can also be found on the ISA Global Cybersecurity Alliance blog, and has helped guide business owners to develop mission-critical solutions that include cybersecurity by design.

Before obtaining the IEC 62443-4-1 certificate in May 2020, Moxa has been following the development of the standard for five years and has designed our products in accordance with its guidelines. In addition, Moxa has spent considerable resources on educating the market about not only the importance of the standard, but how we embed its principles throughout all stages of our hardware and software development. Only when cybersecurity awareness is increased can industrial network security be enhanced by joint forces. Bearing this in mind, Moxa will continue investing in cybersecurity and work closely with our customers to ensure that “secure by design” solutions can be implemented successfully.

About Moxa

Moxa is a leader in edge connectivity, industrial computing, and network infrastructure solutions for enabling connectivity for the Industrial Internet of Things. With over 30 years of industry experience, Moxa has connected more than 71 million devices worldwide and has a distribution and service network to serve customers in more than 80 countries.