Super User

Antimicrobial Technologies – IDTechEx Discusses How They Work

Antimicrobial technologies such as coatings and textiles containing silver and copper are helping people during the COVID-19 pandemic by ensuring that whatever they touch, whether that is a door handle or their own mask, is free from live SARS-CoV-2 particles. But how exactly do these antimicrobial technologies work? How can a silver, copper or even polymeric coating kill microorganisms such as bacteria, fungi, or in the case of COVID-19, viruses? This article explores the mechanisms of action, or the interactions, through which antimicrobials work. IDTechEx have recently published a research report on the antimicrobial technology industry – “Antimicrobial Technology Market 2021– 2031”. Please refer to www.IDTechEx.com/Antimicrobial for more information.

Damaging cell walls and membranes

Microorganisms such as bacteria, viruses, and mold are single cellular organisms surrounded by either a cell wall, cell membrane, or both. Disruption of this outside layer is a common way to kill microorganisms. Like all organisms, the insides of a microorganism are carefully regulated, and ideally, stays inside.

One way to destroy microorganisms is to disrupt the activity of the membrane. For example, silver-based technologies release silver ions that can bind to proteins within the membrane that regulate transport into and out of the cell. Similarly, high concentrations of zinc, itself essential to microorganisms for growth, can end up blocking ion channels that cross the membrane. When nutrients essential to the microorganism cannot enter, cell growth and reproduction is halted.

A more drastic method is to simply break the microorganism open. A wide range of antimicrobial technologies generate reactive oxygen species such as peroxides and singlet oxygen that attack and break down the cell membrane. Others, such as silane quaternary compounds, simply pierce or rupture the membrane through mechanical means.

Binding and inhibiting essential cellular processes

Antimicrobial technologies can also wreak havoc from inside the cell. Metal-based technologies, such as silver, copper, and zinc, release ions that bind to components of the cell’s internal machinery, many of which are a part of pathways essential to the cell’s survival. Metallic ions, being positively charged, also interact with negatively charged genetic material such as DNA and RNA. Access to DNA and RNA is critical – without it, new proteins cannot be created, and in the case of DNA, cell division is halted when DNA cannot be copied.

Preventing adhesion to surfaces

A tactic to combat bacteria and mold is to simply prevent adherence to surfaces. Bacteria and mold have the ability to form biofilm, a dense film-like structure containing and protecting millions of microorganisms. The first step to forming biofilm, is adherence to a surface. Antimicrobial companies have created surfaces that provide an unfavorable environment for adhesion, resulting in a microorganism that simply lives out the rest of its short life in peace without growing and forming problematic films.

Does the mechanism of action matter?

In short, yes!

There is a great concern amongst scientists that antimicrobials that kill microorganisms from within can contribute to the development of antibiotic resistant bacteria. Almost all organisms have a mechanism called an efflux pump that is responsible for removing toxic substances. Extensive exposure to low levels of toxins pressures microorganisms to develop and evolve more effective efflux pumps, which the microorganism can also use to pump out antibiotics.

As far, scientists have only managed to induce resistance to antimicrobial technologies in the laboratory, but it will become a possibility in the wild if antimicrobial technologies are used irresponsibly. Antibiotic resistance is deemed by the World Health Organization as one of the top 10 global public health threats facing humanity – without effective antibiotics, many routine conditions and medical procedures today will become a matter of life and death.

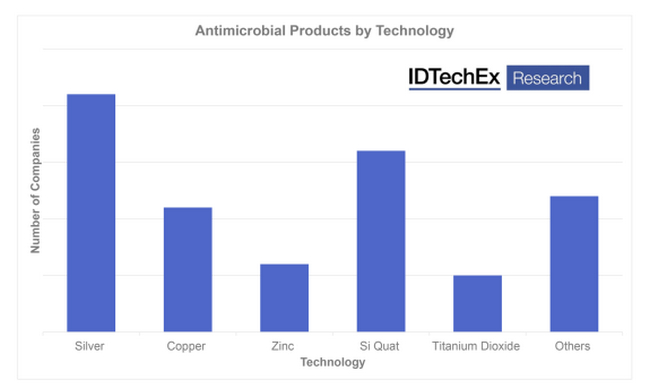

IDTechEx has found that a large portion of antimicrobial companies are developing silver-based technologies. Source: IDTechEx - “Antimicrobial Technology Market 2021– 2031”

IDTechEx have analyzed over 100 companies in the antimicrobial technology market, many of which are developing technologies to circumvent the problem of antimicrobial resistance. For more information on the topic, please refer to www.IDTechEx.com/Antimicrobial, or for the full portfolio of Healthcare related research available from IDTechEx please visit www.IDTechEx.com/Research/Healthcare.

About IDTechEx

IDTechEx guides your strategic business decisions through its Research, Subscription and Consultancy products, helping you profit from emerging technologies. For more information, contact This email address is being protected from spambots. You need JavaScript enabled to view it. or visit www.IDTechEx.com.

Solenis Newly Redesigned Website Features Sustainability Solutions for Water-Intensive Industries

Solenis, a leading global producer of specialty chemicals used in water-intensive industries, recently launched a new redesigned website at solenis.com/explore. The site features enhanced transparency into the company’s sustainability initiatives, easy-to-access product and solution information and an expanded career section.

Website visitors can browse resources related to Solenis’ sustainability work. The site includes a new sustainability and regulatory library that enables easy access to ISO and other regulatory certifications. In addition, visitors can access safety metrics and the company’s annual Sustainability Report. The site also provides information on the Solenis Sustainability Award, a new annual program recognizing customer projects that deliver meaningful, measurable sustainability results.

The website improves user experience, as well, with a new solution finder tool that makes it easier for customers to get industry-specific information for their operational and sustainability challenges. For example, food and beverage packaging customers can find information about the company’s eco-friendly formulations for paper packaging. Likewise, customers in industrial markets, such as geothermal power and mining, can search for innovative water treatment and process improvement solutions. The site also offers fast access to resources, including a new safety data sheet (SDS) library, as well as case histories and upcoming event schedules.

Another important element of the site redesign is the addition of a comprehensive careers section. Prospective employees can now search for Solenis career opportunities globally. The site also allows students and graduates to access information on internships, apprenticeships and the company’s world-class sales technology application rotation (STAR) program. The expanded careers section features information about the company’s diversity and inclusion commitment as well.

“With easy-to-find resources and expanded access to our environmental, social and governance (ESG) efforts, our new website reflects our position as a global solutions provider helping water-intensive customers manage their resources,” said John Panichella, Solenis CEO. “It allows us to better showcase our innovative products and solutions, recruit the industry’s top talent and provide transparency into our commitment to sustainable growth.”

The website will be updated regularly with the company’s latest products, innovations, news and events. Solenis is also planning a new blog and website versions in several additional languages.

For more information about Solenis, visit the new website at solenis.com/explore.

About Solenis

Solenis is a leading global producer of specialty chemicals for water-intensive industries, including the pulp, paper, oil and gas, petroleum refining, chemical processing, mining, biorefining, power and municipal markets. The company’s product portfolio includes a broad array of process, functional and water treatment chemistries, as well as state-of-the-art monitoring and control systems. These technologies are used by customers to improve operational efficiencies, enhance product quality, protect plant assets and minimize environmental impact. Headquartered in Wilmington, Delaware, the company has 39 manufacturing facilities strategically located around the globe and employs a team of approximately 5,200 professionals in 120 countries across five continents. For additional information about Solenis, please visit solenis.com/explore

ZEISS Introduces the First Crystallographic CT System

Expanding the Range of Solutions for Non-destructive Diffraction Contrast Tomography

ZEISS Research Microscopy Solutions, the performance leader in non-destructive 3D imaging systems, has just introduced the new ZEISS Xradia CrystalCT™ micro-computed tomography (microCT) system to enable 3D crystallographic imaging of polycrystalline materials for a wide range of metal and alloy, additive manufacturing, ceramic, and pharmaceutical samples in industrial and academic laboratories.

A world-first commercial implementation, ZEISS Xradia CrystalCT is purpose-built to deliver diffraction contrast tomography (DCT) on a traditional computed tomography system, allowing researchers to complement absorption contrast tomography data with crystallographic information in three dimensions. ZEISS Xradia CrystalCT is the latest Xradia platform to deliver DCT, developed in collaboration with Xnovo Technology ApS, the pioneer in lab-based diffraction imaging.

Seamless large volume grain mapping, increasing data volume representivity compared to traditional, destructive 3D crystallographic methods, is facilitated by advanced acquisition modes that provide stitch-free scanning for fast and accurate 3D grain data. Advanced scanning modes further remove the limitations of size and acquisition speed for a wide range of common samples in high-productivity lab settings. The ability to run larger sample sizes removes limitations in the lab, enabling more sample types and less prep-time resulting in a faster time to analysis. Faster acquisitions speeds enable shorter sample run times, increasing lab productivity.

The ability to image the grain structure and quantify the underlying crystallographic orientation in materials such as metals is instrumental to understanding and optimizing material properties. The non-destructive nature of microCT imaging facilitates the understanding of microstructural evolution in situ, characterizing the impact of thermal, mechanical, or environmental conditions on material behavior. Such studies help to evaluate the performance and durability of new, lighter and stronger advanced materials, and address issues such as functionality, safety, and improved economics.

DCT imaging was previously only available from a synchrotron until it was offered on the ZEISS Xradia 620 Versa 3D X-ray microscope as an extension module. In addition to being a DCT platform, ZEISS Xradia CrystalCT is also a class-leading microCT imaging system, providing superb resolution and image quality for a range of 3D imaging needs. It is built on the highly stable ZEISS Xradia Versa base.

Daniel Sims, head of ZEISS X-ray Microscopy, says, “With CrystalCT, we bring years of leading innovation and advancements on our Xradia Versa platforms to a much wider audience. The market-shaping CrystalCT offers proven performance for a range of 3D imaging needs. Our customers additionally enjoy investment protection as this platform is highly extendable with a wide range of add-on capabilities and can be upgraded to the top of the line Versa models as their business and laboratory needs expand.”

The CEO of Xnovo, Erik Lauridsen, comments, “We are proud to support the next generation of lab-based diffraction imaging that now allows broader access to this capability. By building on our proven expertise in data reconstruction and analysis, we were able to transfer the DCT method to a micro-computed tomography platform. ZEISS’ microCT system provides an ideal environment for this implementation.”

Note: LabDCT, CrystalCT and Xradia are trademarks of Carl Zeiss GmbH. GrainMapper3D is a trademark of Xnovo Technology ApS. Other trademarks that may be mentioned in this release are the intellectual property of their respective owners.

Note to editors: Images and video are available for DCT studies of metals, alloys, pharmaceuticals, geoscience, gemology, semiconductor and other industrial materials.

About ZEISS

ZEISS is an internationally leading technology enterprise operating in the fields of optics and optoelectronics. In the previous fiscal year, the ZEISS Group generated annual revenue totaling 6.3 billion euros in its four segments Semiconductor Manufacturing Technology, Industrial Quality & Research, Medical Technology, and Consumer Markets (status: 30 September 2020).

For its customers, ZEISS develops, produces, and distributes highly innovative solutions for industrial metrology and quality assurance, microscopy solutions for the life sciences and materials research, and medical technology solutions for diagnostics and treatment in ophthalmology and microsurgery. The name ZEISS is also synonymous with the world's leading lithography optics, which are used by the chip industry to manufacture semiconductor components. There is global demand for trendsetting ZEISS brand products, such as eyeglass lenses, camera lenses, and binoculars.

With a portfolio aligned with future growth areas like digitalization, healthcare, and Smart Production, and a strong brand, ZEISS is shaping the future of technology and constantly advancing the world of optics and related fields with its solutions. The company's significant, sustainable investments in research and development lay the foundation for the success and continued expansion of ZEISS' technology and market leadership. ZEISS invests 13 percent of its revenue in research and development – this high level of expenditure has a long tradition at ZEISS and is also an investment in the future.

With over 32,000 employees, ZEISS is active globally in almost 50 countries with around 30 production sites, 60 sales and service companies, and 27 research and development facilities. Founded in 1846 in Jena, the company is headquartered in Oberkochen, Germany. The Carl Zeiss Foundation, one of the largest foundations in Germany committed to the promotion of science, is the sole owner of the holding company, Carl Zeiss AG.

Further information at www.zeiss.com

ZEISS Research Microscopy Solutions

ZEISS Research Microscopy Solutions is the world's only one-stop manufacturer of light, electron, X-ray, and ion microscope systems and offers solutions for correlative microscopy. The portfolio comprises of products and services for life sciences, materials, and industrial research, as well as education and clinical practice. The unit is headquartered in Jena. Additional production and development sites are located in Oberkochen and Munich as well as in Cambourne (UK) and Pleasanton (USA). ZEISS Research Microscopy Solutions is part of the Industrial Quality & Research segment.

Watson-Marlow Fluid Technology Group announces Bredel heavy-duty hose pumps

Watson-Marlow Fluid Technology Group (WMFTG) announces Bredel heavy-duty hose pumps to provide high metering accuracy and excellent resistance to the viscous and abrasive chemicals commonly used in the pulp and paper industry.

Unlike diaphragm, rotary lobe, and PC pumps, the peristaltic design of Bredel hose pumps contains no moving parts that come into contact with the product, and no seals, ball-checks, diaphragms, glands, immersed rotors, stators or pistons to leak, clog, corrode or replace. Bredel hose pumps also obviate the need for ancillary equipment such as dry run protection, seal water flush systems and in-line check valves. A simple hose change takes only minutes and can be performed in-situ without special tools or skilled personnel.

The low maintenance peristaltic design offers a low total cost of ownership. As the fluid is safely contained within the hose or tube, operation and maintenance personnel and the environment are protected from unwanted spillages or exposure to chemicals.

The low maintenance peristaltic design offers a low total cost of ownership. As the fluid is safely contained within the hose or tube, operation and maintenance personnel and the environment are protected from unwanted spillages or exposure to chemicals.

Bredel hose pumps are dry-running and self-priming, and allow no slippage, for true positive displacement to provide accurate and repeatable metering. Only Bredel industrial hose pumps provide this level of engineering expertise for their drives.

The pumped fluid is completely contained in a long-life hose, protecting operation and maintenance personnel and the environment from unwanted spillages or exposure to chemicals. Flow is entirely independent of suction and discharge conditions. Every Bredel hose is precision machined to ensure flow stability and pump performance in tough fluid handling applications.

These industrial pumps achieve flow rates up to 475 GPM, transferring up to 80% solids in suspension.

For more information on Bredel heavy-duty hose, visit www.wmftg.com/en-us/brands/bredel/.

WMFTG is a wholly owned subsidiary of Spirax-Sarco Engineering plc, a global organiation employing 7,900 people, of whom over 1,600 are direct sales and service engineers. Its shares have been listed on the London Stock Exchange since 1959 and it is a constituent of the FTSE 100 index.

WMFTG is headquartered in Falmouth, UK with international operations in 34 countries.

Watson-Marlow Limited was honoured with the Queen’s Award for Enterprise: International Trade 2017 and Innovation 2018.

Further information can be found at www.wmftg.com

Coal production from top ten mining companies expected to increase by up to 6.6% in 2021, says GlobalData

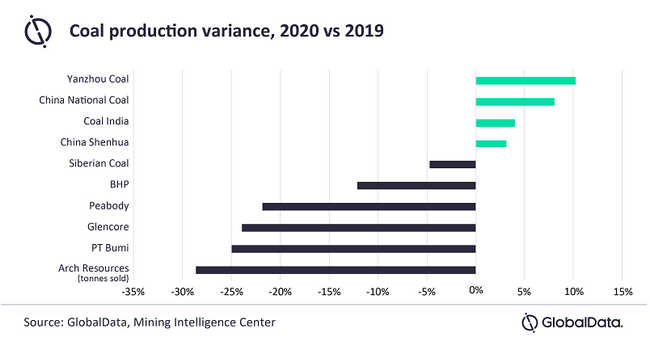

Coal production from the top ten mining companies (Coal India, China Shenhua, Yanzhou Coal, Peabody, China National Coal, Glencore, Siberian Coal, PT Bumi, BHP and Arch Resources) fell from a collective 1,704Mt in 2019 to 1,633Mt in 2020, which is a 4.2% decline. The most significant declines were observed from Arch Resources (28.6%), PT Bumi (24.9%), Glencore (23.9%), and Peabody (21.8%), according to GlobalData, a leading data and analytics company.

GlobalData expects production from the top ten companies to be between 1,683-1,740Mt in 2021, which is an increase of up to 6.6% compared with the collective output in 2020 (1,633Mt). Operating activities, backed by the rollout of vaccine and strict COVID-19 protocols on-site, returning to normal is expected to be a key production driver for companies in 2021.

Production from Arch Resources (formerly Arch Coal) declined primarily due to the sale of the Holden #22 Surface mine in December 2019, coupled with weak economic conditions during Q1 2020. In addition, the temporary suspension of the Viper mine in Q2 2020 further disrupted the company’s coal production.

Vinneth Bajaj, Associate Project Manager at GlobalData, comments: “Heavy rainfall amid the outbreak of COVID-19 impacted PT Bumi’s output in 2020, while Glencore’s coal output fell for the fourth consecutive quarter as the company’s Colombian coal assets remained suspended as part of the COVID-19 preventive measures. Scheduled production cuts across the Australian portfolio also impacted the company’s overall output as did the placement of the Prodeco mine under care and maintenance and strikes at Cerrejon between August and December 2020.”

Peabody’s output dropped primarily due to the upgrade of the main line conveyor system at Shoal Creek, alongside pit sequencing work at Moorvale and a dragline outage at Coppabella. In addition, the company also suspended operations at the Wambo underground mine for around 59 days during the second half of 2020. The closure of mines including Kayenta and Cottage Grove (Q3 2019) and Wildcat Hills (Q2 2020) further impacted the company’s output.

Bajaj continues: “BHP’s coking coal production was impacted by planned maintenance at the Saraji and Caval Ridge mines, environmental disruptions at La Nina, and lower yields at the South Walker Creek and Poitrel mines. Meanwhile, the thermal coal segment, from which the company is expected to exit in the near future, was affected by a 91-day strike at Cerrejon, which started on August 31, 2020.

“In contrast, production from Coal India rose by 4% owing to a recovery in the offtake from India’s power sector, which was supported by a resumption in industrial and commercial activities as the country’s electricity demand started to recover from the COVID-19 setback. Output from China Shenhua, Yanzhou and China National Coal Group also increased, rising by 3.1%, 10.2% and 8.1%, respectively, in 2020, mainly owing to a quick recovery in China, particularly during the second half of 2020.”

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

Metso Outotec to supply large-capacity Grate-Kiln iron ore pellet plant to India

Metso Outotec has signed a contract with an Indian customer for the supply of a large-capacity Grate-Kiln pellet plant in the State of Odisha, India. The contract is booked in Metals’ Q1/2021 orders received. Typically, the value for this type of an order is in the range of EUR 30-40 million, depending on the scope of delivery.

Metso Outotec’s scope of delivery includes basic engineering and process technology for the Grate-Kiln pellet plant, including the core proprietary equipment consisting of traveling grate, kiln, and cooler, as well as supervisory services for commissioning, and spare parts.

Metso Outotec’s scope of delivery includes basic engineering and process technology for the Grate-Kiln pellet plant, including the core proprietary equipment consisting of traveling grate, kiln, and cooler, as well as supervisory services for commissioning, and spare parts.

“The energy-efficient Metso Outotec Grate-Kiln process produces pellets of uniform quality with low emissions, high availability, and it has low investment and operating costs,” says Jari Ålgars, President, Metals business area at Metso Outotec. “With its annual pellet production capacity of 6 million tons, the new plant will be the first large-scale Grate-Kiln pellet plant in the country.”

Find out more about Metso Outotec Grate-Kiln technology on our website.

Further information, please contact:

Christopher Urban, Vice President, Heat Transfer, Metso Outotec, tel.+1 570 850 3251, email: christopher.urban(at)mogroup.com

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki.mogroup.com

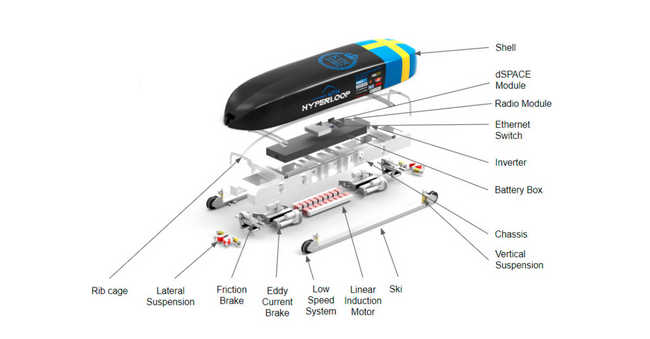

Lesjöfors springs in promising Swedish Hyperloop project

Once again, springs from Lesjöfors play a critical role in a progressive student project. The Hyperloop concept will bring super-fast, fossil-free transportation of both people and goods. A group of technical students in Sweden is competing in global events to develop the groundbreaking technology.

The Hyperloop concept is an initiative from Elon Musk, the founder of Tesla and SpaceX that gathers scientists, students, designers, programmers, venture capitalists and other businesses in cross-border development projects. The high-speed solution that Hyperloop is planned to be will be both faster, safer, cheaper, more comfortable and energy efficient than today’s transportation systems. The vessels will have top speeds of 1 000-1 200 km/h and will bring transports from e.g. Stockholm to Gothenburg in 30 minutes.

High speed thanks to levitation

The concept is basically a pod placed in a tunnel or tube that moves with levitation driven by magnetism. The levitation eliminates friction from the surface and since the tube is a closed environment, there is no impact from the outside. The air pressure is reduced to almost vacuum inside the tube and the reduced air resistance means that the speed can be increased significantly with reduced energy consumption.

“To be able to reach speeds of more than 1,000 km/h, a technology based on levitation is required. Some teams have instead used wheels, achieving a high place in competitions, but at 500km/h and upwards, the friction from the wheels will quickly become too high for the pod to continue to increase in speed. Instead, if magnetic-based levitation is used, the resistance is reduced for higher speeds.”, says Claes Henriksson, team captain for KTH Hyperloop.

Sponsored springs with critical function

The springs, with which Lesjöfors sponsor the team, will be used for the lateral control of the pod. Since a Hyperloop pod travels mainly without friction, it is extremely important that the pod does not come into excessive contact with the monorail (I-beam). The springs ensure that the pod always keeps the right course and does not rub against the rails. In addition to the fact that well-defined springs ensure that the pod maintains its speed, they are also important for safety reasons; should the pod crash into the monorail at high speed, there is a risk for serious damage.

“We are happy to be part of such an exciting and important futuristic project. Sponsoring students for us is both about making important contacts for the future and spreading knowledge about our unique spring expertise ", says Mattias Hartvigsson, product specialist at Lesjöfors.

In operation next decade

There is still a long way to go before the Hyperloop vision can be realized. However, development is progressing quickly and experts believe that the Hyperloop technology can begin to roll out around 2030. Some countries have even higher ambitions and, among others, Saudi Arabia and United Arab Emirates have the goal of having a Hyperloop operating already in 2024.

"Our team’s ambition does not end with the competitions, we want to continue to optimize the systems and assist with expertise for a full-scale Hyperloop network we hope to see in Sweden in the future," says Claes Henriksson.

The Lesjöfors Group provides the widest range of springs and pressings to customers in diverse industries across the world. With a unique expertise in high technological, custom-made solutions and a flexible manufacturing capacity, Lesjöfors is the premier partner for all spring requirements. Lesjöfors, owned by Beijer Alma a listed company on the Stockholm Stock Exchange, comprises almost 40 manufacturing and sales companies in many countries. As a long-term and committed spring innovator, the Group continuously grows with a good profitability, both organically and by acquisitions.

CREATING A SOLID FOUNDATION FOR ECONOMIC DEVELOPMENT

The Dangote Group planned a world-class new refinery in Nigeria that would reduce the country’s reliance on imported energy and bring with it over 30,000 jobs. It was a project requiring some truly massive moves – among the continent’s largest, in many cases. But before work could even begin, the team had to tame this patch of reclaimed swampland, turning it into a stable heavy lift surface.

To support the drive for growth, Africa is looking to reduce reliance on imports; producing more of its own energy and raw materials. In Nigeria, this drive is led by businesses such as the Dangote Group of Companies, which is putting the finishing touches on the continent’s largest oil refinery in Lekki Free Zone, Lagos State.

This development has been on a truly epic scale. The journey from Dangote’s new, purpose-built jetty to the construction site was more of a commute than a transportation; covering some 10km. Over 52,000t of components were planned for construction - including a 2,000t crude column that is the largest ever fabricated, and the heaviest item ever transported on public roads in Africa: a 3,000t regenerator.

The demands here were not simply to move such exceptional dimensions and weights but also to ensure all components were coordinated to arrive in the desired sequence - minimizing the risk of delays and additional costs.

Giuseppe Surace, Chief Operations Officer at Dangote Refinery, explains: “Our new refinery is the most ambitious project of its kind ever seen in Africa. Given the scale and importance of the work involved, we knew that we needed an experienced engineered heavy logistics partner who could successfully overcome challenges in the site terrain as well as the volume and size of construction components.

“This was key to ensuring that delays to our critical path were kept to a minimum, and that we are able to have the plant operational as quickly as possible.”

Installation of CDU using 5,000t capacity ringer as a main crane and 1,600t capacity crawler for tailing

Installation of CDU using 5,000t capacity ringer as a main crane and 1,600t capacity crawler for tailing

Avoiding that sinking feeling

In any part of the globe, this would be a challenge very few organizations could fulfil. Yet the requirements in Lekki Free Zone were complicated further by its location on reclaimed ground next to the coast.

To withstand the required weight and frequency of traffic, surrounding swampland needed to be reinforced. Conventional approaches to this problem include piling, or soil stabilization, which requires excavation work and high volumes of aggregates. Although effective in providing the required stability these solutions can be expensive, time consuming and in some cases cause land reclamation problems, later on.

Working with Nigerian partner Northridge Engineering, Mammoet was selected to meet this challenge. A solution was laid down that could support this web of logistical activity, providing the sheer strength needed to withstand the transport of such massive cargo across this former river delta.

This solution – Enviro-Mat - is a highly-developed soil improvement methodology, consisting of a combination of local soil, cement and additives including minerals, salt and zeolites, which increases ground bearing capacity up to 50t/m². At Dangote, Mammoet applied this additive to laydown areas, hard stands and crane pads covering over 500,000 square meters of the site.

A significant endeavor – equivalent in area to over 50 soccer pitches – but its benefits extended well beyond the establishment of a flat, solid surface. Harm Tiddens, Mammoet’s General Manager for West Africa, explains:

“The need for ground stabilization can have a significant bearing on projects, so using the Enviro-Mat system gave us some real advantages. Not only were we able to undertake lifts of up to 3,000t on reclaimed swampland, but the huge area stabilized proved crucial for laydown operations to continue smoothly throughout the rainy season – when this kind of land could otherwise be a challenge to operate on.”

Enviro-Mat allowed for quick and easy site upgrades, where required. Following discussions early in the project, Mammoet advised Dangote on roads that needed civil works to support the planned traffic – for example by widening and levelling turns. Works were undertaken to ensure that these roads were well-prepared for the weight of cargo they would carry, in particular between the site and its jetty.

Two of Mammoet’s largest super heavy lift ring cranes – the PTC 200 DS and PT 50 - completed key lifts at the refinery. The combination of mobility offered by crawler cranes on site and the sheer lifting power – over 3,000t – of the ring cranes meant there was equipment on site to meet a wide range of lift requirements.

Rather than being dismantled and re-assembled, the high ground bearing pressure capability provided by Enviro-Mat allowed for the PT-50 crane to be simply picked up and carried via SPMT between major lifts. This process saved four weeks of time for each crane relocation phase, adding up to a significant schedule enhancement for the project as a whole.

To ensure cargo was on site and ready for installation when needed, Mammoet mobilized a huge selection of equipment during its two-year stay on site. Hundreds of axle lines of SPMT, the two ring cranes, plus many crawler cranes and auxiliary equipment were available when needed – even when plans changed at short notice.

All surface and substance

In all, seven Enviro-Mat yards were created, including laydown areas totaling 253,776 m2, assembly surfaces totaling 36,059 m2 and 78 heavy lift crane hardstands totaling 80,000 m2 - at a maximum rate of around 5,000m2 per day. Following demobilization, these surfaces will either be reused as the base-course for new roads, or finely milled back into the local soil - without pollutants seeping into the groundwater.

Once fully operational later in 2021, the refinery will process 650,000 barrels of crude oil per day. It will transform the local economy, creating thousands of jobs and helping to secure a more prosperous future for African industry.

Tiddens looks back on a job well done: “The successful completion of our scope at the Dangote Project has required a balance of planning expertise and the smart use of equipment to ensure the right solution was on hand when needed.

A project of this scale demands a high degree of flexibility in when and how items are needed to be transported to the site and installed, which is where Mammoet’s large global network of equipment and expertise became invaluable.

The team deserves significant credit, having operated under some of the most challenging circumstances to make the project succeed. For example, when the coronavirus pandemic arrived, they found new ways to keep productivity high while making sure everyone stayed safe.”

Expert planning was required to tackle the demanding scale of the Dangote refinery – in terms of cargo weights, volumes and the vast web of delivery schedules. All the while, Enviro-Mat provided the foundation for this transformation - turning barren swampland into a platform for meaningful economic growth.

Mammoet

Mammoet helps clients with Smarter, Safer and Stronger solutions to any heavy lifting or transport challenge. We aim to develop long term relationships in order to understand their businesses and challenges best, so we can realize the most efficient and cost-effective approaches. We have a unique global network and an unparalleled fleet of equipment. Through deep and longstanding engineering expertise and the highest quality and safety standards in execution we bring an intelligent and flexible approach to projects across a wide breadth of industry sectors. Clients trust us to help them achieve feats that were once considered impossible, and we have often broken records in doing so. For more information, visit www.mammoet.com

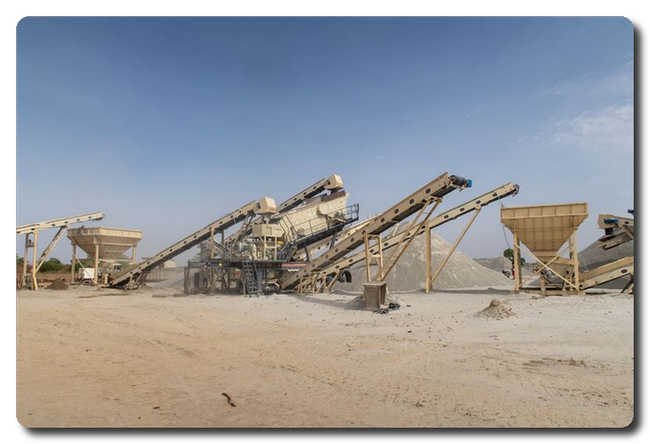

Metso Outotec and BIA Group expand distribution partnership to Africa

Metso Outotec and its distribution partner BIA Group have signed a contract to expand their aggregates distribution coverage to Africa. Starting in March 2021, Metso Outotec’s stationary and mobile equipment, spare and wear parts coupled with BIA’s technical expertise and local presence will be available for aggregates customers in West and Central Africa.

The two companies have successfully partnered in the Benelux region since 1930. The decision to expand the long-lasting partnership to Africa was driven by shared ambition to reach and serve customers in the region better than ever before. Enhancing both companies’ offering, Metso Outotec and BIA put themselves in an unrivalled position now able to offer a complete product portfolio with the highest possible services levels.

With the dynamic nature of the African markets driven by both GDP and population growth and large construction projects impacting positively the aggregate demand, Metso Outotec and BIA have high expectations on the possibilities provided by the expansion.

“This expansion of our distribution partnership with BIA enables us to reach out to new territories, where we were not present earlier,” explains Olli-Pekka Oksanen, Senior Vice President, Global Distribution Management at Metso Outotec. “With the agreement, we provide equipment, parts and support for customers in new areas. Whether the customer is looking for a full stationary plant or a single mobile equipment, we can offer them all – with the desired support level. Our portfolio covers the needs of different types of customers and applications and meets the local requirements and standards.” He concludes: “We are happy to be able to utilize the opportunities in the region in collaboration with BIA.”

“This distribution agreement extension for West and Central Africa demonstrates the willingness of BIA and Metso Outotec to strengthen their historical partnership that started over 90 years ago with Nordberg for Belgium,” says Vincent Bia, the CEO of BIA Group. “Since then, both companies have continuously developed their products and services to gain an unrivalled expertise that serves both the aggregates and mining customers. We are confident that BIA’s market knowledge and local presence together with Metso Outotec’s solutions and technologies will form complementary assets to meet the ever-growing customer needs.“

Further information, please contact:

Karima Dargaud, Head of Aftermarket Sales EMEA, Distributor Management Office, Metso Outotec, tel. +33 631 522 413, karima.dargaud(at)mogroup.com

Carlos Padin, Head of Capital Equipment Sales EMEA Hub South, Distributor Management Office, Metso Outotec, tel. +33 607 272 002, carlos.padin(at)mogroup.com

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

COVID-19 and sustainability among top themes set to impact power industry in 2021, according to GlobalData

COVID-19 and sustainability will continue to heavily impact the power industry, according to data and analytics company GlobalData, which has identified the top 20 themes set to have the most influence on the sector.

GlobalData’s report, ‘Power Predictions 2021 – Thematic Research’, also identifies the other key themes that will shape the industry in 2021, such as hydrogen, renewable energy, electric vehicles (EVs), energy storage, technology diversification and mergers and acquisitions (M&A).

Sneha Susan Elias, Power Analyst at GlobalData, comments: “Tech themes such as drones, artificial intelligence (AI), big data, internet of things (IoT), cloud computing, virtual and augmented reality (VR/AR), microgrids and digitalization will be of paramount importance as the industry looks to function with the highest efficiency and reliability levels. Power companies are likely to take a varied approach concerning different tech themes, depending upon their immediate requirements.”

Sneha Susan Elias, Power Analyst at GlobalData, comments: “Tech themes such as drones, artificial intelligence (AI), big data, internet of things (IoT), cloud computing, virtual and augmented reality (VR/AR), microgrids and digitalization will be of paramount importance as the industry looks to function with the highest efficiency and reliability levels. Power companies are likely to take a varied approach concerning different tech themes, depending upon their immediate requirements.”

Cloud computing and VR and AR themes will come to the fore with the post-pandemic new normal of remote working. The ongoing COVID-19 pandemic has pushed businesses and power utilities to opt for remote working, and this is when cloud computing solutions have played a role in maintaining business continuity. Cloud adoption in the utilities industry is expected to pick up in 2021. Early cloud adopters have taken advantage of these turbulent COVID times, while the ones that were previously apprehensive about adopting cloud computing solutions are now planning to deploy them. COVID-19 has also led to an increased demand for virtual collaboration tools that are based on AR and VR technologies. These technologies have proven use cases of enhanced safety, remote assistance and improved productivity.

The ongoing COVID-19 pandemic has also affected stakeholders across the power sector value chain, to varying levels. Decreased cash flows, limited workforce availability, and changes in consumer behavior are some of the effects on the power sector caused by COVID.

Elias continues: “Pre-COVID-19, clean energy transition was at the forefront in the minds and policies of governments, corporate agencies, developers and investors. Due to the ongoing pandemic, the course of action taken by them to alleviate the detrimental impact of COVID had initially dented the progress towards clean energy. However, globally, renewable energy has remained resilient during the pandemic crisis and this is likely to continue into 2021. GlobalData forecasts continued growth in renewables throughout 2021 due to electricity demand returning to pre-pandemic levels, low operating costs, and priority or guaranteed access of renewable power generators to the grid through regulations.”

In addition to these trends, the renewable energy industry will witness a major shift toward local manufacturing, reducing supply chain dependence on imports and encouraging the setup of new domestic manufacturing facilities. The pandemic has underscored the need for clean air and healthful considerations more generally. Emissions reductions due to COVID-19 have led environmentalists to advocate for more renewable energy to maintain these levels and avoid potential crisis in future. This will further help to boost renewable energy.

Elias adds: “COVID-19 will also drive sustainability changes. The pandemic is driving the urgent need for evaluation of issues in the power sector which have potentially been underplayed, including environmental, social and governance policies. As consumers are looking towards brands for environmental leadership, many companies have pledged to drive sustainability changes, most notably in the power sector by announcing a transition to cleaner resources and energy efficiency. Climate change will become a greater priority for communities’ post-COVID-19, henceforth, utility providers can no longer position themselves as monolithic providers and will have to understand the business climate in which they operate. Moreover, they will have to consider demographic, economic, political, as well as consumer sentiments related to energy transition.”

- Quotes provided by Sneha Susan Elias, Power Analyst at GlobalData

- Information based on GlobalData’s thematic report: ‘Power Predictions 2021 - Thematic Research’

- GlobalData classifies the top 20 themes for 2021 into three categories – industry, technology and macroeconomic themes

- This press release was written using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.